Memphis Tennessee Material Requirements Planning

State:

Multi-State

City:

Memphis

Control #:

US-0017SB

Format:

Word;

Rich Text

Instant download

Description

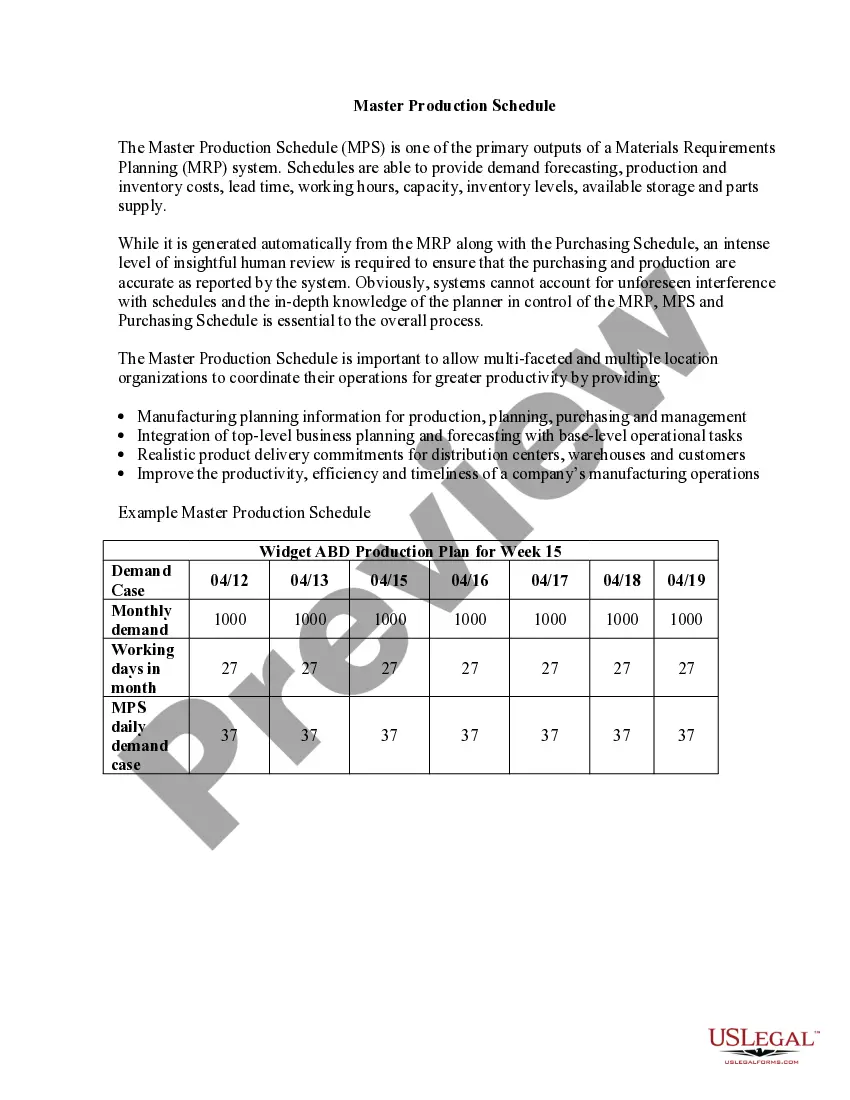

Material Requirements Planning

Free preview