Mississippi Maintenance Assistance - Technician Checklist

Description

How to fill out Maintenance Assistance - Technician Checklist?

Are you presently in a situation where you need to obtain documentation for various company or personal purposes almost every workday.

There are numerous legal document templates accessible online, but locating trustworthy ones is not straightforward.

US Legal Forms provides a vast array of form templates, such as the Mississippi Maintenance Assistance - Technician Checklist, which are designed to comply with federal and state regulations.

Choose the pricing plan that suits you, fill in the necessary details to create your account, and pay for the order using PayPal or a credit card.

Select a convenient file format and download your copy.

- If you are already acquainted with the US Legal Forms site and possess an account, simply Log In.

- Afterward, you can download the Mississippi Maintenance Assistance - Technician Checklist template.

- If you do not have an account and wish to begin using US Legal Forms, follow these steps.

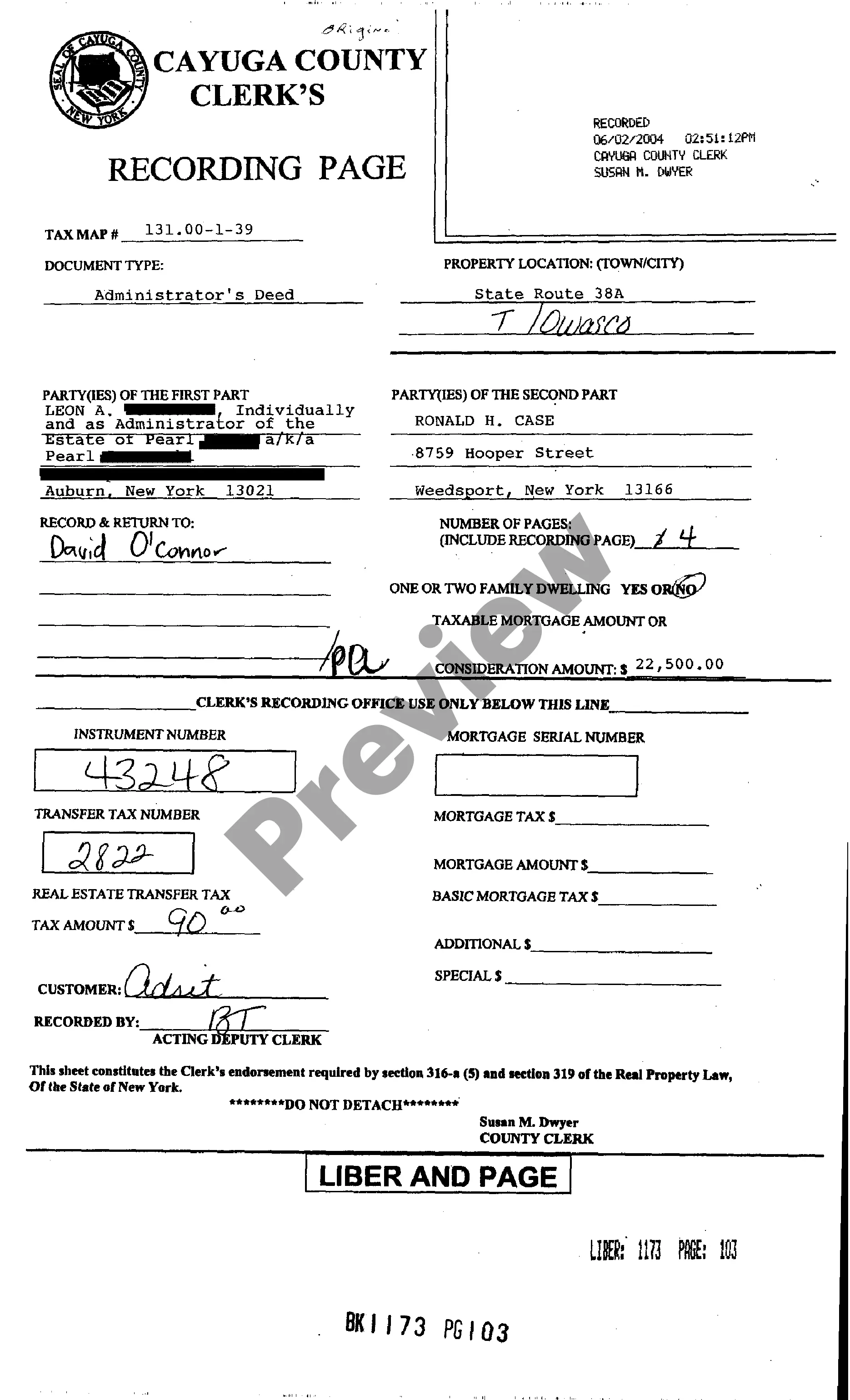

- Obtain the form you need and ensure it is for the correct city/county.

