Manufacturing Capacity Formula

Description

How to fill out Sample Joint Venture Agreement Regarding The Expansion Of Production Capacity?

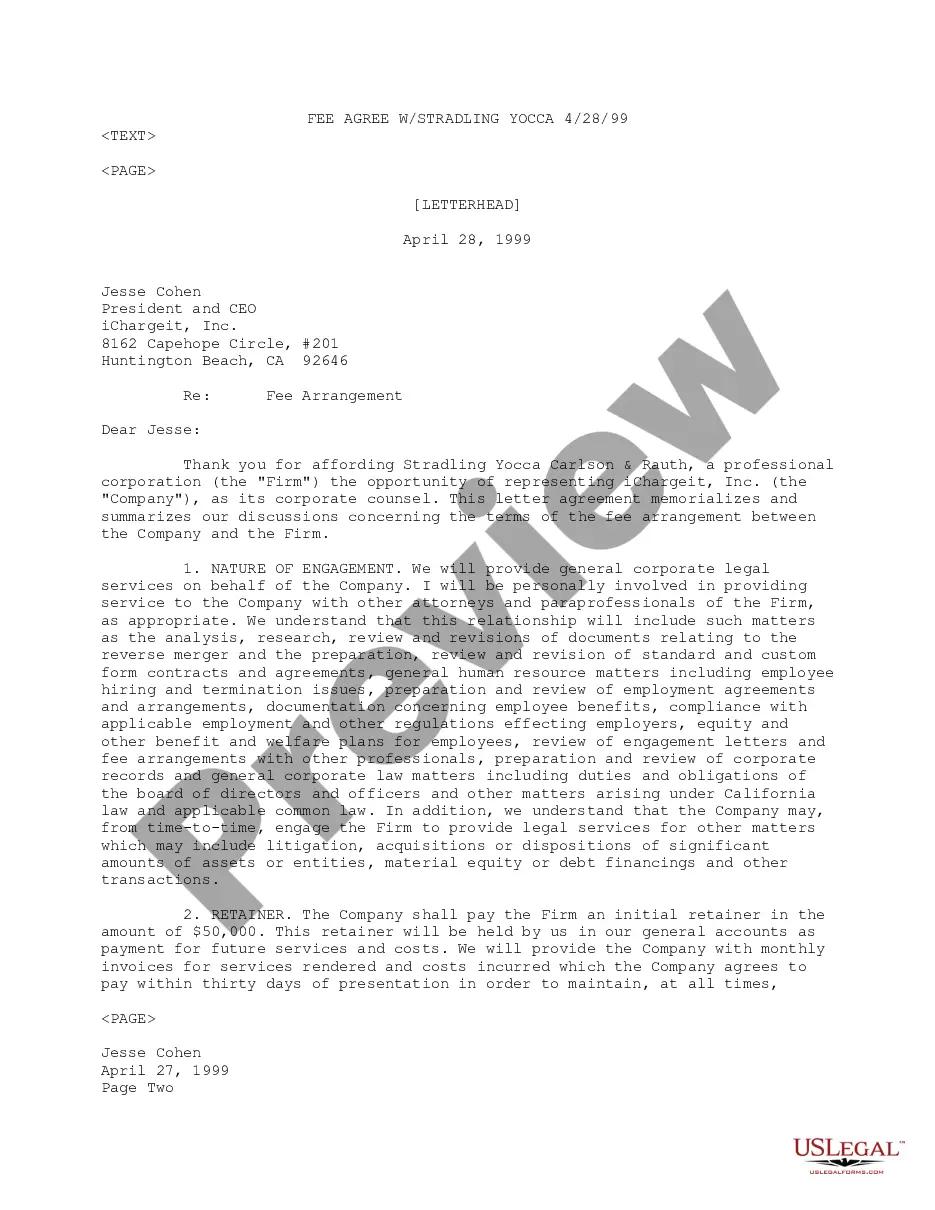

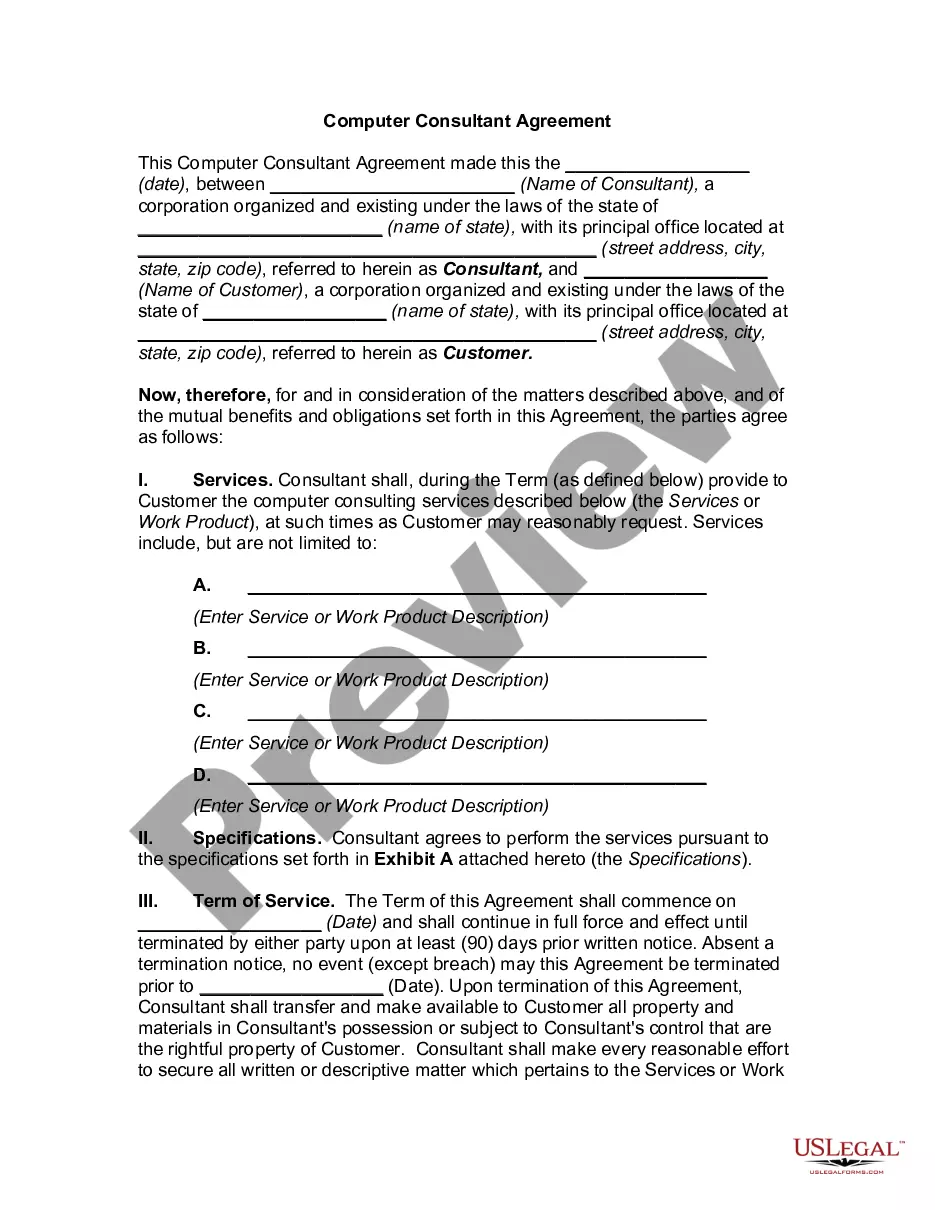

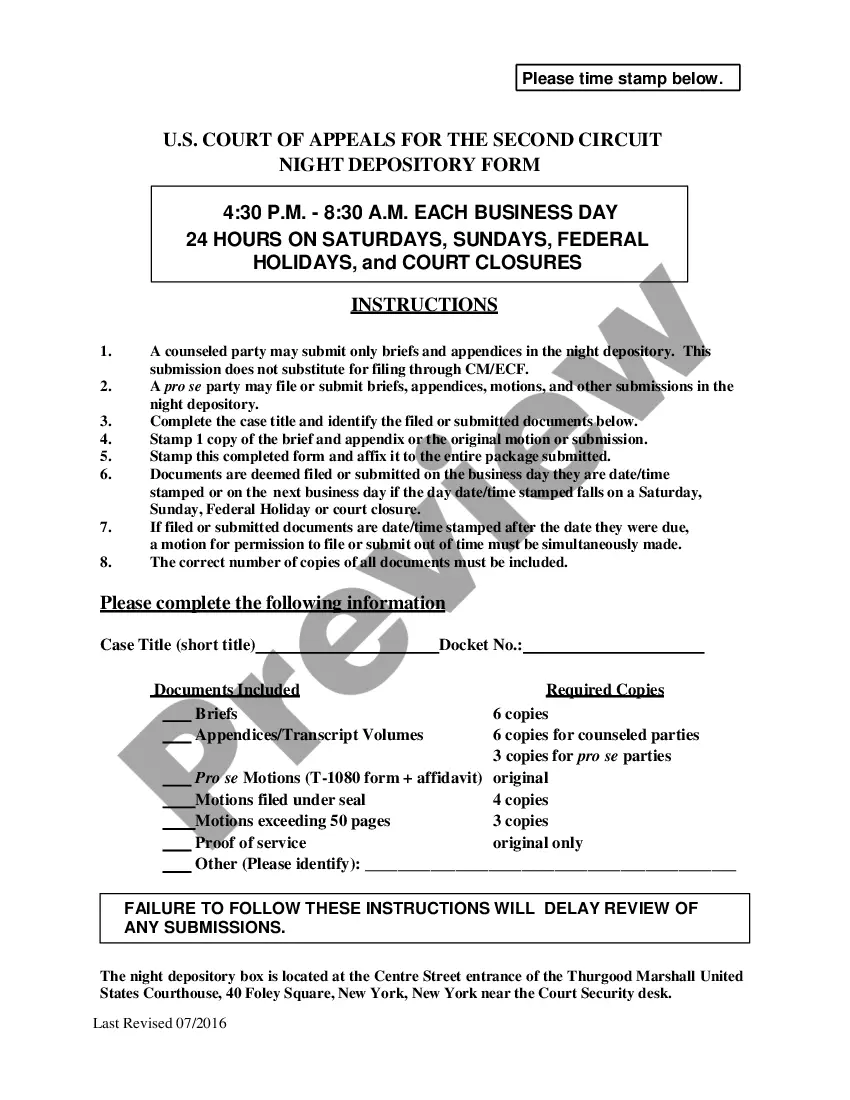

The Manufacturing Capacity Formula you see on this page is a multi-usable legal template drafted by professional lawyers in line with federal and local laws. For more than 25 years, US Legal Forms has provided individuals, businesses, and attorneys with more than 85,000 verified, state-specific forms for any business and personal situation. It’s the fastest, most straightforward and most reliable way to obtain the paperwork you need, as the service guarantees bank-level data security and anti-malware protection.

Getting this Manufacturing Capacity Formula will take you only a few simple steps:

- Browse for the document you need and review it. Look through the file you searched and preview it or review the form description to verify it fits your requirements. If it does not, make use of the search bar to find the right one. Click Buy Now once you have located the template you need.

