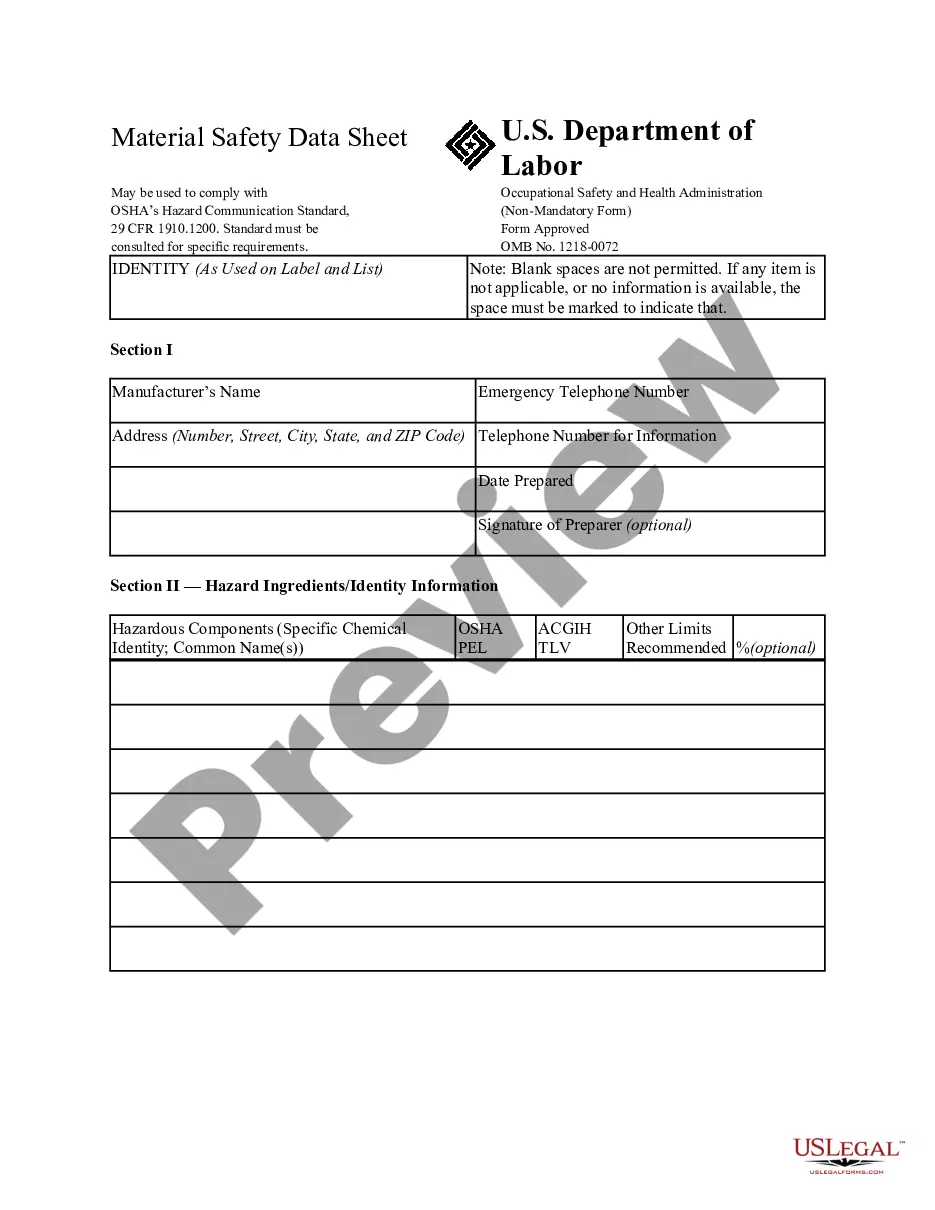

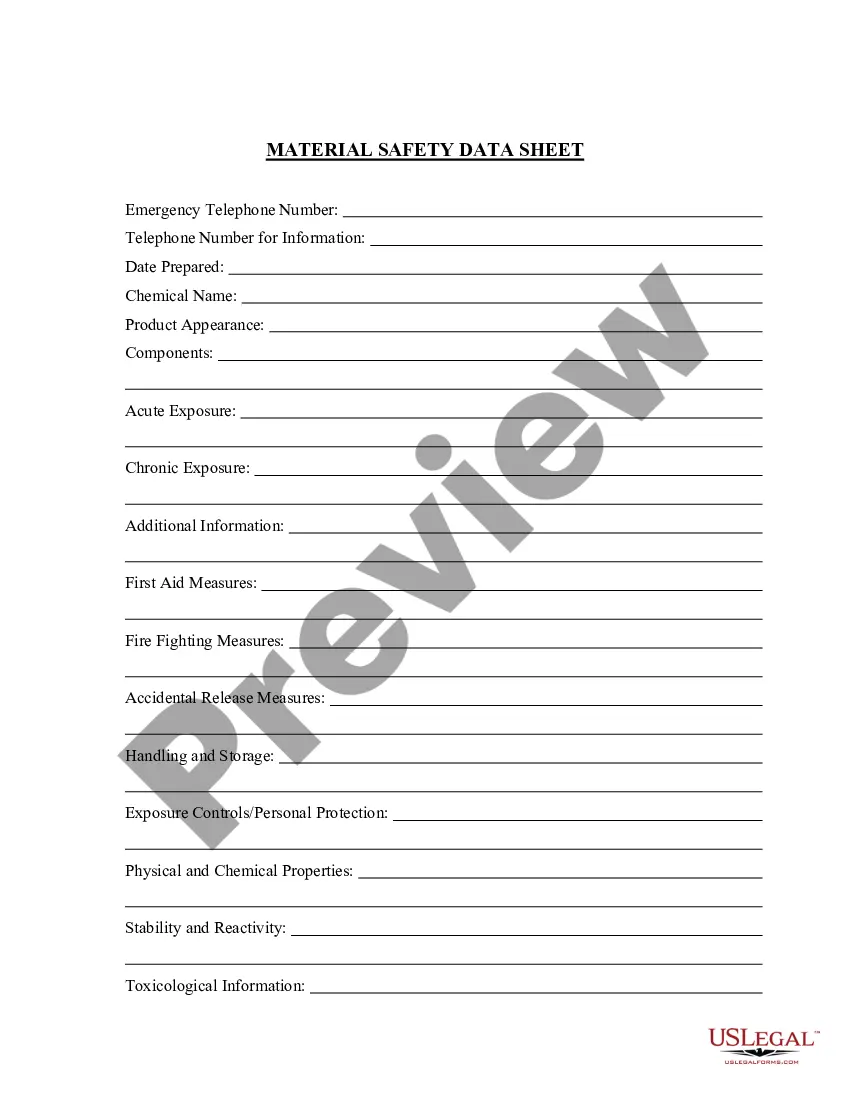

Tennessee Material Safety Data Sheet from the U.S. Dept. of Labor and OSHA

Description

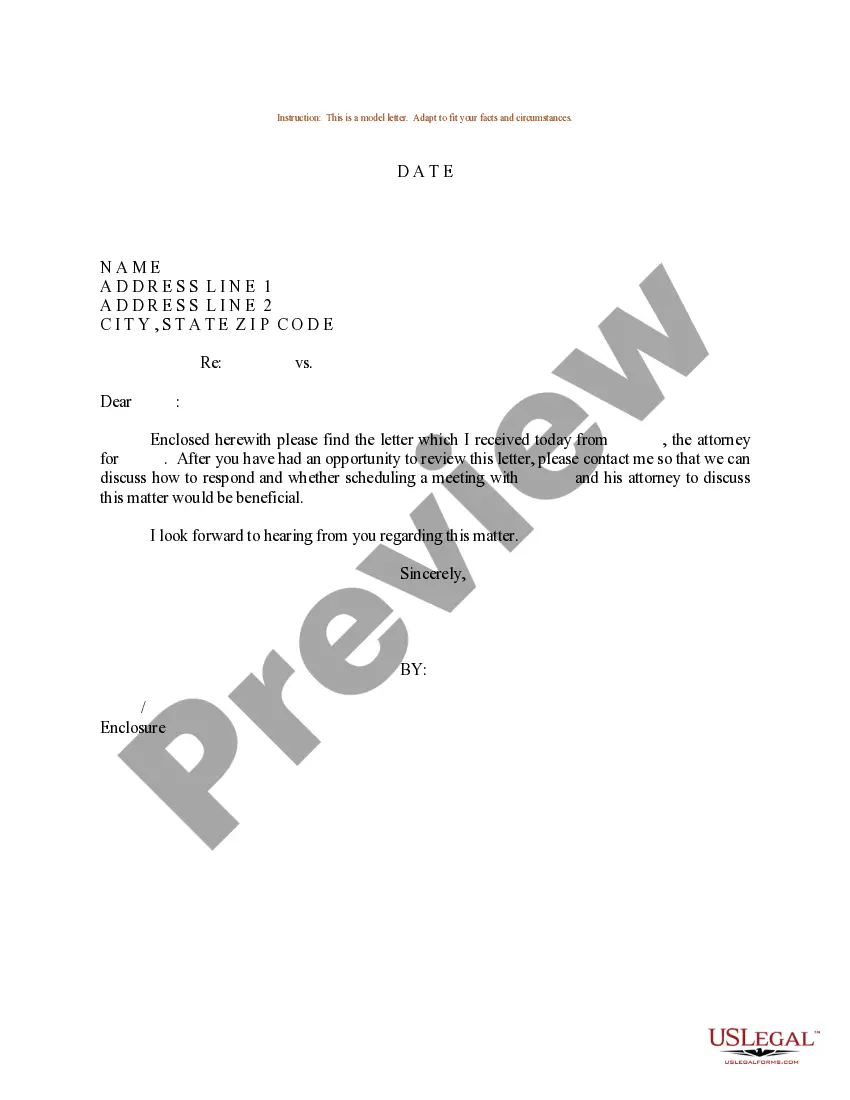

How to fill out Material Safety Data Sheet From The U.S. Dept. Of Labor And OSHA?

US Legal Forms - one of the largest collections of legal documents in the United States - provides a variety of legal document templates that you can download or create.

Through the website, you can access thousands of forms for business and personal use, categorized by types, states, or keywords.

