Consignment Contract Sample With Food In Travis

Description

Form popularity

FAQ

Sample Size Formula n = NX / (X + N – 1), Where, X = Zα/22 p(1-p) / MOE2, Zα/2 is the critical value of the Normal distribution at α/2 (for a confidence level of 95%, α is 0.05, and the critical value is 1.96).

The Formula of Random Sampling Here P is a probability, n is the sample size, and N represents the population. Now if one cancels 1-(N-n/n), it will provide P = n/N. Moreover, the chance of a sample getting selected more than once is needed: P = 1-(1-(1/N)) n.

Each sub will consist of a minimum of 100 g (approx. 3.53 oz). The usual subsample is a consumer size container of a product. Subsamples should be obtained at random to insure that the total sample is representative of the lot.

Sampling is the process of collecting and testing food, ingredients, the environment or other materials. Sampling is commonly used to monitor or verify the effectiveness of control measures put in place to prevent, eliminate or reduce to an acceptable level the hazards that present a risk of contamination to a food.

Sample rate is specified in units of samples per second. If you have 1000 samples taken over 1.92 seconds, then that would give you a sampling rate of 1000/1.92 = 520.83 S/s (or 0.52083 kS/s) where S represents samples.

The sample size depends on and the number of lots or packages per batch of food. We need to make sure the sample of food we take is representative of the lot and is enough for laboratories to do analytical testing. The sampling plans we use generally require 5 x 100-gram samples from each lot to be taken at random.

Samples are taken by using the formula n=1+√N, where n is the number of samples taken, and N is the lot size or the number of total sampling units. p-plan: This sampling plan can be employed particularly when the material is received and identification is being carried out. Sampling is done using the formula p=0.4√N.

Food sampling is extremely important in the food industry. Quality control is a process that helps to target, identify and rectify defects in finished food products. This can be achieved by eliminating the sources of quality problems to ensure safety and customer requirements are continually met.

