Quality Check Process

Description

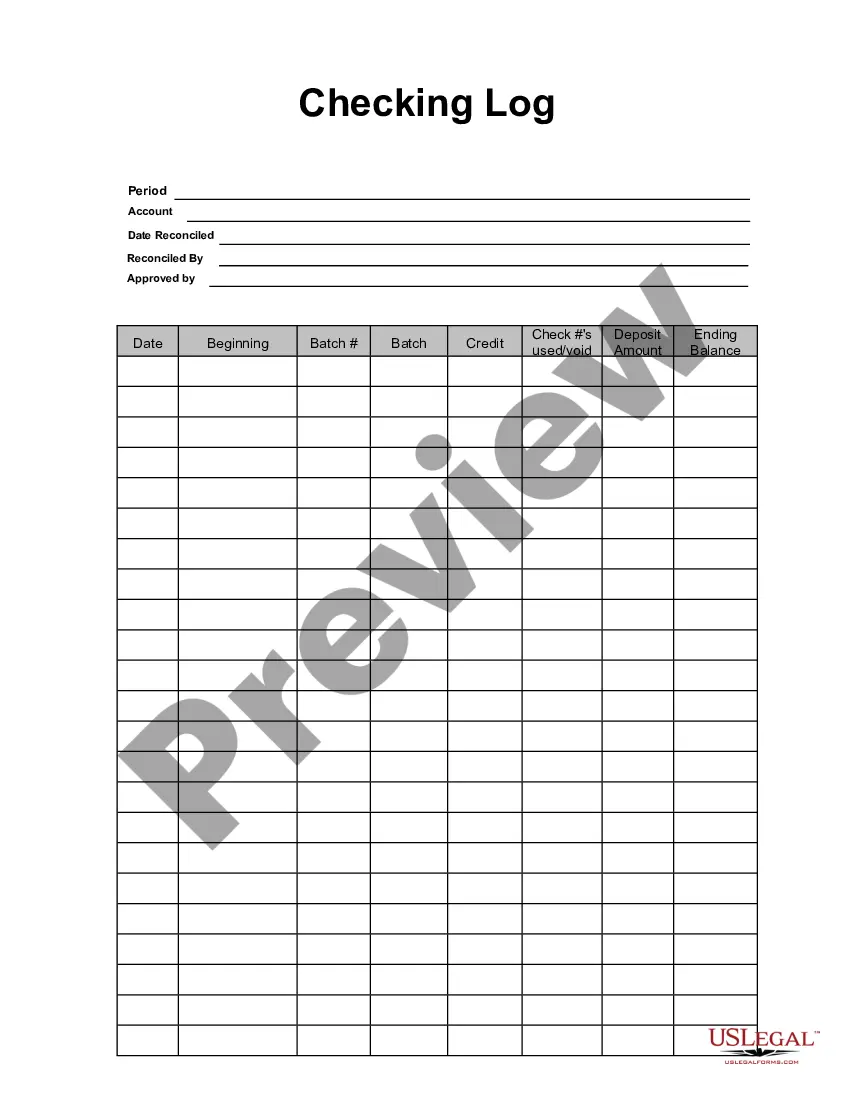

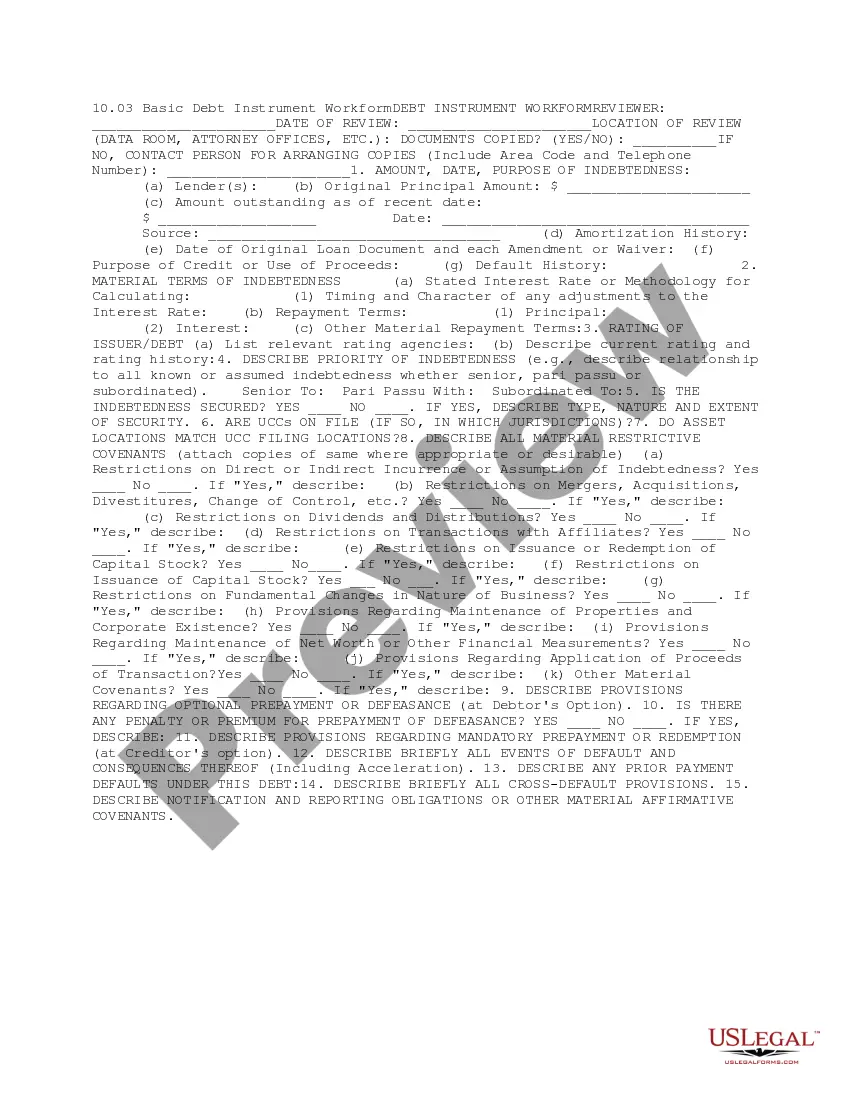

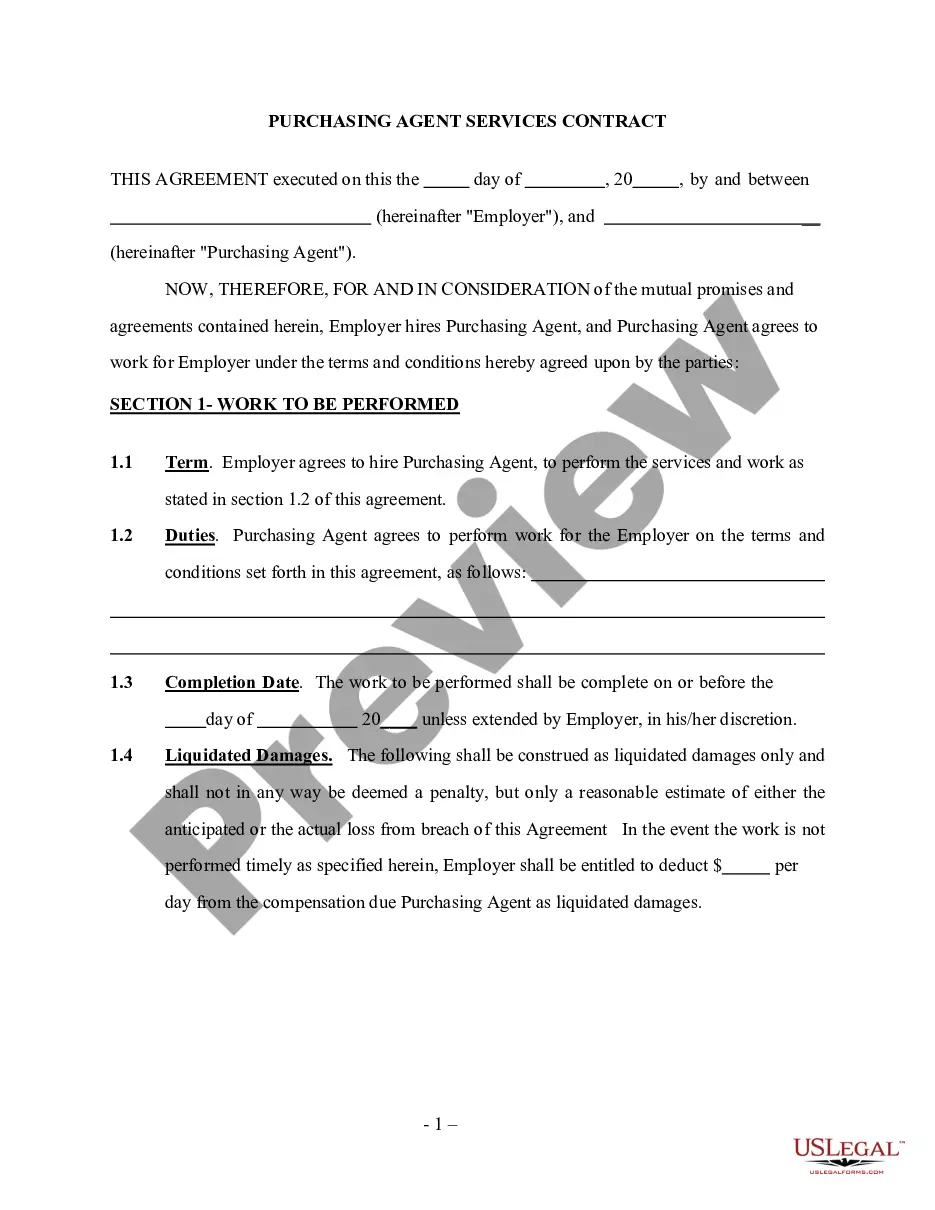

