Pennsylvania Toll Manufacturing Agreement

Description

How to fill out Toll Manufacturing Agreement?

You can dedicate hours on the web looking for the appropriate document template that fulfills the federal and state requirements you require.

US Legal Forms offers thousands of legal documents that can be reviewed by professionals.

It is easy to download or print the Pennsylvania Toll Manufacturing Agreement from their service.

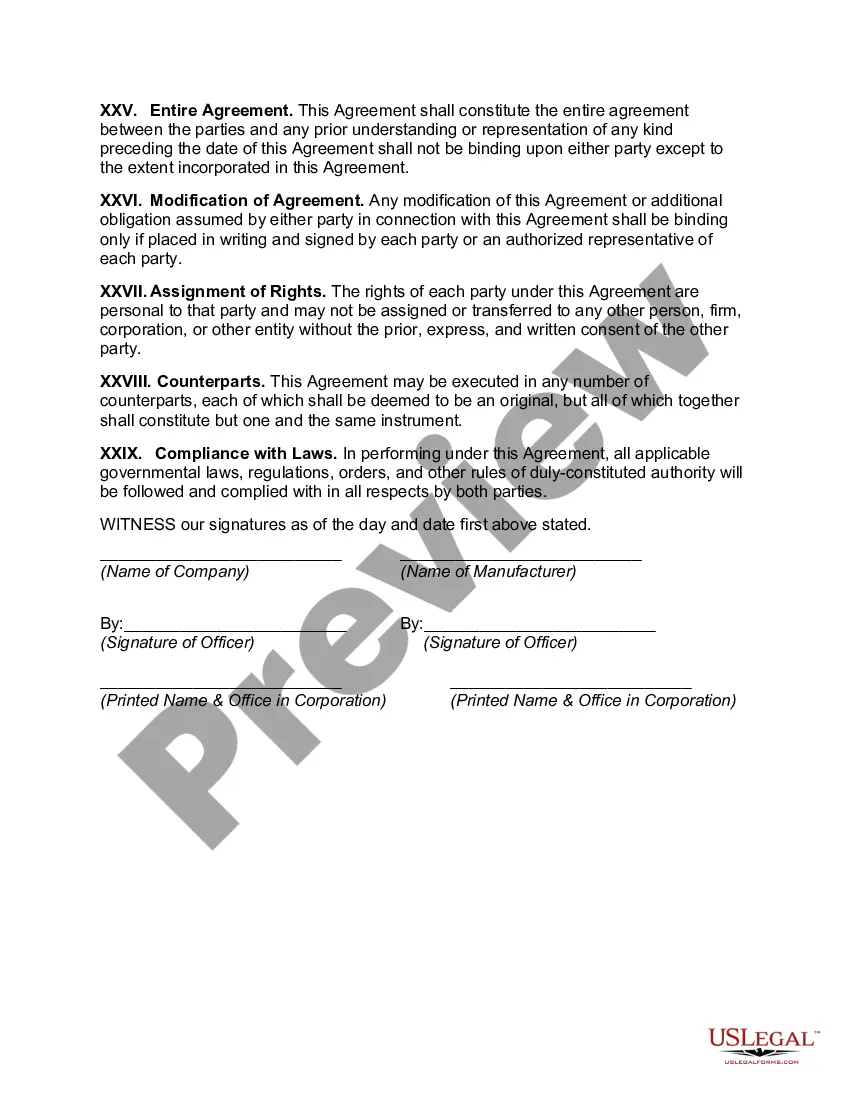

If available, utilize the Preview button to review the document template as well. To find another version of the form, use the Search field to locate the template that suits your needs and specifications.

- If you already have a US Legal Forms account, you can sign in and click the Download button.

- After that, you can complete, modify, print, or sign the Pennsylvania Toll Manufacturing Agreement.

- Each legal document template you acquire is yours permanently.

- To get another version of a purchased form, visit the My documents tab and click the corresponding button.

- If you are using the US Legal Forms website for the first time, follow the simple instructions below.

- First, make sure you have selected the correct document template for the state/city of your choice.

- Read the form description to ensure you have chosen the right one.

