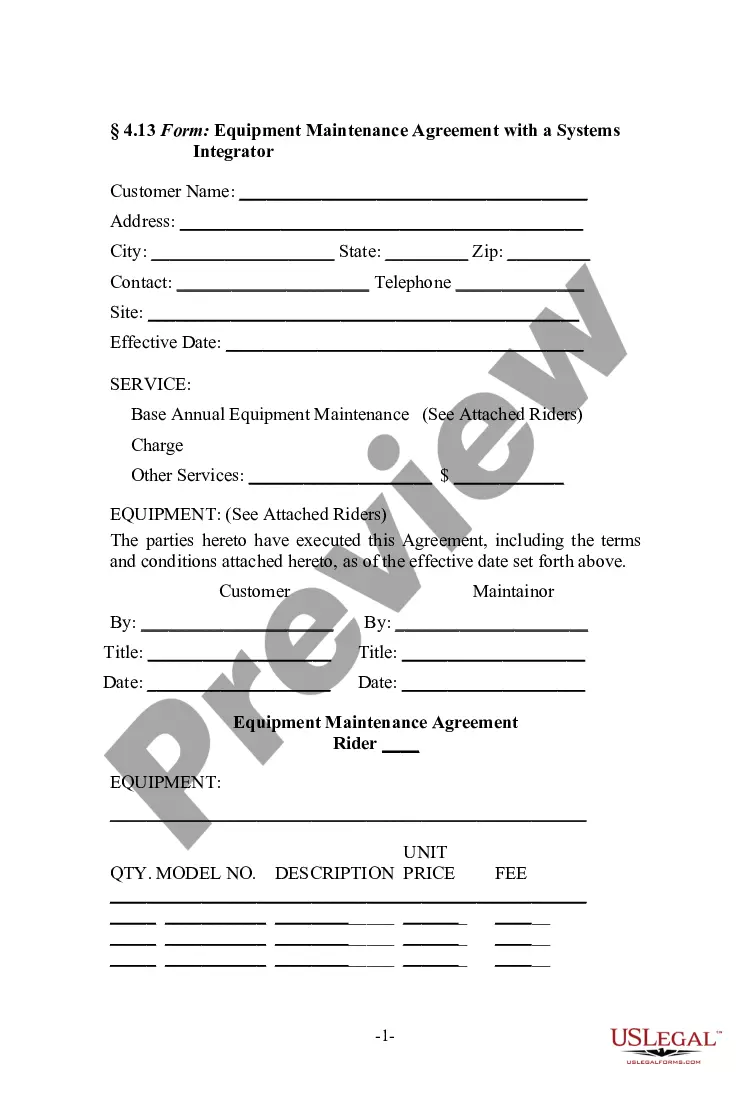

Minnesota Equipment Maintenance Agreement with a Systems Integrator

Description

How to fill out Equipment Maintenance Agreement With A Systems Integrator?

Are you inside a position where you will need files for both enterprise or individual functions almost every time? There are tons of lawful record layouts accessible on the Internet, but discovering types you can trust is not simple. US Legal Forms offers a large number of type layouts, just like the Minnesota Equipment Maintenance Agreement with a Systems Integrator, that happen to be written to satisfy state and federal requirements.

In case you are currently acquainted with US Legal Forms web site and get a merchant account, merely log in. Next, you are able to acquire the Minnesota Equipment Maintenance Agreement with a Systems Integrator template.

Unless you come with an account and would like to begin to use US Legal Forms, adopt these measures:

- Discover the type you will need and ensure it is for your correct town/area.

- Utilize the Review button to examine the shape.

- See the outline to actually have selected the correct type.

- When the type is not what you`re trying to find, utilize the Research discipline to obtain the type that meets your requirements and requirements.

- If you obtain the correct type, click Purchase now.

- Select the prices strategy you would like, complete the required info to make your money, and pay money for your order utilizing your PayPal or charge card.

- Decide on a hassle-free paper file format and acquire your version.

Locate all of the record layouts you may have purchased in the My Forms food selection. You can get a more version of Minnesota Equipment Maintenance Agreement with a Systems Integrator whenever, if necessary. Just click the necessary type to acquire or printing the record template.

Use US Legal Forms, one of the most extensive collection of lawful types, to save efforts and steer clear of mistakes. The assistance offers appropriately created lawful record layouts which can be used for a variety of functions. Generate a merchant account on US Legal Forms and start generating your daily life a little easier.

Form popularity

FAQ

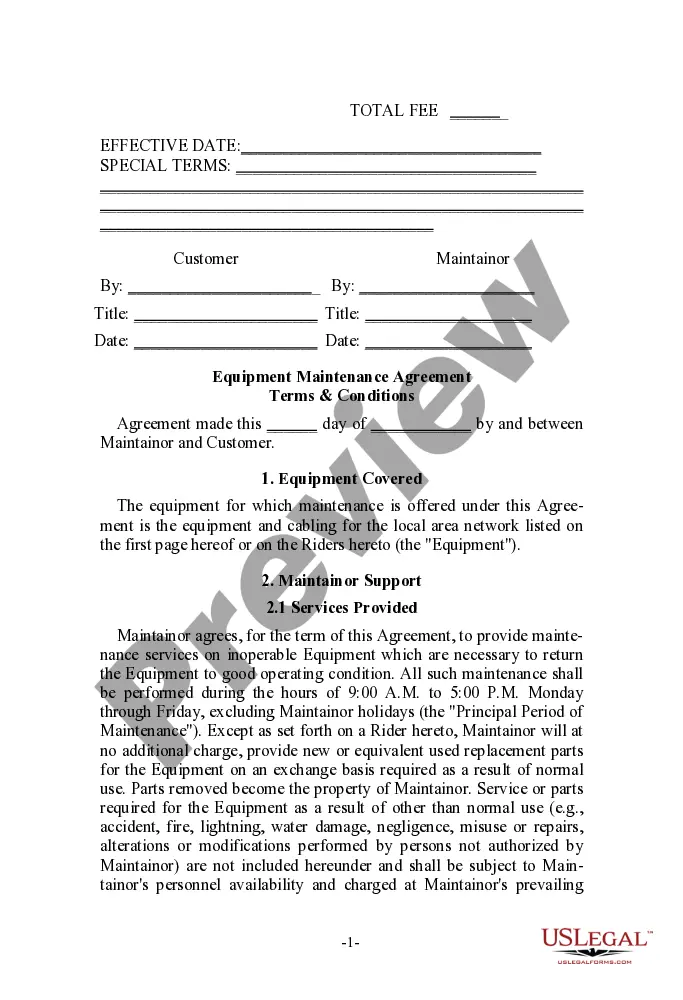

An agreement drafted from the supplier's point of view, in which the supplier agrees to provide support and maintenance for certain hardware supplied by the supplier.

These are preventive and remedial services that physically repair or optimize hardware, including basic installation, contract maintenance and per-incident repair ? both on-site and at a centralized repair depot.

A maintenance agreement (contract), sometimes called a service agreement (contract), is an agreement which requires specific performance of repairing, cleaning, altering, or improving tangible personal property on a regular or irregular basis to ensure the product's continued satisfactory operation.

The typical annual maintenance contract format includes: The name and address of the involved parties, usually a business and the company providing the service. Price of the contract. Annual maintenance contract terms and conditions. Penalties for breaking contract or contract termination.

By Practical Law Commercial. A B2B agreement in which the supplier agrees to provide a maintenance and support service for equipment. The agreement is drafted to be broadly neutral between the parties. To access this resource, sign in below or register for a free, no-obligation trial.