Washington Rigging Safety: Construction Rigging Requirements are rules and regulations created by the state of Washington to ensure the safety of workers and the public during construction operations that involve the use of rigging. The requirements cover the use of equipment, such as slings, chains, and shackles, as well as the installation of rigging systems and the inspection of such systems. The Washington Rigging Safety: Construction Rigging Requirements are divided into three main categories: General Requirements, Load Handling Requirements, and Safety Requirements. General Requirements include the use of proper rigging equipment, the installation of appropriate rigging systems, and the safe operation of rigging systems and equipment. Load Handling Requirements include the appropriate use of rigging hardware, such as shackles, and the proper selection of rigging systems and equipment that are appropriate for the load. Safety Requirements address the proper inspection and maintenance of rigging systems and equipment, as well as the appropriate storage and transportation of such systems and equipment. Washington Rigging Safety: Construction Rigging Requirements are designed to protect workers and the public from the risks associated with the use of rigging during construction operations and are enforced by the Washington Department of Labor and Industries.

Washington Rigging Safety: Construction Rigging Requirements

Description

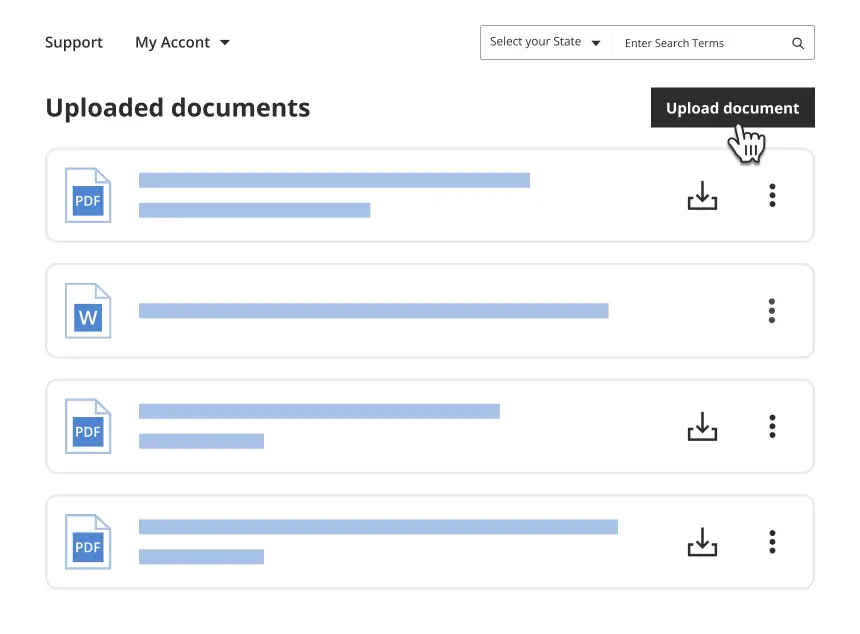

Get your form ready online

Our built-in tools help you complete, sign, share, and store your documents in one place.

Make edits, fill in missing information, and update formatting in US Legal Forms—just like you would in MS Word.

Download a copy, print it, send it by email, or mail it via USPS—whatever works best for your next step.

Sign and collect signatures with our SignNow integration. Send to multiple recipients, set reminders, and more. Go Premium to unlock E-Sign.

If this form requires notarization, complete it online through a secure video call—no need to meet a notary in person or wait for an appointment.

We protect your documents and personal data by following strict security and privacy standards.

Make edits, fill in missing information, and update formatting in US Legal Forms—just like you would in MS Word.

Download a copy, print it, send it by email, or mail it via USPS—whatever works best for your next step.

Sign and collect signatures with our SignNow integration. Send to multiple recipients, set reminders, and more. Go Premium to unlock E-Sign.

If this form requires notarization, complete it online through a secure video call—no need to meet a notary in person or wait for an appointment.

We protect your documents and personal data by following strict security and privacy standards.

Looking for another form?

How to fill out Washington Rigging Safety: Construction Rigging Requirements?

Handling legal documentation requires attention, accuracy, and using well-drafted blanks. US Legal Forms has been helping people across the country do just that for 25 years, so when you pick your Washington Rigging Safety: Construction Rigging Requirements template from our service, you can be sure it complies with federal and state laws.

