South Carolina Maintenance Engineer Checklist

Description

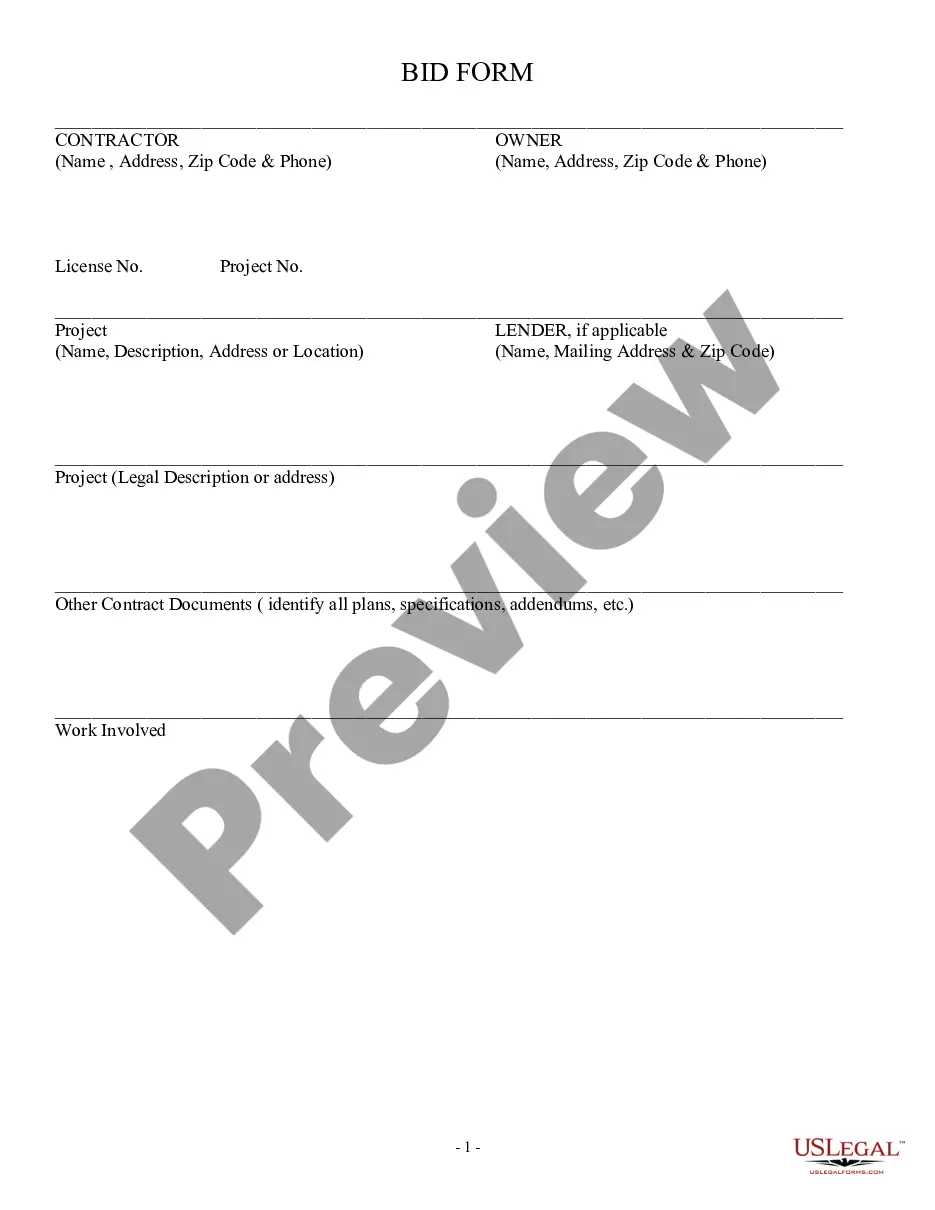

