Cost For Failure

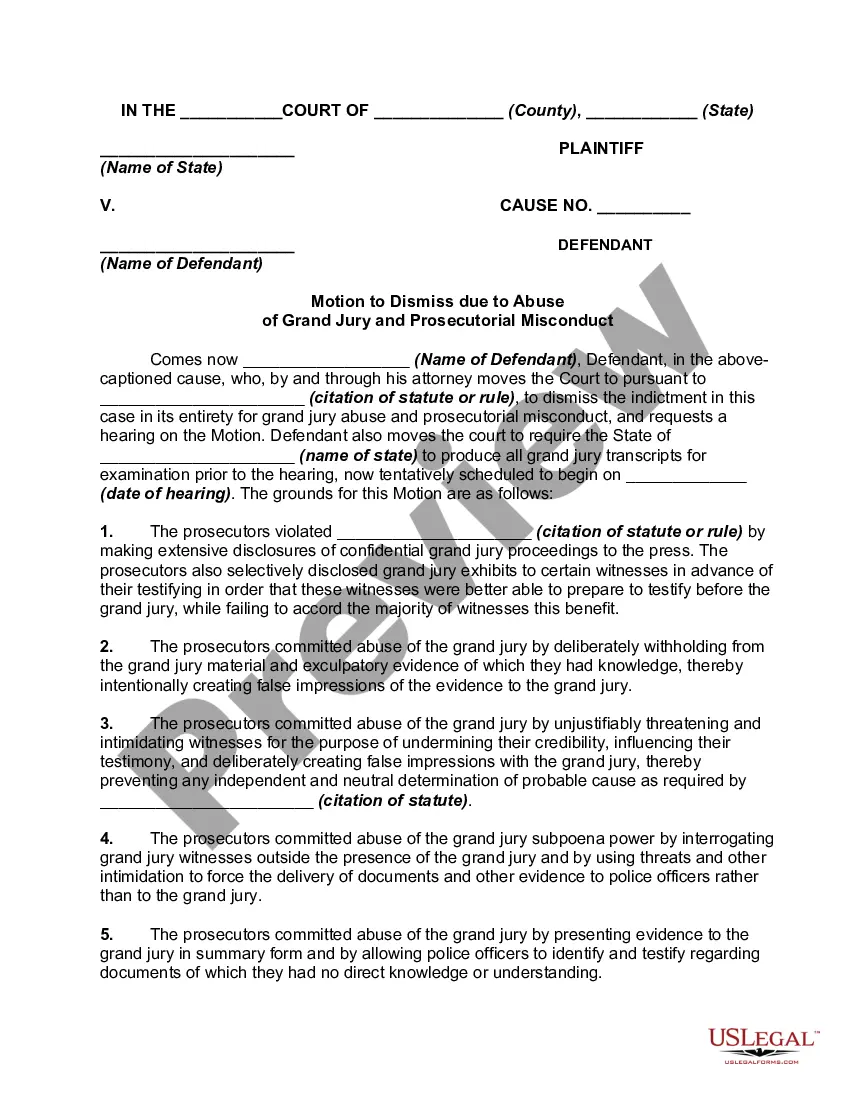

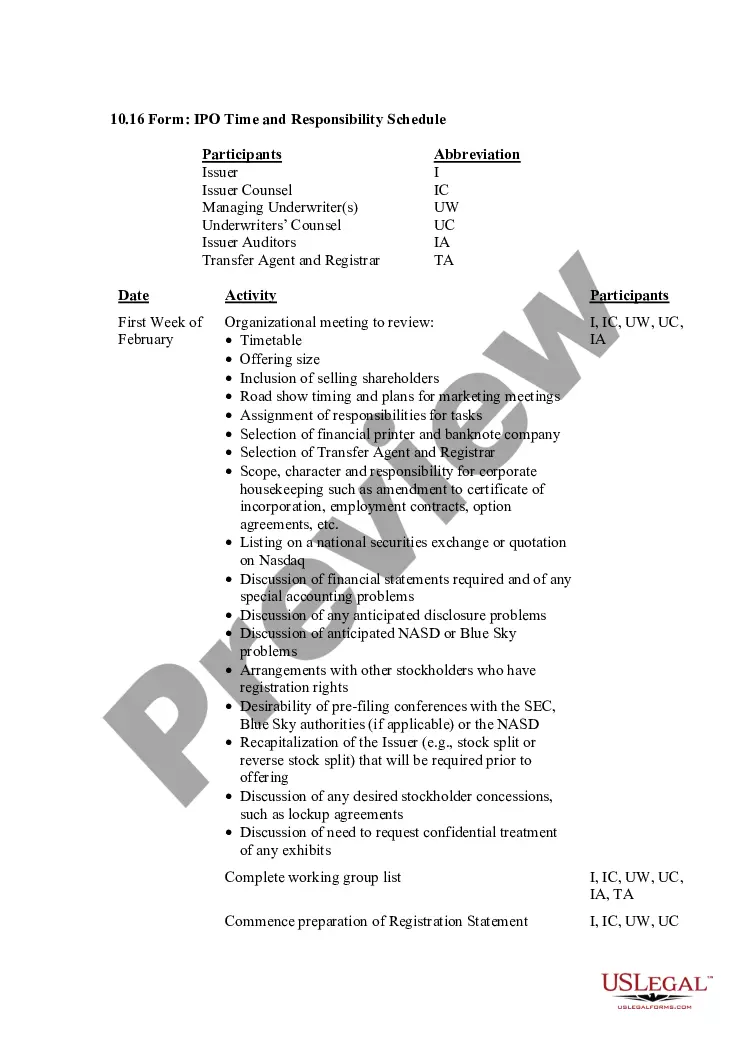