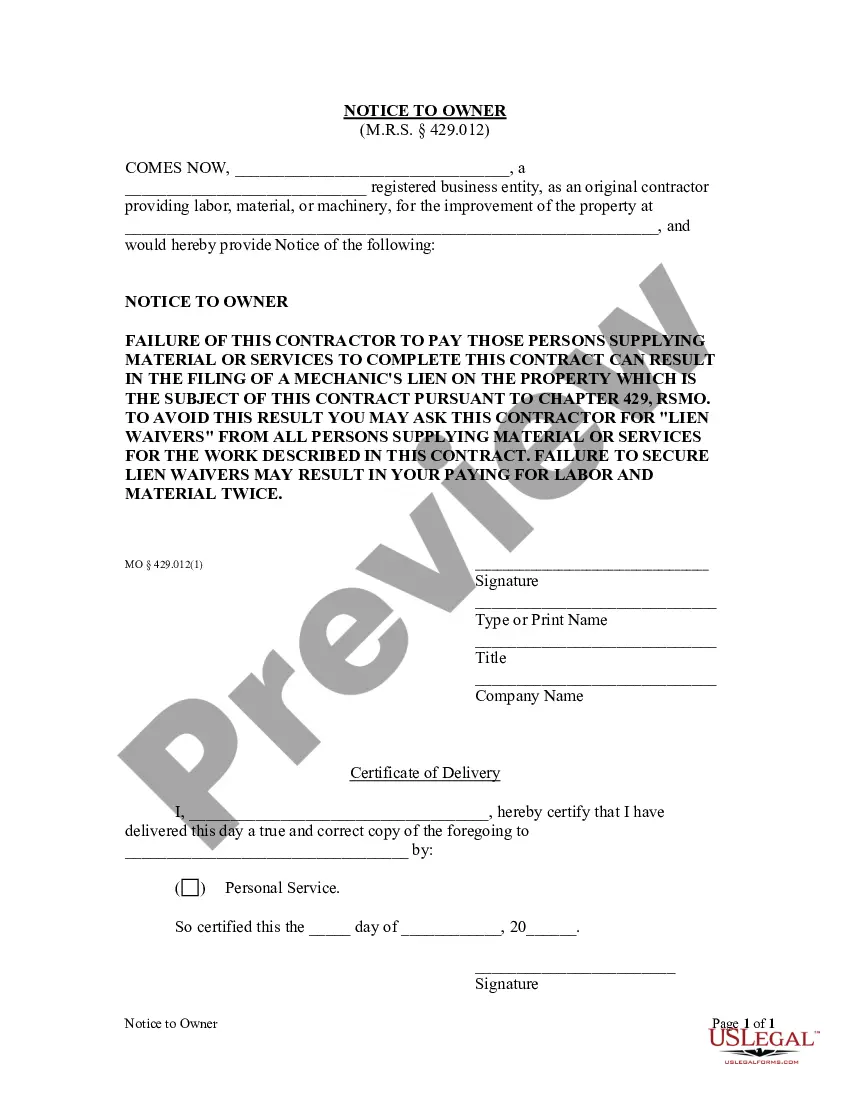

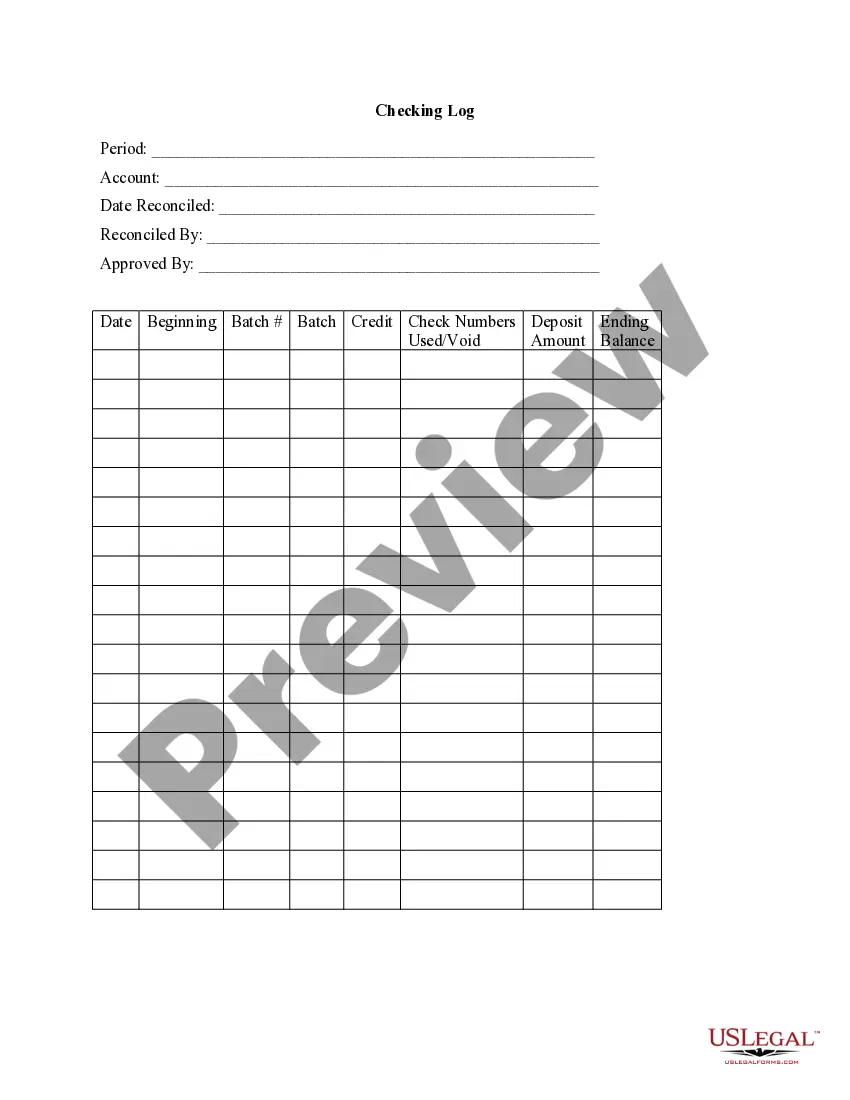

Get your form ready online

Our built-in tools help you complete, sign, share, and store your documents in one place.

Make edits, fill in missing information, and update formatting in US Legal Forms—just like you would in MS Word.

Download a copy, print it, send it by email, or mail it via USPS—whatever works best for your next step.