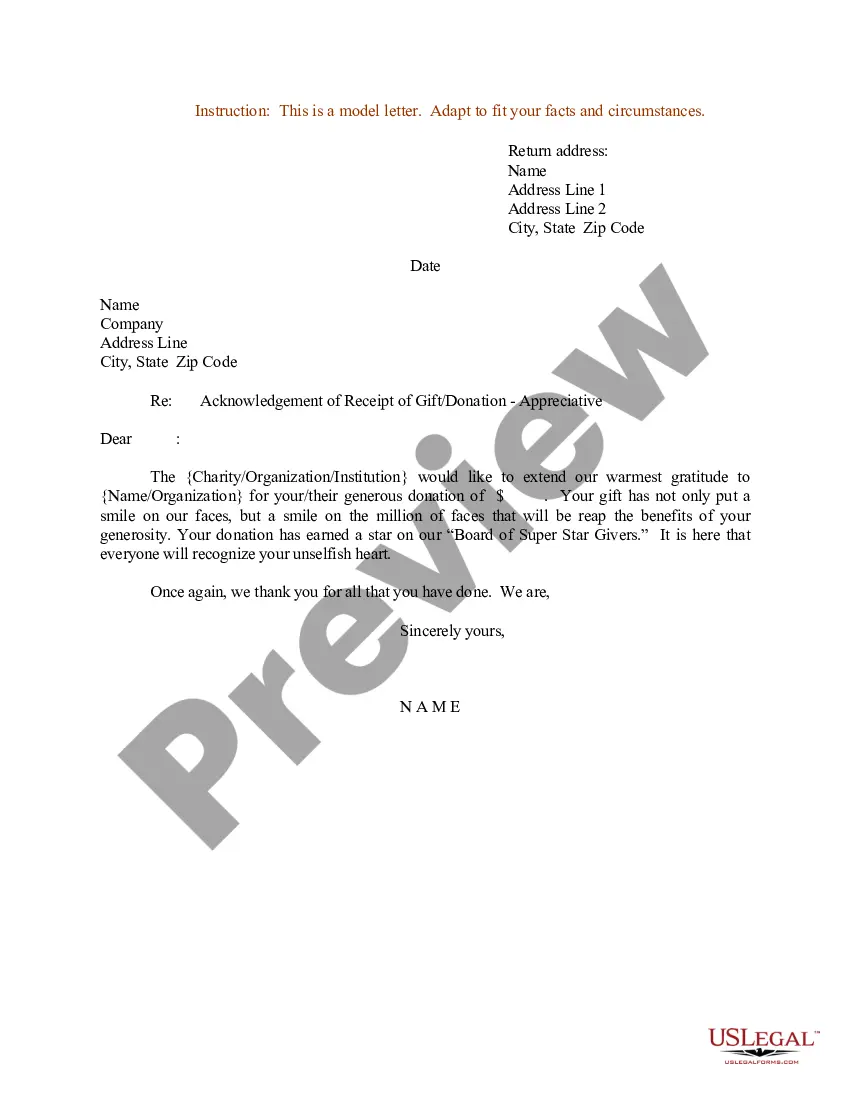

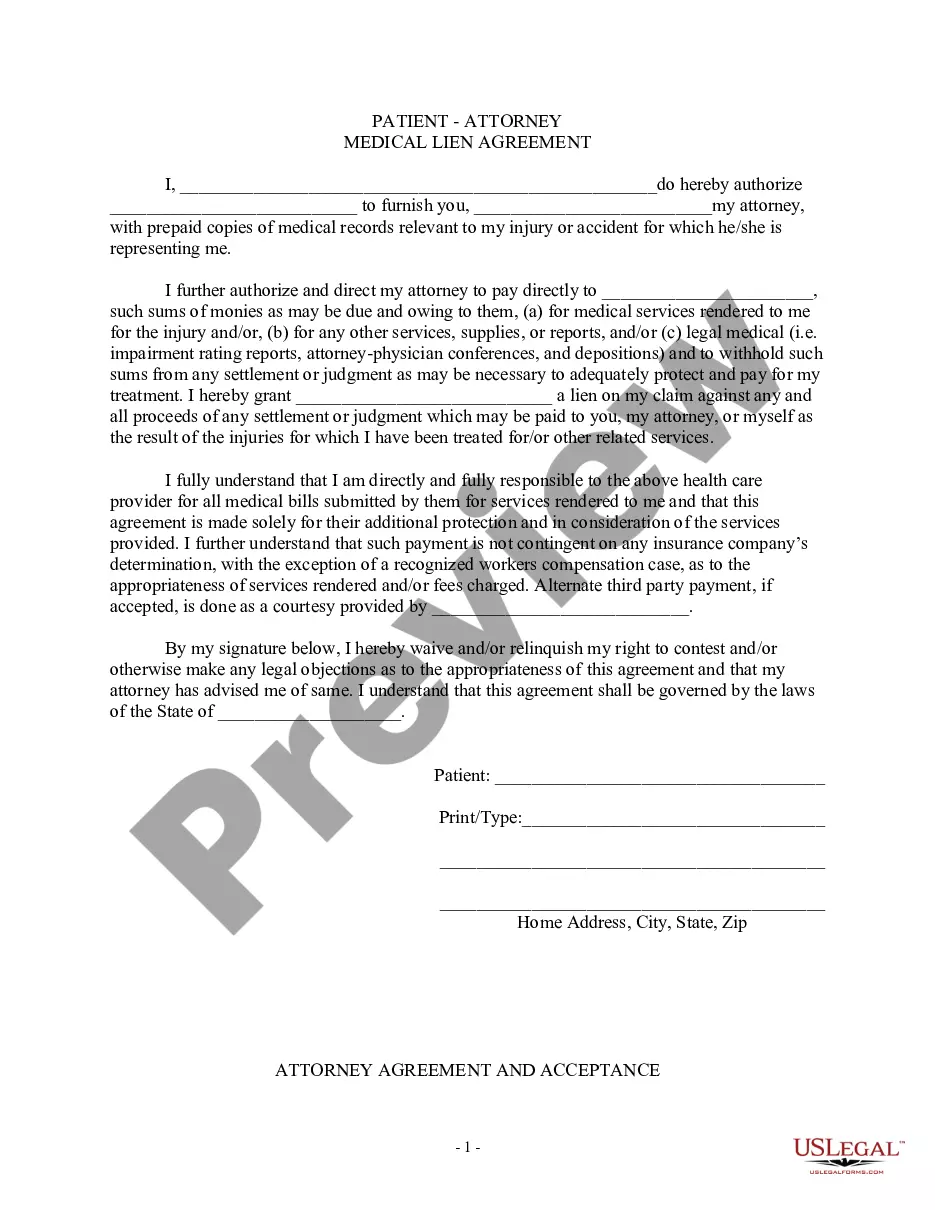