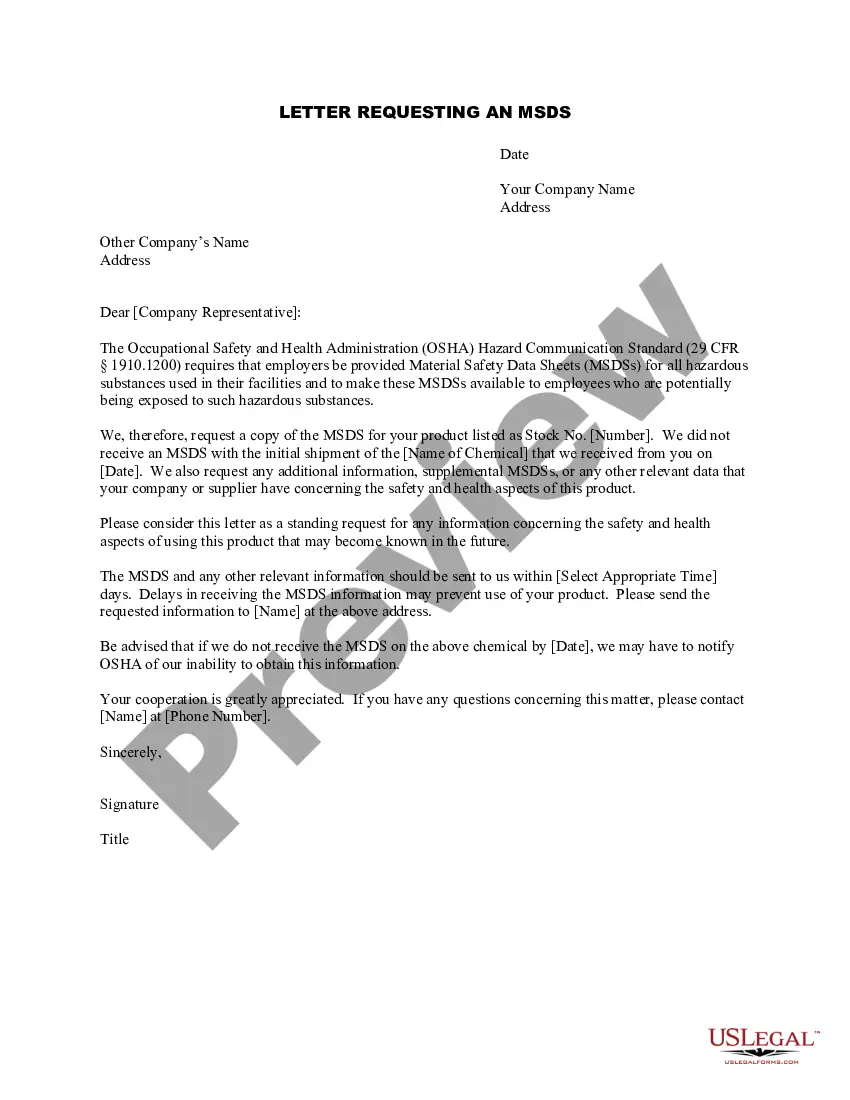

You can obtain the latest versions of forms such as the Tennessee Material Safety Data Sheet from the U.S. Department of Labor and OSHA in just moments.

If the form does not meet your needs, use the Search field at the top of the page to find one that does.

If you are satisfied with the form, confirm your choice by clicking the Get now button. Then, select the payment plan you prefer and provide your credentials to register for an account.

- If you already hold a subscription, Log In and retrieve the Tennessee Material Safety Data Sheet from the U.S. Department of Labor and OSHA using the US Legal Forms library.

- The Download button will be visible on every form you view.

- You can access all previously downloaded forms from the My documents section of your account.

- To use US Legal Forms for the first time, below are simple steps to get you started.

- Ensure you have selected the correct form for your region/county.

- Click the Preview button to review the form's details.

