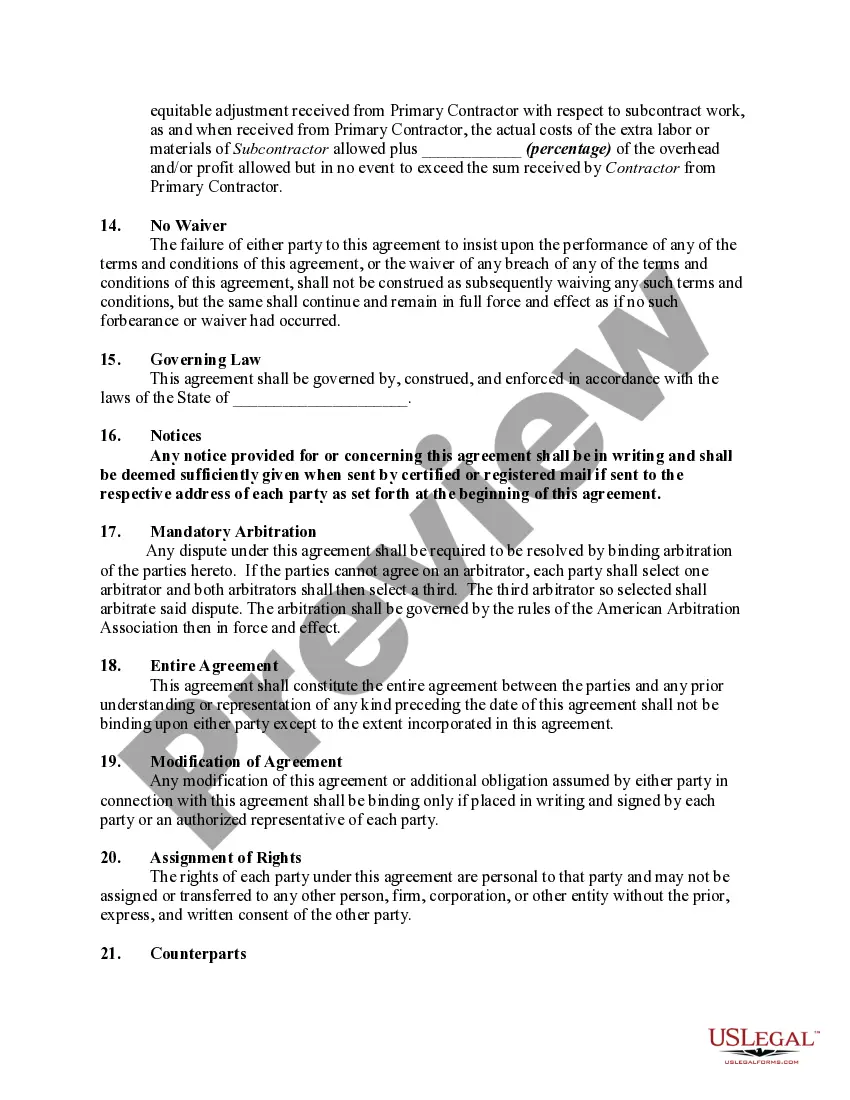

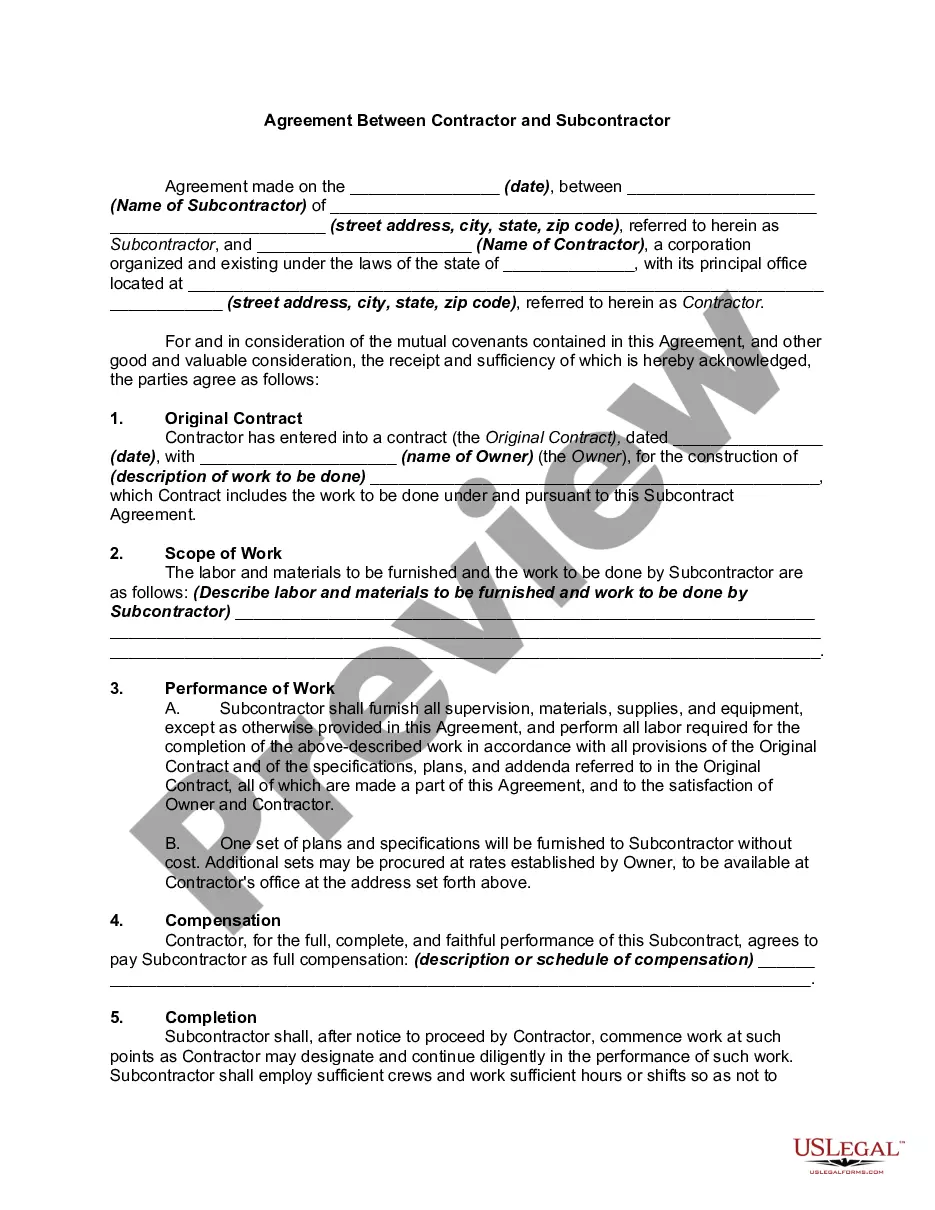

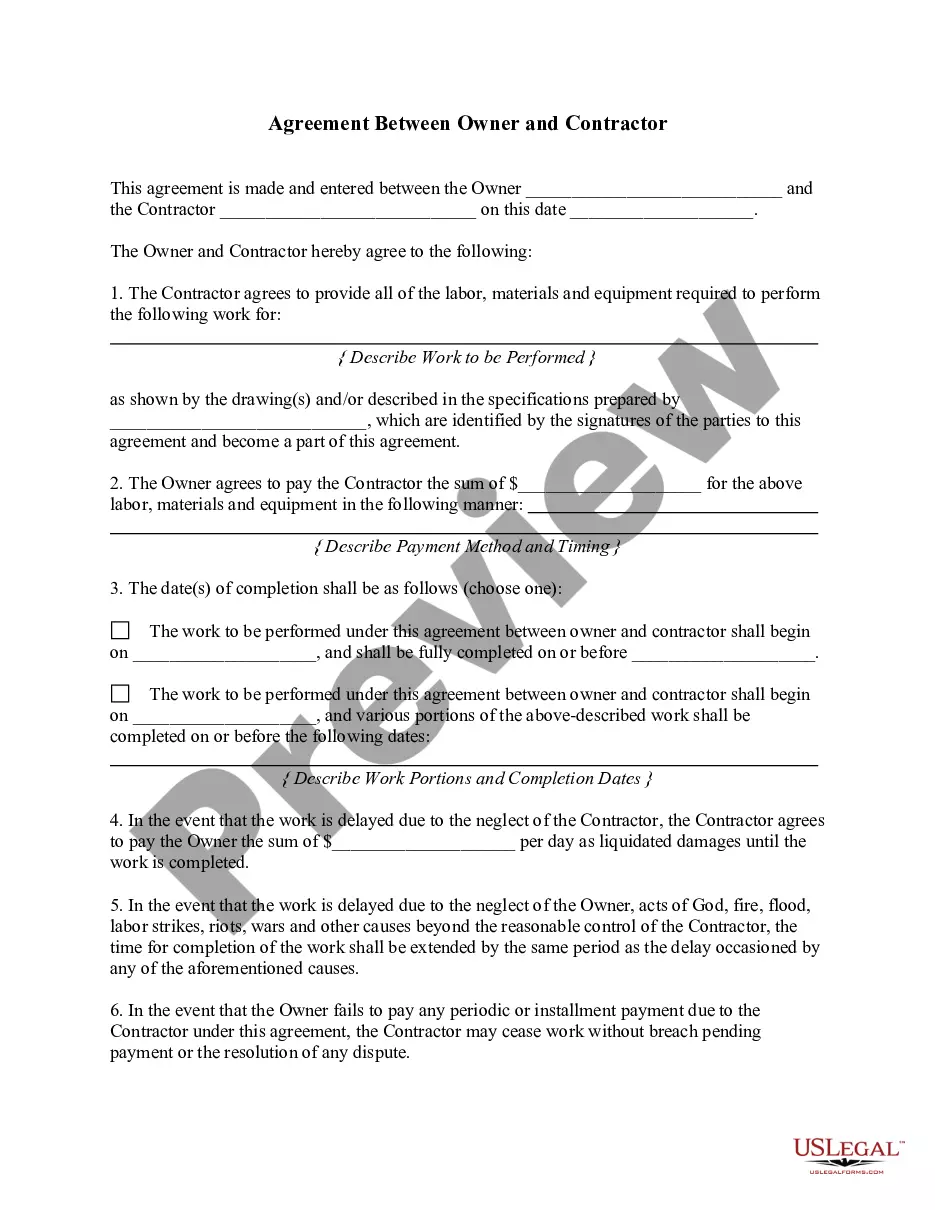

In this agreement, a subcontractor is subcontracting all work agreed to in the original agreement with the primary contractor, to another subcontractor.

Virginia Agreement to Subcontract Steel Erection for the Steel Fabricator

Description

How to fill out Agreement To Subcontract Steel Erection For The Steel Fabricator?

Locating the appropriate sanctioned document format can pose challenges.

Clearly, there are numerous templates available online, but how can you locate the authorized version you seek.

Utilize the US Legal Forms website. The service provides thousands of templates, such as the Virginia Agreement to Subcontract Steel Erection for the Steel Fabricator, which can be utilized for business and personal requirements. All documents are reviewed by professionals and comply with state and federal regulations.

If the form does not meet your expectations, utilize the Search field to find the appropriate form. Once you are sure the form is correct, click the Acquire now button to obtain the form. Choose the pricing plan you desire and enter the necessary information. Create your account and process the payment using your PayPal account or credit card. Select the file format and download the authorized document to your device. Complete, modify, print, and sign the received Virginia Agreement to Subcontract Steel Erection for the Steel Fabricator. US Legal Forms is the largest repository of legal forms where you can find a variety of document templates. Use the service to download professionally created paperwork that meets state requirements.

