Oklahoma Maintenance Engineer Checklist

Description

How to fill out Maintenance Engineer Checklist?

US Legal Forms - one of the largest repositories of legal documents in the United States - offers a vast array of legal document templates that you can download or print.

By using the website, you can access thousands of forms for business and personal purposes, organized by categories, states, or keywords.

You can find the latest versions of forms such as the Oklahoma Maintenance Engineer Checklist in just moments.

If the form does not meet your needs, utilize the Search field at the top of the screen to find one that does.

Once you are satisfied with the form, confirm your selection by clicking the Buy now button. Then, choose the payment plan you prefer and provide your details to register for an account.

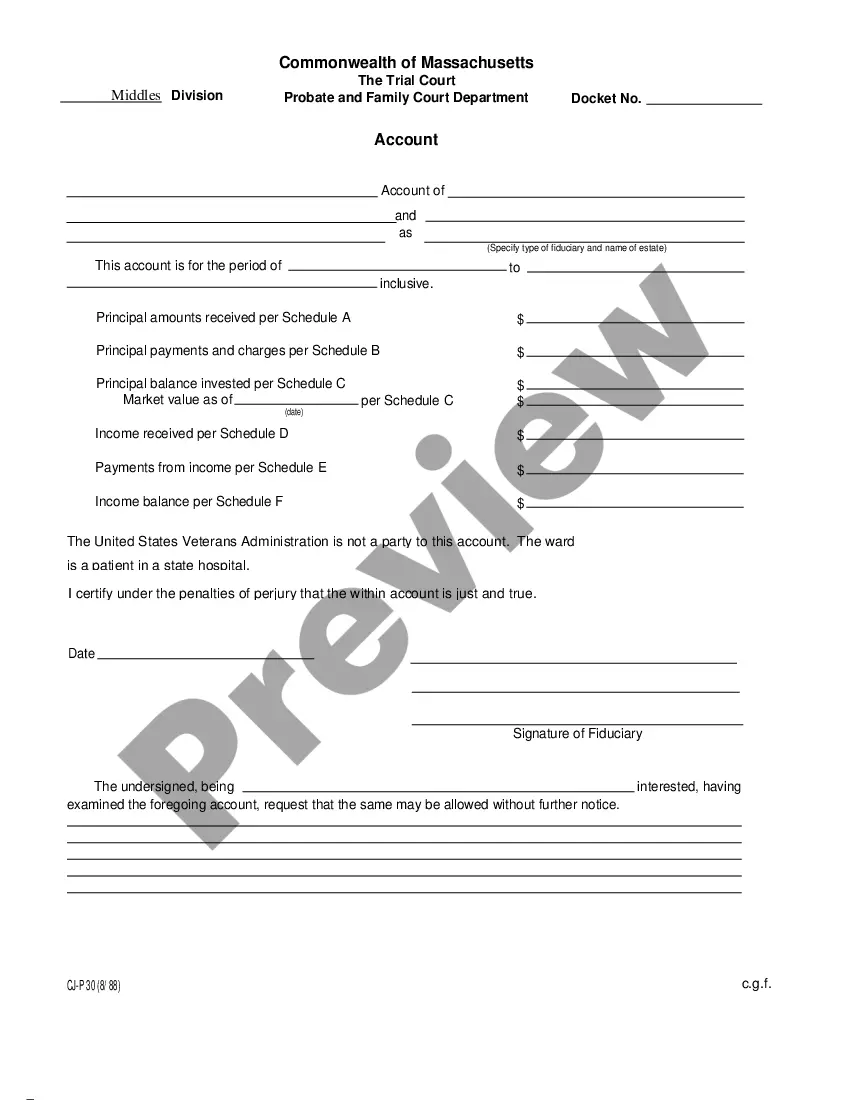

- If you already possess a subscription, Log In and download the Oklahoma Maintenance Engineer Checklist from your US Legal Forms account.

- The Download button appears on every form you view.

- You have access to all previously saved forms from the My documents section of your account.

- If you want to use US Legal Forms for the first time, here are simple instructions to help you get started.

- Ensure you have selected the correct form for the region/area.

- Click the Review button to examine the form's content.