Working with our service is simple and quick. To obtain the necessary paperwork, all you’ll need is an account with a valid subscription. Here’s a quick guide for you to find your Washington Rigging Safety: Construction Rigging Requirements within minutes:

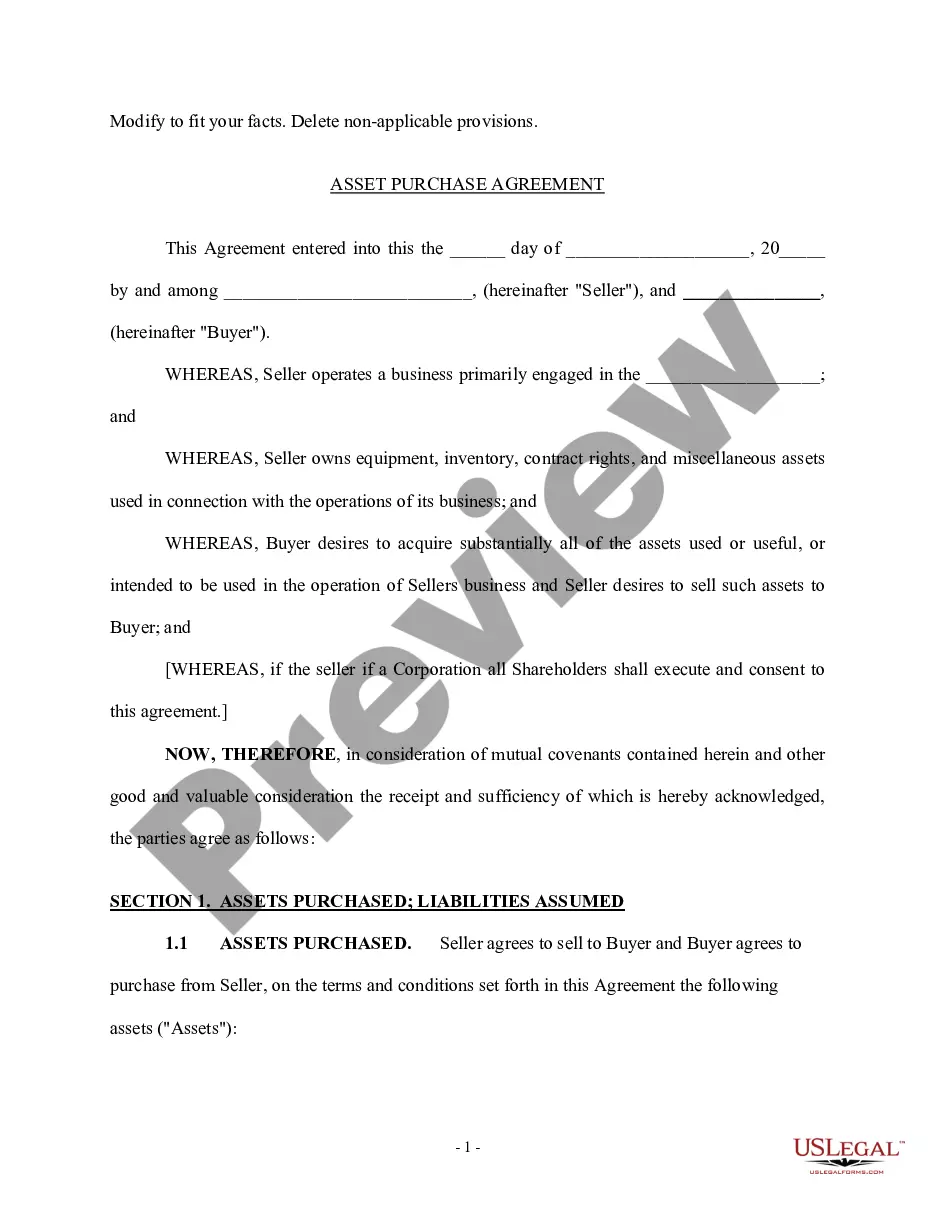

- Make sure to attentively check the form content and its correspondence with general and law requirements by previewing it or reading its description.

