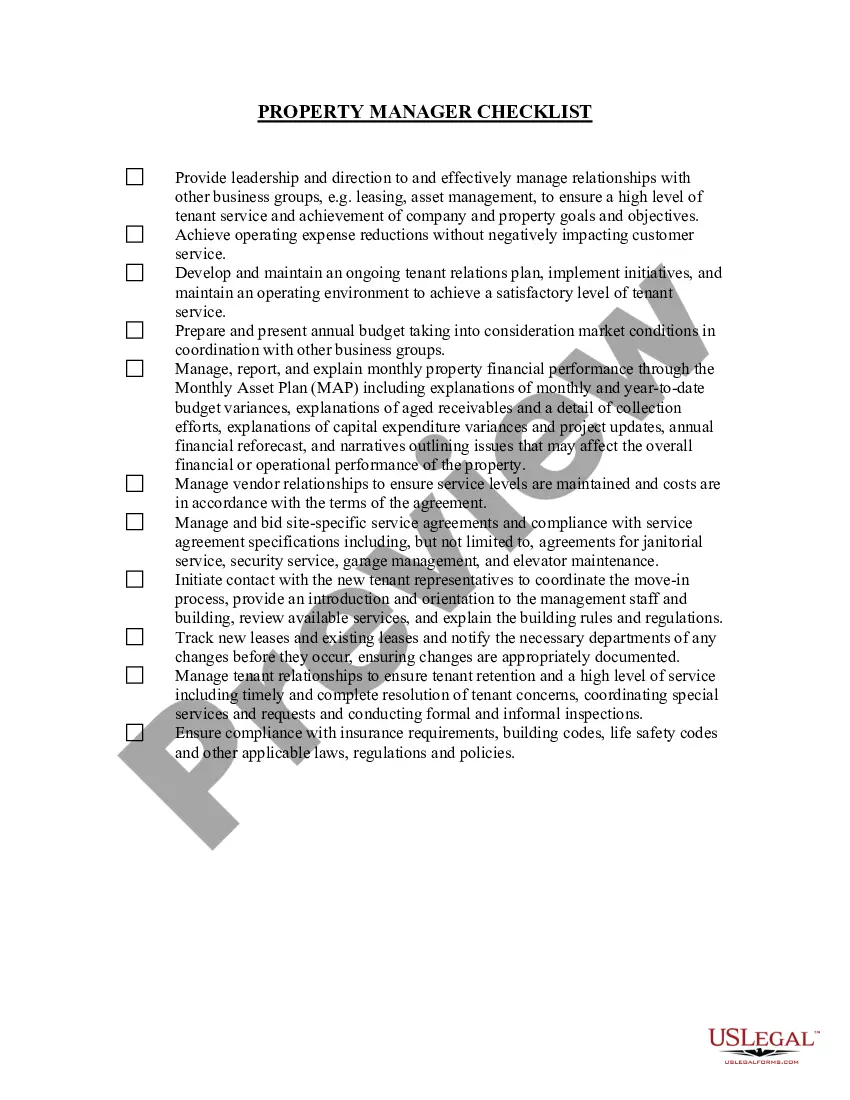

South Carolina Maintenance Supervisor Checklist

Description

How to fill out Maintenance Supervisor Checklist?

Selecting the correct legal document template can be a challenge. It goes without saying that there are numerous formats accessible online, but how do you find the legal document you need.

Utilize the US Legal Forms website. The service offers thousands of templates, including the South Carolina Maintenance Supervisor Checklist, which can be utilized for both business and personal purposes. All forms have been reviewed by professionals and comply with state and federal regulations.

If you are already registered, Log In to your account and press the Download button to obtain the South Carolina Maintenance Supervisor Checklist. Use your account to search for the legal documents you have purchased previously. Navigate to the My documents section of your account to retrieve another copy of the document you need.

US Legal Forms is the largest collection of legal documents where you can find a variety of document templates. Take advantage of the service to download professionally crafted papers that comply with state regulations.

- Firstly, ensure you have selected the correct form for your city/region. You can review the template by clicking the Review button and examine the document summary to confirm it is suitable for you.

- If the form does not suit your requirements, utilize the Search box to find the appropriate document.

- Once you are confident that the form is correct, click the Buy Now button to purchase the document.

- Select your desired payment plan and provide the necessary information. Create your account and finalize the purchase using your PayPal account or Visa or Mastercard.

- Choose the file format and download the legal document template to your device.

- Complete, modify, print, and sign the downloaded South Carolina Maintenance Supervisor Checklist.

Form popularity

FAQ

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

Here Are the 8 Skills Every Maintenance Manager Needs to Master to be SuccessfulLeadership. Maintenance managers need to exhibit leadership capability.Good Interpersonal Skills.Time Management.Know How to Groom Individuals.Problem Solving Skills.Flexibility.Team Work.Technical Expertise.

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

Four key elements are work order management, empowering with technology, gaining asset and maintenance intelligence, and transitioning from a reactive to proactive maintenance approach.

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

A preventive maintenance checklist details the tasks that your technicians must complete during a maintenance check. A PM checklist will include both time-based (routine) and condition-based (non-routine) tasks, ensuring that critical issues are both prevented and corrected.

Steps to creating an effective maintenance planDetail the work that you'll need to do on each asset.Schedule the work Use a dating frequency, running hours, or measures that will provide insight into the condition of an asset.Add workers or contractors including the estimated working hours.Add spare parts.More items...?

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.