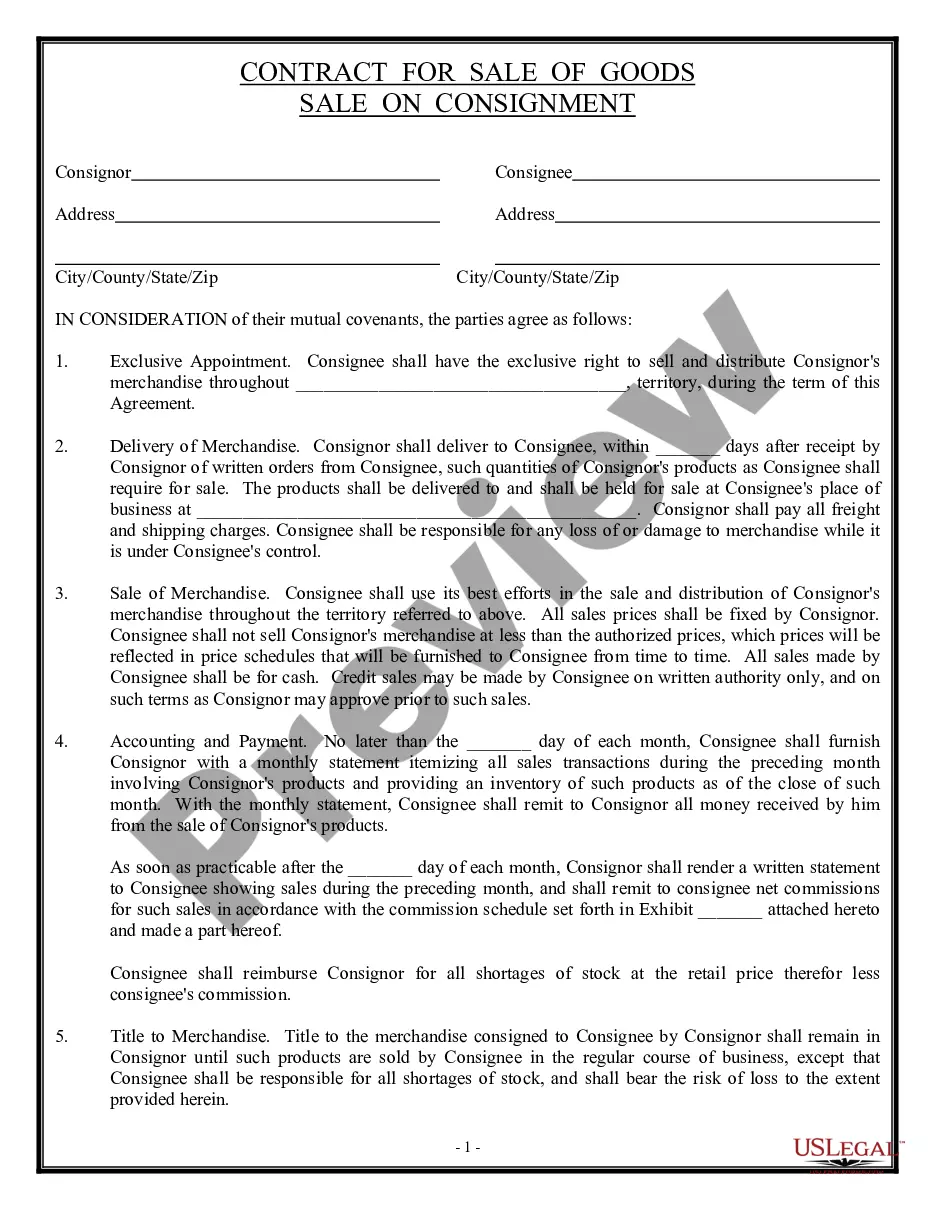

Please provide full description of goods, number of packages, gross weight and consignment dimensions. Customer reference. You can enter any internal reference code that you would like to be printed on the invoice, with a maximum of 24 characters. Delivery address. Dutiable shipment details.