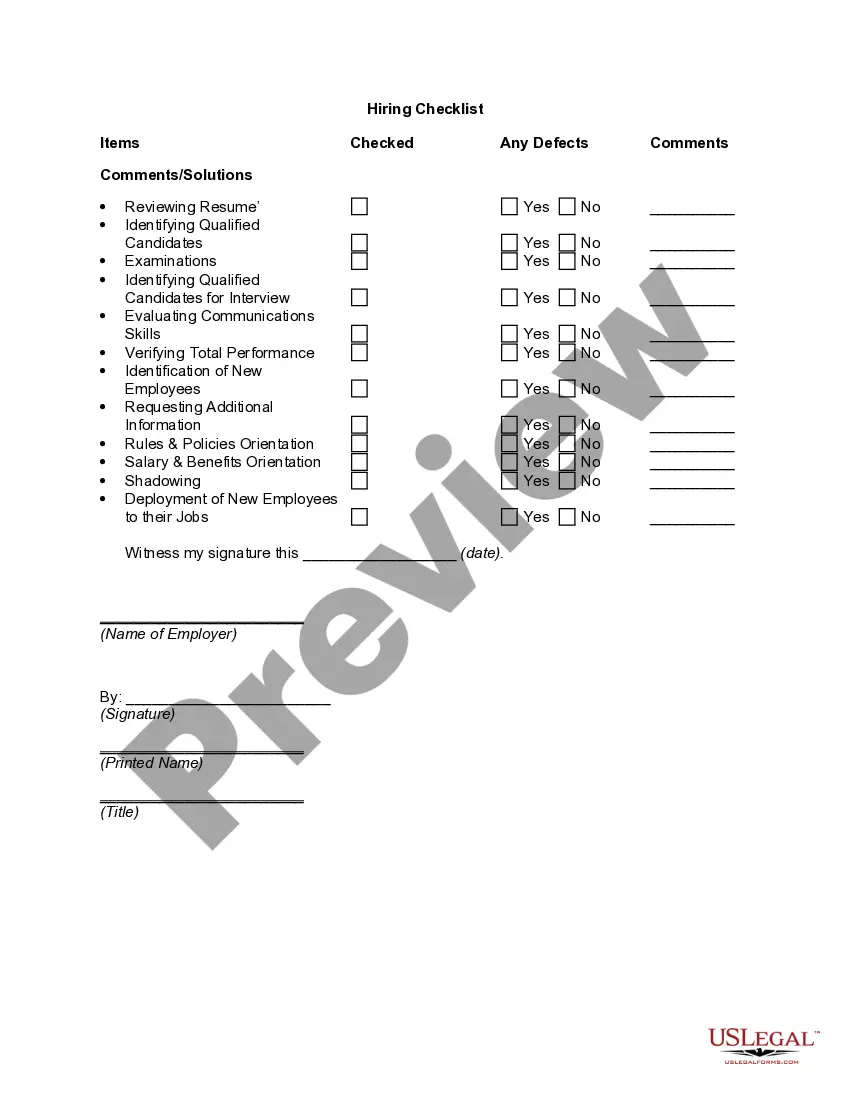

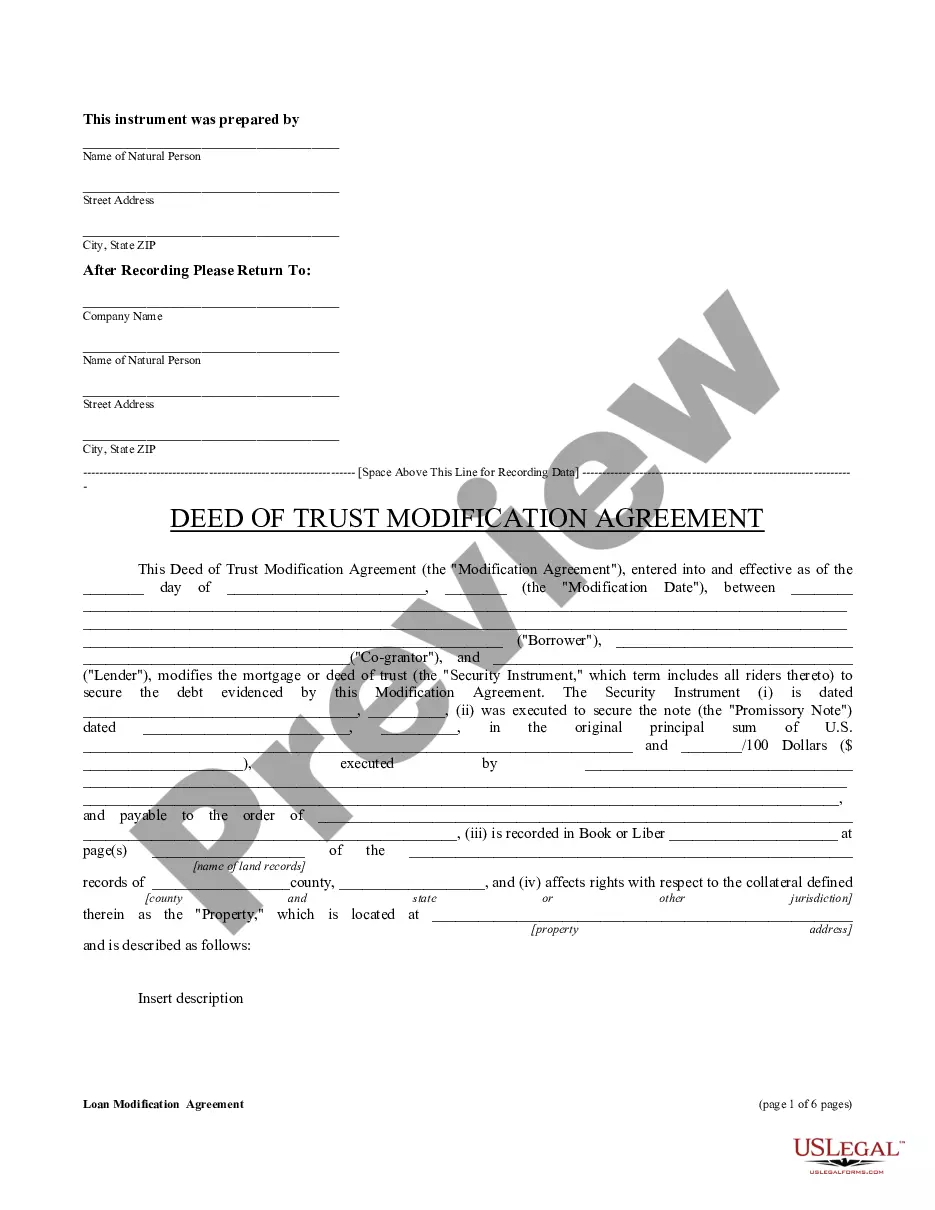

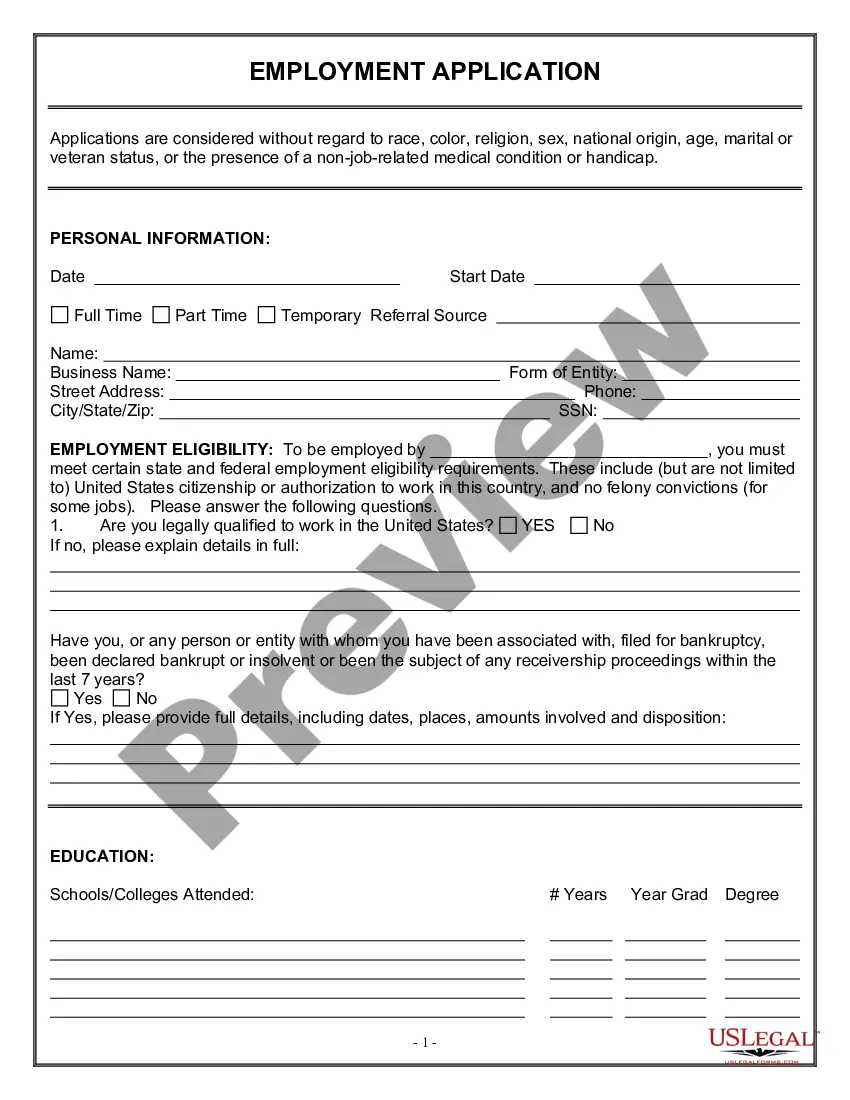

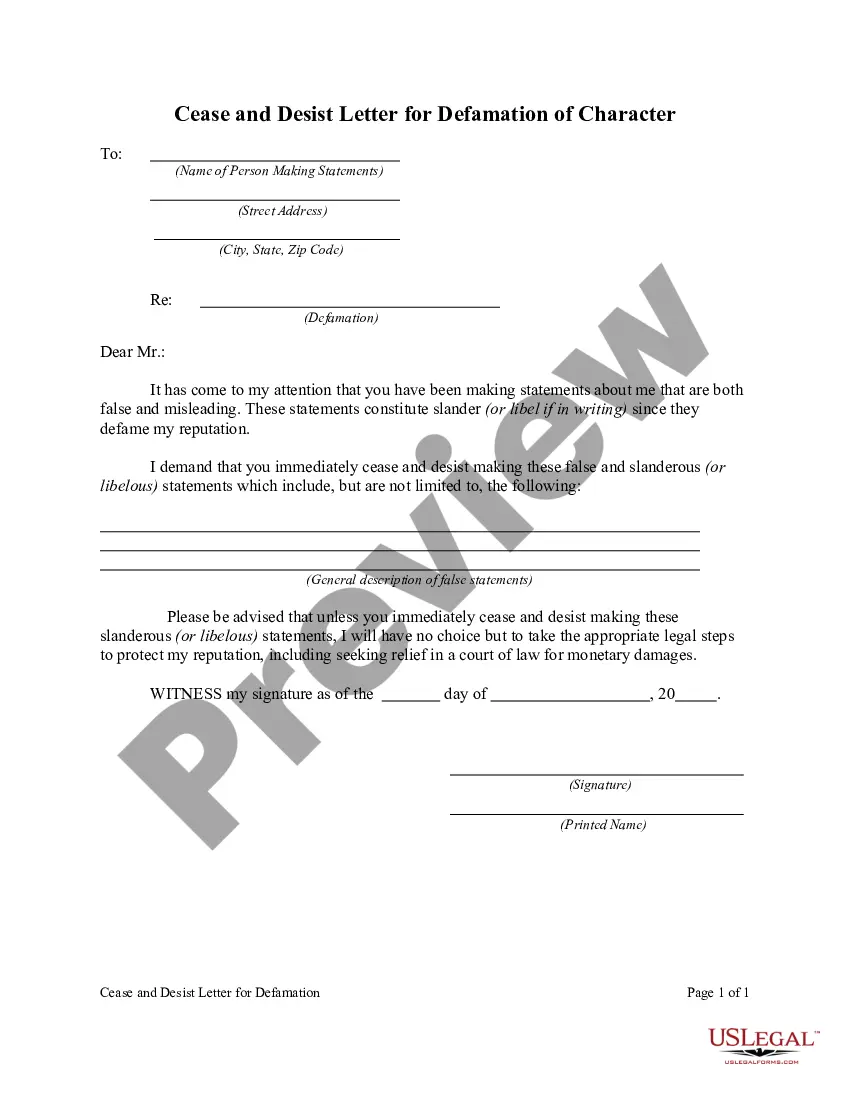

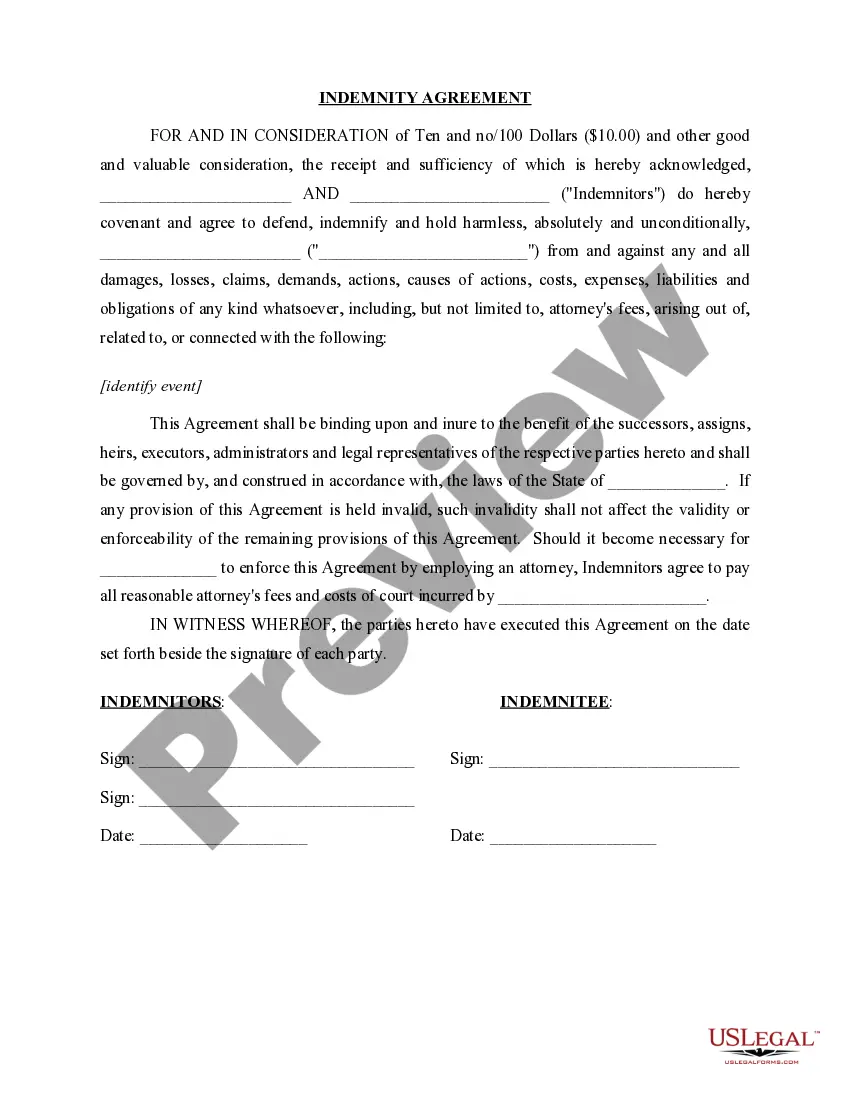

- Utilize the Preview button to inspect the form.

- Read the description to confirm you have selected the correct document.

- If the document isn’t what you are looking for, use the Search field to find the form that meets your needs.

- Once you find the appropriate document, click Purchase now.

Form popularity

FAQ

Engineering Technician I: One year of journey level technical engineering experience. Engineering Technician