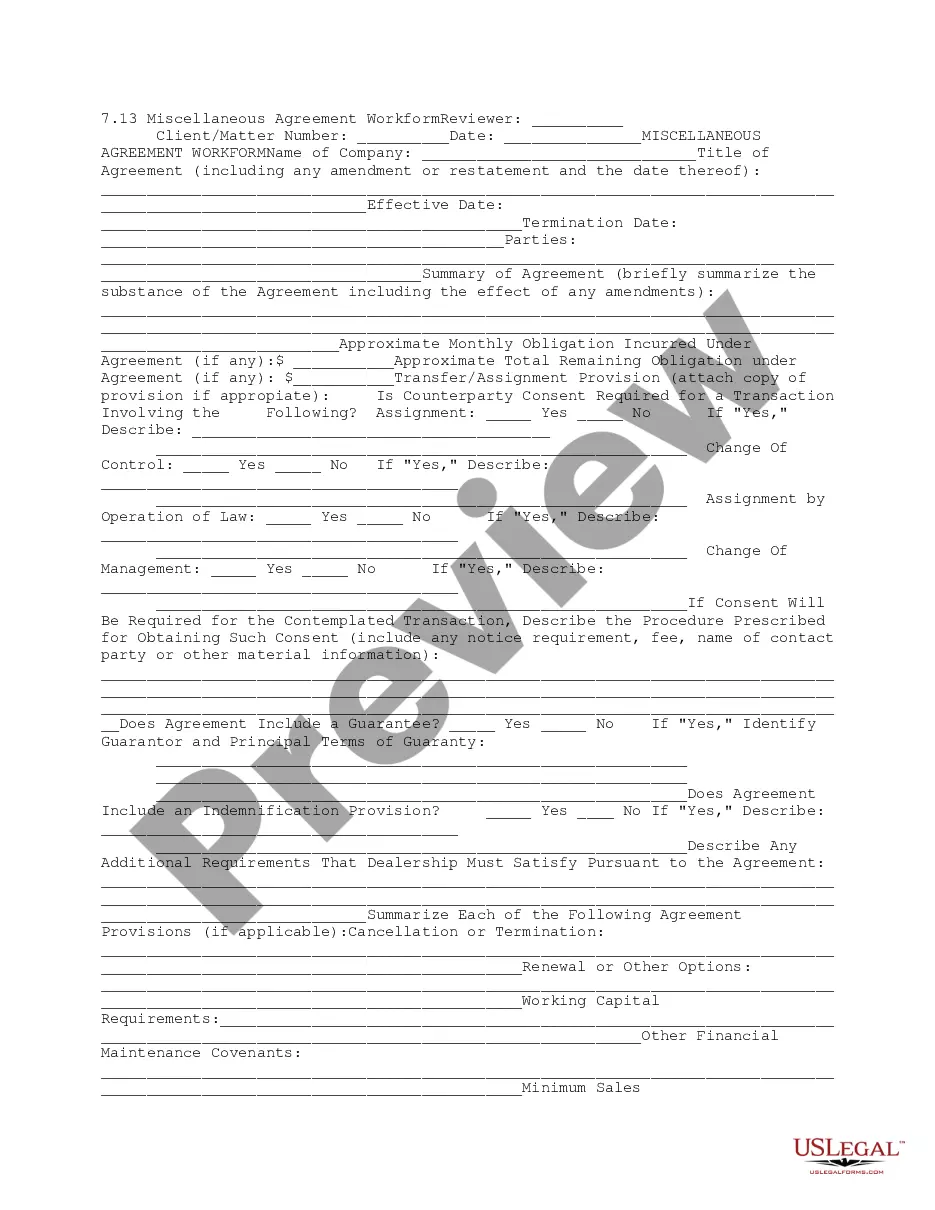

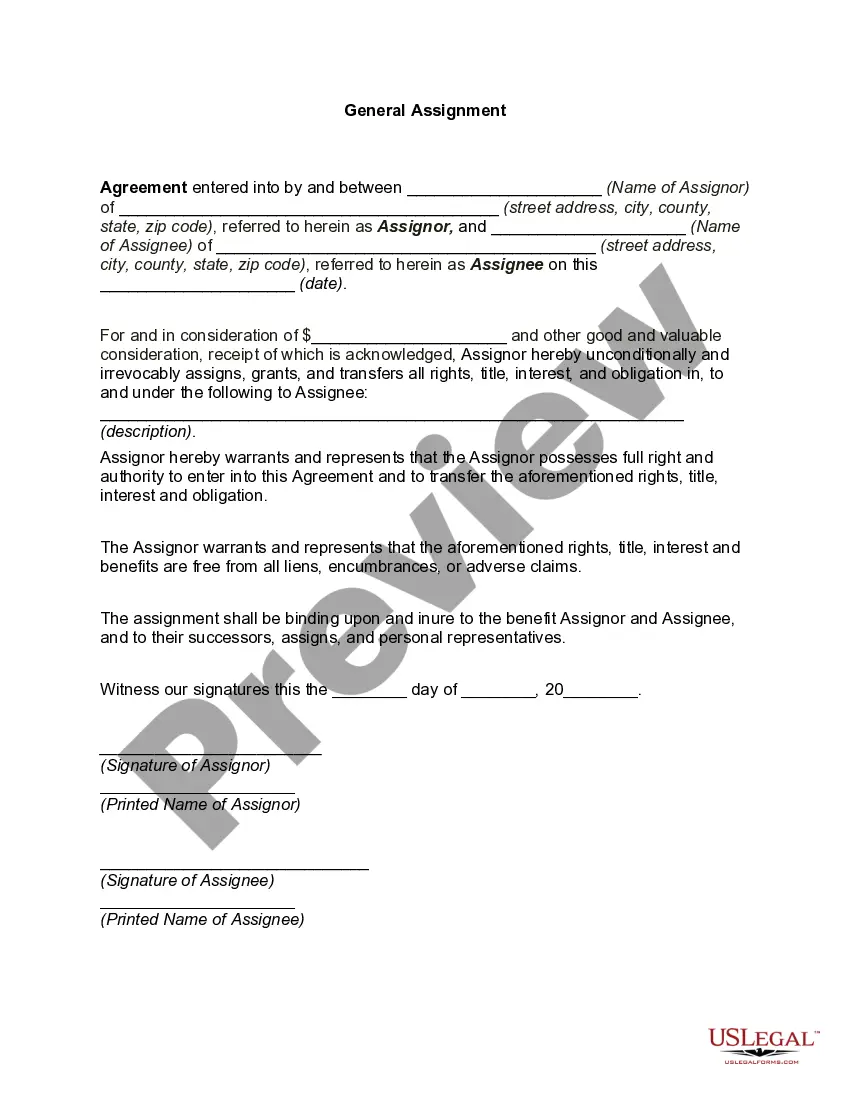