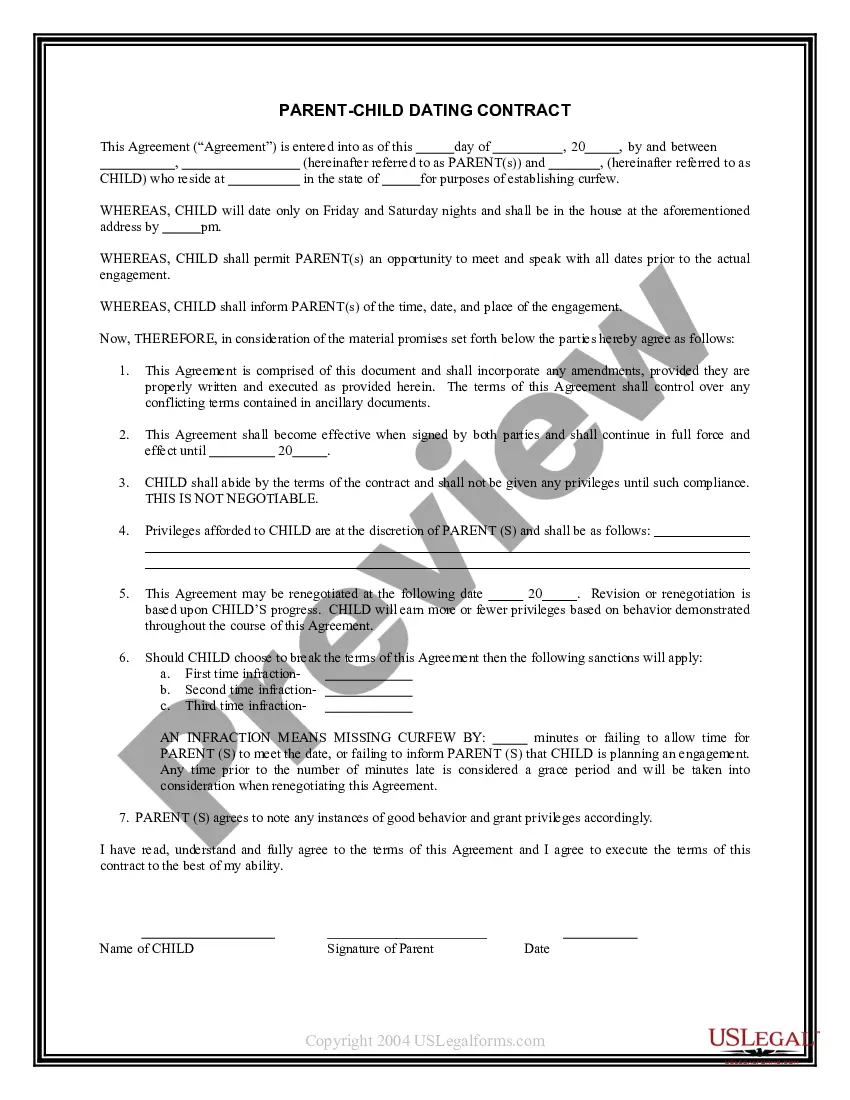

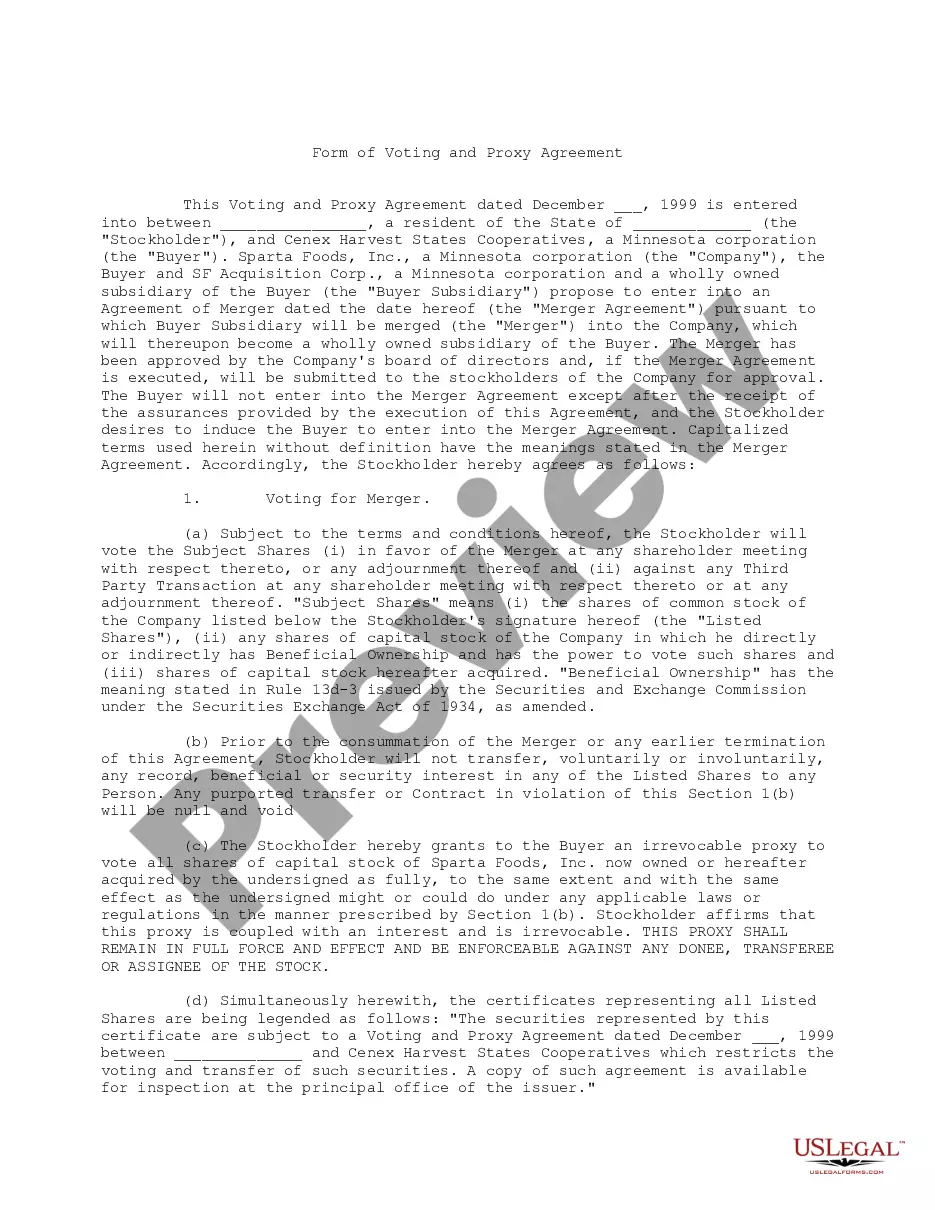

Description

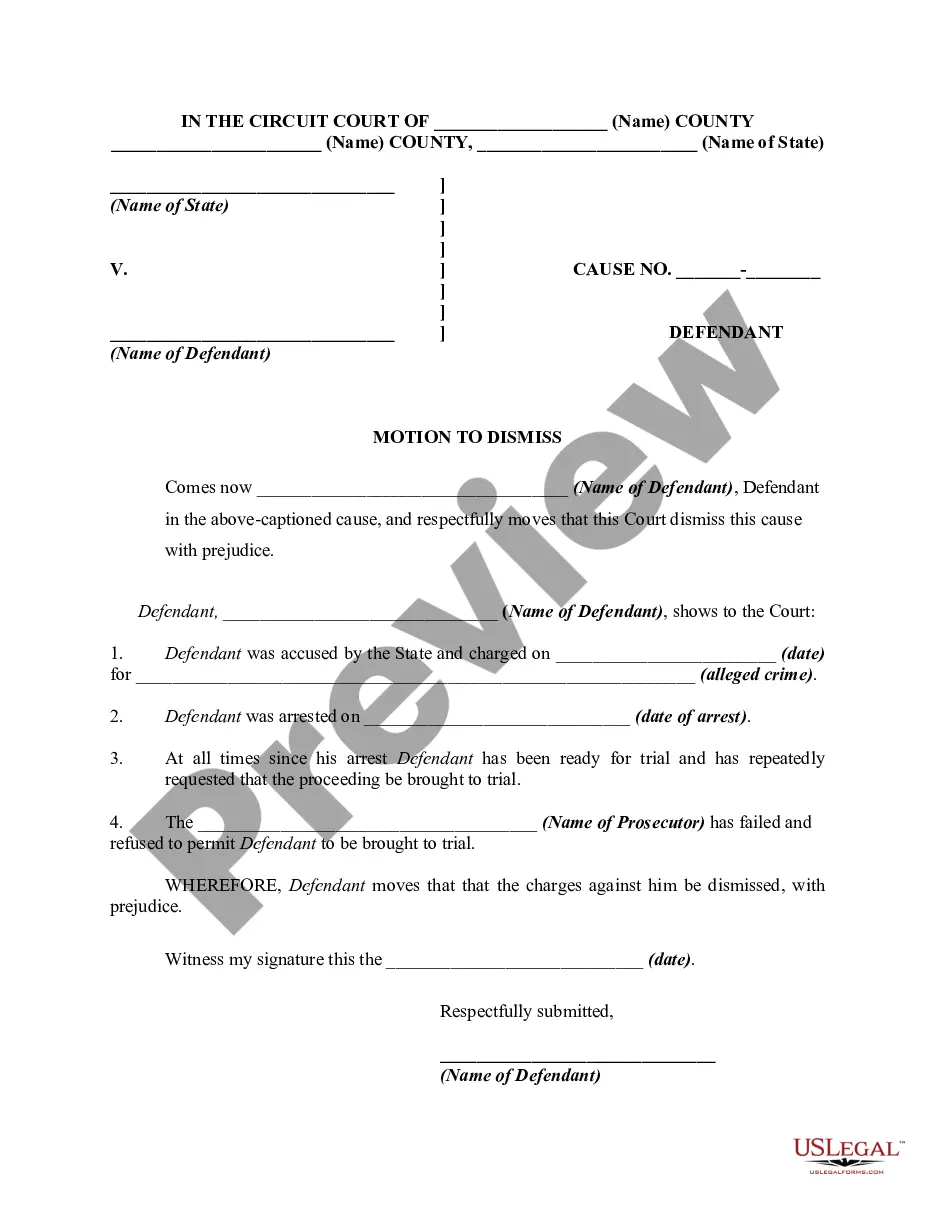

