Bulk Transfers For Shirts In Texas

Description

Form popularity

FAQ

DTF transfers, also known as Direct-to-Film transfers, use specialized printers to apply ink onto a thin film which is then backed by an adhesive powder. The adhesive-backed ink is then transferred onto garments using a heat press machine, resulting in vibrant and long-lasting prints.

Common Temperature Settings for DTF Transfers The following is a summary of the typical temperature settings and times for DTF: Cotton: 335°F for 10 seconds. Polyester: 320°F for 10 sec. Cotton/Polyester Blends: 335°F for 10.

Optimal Room Temperature: Extreme temperatures can affect the integrity of DTF transfers. Storing transfers in excessively hot or cold environments can lead to damage.

Place the transfer print-side down so that the ink is touching the garment - make sure it's not upside down! The clear film is super helpful with making sure you're placing the transfer correctly. Press the transfer for 7-10 seconds at 300˚F. Our DTF transfers can be peeled hot or cold.

The typical temperature range for DTF is usually somewhere between 280 – 325 degrees Fahrenheit. The typical pressure range is usually between 30 – 60 PSI (medium to firm). It's a good idea to perform testing to find the ideal heat press settings for your particular DTF transfers.

Steps to perform DTF printing at home Prepare the design: Use a graphic design software to create or select the design you want to print. Print the design on a special film: Load the DTF printer with the specially-coated DTF film. Apply adhesive powder. Transfer the design onto fabric:

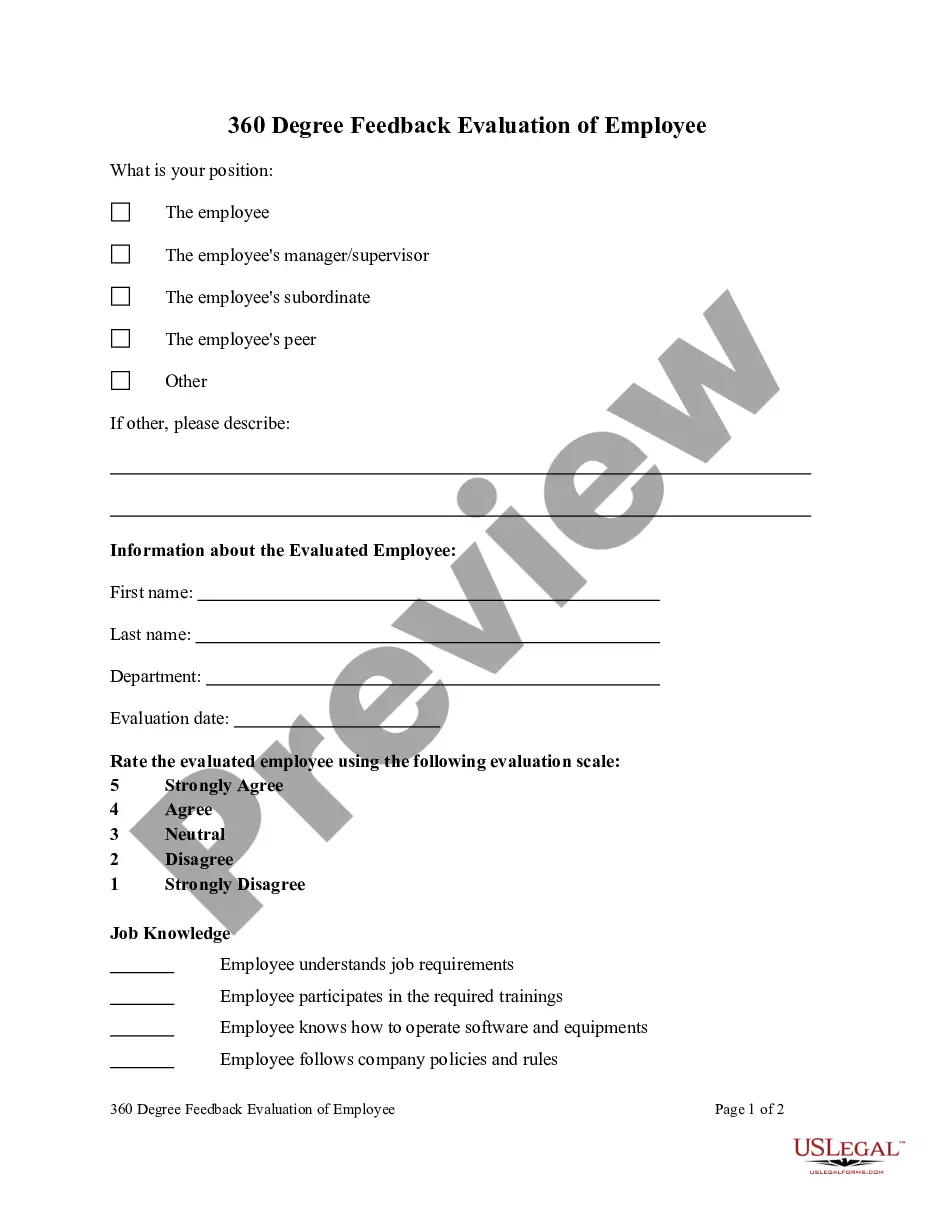

DTF Heat Press Settings Guide MaterialTemperatureTime Cotton 320-350°F (160-180°C) 10-15S 50/50 Blends 320-350°F (160-180°C) 10-15S Synthetic & Polyester Fabrics 280-300°F (140-150°C) 10-15S

Ship a DTF sheet with ease by placing it in a protective sleeve and a sturdy mailer. Ensure it's marked 'Do Not Bend. ' Select a trustworthy carrier and add tracking and insurance for peace of mind.

Image Transfer onto Fabric in 10 Minutes Print a high contrast image using a laser or ink jet printer. Cut out image and move excess paper from edges. Place on non-stick surface, such as plastic or silicone. Apply thin layer of matt medium to front of image. Place fabric face down on the wet image.

To make your iron-on transfers, print your desired design onto special transfer paper using an inkjet printer. Remember to mirror the image if necessary. Place the cutout face down on the fabric and then apply the hot iron for about 20-30 seconds. Let it cool and then peel off the backing to reveal your custom print!