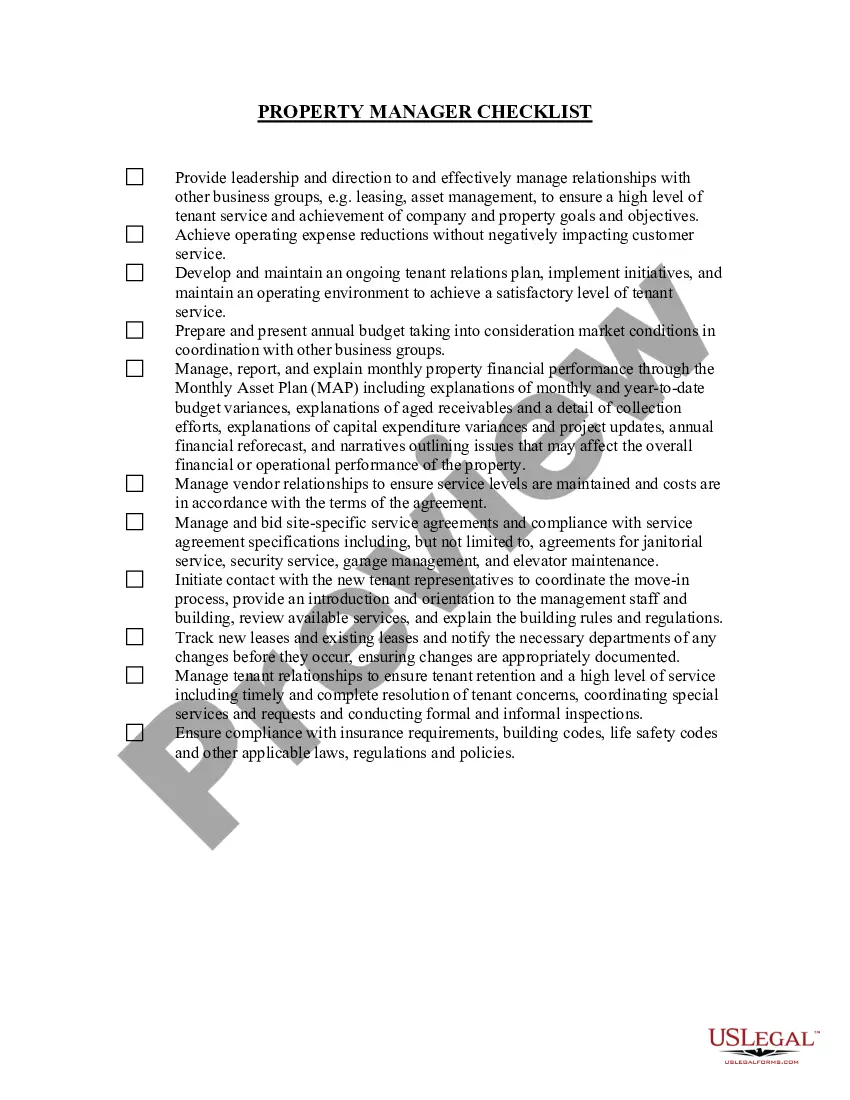

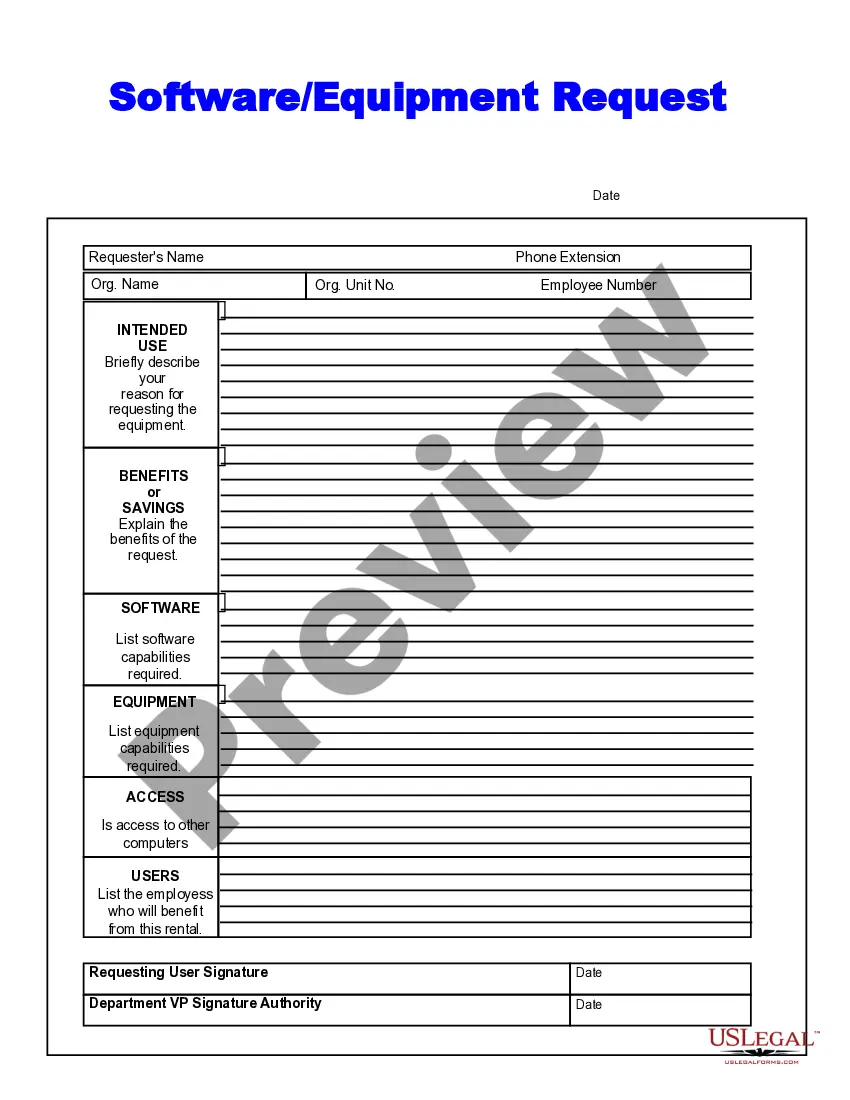