Form popularity

FAQ

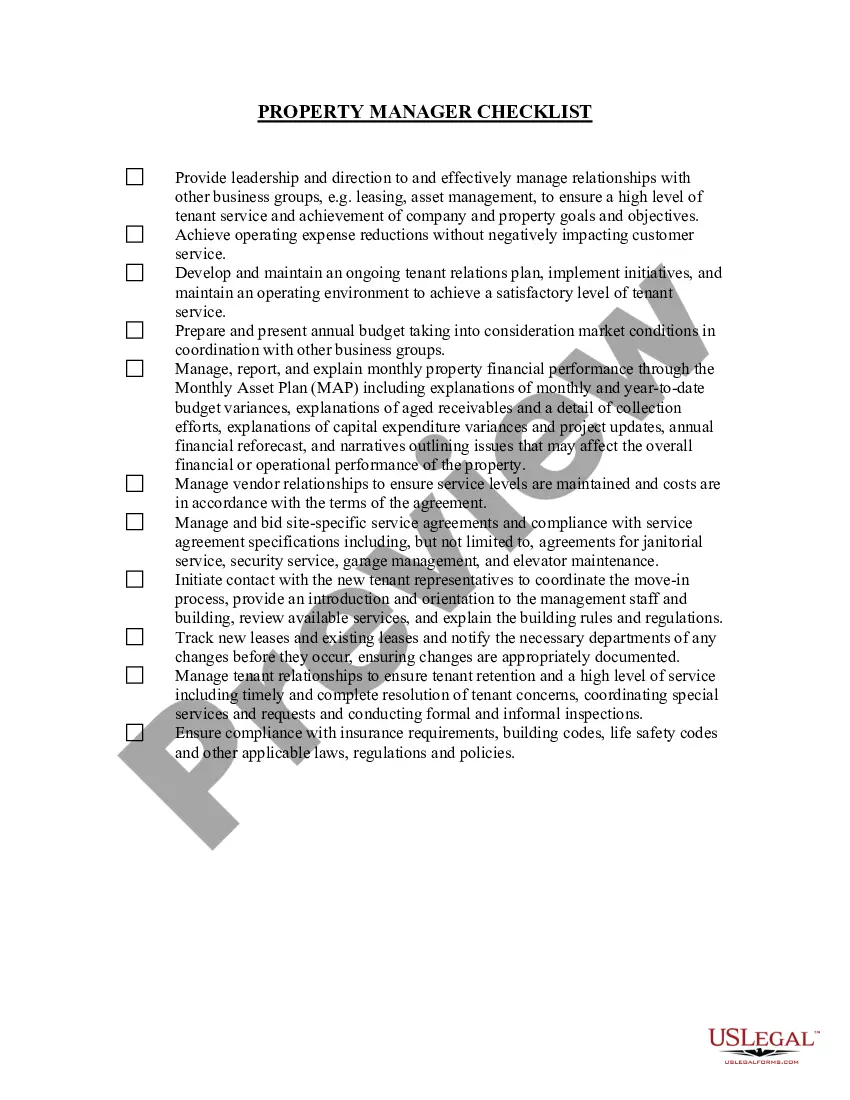

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

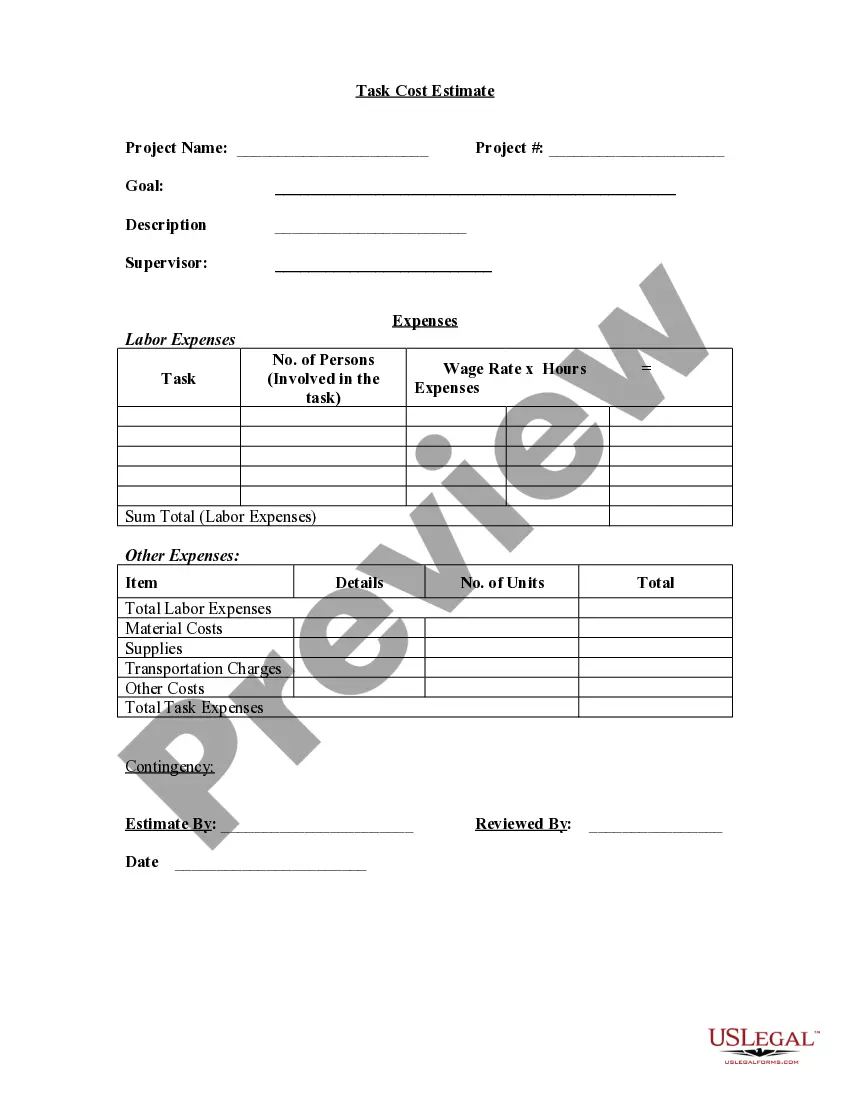

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

What is the difference between maintenance service and technical inspection? Maintenance service keeps a machine running, technical inspection cares for perfect performance and longevity.

In order to build a most effective checklist that fits their enterprise, businesses should first:Delegate maintenance duties to relevant people.Set preventive maintenance program goals.Gether information about existing equipment.Shortlist equipment before including in the checklist.More items...?

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

Six Tips for Creating a PM ChecklistInvolve the Right People in the Process. When planning the assets to maintain and creating PMs for each one, it helps to have the right types of expertise on board.Be Detailed, but Concise.Include Pictures.Include Safety Measures.Make Your Checklists Mobile.Update as Needed.

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.