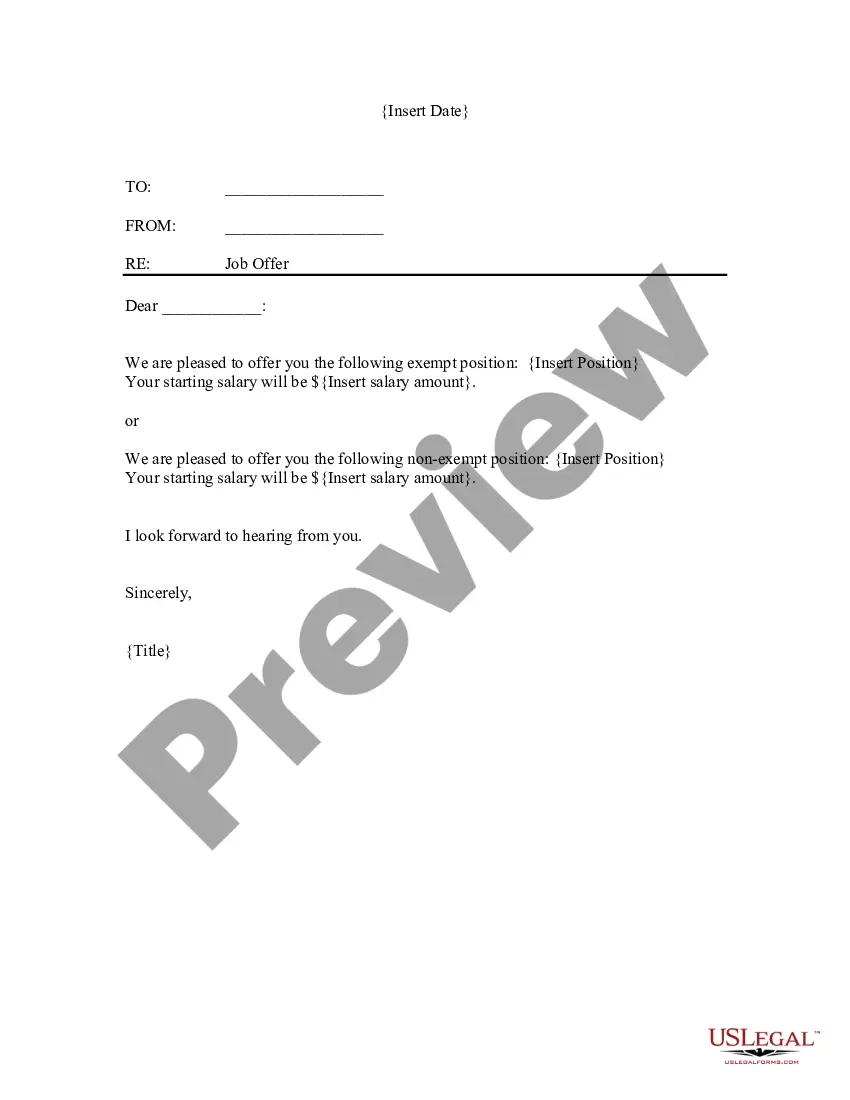

How to fill out Maintenance Engineer Checklist?