II: Two years of journey level technical engineering experience. Engineering Technician III: Three years of journey level technical engineering experience.

Problem-solving skills Maintenance workers need to make quick decisions and solve problems correctly and efficiently. Some repairs might be more complex or challenging than others. It's important to strive to master your diagnostic skills and prepare yourself to come up with more unconventional solutions when needed.

Maintenance Technician Responsibilities:Inspect buildings, equipment, and systems to identify any issues.Repair faulty equipment units and damaged structures.Develop and implement preventative maintenance procedures.Manage heating and plumbing systems to guarantee functionality.Plan and schedule repairs.More items...

General Maintenance Worker II maintains, services, and conducts minor repairs on buildings and equipment. Performs a variety of semiskilled duties in the areas of plumbing, carpentry, electrical, painting, or plastering.

A maintenance technician is responsible for the upkeep of a facility, such as an apartment building or business office. They are skilled in a variety of areas including plumbing, carpentry, and electrical systems. Duties include inspecting buildings, maintaining inventory, and scheduling repairs.

Technical knowledge.Attention to details.Organization and task prioritization skills.Ability to see the big picture.Proactiveness.Excellent verbal communication skills.Comfortable working in a team.Ability to work quickly under pressure.More items...?

A Maintenance Technician, is responsible for completing routine and emergency repairs to equipment, fixtures, fittings and building systems. Their duties include responding to reports of broken or faulty items, conducting routine inspections of buildings and liaising with external specialists and contractors.

Maintenance mechanics, while they are more specialized, focus on one singular area: machines and mechanical equipment. Maintenance technician, on the other hand, is a more general label. A technician might work with machinery, or they might work in apartments patching walls and fixing piping.

Maintenance Technician II is the experienced journey level class in the series, fully competent to independently perform duties. This class is distinguished from the lower classification of Maintenance Technician I by the relative independence with which duties are performed.

4 Essential Skills Any Maintenance Technician Should HaveProblem Solving.Physical Ability.Attention to Detail.Versatility.