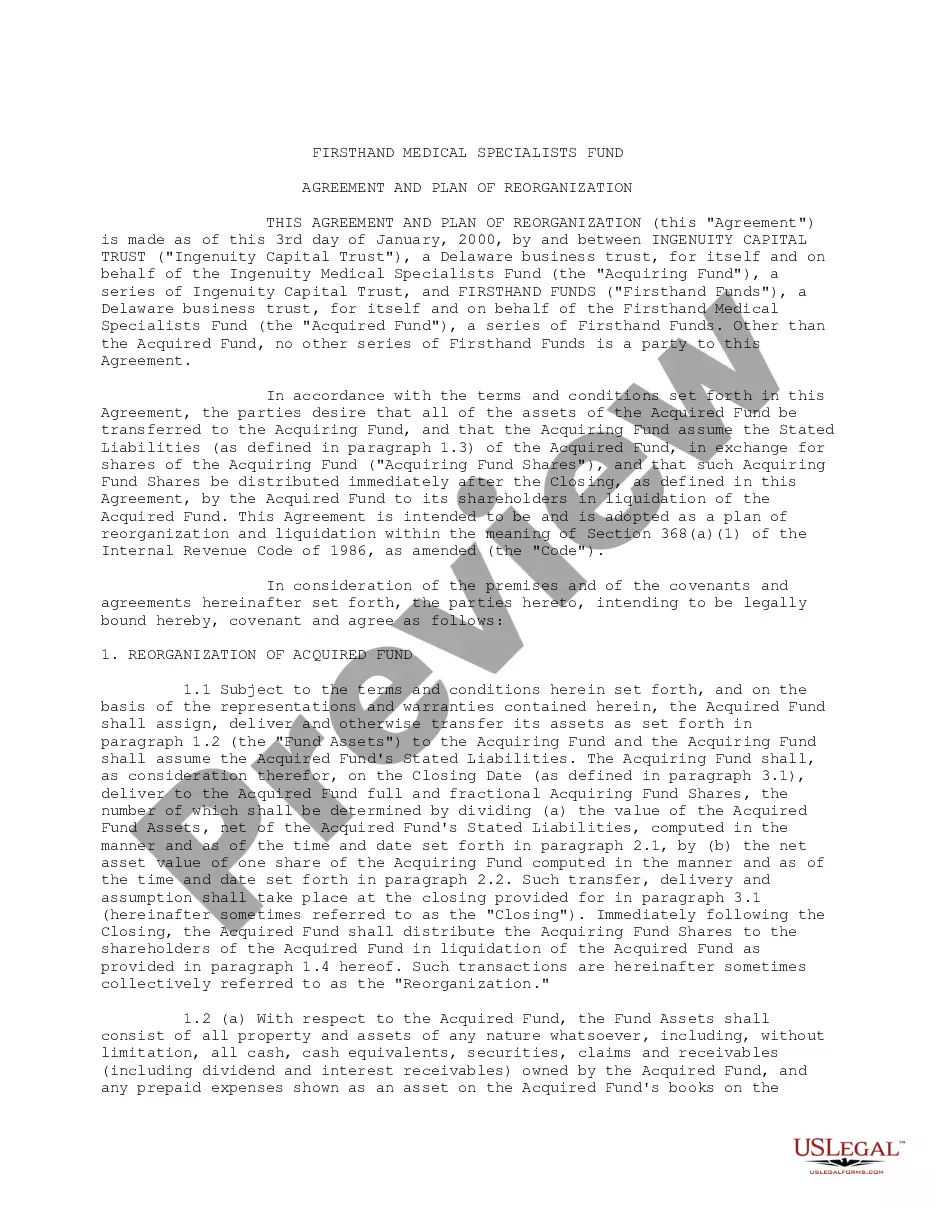

Sign and collect signatures with our SignNow integration. Send to multiple recipients, set reminders, and more. Go Premium to unlock E-Sign.

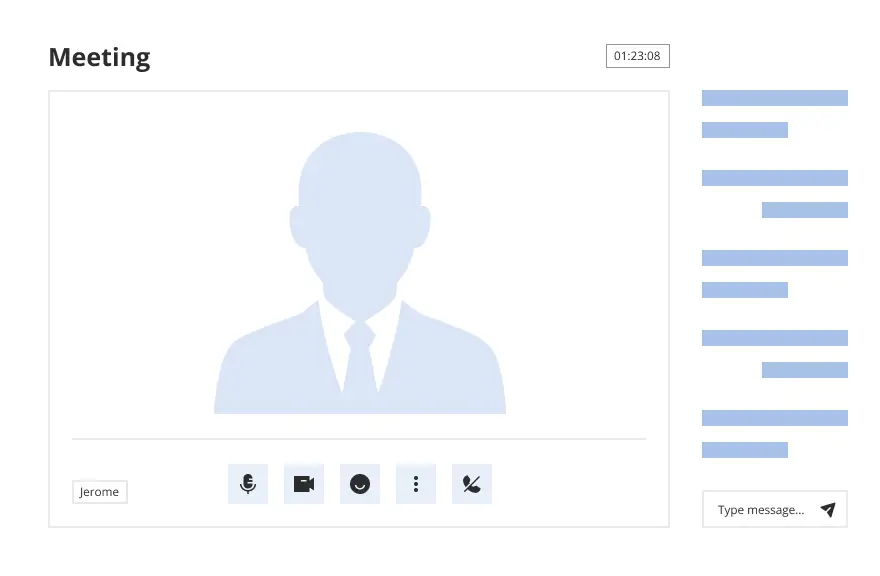

If this form requires notarization, complete it online through a secure video call—no need to meet a notary in person or wait for an appointment.