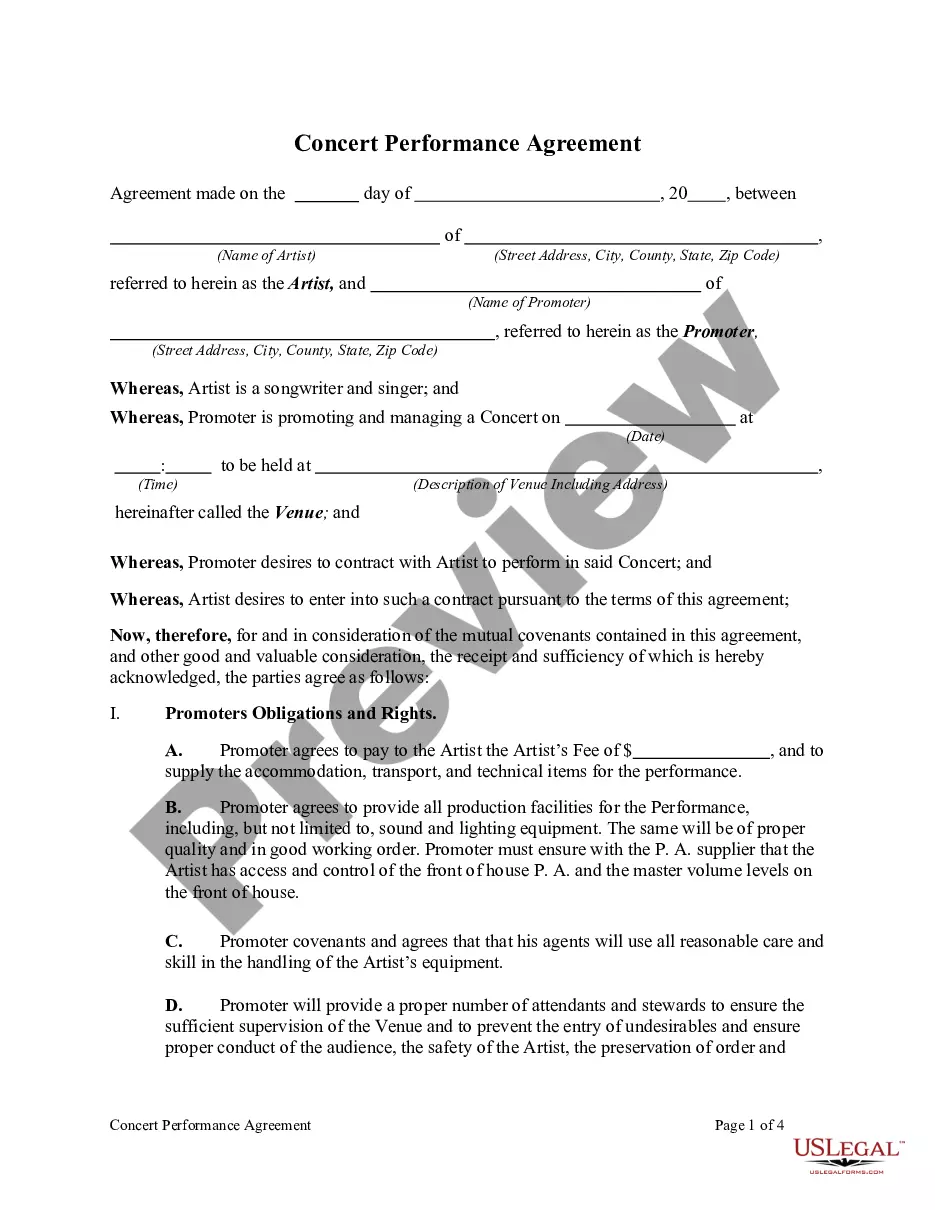

It is feasible to utilize the internet to search for the legal document template that meets the federal and state requirements you require.

US Legal Forms offers a vast array of legal forms that have been reviewed by professionals.

You can easily download or print the South Carolina Maintenance Engineer Checklist from the platform.

If available, utilize the Review button to examine the document template as well.