Form popularity

FAQ

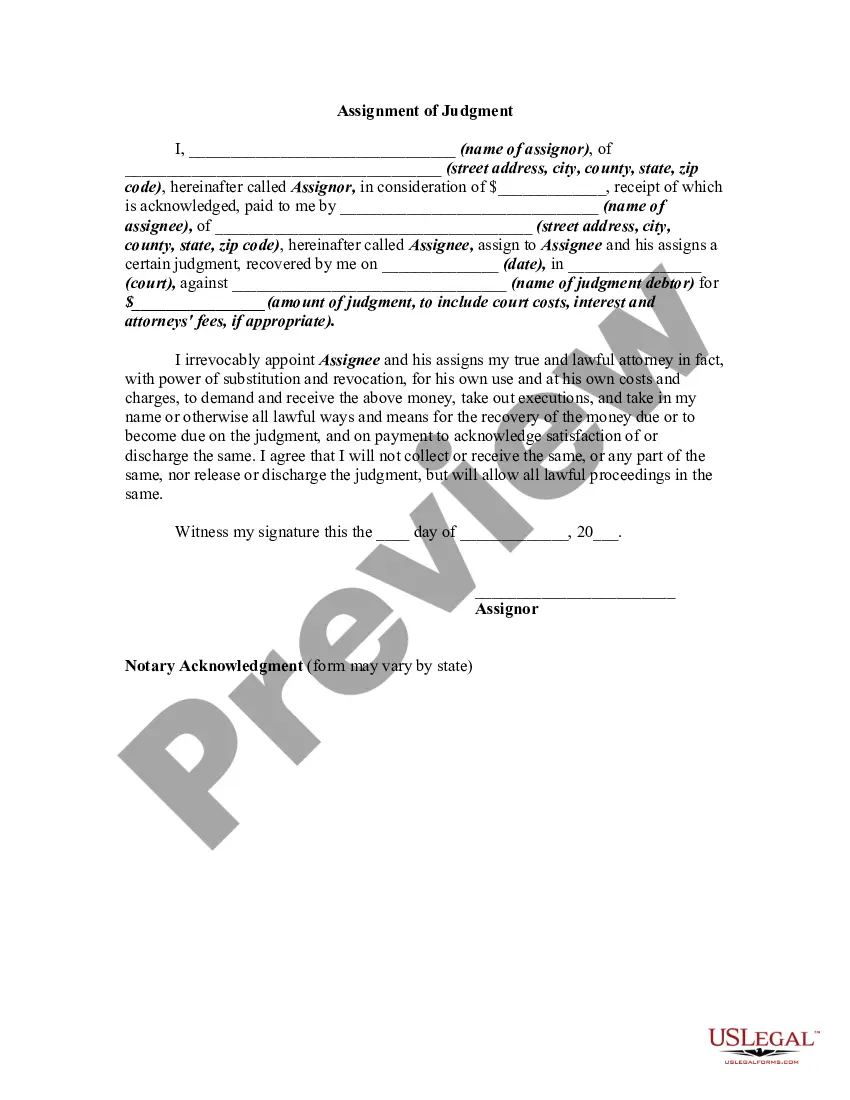

A toll agreement is a legally binding contract that outlines the terms between a manufacturer and a third-party processor. In the context of a Pennsylvania Toll Manufacturing Agreement, this document specifies the responsibilities related to processing, timelines, costs, and quality standards. Establishing clear terms in a toll agreement helps ensure smooth operations and protects both parties’ interests, ultimately leading to a successful partnership.

Toll manufacturing and subcontracting are distinct processes with unique implications. While toll manufacturing, facilitated through a Pennsylvania Toll Manufacturing Agreement, involves a third party processing raw materials into finished products, subcontracting typically involves hiring another company to perform specific tasks or services. Understanding this difference helps businesses choose the right approach based on their production needs and operational strategies.

Toll manufacturing offers several advantages for businesses seeking flexibility and efficiency. With a Pennsylvania Toll Manufacturing Agreement, companies can reduce costs related to equipment and labor by outsourcing production. This approach allows you to focus on core business activities while maintaining product quality. Moreover, it enables quicker scaling of production to meet market demands without significant upfront investments.

Profits from toll roads typically benefit the regional economy through infrastructure improvements and job creation. The Pennsylvania Turnpike Commission reinvests toll revenues into road maintenance and upgrades, fostering safe travel and enhanced connectivity. Understanding the mechanisms of profit sharing, including the implications of the Pennsylvania Toll Manufacturing Agreement, can help clarify the broader impact on local communities.

The Pennsylvania Turnpike Commission carries significant debt, primarily due to past construction projects and ongoing maintenance of the roadways. This debt reflects the long-term investment in infrastructure, aiming to enhance travel and transport efficiency in the region. As part of your exploration of the Pennsylvania Toll Manufacturing Agreement, you may find insights into how financial strategies influence roadway development.

The Pennsylvania Turnpike generates considerable revenue from tolls, with figures reaching into the hundreds of millions annually. This income supports various projects, including road reconstruction, maintenance, and new travel facilities. Additionally, understanding the role of the Pennsylvania Toll Manufacturing Agreement can help businesses strategize around toll expenses and operational costs.

The budget of the Pennsylvania Turnpike Commission focuses primarily on maintaining and improving the state's toll roads. Typically, it includes funding for infrastructure projects, operations, and debt service. The Pennsylvania Toll Manufacturing Agreement also plays a role in how resources are allocated, ensuring efficient use of funds to support road maintenance and enhancement.

Contract manufacturing involves producing goods for another company, where the client usually provides a design but may not supply raw materials. Conversely, toll manufacturing specifically requires the client to supply raw materials, making the relationship more collaborative. A Pennsylvania Toll Manufacturing Agreement focuses on processing these supplied materials, ensuring the product aligns with the client's specifications while allowing for consistent quality control.

A manufacturer typically produces their products to sell directly to consumers or businesses, while a contract manufacturer produces goods under contract for another brand. The key distinction lies in ownership and branding; manufacturers own the product and brand, whereas contract manufacturers operate under the brand name of their clients. Engaging in a Pennsylvania Toll Manufacturing Agreement allows companies to outsource production while keeping their brand identity intact.

A tolling manufacturer is a company that produces goods on behalf of another company under a toll manufacturing agreement. In this arrangement, the client provides raw materials, and the toll manufacturer processes these materials to create the final product. This model allows companies to leverage specialized manufacturing capabilities without investing in their own facilities. Utilizing a Pennsylvania Toll Manufacturing Agreement can help streamline production while maintaining quality and efficiency.