Virgin Islands Maintenance Engineer Checklist

Description

How to fill out Maintenance Engineer Checklist?

If you need to obtain, acquire, or print sanctioned document templates, utilize US Legal Forms, the largest collection of legal forms that is accessible online.

Employ the website's straightforward and user-friendly search feature to find the documents you require.

A selection of templates for corporate and personal needs is organized by categories and states, or keywords.

Step 4. Once you have located the form you need, click the Acquire now button. Select the pricing plan you prefer and provide your information to create an account.

Step 5. Complete the payment process. You can use your credit card or PayPal account to finalize the transaction. Step 6. Choose the format of the legal form and download it to your device.Step 7. Complete, edit, and print or sign the Virgin Islands Maintenance Engineer Checklist.

- Use US Legal Forms to get the Virgin Islands Maintenance Engineer Checklist with just a few clicks.

- If you are already a US Legal Forms user, Log In to your account and click the Obtain button to access the Virgin Islands Maintenance Engineer Checklist.

- You can also retrieve forms you previously downloaded from the My documents section of your account.

- If you are using US Legal Forms for the first time, refer to the guidelines below.

- Step 1. Ensure you have chosen the form for your specific city/state.

- Step 2. Use the Preview option to review the contents of the form. Don’t forget to check the summary.

- Step 3. If you are unsatisfied with the form, utilize the Search area at the top of the screen to find alternative versions of the legal form template.

Form popularity

FAQ

For proper vehicle maintenance, inspect the following:OIL AND COOLANT LEVELS.AIR FILTER.TIRE PRESSURE AND TREAD DEPTH.HEADLIGHTS, TURN SIGNALS, BRAKE, AND PARKING LIGHTS.OIL & FILTER.ROTATE TIRES.WAX VEHICLE.TRANSMISSION FLUID.More items...?