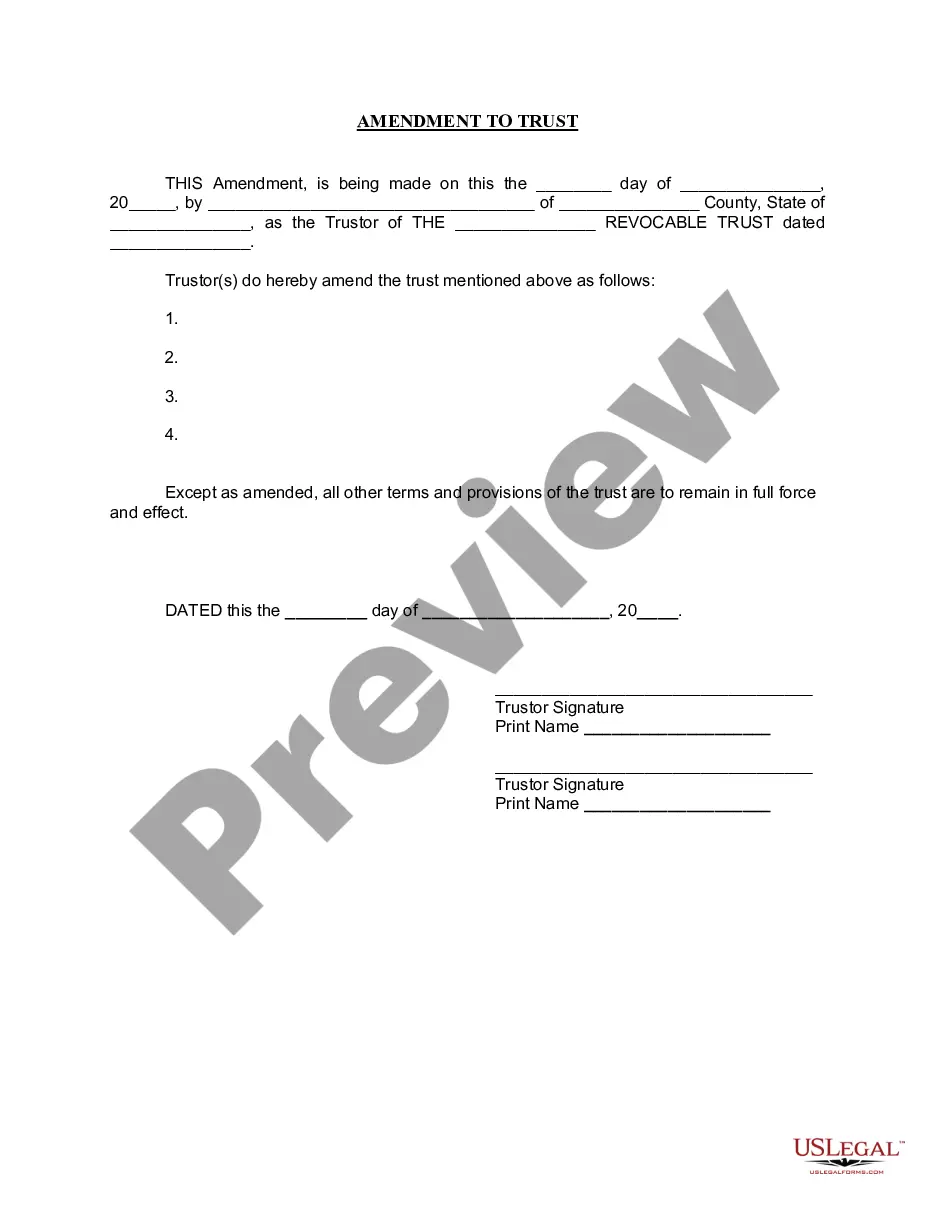

- If you already have a US Legal Forms account, you may sign in and click the Obtain button.

- Then, you can complete, modify, print, or sign the South Carolina Maintenance Engineer Checklist.

- Every legal document template you purchase is yours forever.