Form popularity

FAQ

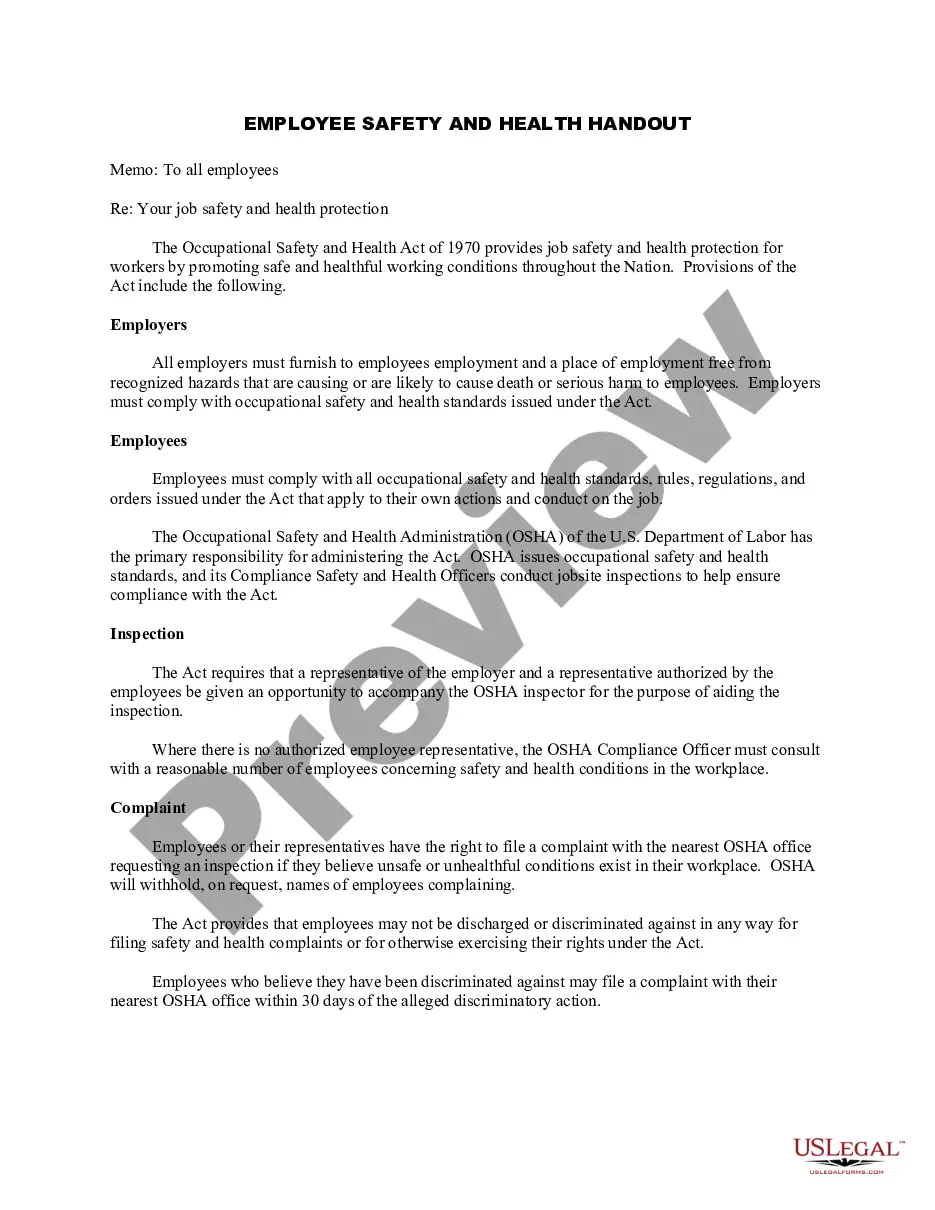

4 Basic Steps to Conducting a Job Safety AnalysisStep 1: Select the Jobs to Be Analyzed.Step 2: Break the Job into a Defined Sequence.Step 3: Identify the Potential Hazards of Each Task.Step 4: Develop Preventive Measures to Reduce or Eliminate Hazards.