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

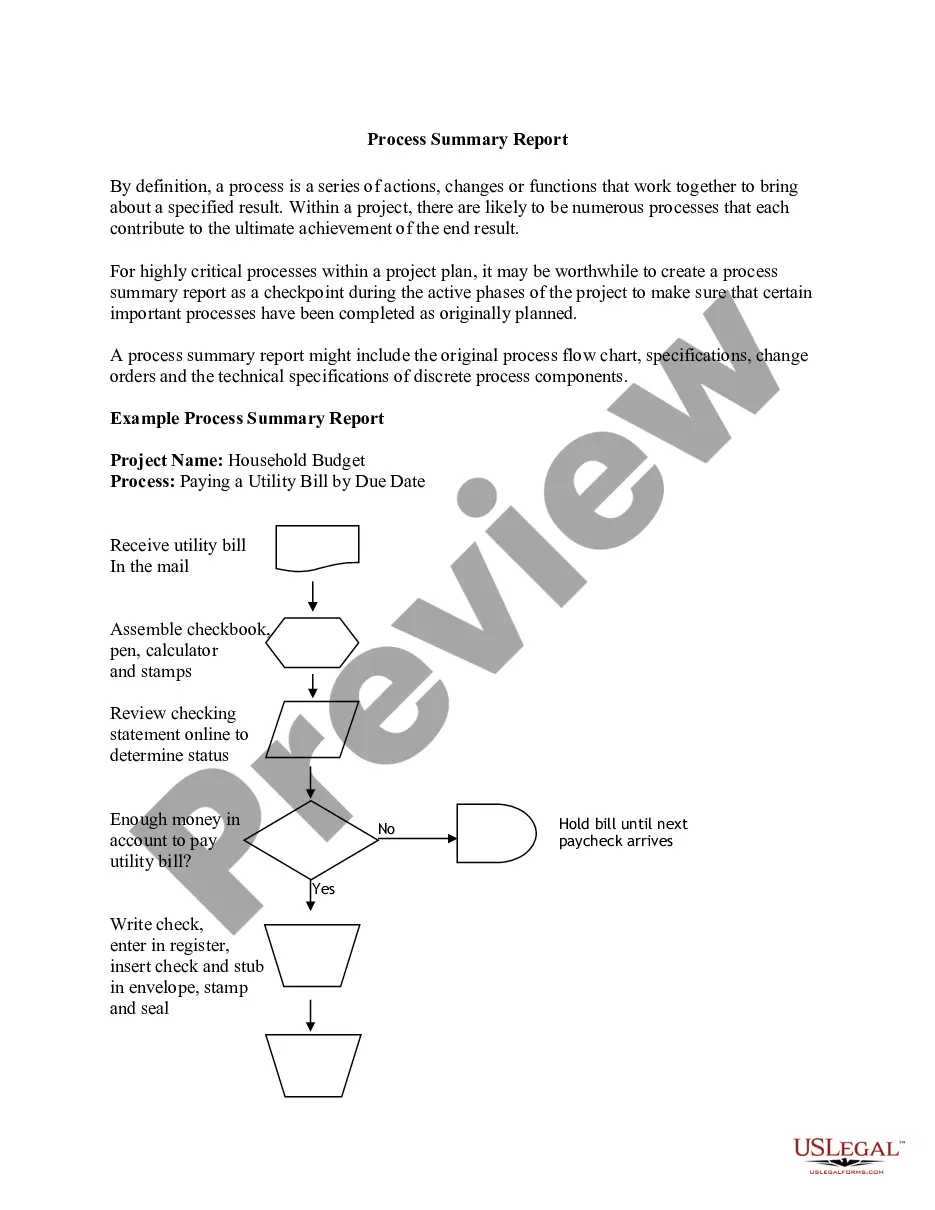

Calendar Based Maintenance refers to replacing or renewing an item to restore its reliability at a fixed time regardless of its condition. The time interval may be fixed at every week, every month or every three months. This maintenance strategy is also referred to as Time Based or Clock Based Maintenance.

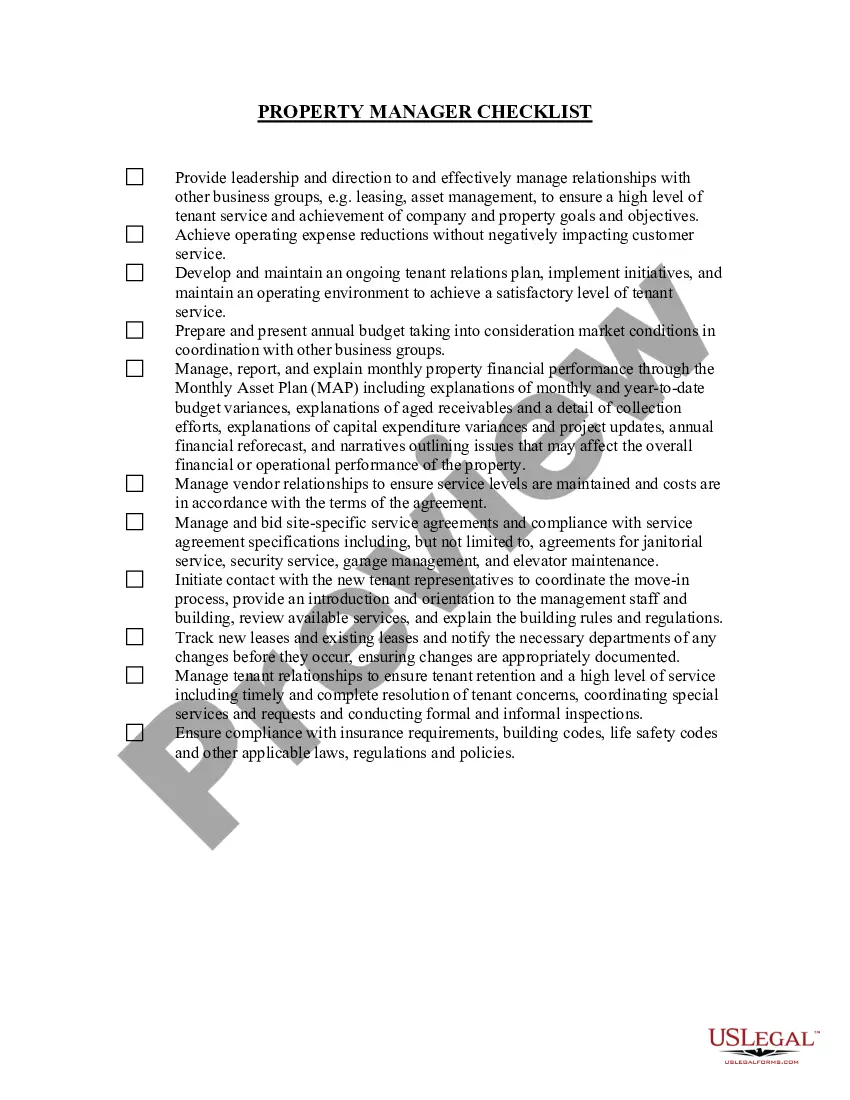

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

Maintenance activities include partial or complete overhauls at specified periods, oil changes, lubrication, minor adjustments, and so on. In addition, workers can record equipment deterioration so they know to replace or repair worn parts before they cause system failure.

Scheduled maintenance includes inspections, adjustments, regular service, and planned shutdowns. An example of scheduled maintenance occuring at repeating intervals is changing a bearing on a conveyor belt every 30 days or inspecting the condition of a motor every 90 days.

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...