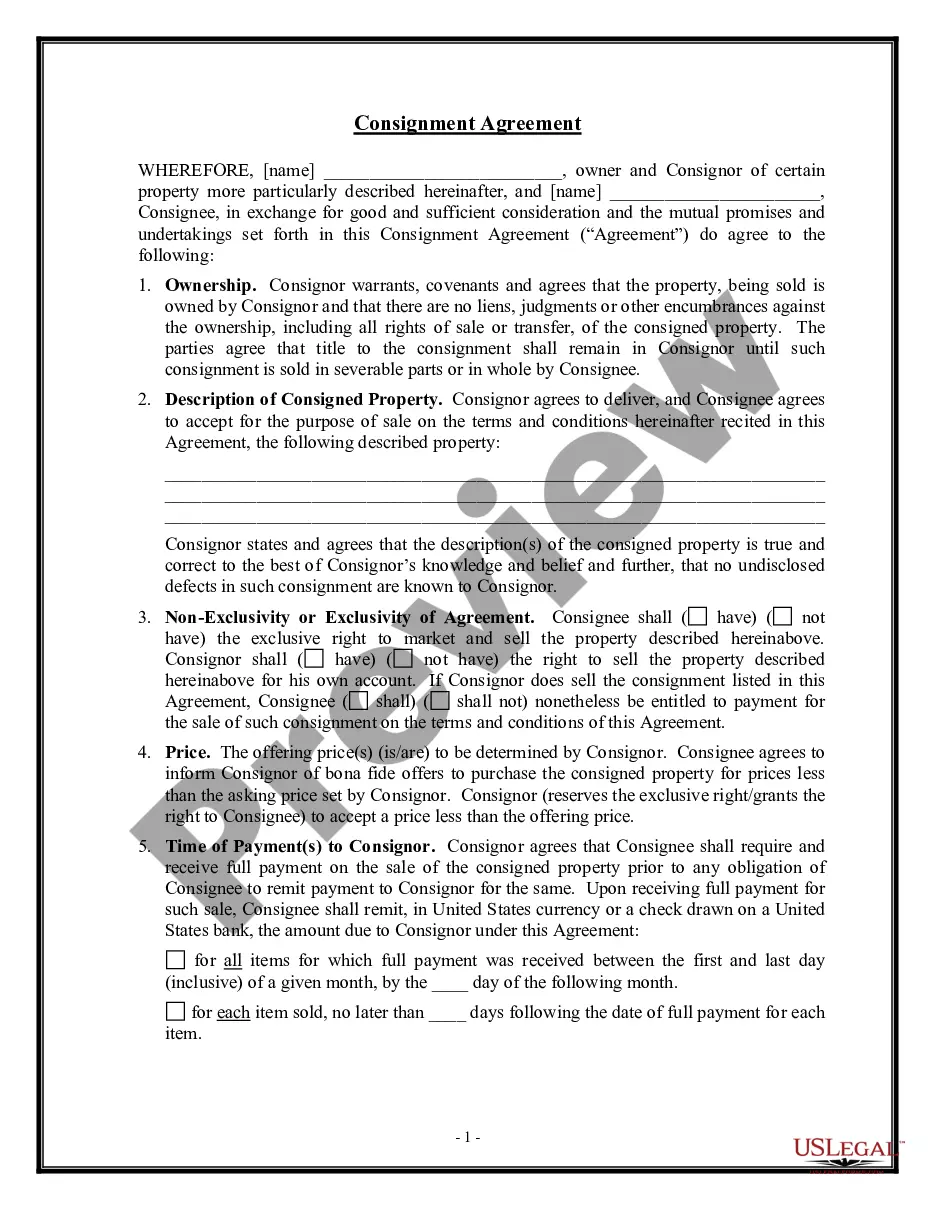

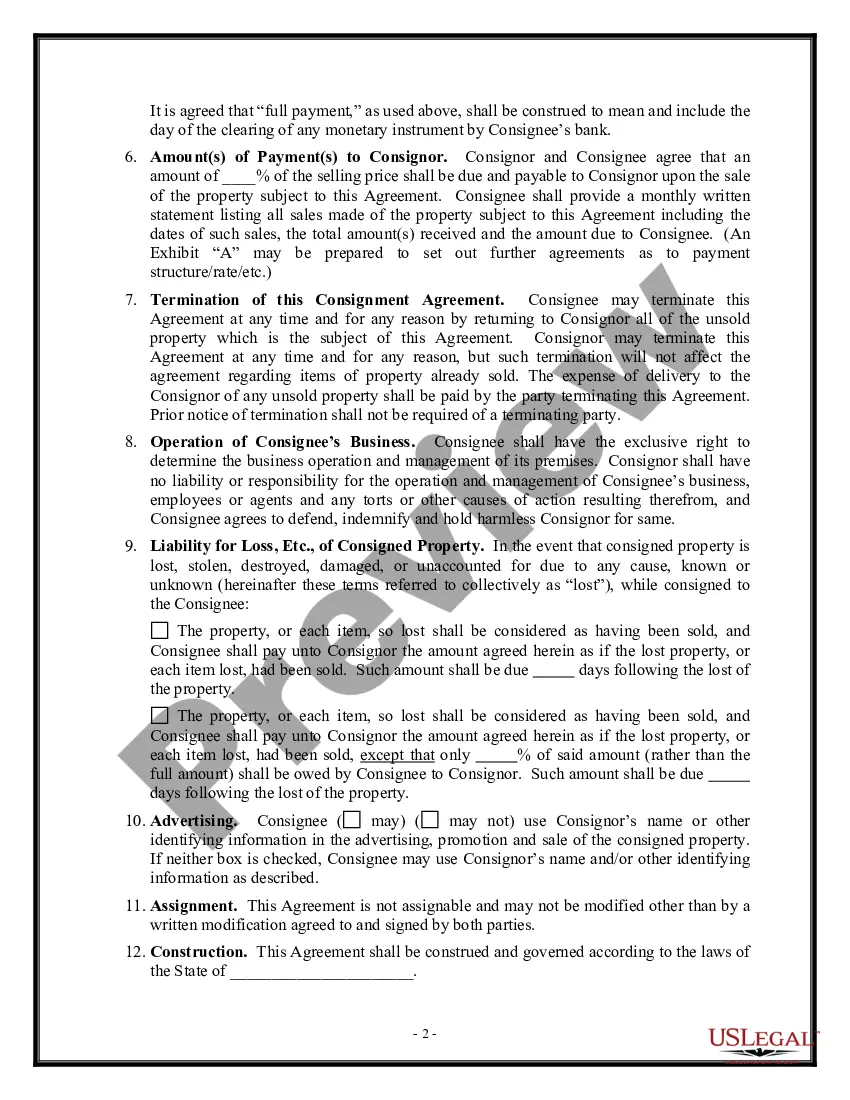

Here are the essential components to include: Parties Involved: Names and contact information of the consignor and the consignee. Consigned Goods: Detailed description of the goods being consigned, including quantities and specifications. Consignment Period: Duration of the consignment arrangement.