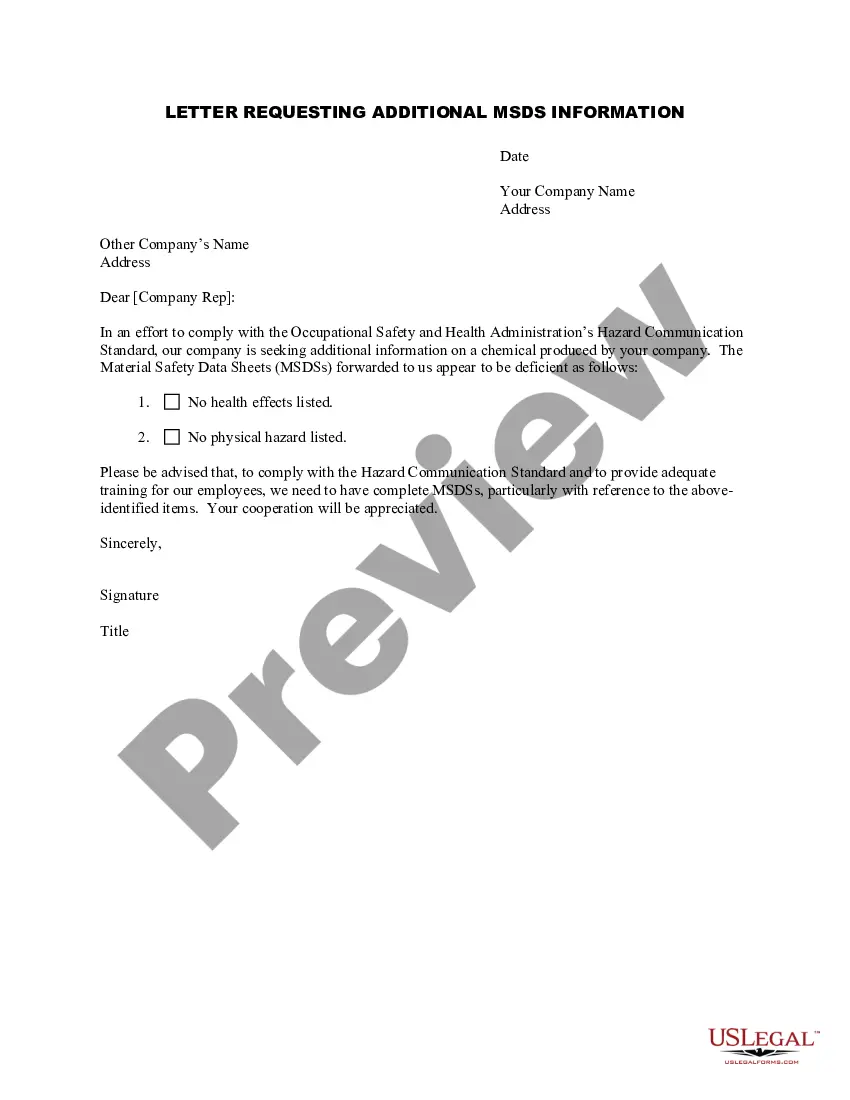

Requirementsthe name of the chemical (same as on the label)the chemical and common names of the substance.a listing of the ingredients.a statement of the ingredients that are known carcinogens or that present other known hazards.any specific hazards.

Steps of the JHA ProcessStep 1: Begin the JHA for a specific job by breaking the job down into the steps or tasks performed while doing the job.Step 2: Identify and list the hazards associated with each task (do one task first, then another, etc.)Step 3: Write a hazard description (also called a hazard scenario)More items...

How to Fill Out a JHA: Step by StepStep 1: Choose a job from your list (according to priority) and break it down into tasks or steps.Step 2: Identify all hazards for each task.Step 3: Create hazard descriptions.Step 4: Create a plan for hazard control.Step 5: Control hazards and repeat.More items...?

The Job Hazard Analysis tool is used to identify how to perform task step-by-step, any hazards associated with the task and controls to mitigate the hazards. List of Documents and Appendices.

