Wisconsin Maintenance Supervisor Checklist

Description

How to fill out Maintenance Supervisor Checklist?

It is feasible to spend hours on the internet seeking the legal document template that meets the federal and state standards you require.

US Legal Forms offers thousands of legal forms that have been evaluated by professionals.

You can easily download or print the Wisconsin Maintenance Supervisor Checklist from my services.

If available, take advantage of the Preview option to view the document template as well.

- If you already have a US Legal Forms account, you can Log In and click on the Download button.

- Then, you can fill out, modify, print, or sign the Wisconsin Maintenance Supervisor Checklist.

- Every legal document template you purchase is yours permanently.

- To obtain another copy of a purchased form, go to the My documents section and click on the relevant option.

- If you are using the US Legal Forms website for the first time, follow the simple instructions listed below.

- First, ensure that you have selected the proper document template for the state/town of your choice.

- Review the form description to make sure you have selected the correct form.

Form popularity

FAQ

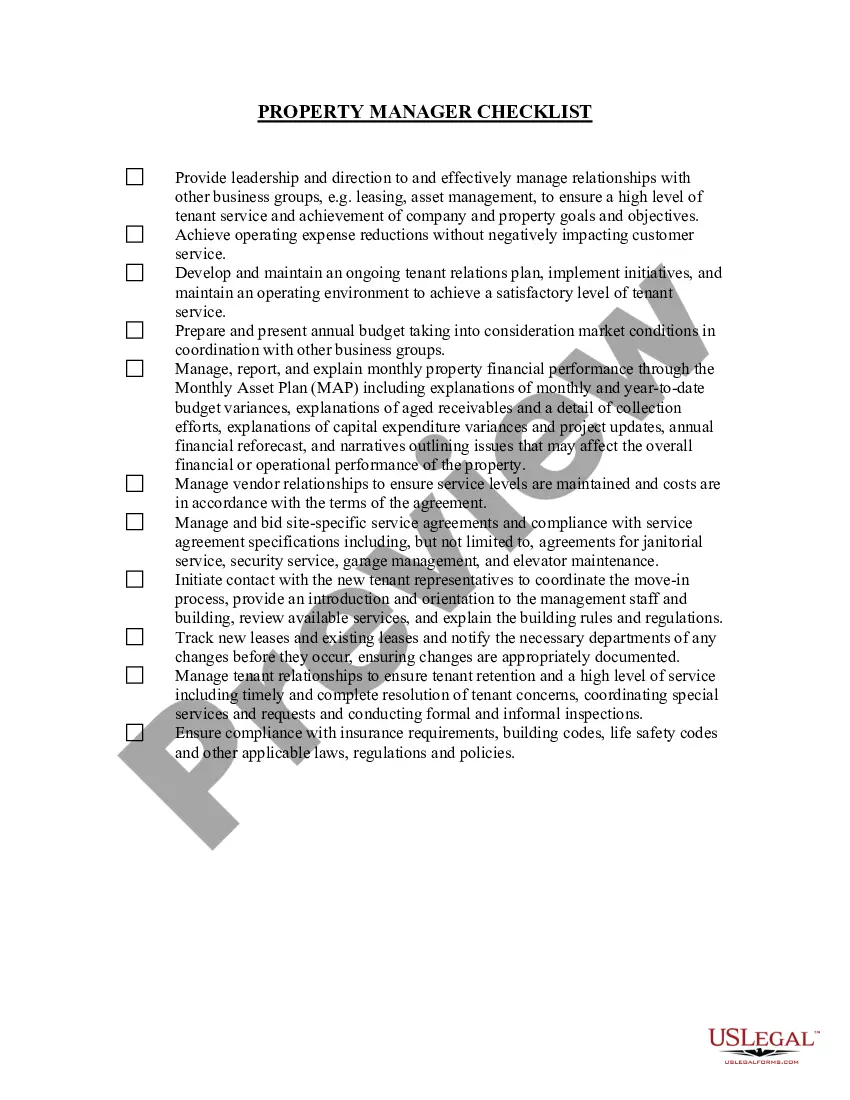

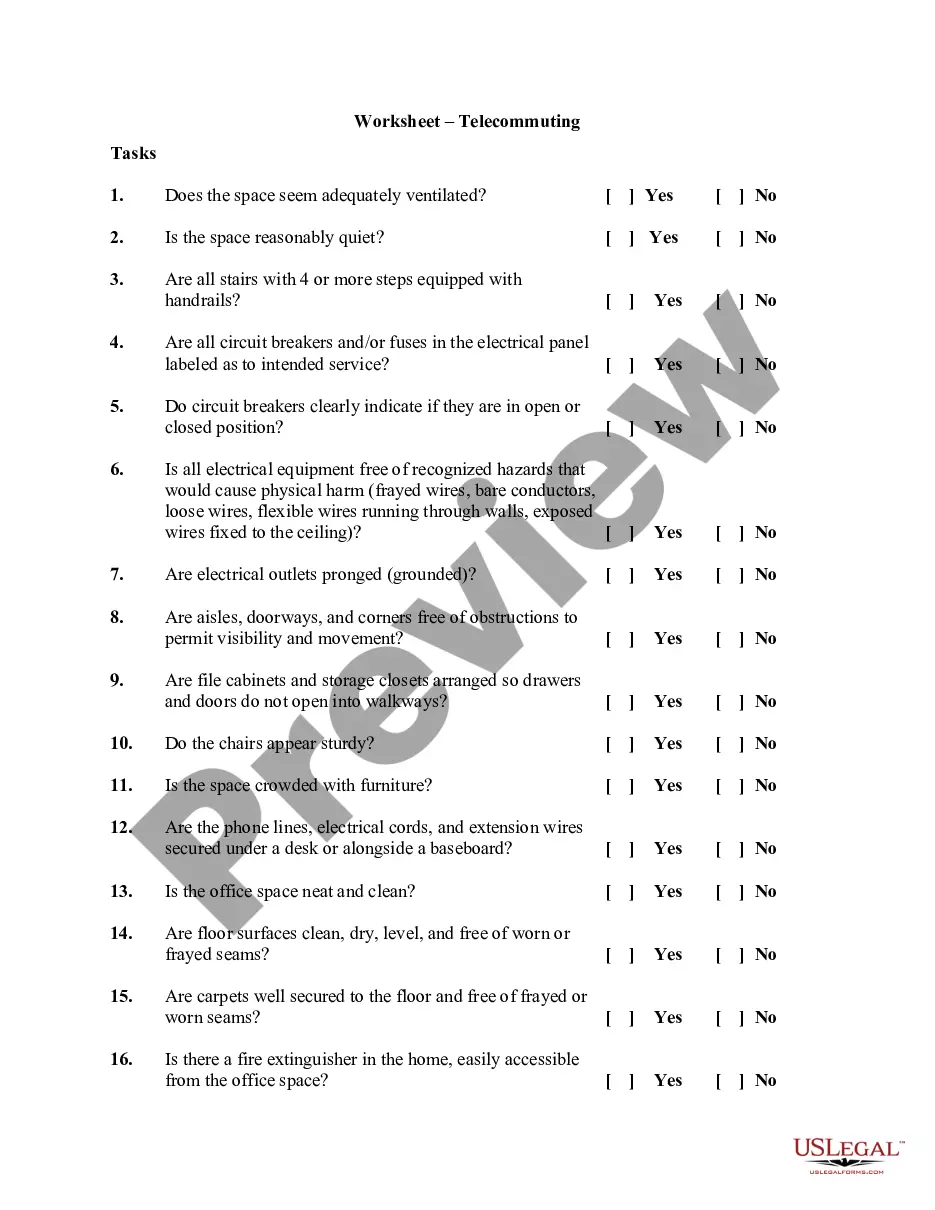

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

Examples of routine maintenance Routine maintenance in a factory setting involves lubricating, cleaning, and adjusting machines, replacing equipment parts on a schedule, inspecting certain components, or performing conditioned monitoring exercises.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

5 types of maintenance to know aboutcorrective maintenance.preventive maintenance.predictive maintenance.systematic preventive maintenance.conditional preventive maintenance.

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

This blog cover four key elements for a successful maintenance program:Work order management.Empowering with technology.Gaining asset and maintenance intelligence.Transitioning from reactive to proactive maintenance.

In order to build a most effective checklist that fits their enterprise, businesses should first:Delegate maintenance duties to relevant people.Set preventive maintenance program goals.Gether information about existing equipment.Shortlist equipment before including in the checklist.More items...?

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

Four general types of maintenance philosophies can be identified, namely corrective, preventive, risk-based and condition-based maintenance.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.