- Subscribe and log in. Choose the pricing plan that suits you and create an account. Use PayPal or a credit card to make a prompt payment. If you already have an account, log in and check your subscription to proceed.

- Get the fillable template. Select the format you want for your Manufacturing Capacity Formula (PDF, Word, RTF) and save the sample on your device.

- Fill out and sign the paperwork. Print out the template to complete it by hand. Alternatively, utilize an online multi-functional PDF editor to quickly and accurately fill out and sign your form with a eSignature.

- Download your papers one more time. Make use of the same document again whenever needed. Open the My Forms tab in your profile to redownload any previously saved forms.

Sign up for US Legal Forms to have verified legal templates for all of life’s scenarios at your disposal.

Form popularity

FAQ

Capacity Utilization = (Actual Output / Maximum Potential Output) x 100 The maximum potential output of the manufacturing plant. The actual output of the manufacturing plant.

Capacity Utilization = (Actual Output / Maximum Potential Output) x 100 The maximum potential output of the manufacturing plant. The actual output of the manufacturing plant.

How to Calculate Production Capacity? ?No. of Usable Machines? x ?No. Of Working Hours? = Machine Hour Capacity. 8 x 20 = 160 Machine hours (Machine Hour Capacity) 0.25 hours = Time to make one shirt. 160 / 0.25 = 640 T-shirts made per day (Production Capacity)

Production capacity is the maximum output that can be achieved in the production process of manufactured goods. It's generally a part-based metric that identifies the most goods that can be created given a set amount of resources (time, labor, materials).

Answer: An example of capacity in manufacturing would be the number of units of a product that can be produced in a given time, such as per day, week, or month. For instance, a manufacturing plant may have a production capacity of 10,000 units of a particular product per day.