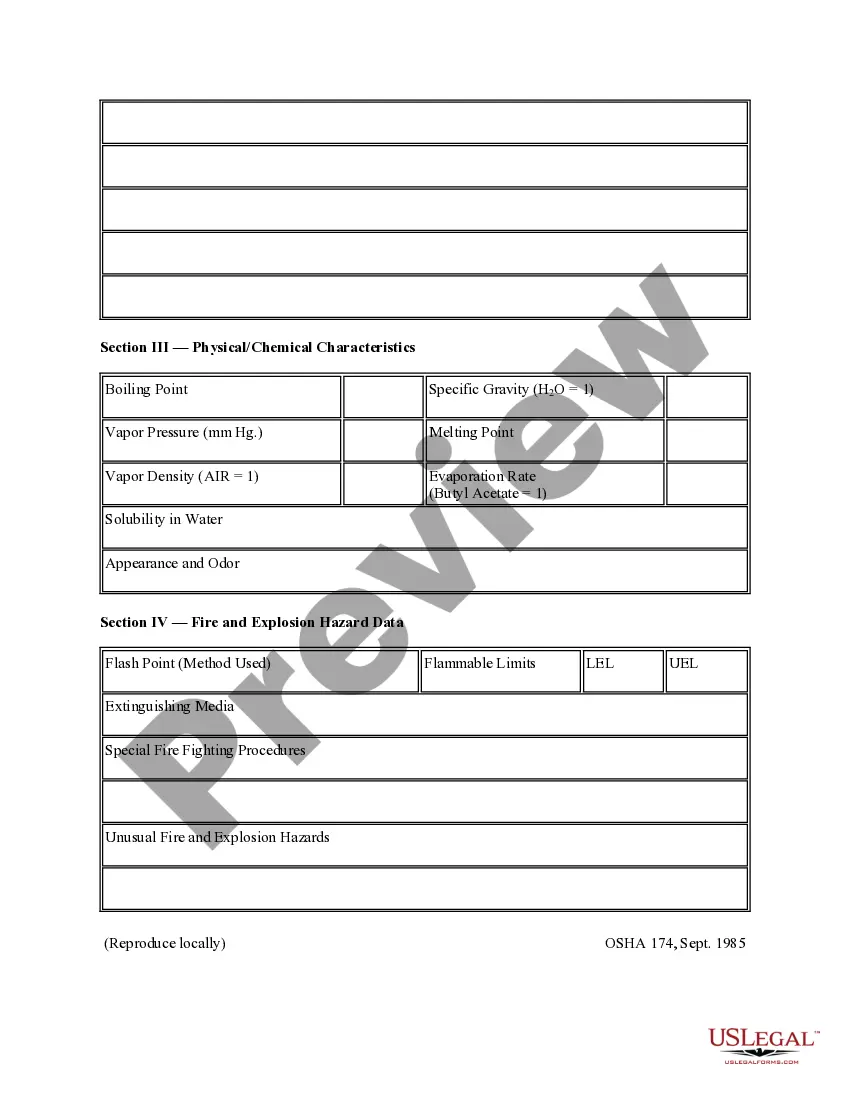

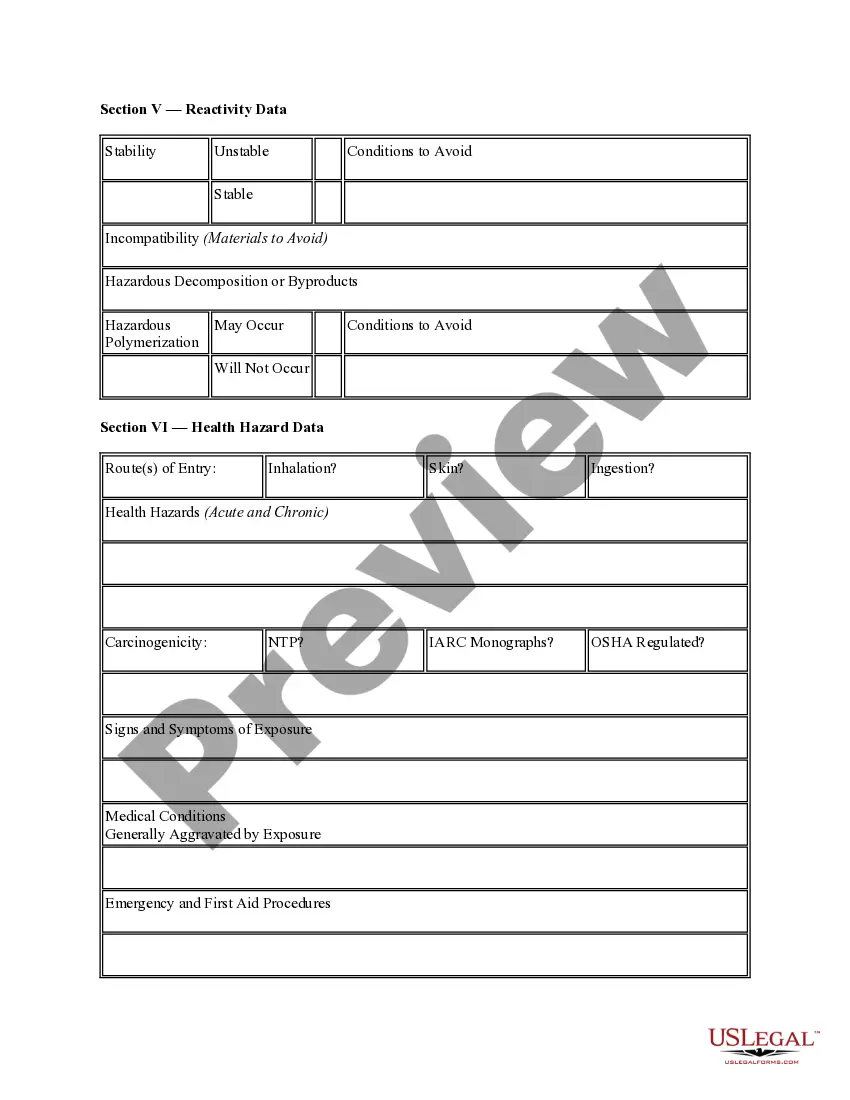

What information is on the MSDS?Product Information: product identifier (name), manufacturer and suppliers names, addresses, and emergency phone numbers.Hazardous Ingredients.Physical Data.Fire or Explosion Hazard Data.More items...