- To access another copy of a purchased document, visit the My documents tab and click the corresponding button.

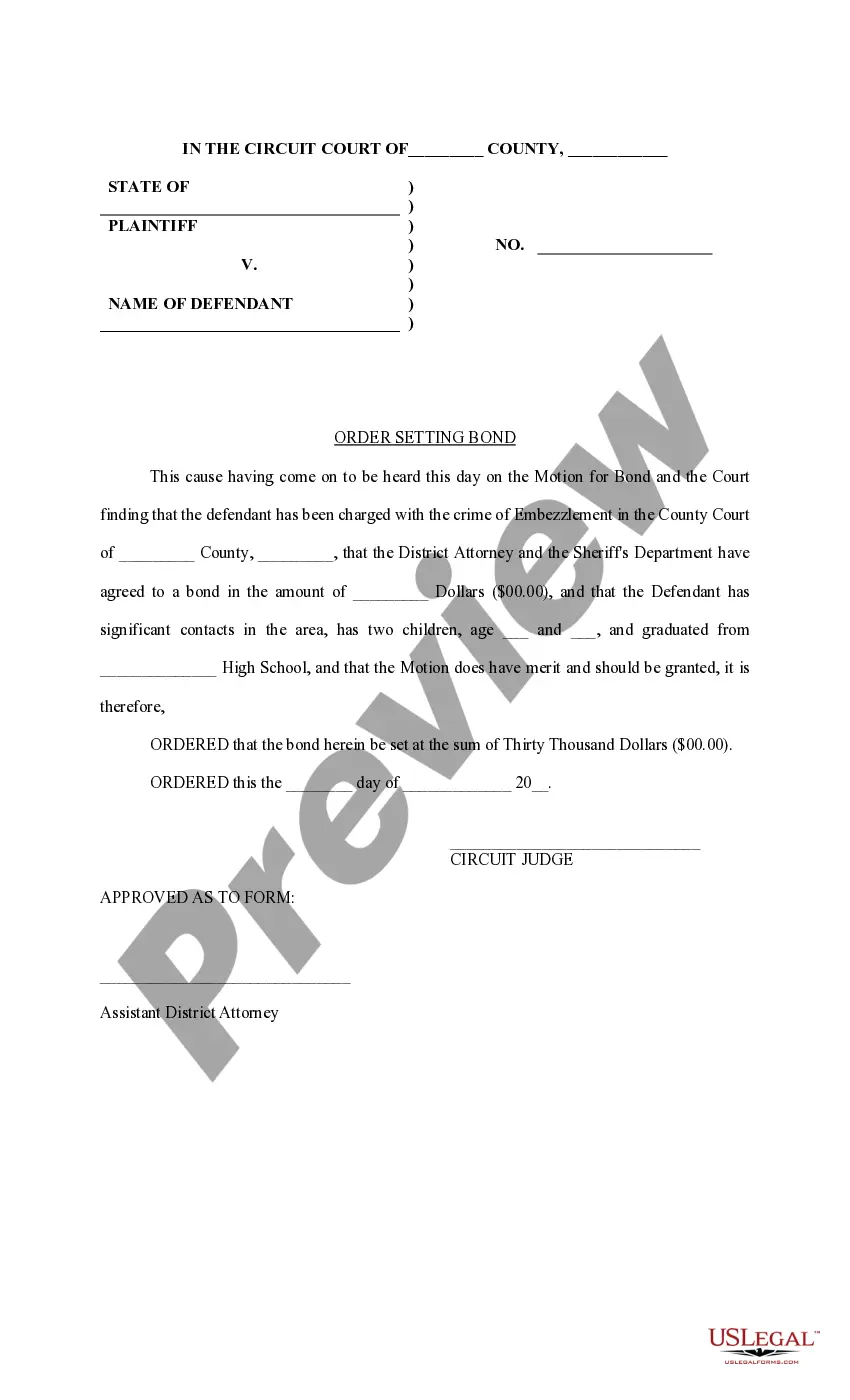

- If you are using the US Legal Forms website for the first time, follow the straightforward instructions below.