- Search for another official blank if the previously opened one doesn’t match your situation or state regulations (the tab for that is on the top page corner).

- Log in to your account and download the Washington Rigging Safety: Construction Rigging Requirements in the format you need. If it’s your first experience with our service, click Buy now to proceed.

- Create an account, choose your subscription plan, and pay with your credit card or PayPal account.

- Decide in what format you want to obtain your form and click Download. Print the blank or add it to a professional PDF editor to submit it electronically.

All documents are drafted for multi-usage, like the Washington Rigging Safety: Construction Rigging Requirements you see on this page. If you need them in the future, you can fill them out without re-payment - just open the My Forms tab in your profile and complete your document any time you need it. Try US Legal Forms and prepare your business and personal paperwork rapidly and in total legal compliance!

Form popularity

FAQ

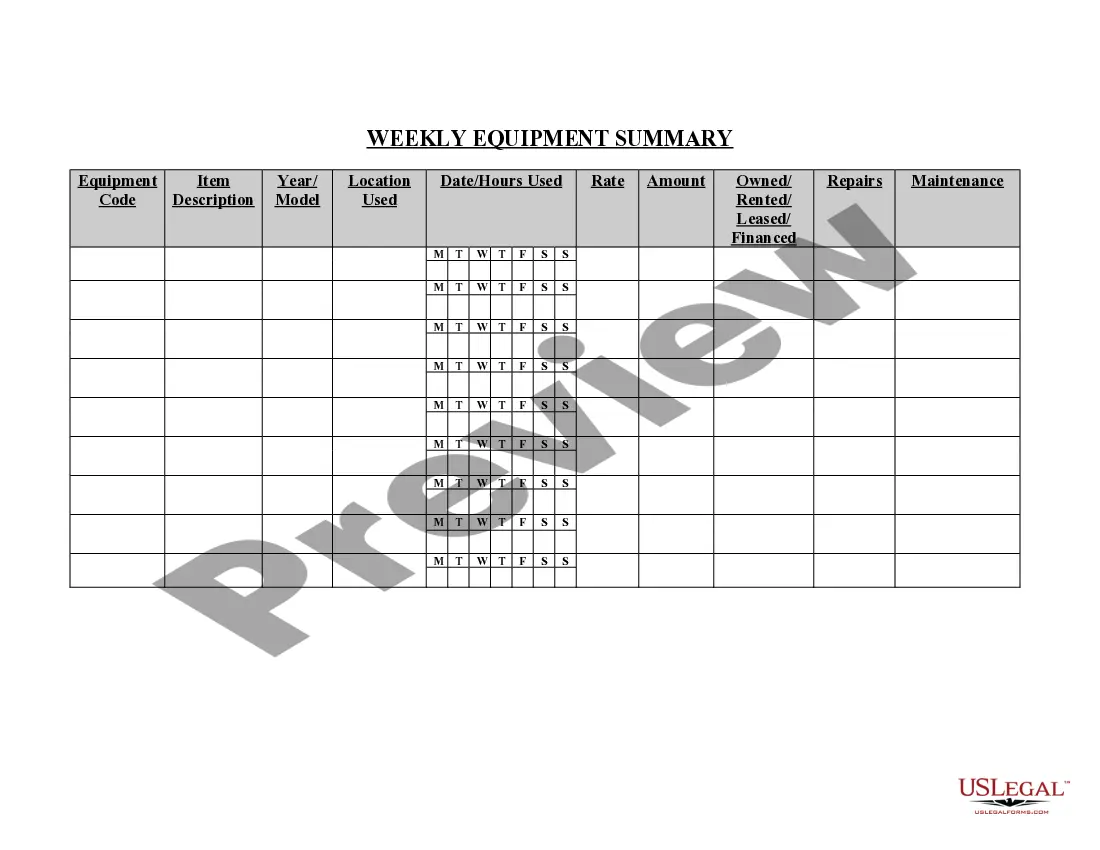

Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is safe. Defective rigging equipment shall be removed from service. Not be used without affixed, legible identification markings, required by paragraph (a)(2)(i) of this section.