We protect your documents and personal data by following strict security and privacy standards.

Make edits, fill in missing information, and update formatting in US Legal Forms—just like you would in MS Word.

Download a copy, print it, send it by email, or mail it via USPS—whatever works best for your next step.

Sign and collect signatures with our SignNow integration. Send to multiple recipients, set reminders, and more. Go Premium to unlock E-Sign.

If this form requires notarization, complete it online through a secure video call—no need to meet a notary in person or wait for an appointment.

We protect your documents and personal data by following strict security and privacy standards.

Looking for another form?

Key Concepts & Definitions

The quality check process refers to the systematic review of products, services, or processes to ensure they meet predefined standards and specifications. This includes various methods like inspections, audits, and testing to identify and correct defects before products reach the consumer. Commonly used in manufacturing, software development, and service delivery, it is crucial for maintaining high standards and customer satisfaction.

Step-by-Step Guide

- Establish Standards: Define clear, achievable standards for the product or service quality.

- Design Checkpoints: Identify critical points in the production or service process where quality checks can be implemented effectively.

- Implement Inspection Procedures: Develop detailed protocols for how inspections are to be conducted, specifying who will perform the check and how often.

- Analyze Data: Collect and analyze data from quality checks to identify trends or recurring issues.

- Continuous Improvement: Use insights from the data analysis to make improvements to the process or product.

Risk Analysis

- Failure to Comply with Regulations: Skipping or inadequate quality checks can lead to non-compliance with industry regulations, resulting in legal penalties and financial loss.

- Customer Dissatisfaction: Poor quality control can result in defects that lead to customer dissatisfaction and damage to brand reputation.

- Increased Costs: Defects caught late in the process typically are more costly to address than those identified earlier.

Best Practices

- Regular Training: Continuously train personnel on the latest quality standards and inspection techniques.

- Technology Integration: Use technology to automate parts of the quality check process for more accuracy and efficiency.

- Feedback Loop: Implement a robust feedback mechanism to promptly address the internal and external feedback for quality improvement.

Common Mistakes & How to Avoid Them

- Inconsistent Application: Ensure the quality check process is uniformly applied across all stages of production or service delivery to prevent lapses in quality.

- Overlooking Employee Input: Encourage and value feedback from employees who are directly involved in the quality checks. They often have firsthand insights that can lead to significant improvements.

- Ignoring Data: Regularly review and act on the data collected during quality checks to avoid missing patterns that could indicate larger issues.