- First, ensure you have selected the correct document template for the county/town of your choice.

- Review the form outline to verify that you have chosen the appropriate document.

Form popularity

FAQ

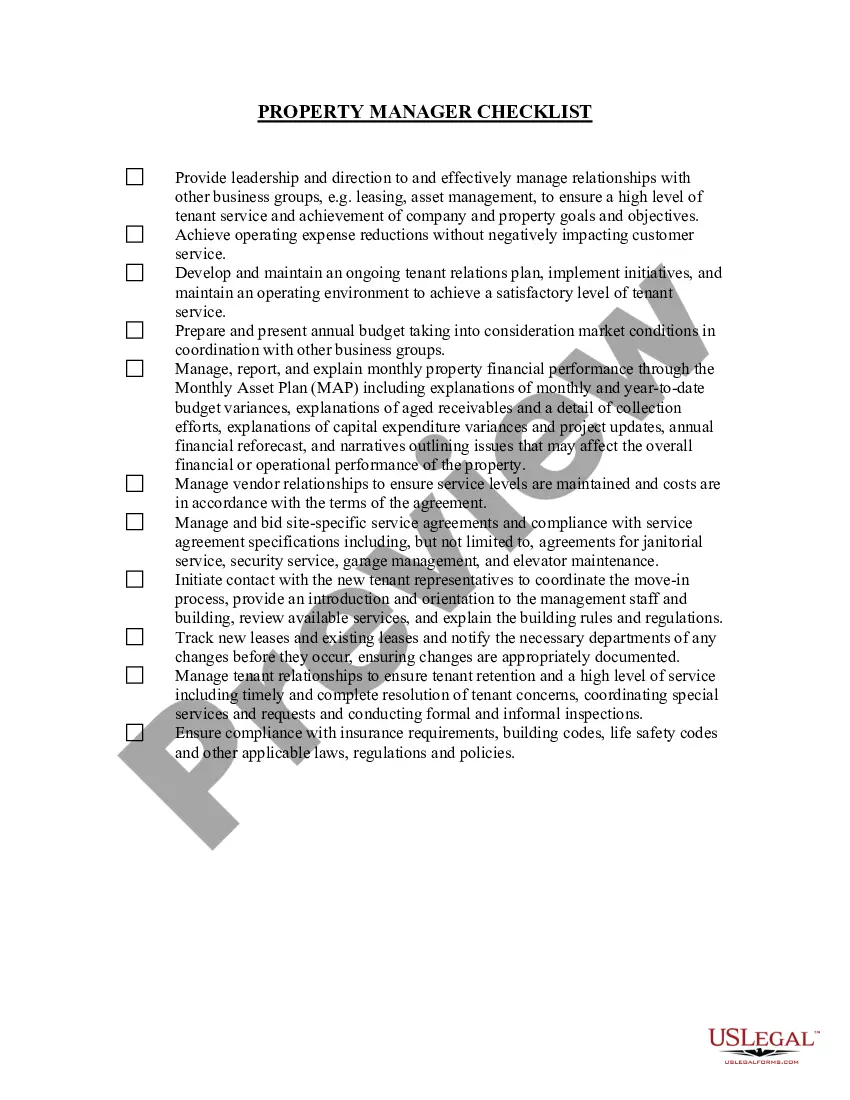

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

Six Tips for Creating a PM ChecklistInvolve the Right People in the Process. When planning the assets to maintain and creating PMs for each one, it helps to have the right types of expertise on board.Be Detailed, but Concise.Include Pictures.Include Safety Measures.Make Your Checklists Mobile.Update as Needed.

Preventive maintenance, when performed regularly, can extend the lifespan of diesel trucks and improve fuel economy. It can also play an important role in sustaining a truck's value in resale, as buyers usually want to see the vehicle's full maintenance record before making their purchase.

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

A preventive maintenance checklist is an itemized list of written tasks that guide technicians through a process of asset's preventive maintenance (PM).

A checklist is a list of items you need to verify or check or inspect. They are used in a variety of fields from construction to health service. A preventive maintenance checklist helps to identify maintenance actions on equipment to maintain it in good conditions and to improve plant reliability.

In his book Uptime, author John Dixon Campbell defines the six steps of the maintenance planning and control cycle as follows:Identify the problem.Plan the maintenance task.Schedule the work.Allocate the task to specific people.Ensure the work is executed properly.More items...