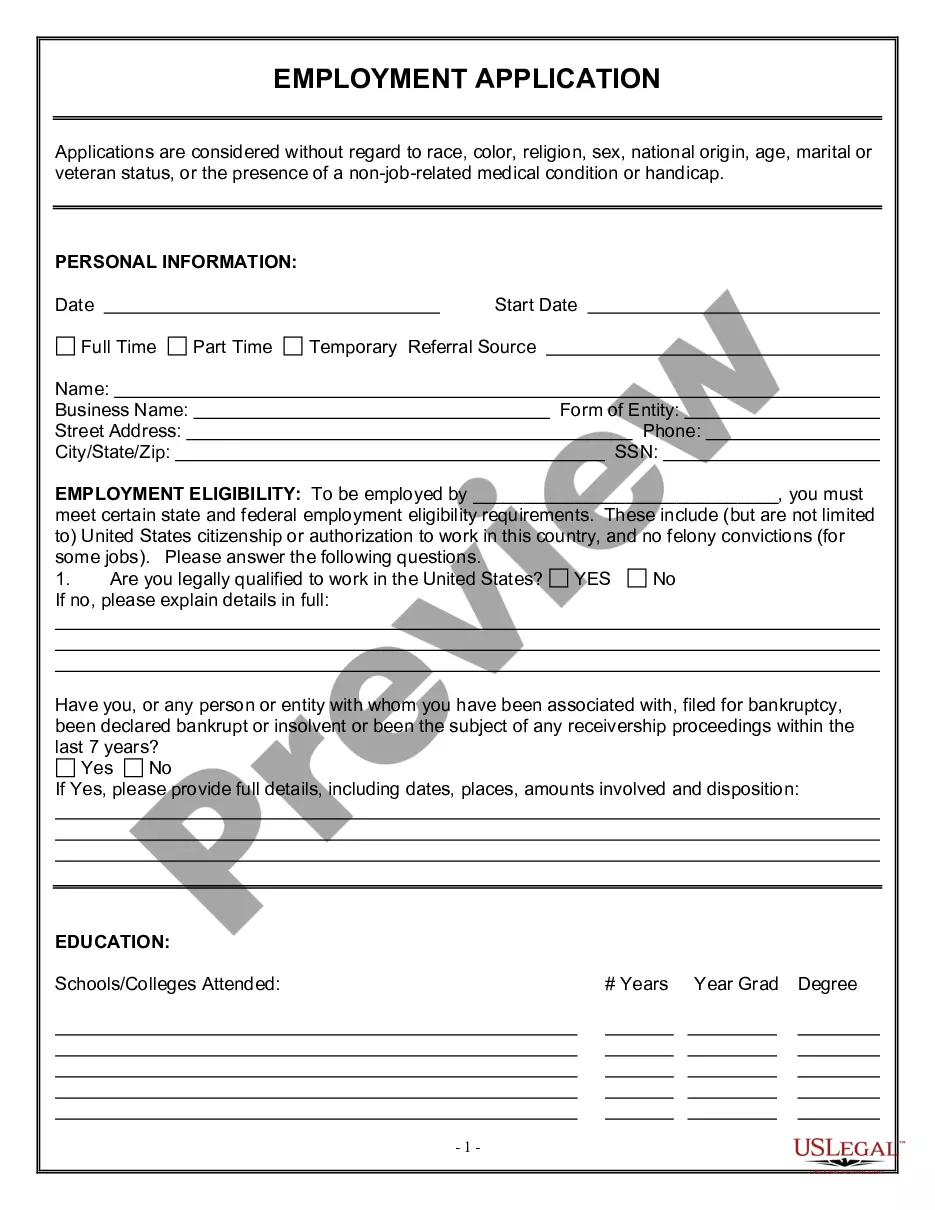

Pennsylvania Maintenance Supervisor Checklist

Description

How to fill out Maintenance Supervisor Checklist?