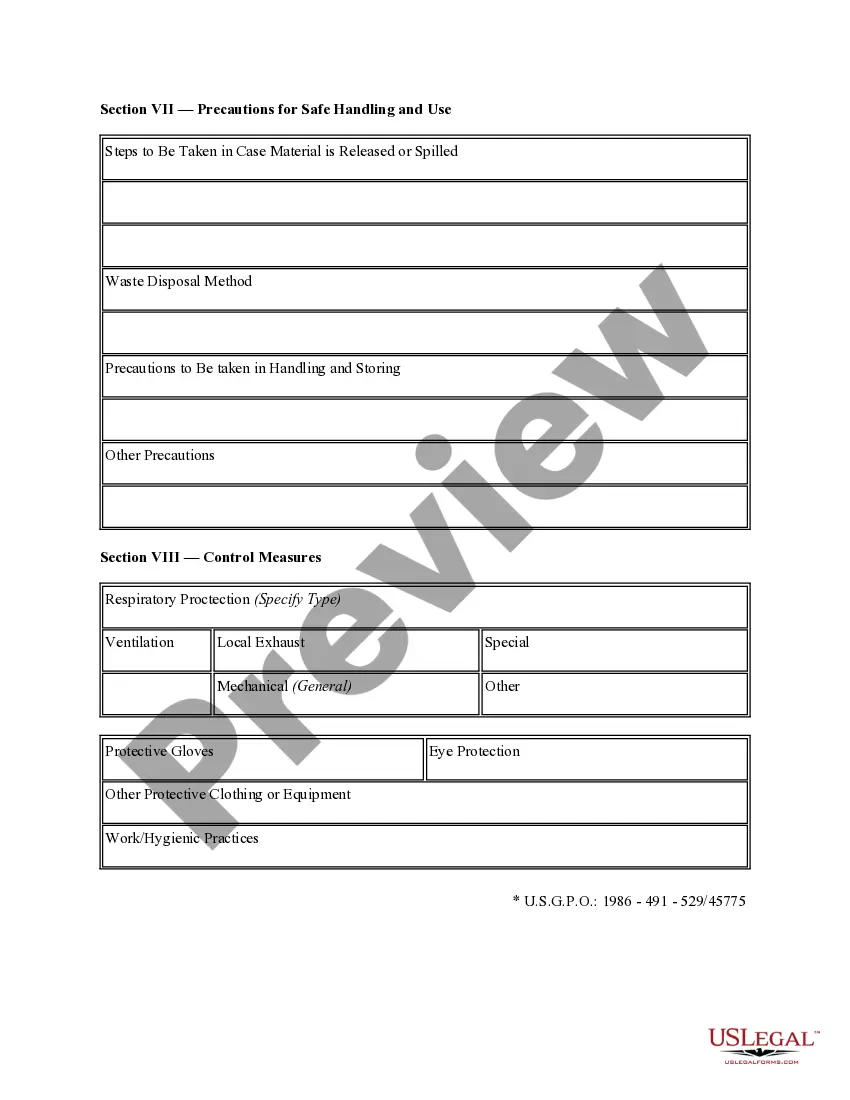

An SDS (formerly known as MSDS) includes information such as the properties of each chemical; the physical, health, and environmental health hazards; protective measures; and safety precautions for handling, storing, and transporting the chemical.

A Breakdown of the 4 Steps of a Job Safety Analysis (JSA)Choose a job to analyze. At some point you would ideally do a JSA for every job performed in your workplace.Break the job down into specific tasks.Determine hazards and risk present in each task.Identify preventative controls and residual risk.

OSHA encourages employers conduct JHAs at worksites with occupations: With the highest injury or illness rates. With the potential to cause severe or disabling injuries or illnesses, even if there is no history of previous incidents. In which one simple human error could lead to a severe accident or injury.