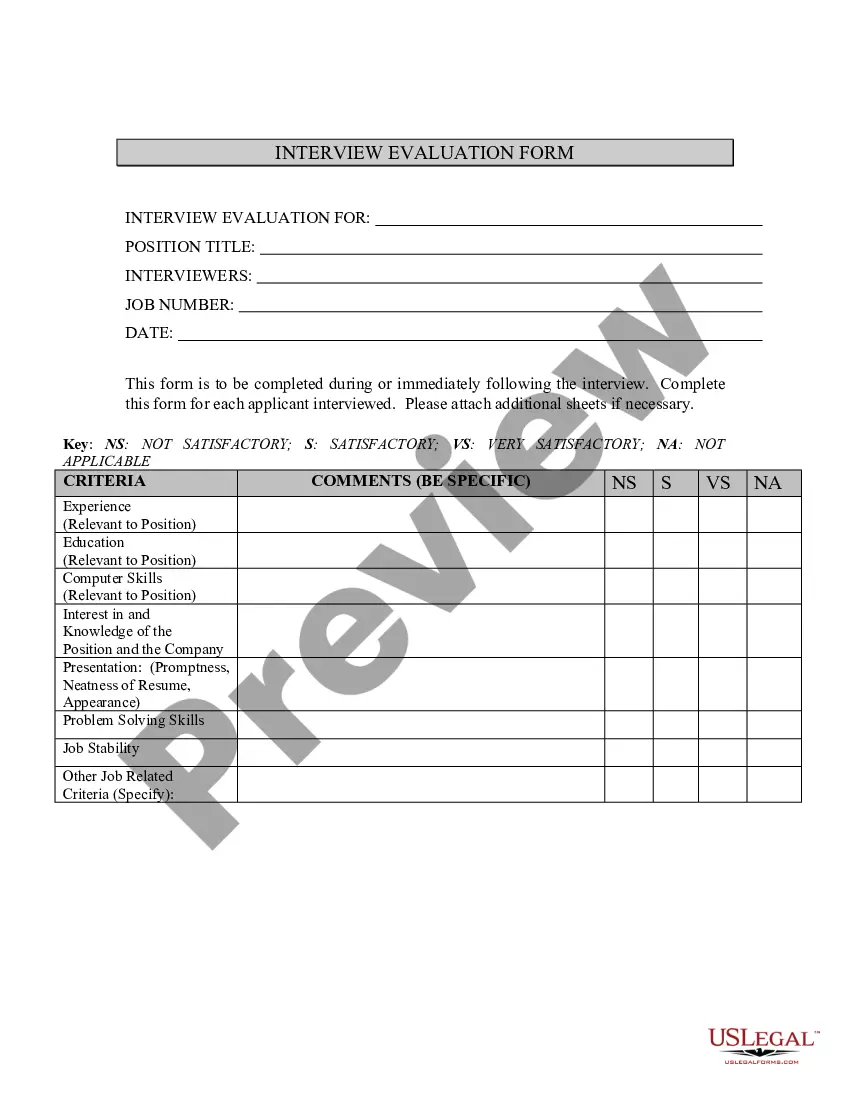

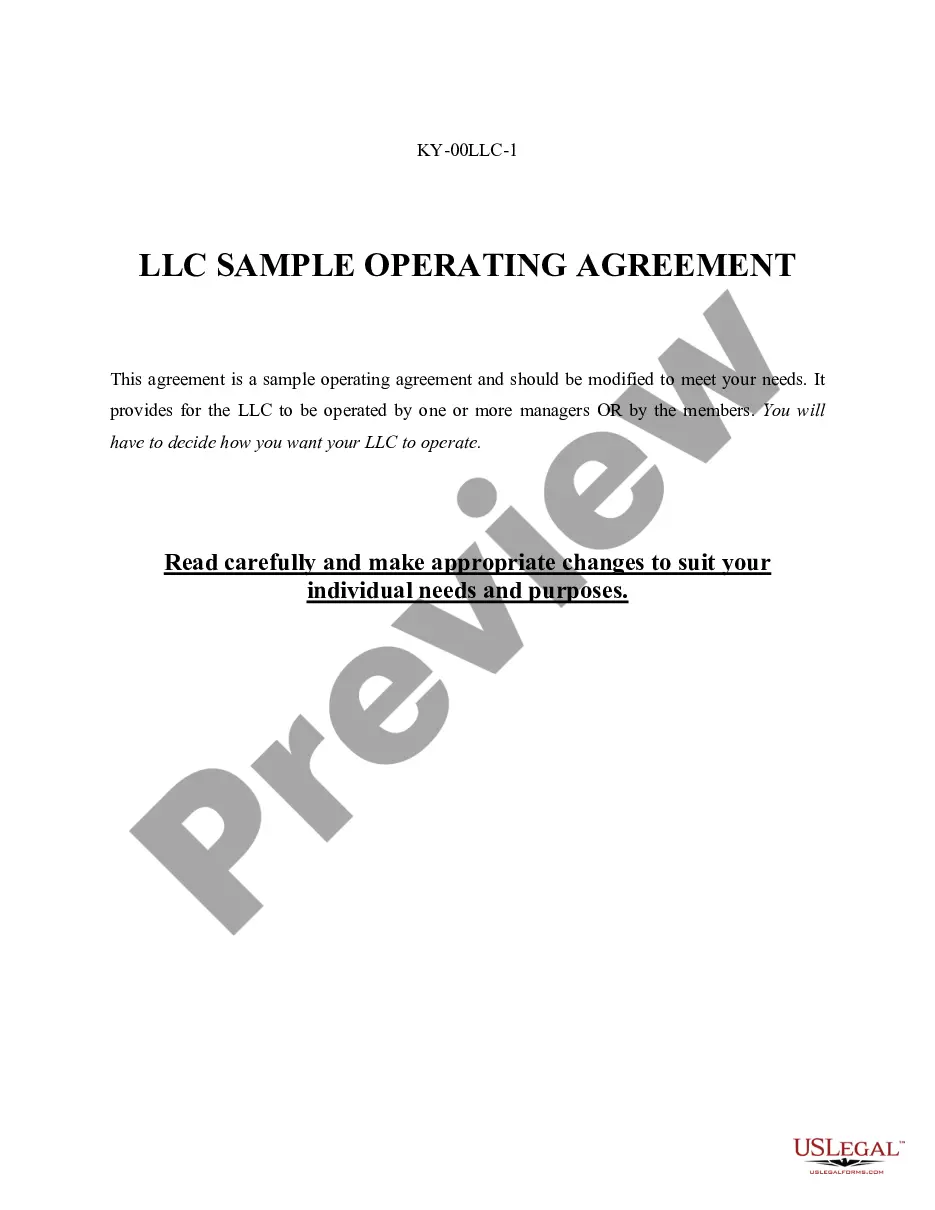

How to fill out Quality Check Process?