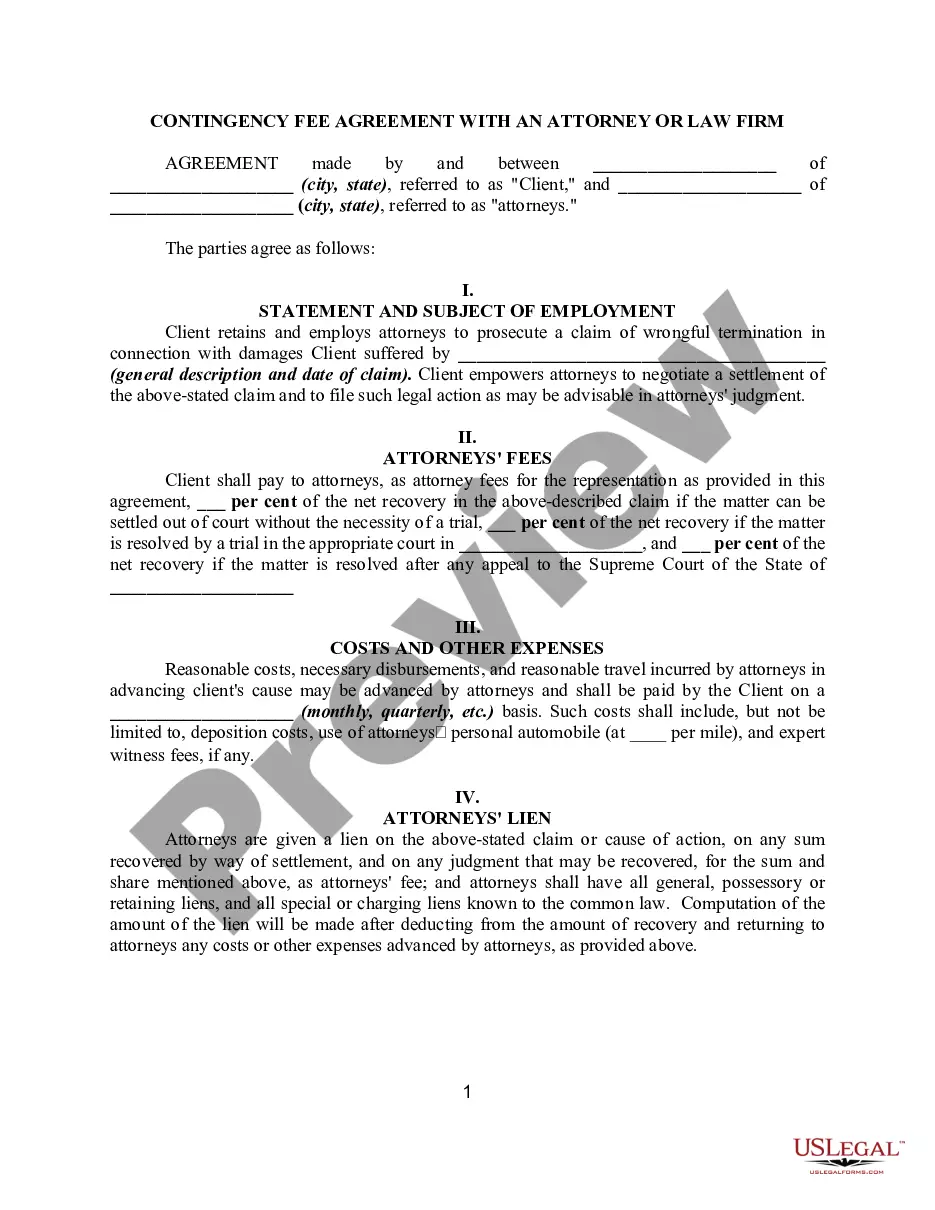

You can spend several hours online searching for the legal form template that meets the state and federal requirements you will need.

US Legal Forms provides thousands of legal documents that have been vetted by professionals.

You can easily obtain or print the Pennsylvania Maintenance Supervisor Checklist from our service.

If available, utilize the Preview option to examine the document template at the same time. If you wish to find another version of the form, take advantage of the Search field to locate the template that suits your needs and requirements.

- If you already possess a US Legal Forms account, you can Log In and click on the Download option.

- Then, you can complete, modify, print, or sign the Pennsylvania Maintenance Supervisor Checklist.

- Each legal form template you acquire is yours to keep forever.

- To obtain a duplicate of any purchased document, navigate to the My documents section and select the relevant option.

- If this is your first time using the US Legal Forms website, follow the simple instructions provided below.

- First, ensure you have selected the correct document template for the state/region you choose.

- Read the form description to confirm you have selected the right form.

Form popularity

FAQ

Preventive maintenance (PM) is the regular and routine maintenance of equipment and assets in order to keep them running and prevent any costly unplanned downtime from unexpected equipment failure. A successful maintenance strategy requires planning and scheduling maintenance of equipment before a problem occurs.

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

Wipe machine surfaces of lubricant, dirt and other loose debris each day. Regularly inspect tools for sharpness. Check for and replace worn or damaged tools. Routinely check all machinery fluid levels and air filters and replace as needed. Calibrate machines regularly.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

In order to build a most effective checklist that fits their enterprise, businesses should first:Delegate maintenance duties to relevant people.Set preventive maintenance program goals.Gether information about existing equipment.Shortlist equipment before including in the checklist.More items...?

PM A service is also known as a maintenance check-out or safety inspection and generally consists of a safety check and lubrication as well as checks of key components such as brakes, lights, tire condition and inflation, and fluids. It also includes checking and adjusting high-wear components.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

A preventive maintenance checklist details the tasks that your technicians must complete during a maintenance check. A PM checklist will include both time-based (routine) and condition-based (non-routine) tasks, ensuring that critical issues are both prevented and corrected.

A general procedure for performing preventive maintenance work, such as changing a filter or inspecting an alarm system. Once you define a PM procedure, you can assign it to particular equipment items or areas that require the periodic maintenance described in the procedure.