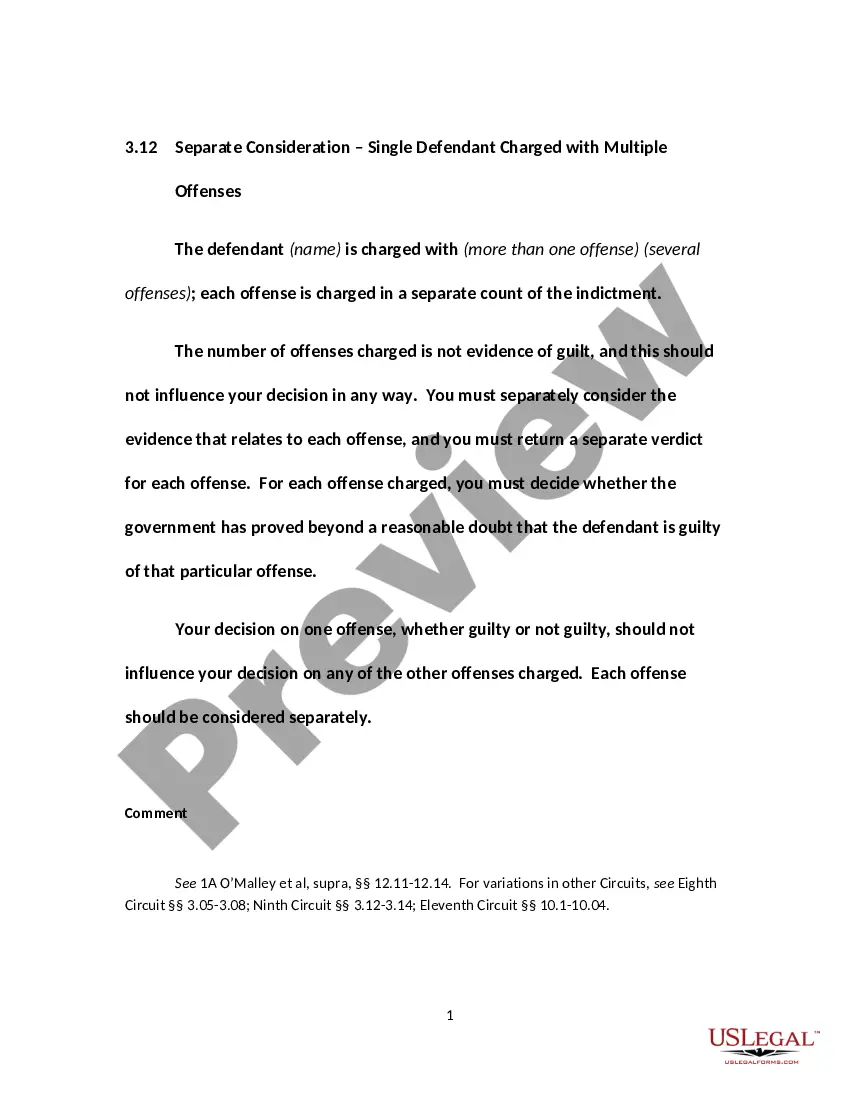

In order for a rigger to be considered a qualified rigger, they must meet two primary criteria: They must have in their possession a recognized degree, certificate, or professional standing, or otherwise have extensive (and verifiable) knowledge, training, and experience.

In regard to qualifying riggers, a qualified rigger is a person who, by possession of a recognized degree, certificate, or professional standing, or by extensive knowledge, training and experience, successfully demonstrated the ability to solve/resolve problems related to the subject matter, the work, or the project.

5 Rules for Safe Rigging Let Qualified Workers Do the Job. All the workers at the job site should be certified on rigging safety.Make Sure the Equipment and Environment Is Safe.Make Sure That the Load Is Balanced.Always Have a Qualified Spotter on Site.Store Your Equipment Safely.