Coping with legal documentation requires attention, accuracy, and using well-drafted blanks. US Legal Forms has been helping people across the country do just that for 25 years, so when you pick your Quality Check Process template from our library, you can be certain it meets federal and state regulations.

Working with our service is easy and quick. To get the necessary document, all you’ll need is an account with a valid subscription. Here’s a brief guideline for you to get your Quality Check Process within minutes:

- Remember to attentively look through the form content and its correspondence with general and legal requirements by previewing it or reading its description.

- Look for another official blank if the previously opened one doesn’t suit your situation or state regulations (the tab for that is on the top page corner).

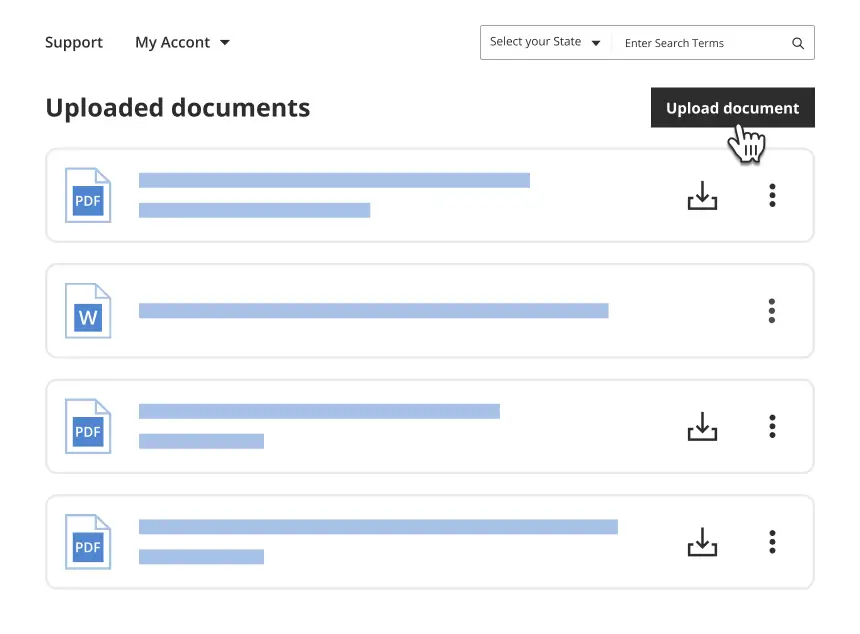

- Log in to your account and download the Quality Check Process in the format you prefer. If it’s your first time with our website, click Buy now to continue.

- Create an account, select your subscription plan, and pay with your credit card or PayPal account.

- Decide in what format you want to obtain your form and click Download. Print the blank or upload it to a professional PDF editor to prepare it paper-free.

All documents are created for multi-usage, like the Quality Check Process you see on this page. If you need them in the future, you can fill them out without re-payment - just open the My Forms tab in your profile and complete your document any time you need it. Try US Legal Forms and accomplish your business and personal paperwork rapidly and in full legal compliance!

Form popularity

FAQ

In quality control, there are 4 types of quality inspections, namely: pre-production inspection, during production inspection, pre-shipment inspection, and container loading/unloading inspections. Each of these types of inspection has its own purpose.

The four main components of a quality management process are Quality Planning, Quality Assurance, Quality Control and Continuous Improvement.

Stages of Quality Management In order to be effective, quality control management can be split down into four main components: quality planning, quality control, quality assurance, and quality improvement.

A quality management process consists of four main components: Quality Planning, Quality Assurance, Quality Control, and Continuous Improvement.

The four main stages of project quality management are quality planning, quality control, quality assurance, and quality improvement.

A quality checker assures that the items are safe and fulfil the manufacturer's specifications before they leave the factory or facility. They inspect each product to ensure uniformity and that buyers obtain a standard and suitable product.