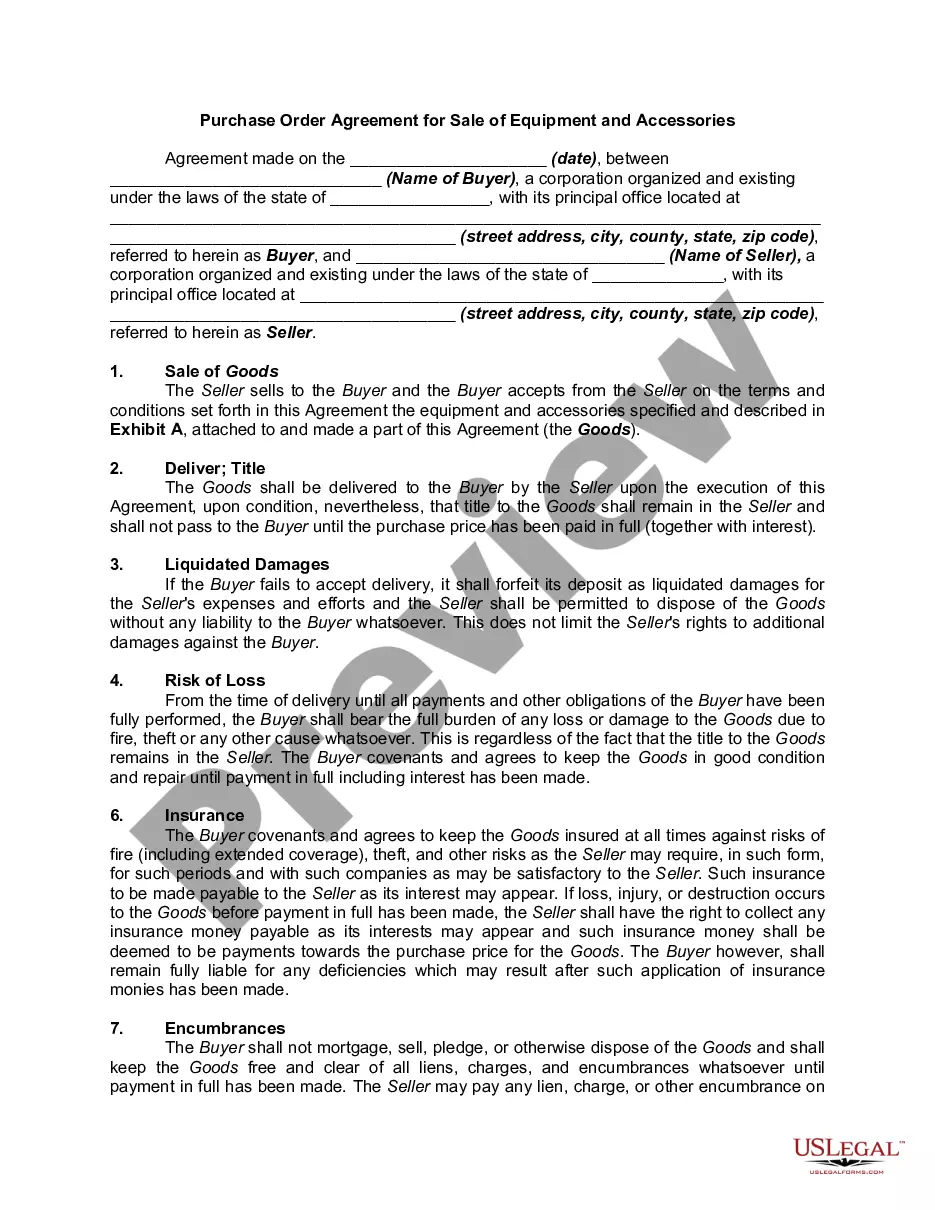

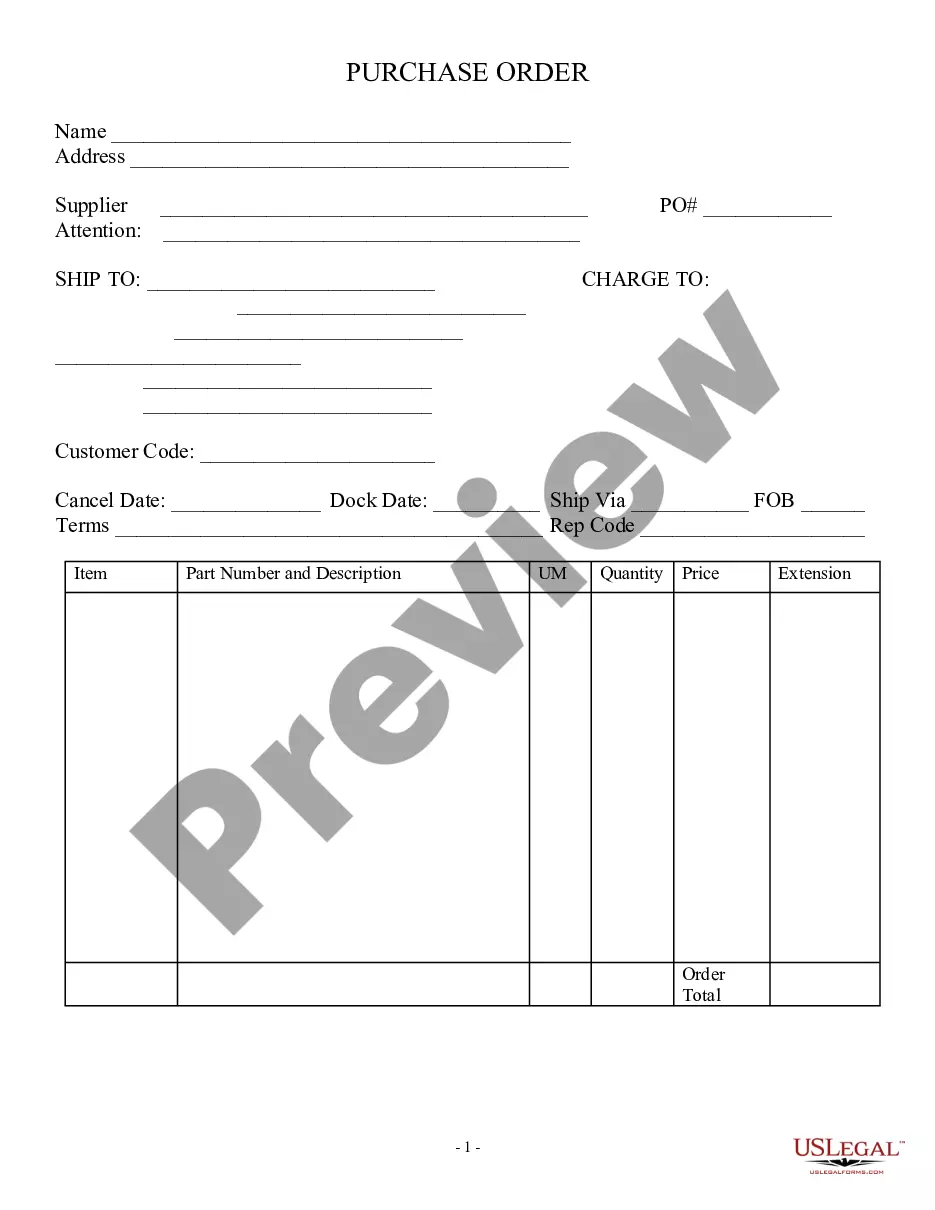

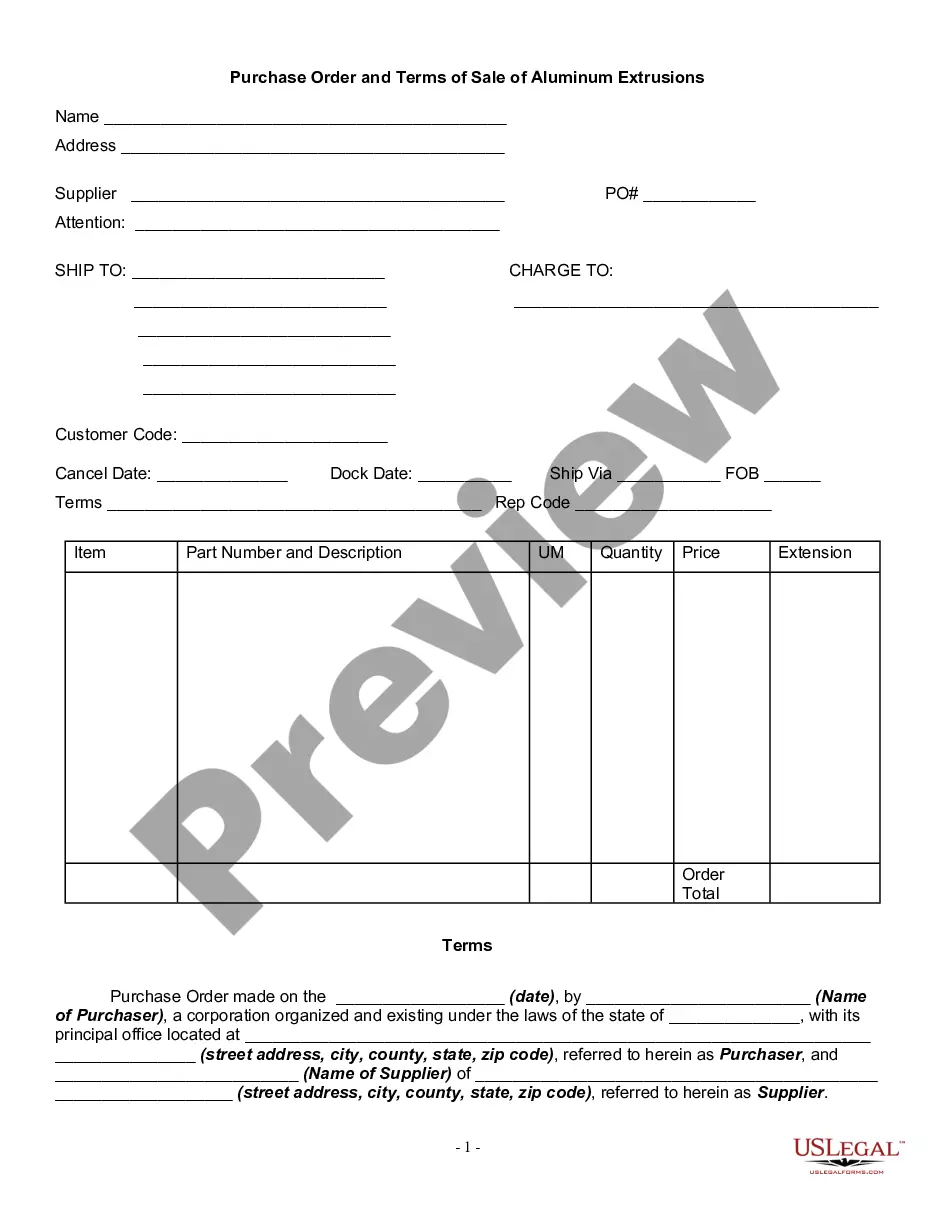

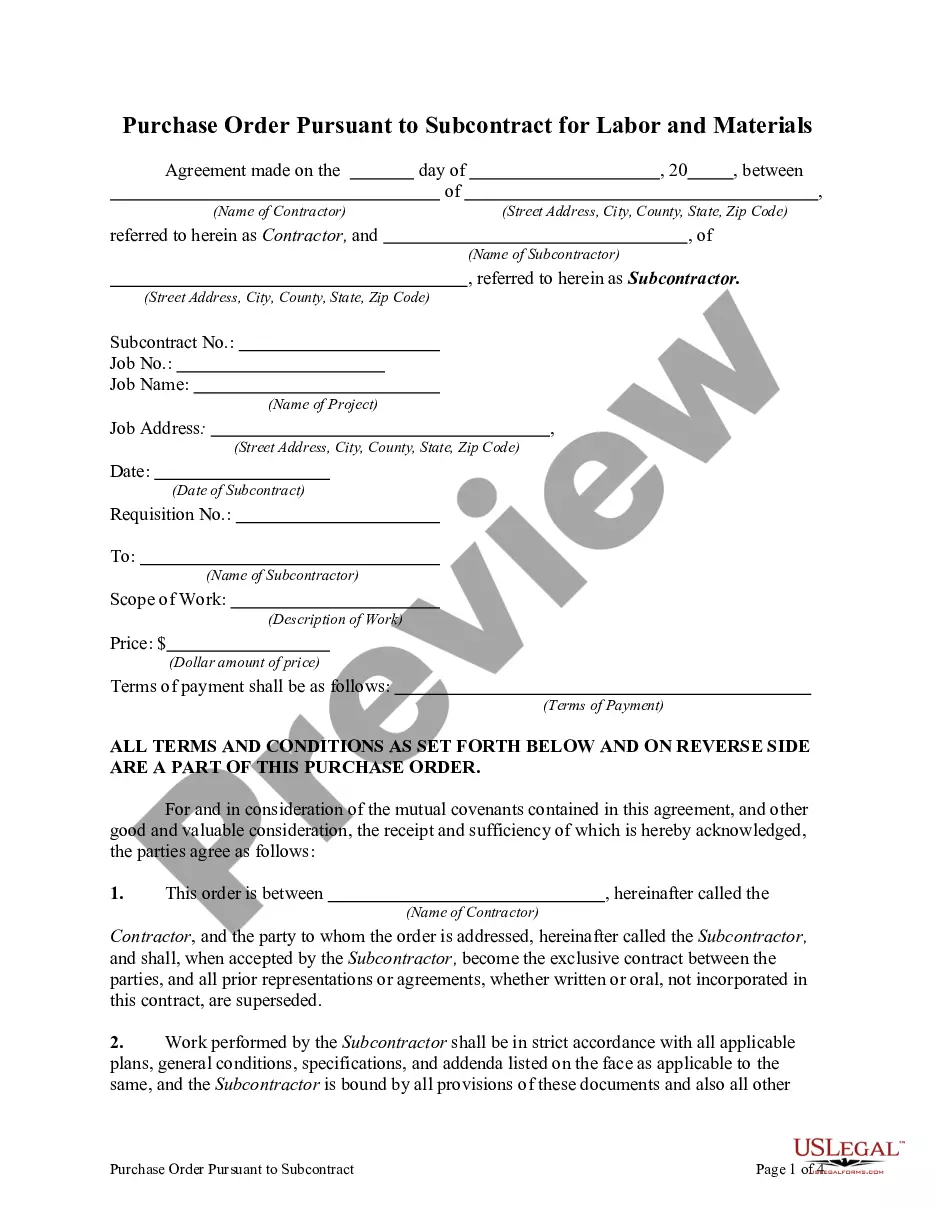