- If you are already registered, Log In to your account and click the Obtain button to access the Virginia Agreement to Subcontract Steel Erection for the Steel Fabricator.

- Use your account to review the legal documents you have previously obtained.

- Visit the My documents section of your account to retrieve another copy of the document you need.

- If you are a new user of US Legal Forms, follow these simple instructions.

- First, ensure that you have selected the correct form for your jurisdiction.

- You can browse the form using the Review button and examine the form description to confirm it is suitable for you.

Form popularity

FAQ

The erection of structural steelwork consists of the assembly of steel components into a frame on site. The processes involve lifting and placing components into position, then connecting them together. Generally this is achieved through bolting but sometimes site welding is used.

The duties of controlling contractors under the new standards include provisions governing construction sequence, column anchorage, falling object protection, and fall protection.

Steel erection activities include hoisting, laying out, placing, connecting, welding, burning, guying, bracing, bolting, plumbing and rigging structural steel, steel joists and metal buildings; installing metal decking, curtain walls, window walls, siding systems, miscellaneous metals, ornamental iron and similar

OSHA standards are rules that describe the methods that employers must use to protect their employees from hazards. There are four groups of OSHA standards: General Industry, Construction, Maritime, and Agriculture. (General Industry is the set that applies to the largest number of workers and worksites).

Steel erection work includes heavy duty high rise structures, metal buildings and even signs. Steel erection is often the skeletal core of bridges, office buildings, commercial, retail and industrial structures. OSHA published Subpart R, 1926.750, the current steel erection rule in 2001.

Where employers elect, due to conditions specific to the site, to develop alternate means and methods that provide employee protection in accordance with § 1926.753(c)(5), A§ 1926.757(a)(4) or A§ 1926.757(e)(4), a site-specific erection plan shall be developed by a qualified person and be available at the work site.

Steel erection activities include hoisting, laying out, placing, connecting, welding, burning, guying, bracing, bolting, plumbing and rigging structural steel, steel joists and metal buildings; installing metal decking, curtain walls, window walls, siding systems, miscellaneous metals, ornamental iron and similar

Steel erection means the construction, alteration or repair of steel buildings, bridges and other structures, including the installation of metal decking and all planking used during the process of erection.

(b) Fall hazard training. The employer shall train each employee exposed to a fall hazard in accordance with the requirements of this section. The employer shall institute a training program and ensure employee participation in the program.

Training 29 CFR 1926.761 In steel erection, training is a key element in the employer's accident prevention program.