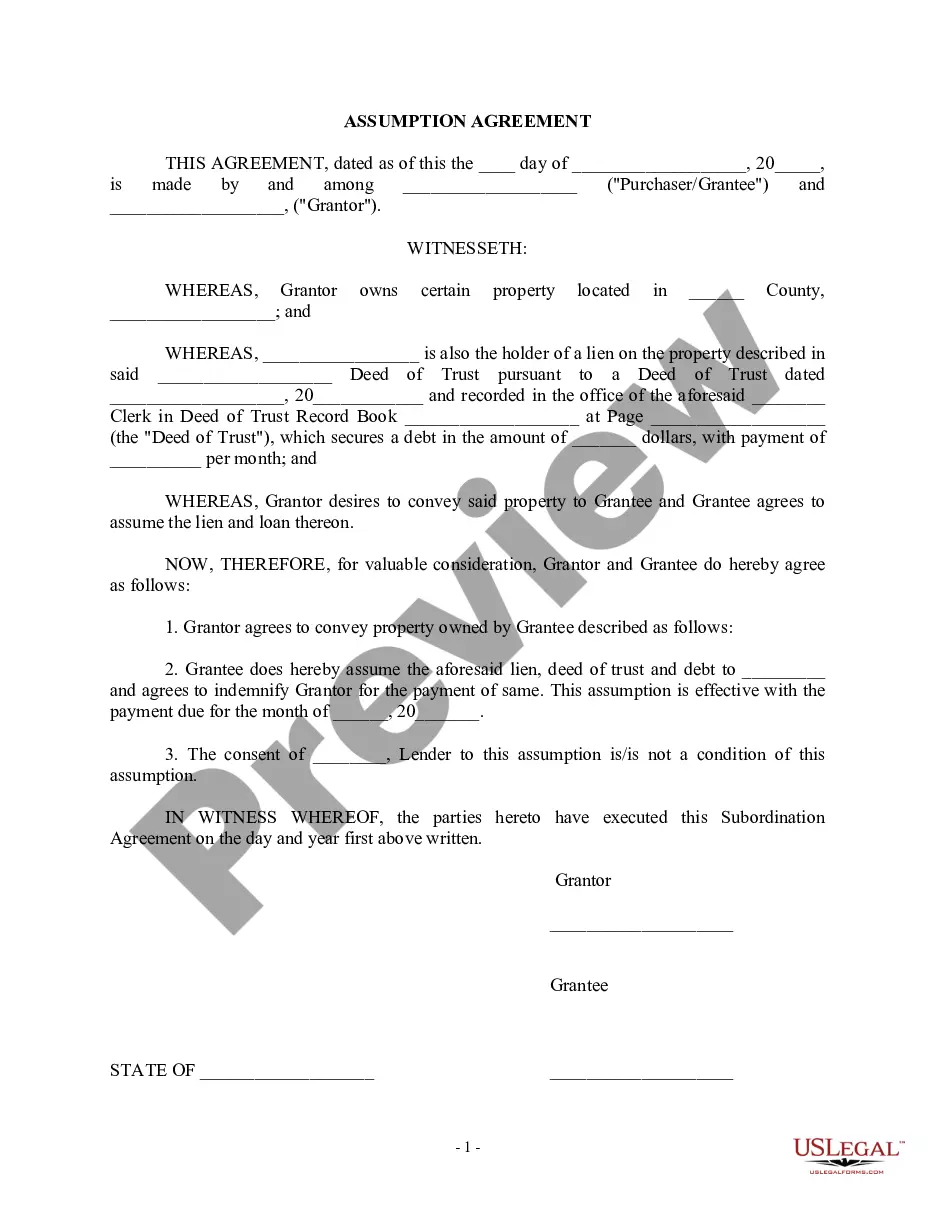

Multiple lift rigging procedure. This capacity, certified by the manufacturer or a qualified rigger, shall be based on the manufacturer's specifications with a 5 to 1 safety factor for all components.

Safety Factor Meaning It is commonly stated as a ratio, such as . This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break. So, if a wire rope's SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs.

The safety factor for lifting is the ratio between force applied to a component in a system, and the minimum breaking strength of the component. The safety factor is calculated by dividing the minimum breaking strength of the gear by the maximum force that can be supported by the lifting gear.

These slings are designed with a safety factor of . This means that 5 times as much force as the working load limit has to be applied to the sling before it potentially fails.