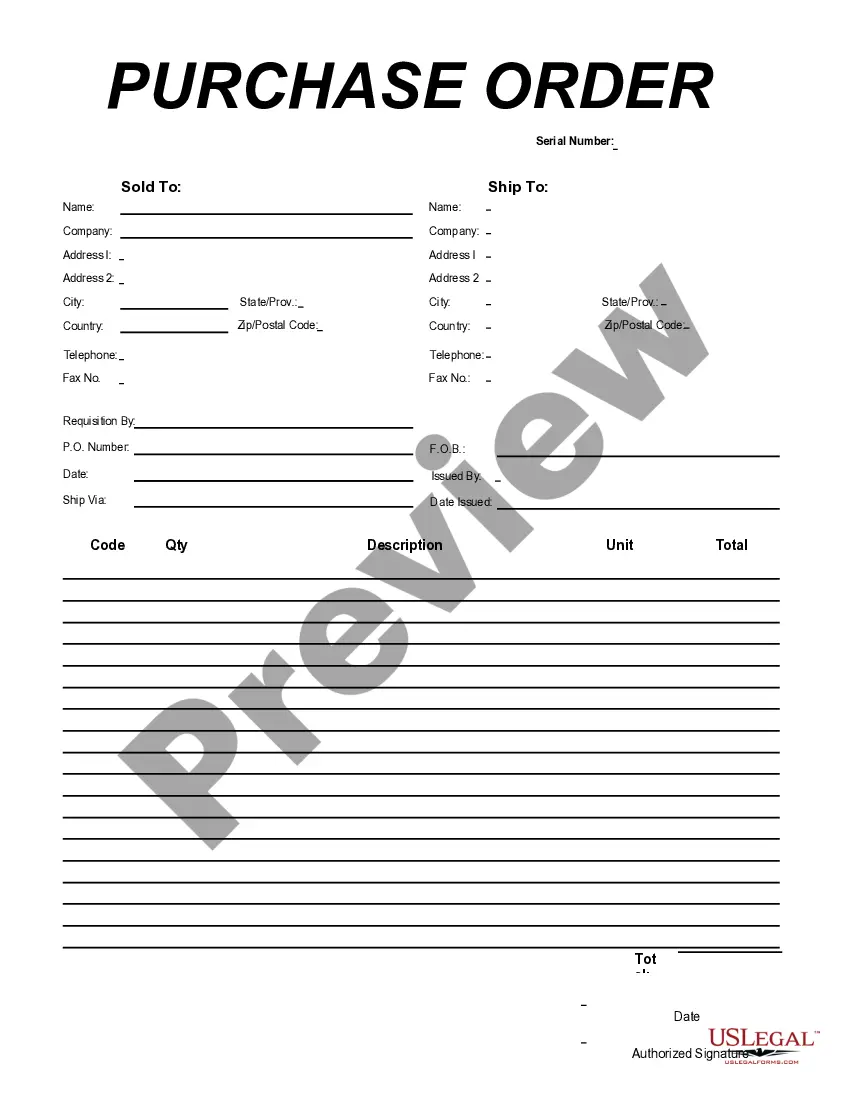

A purchase order represents the formal and final agreement to a purchasing transaction with a vendor. It identifies:

1. the vendor,

2. the material to be ordered (which in this form is described in Exhibit A),

3. the quantity (which in this form is described in Exhibit A),

4. the price (which in this form is described in Exhibit A),

5. the delivery date and terms of delivery (which in this form is described in Exhibit A), and

6. the terms of payment (which in this form is described in Exhibit A).