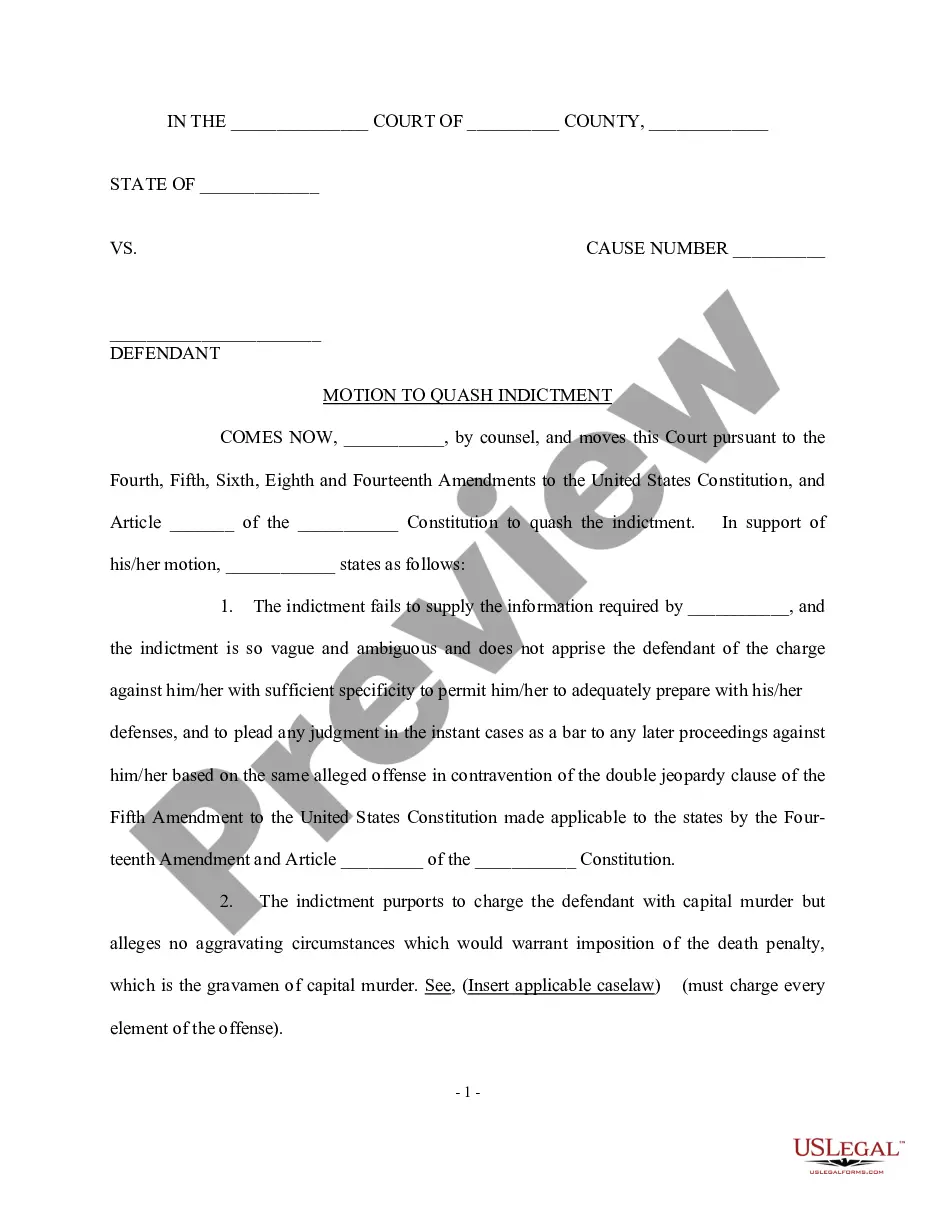

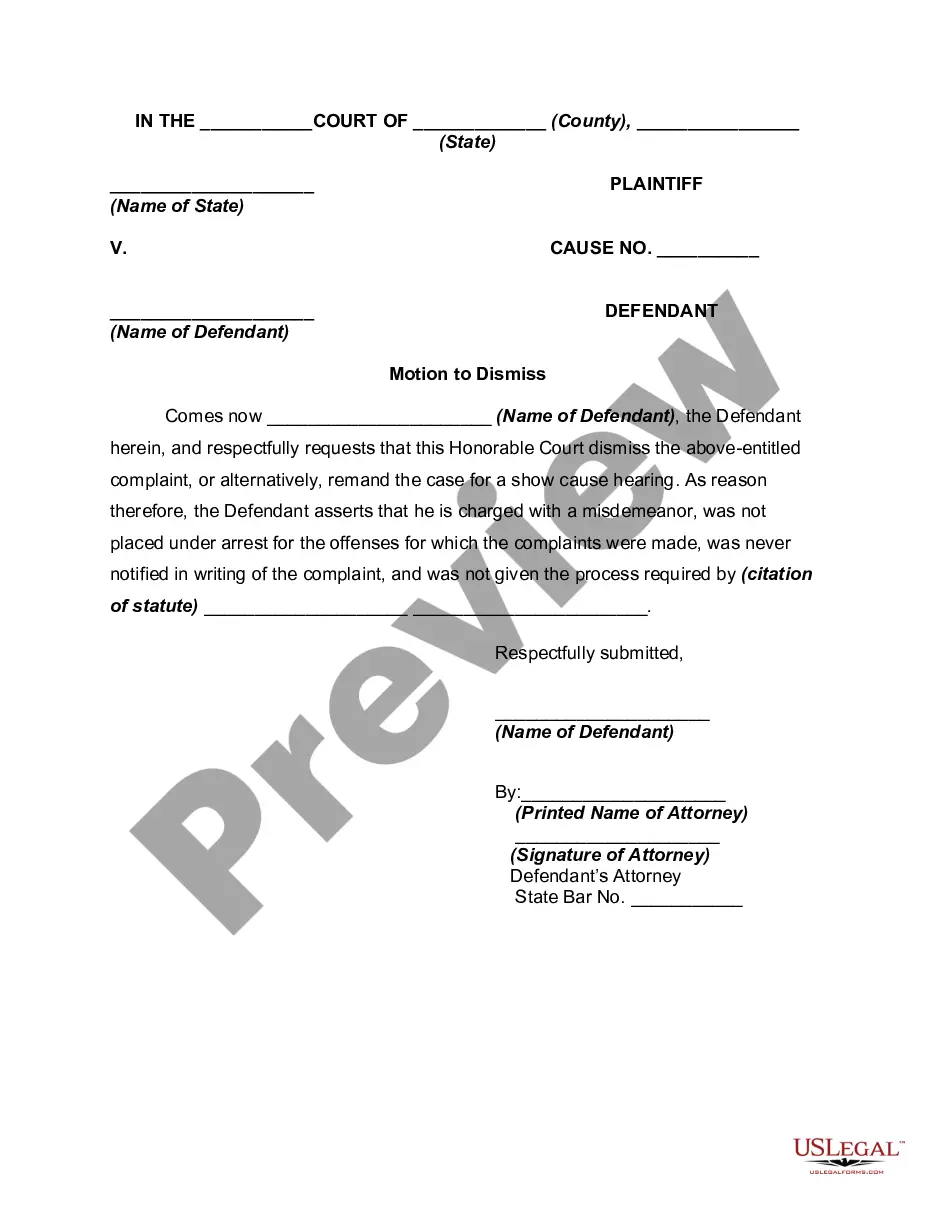

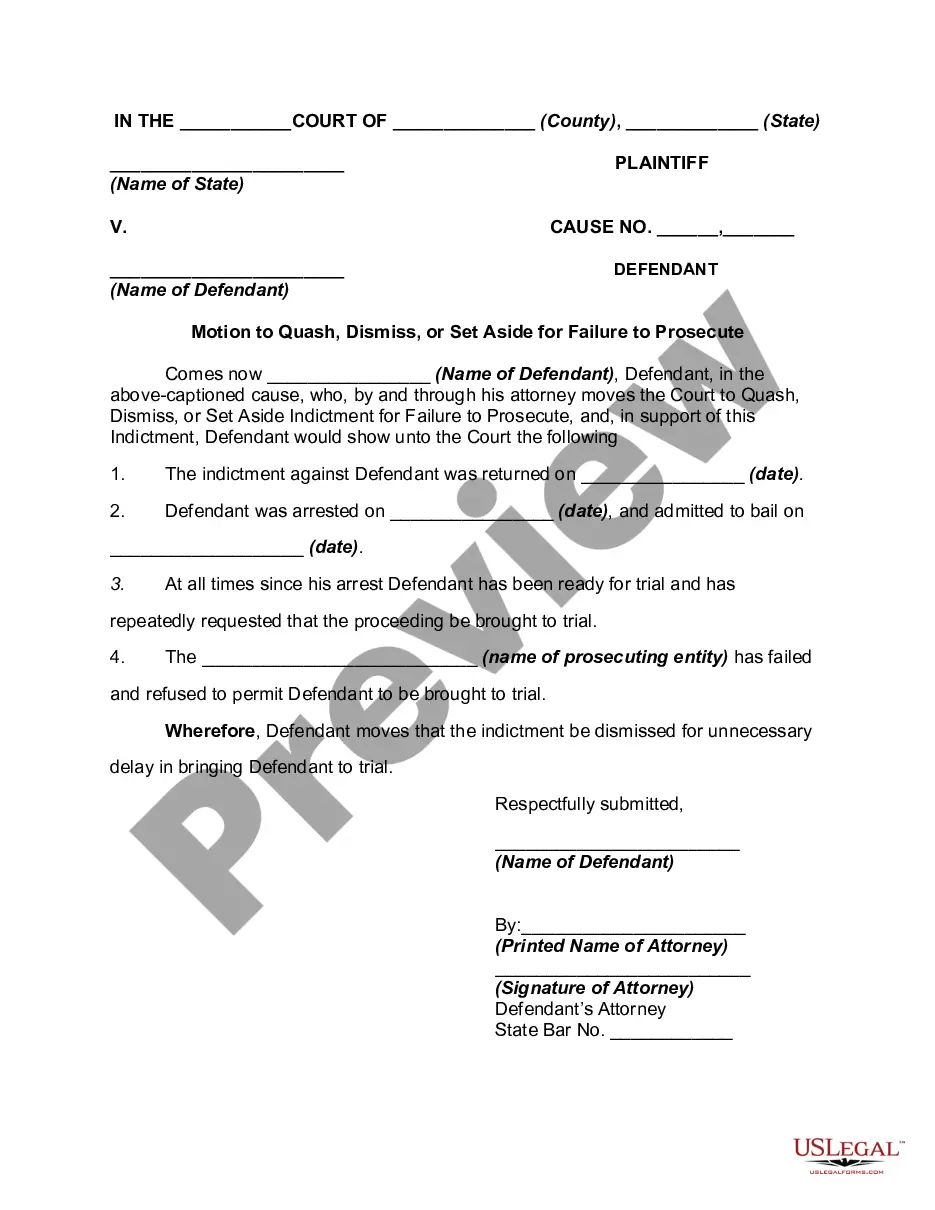

How to fill out Motion To Quash, Dismiss, Or Set Aside Criminal Charges For Failure To Prosecute?

Whether for business purposes or for individual matters, everybody has to deal with legal situations at some point in their life. Completing legal papers demands careful attention, starting with picking the proper form template. For instance, if you pick a wrong version of a Cost For Failure, it will be declined once you send it. It is therefore important to have a dependable source of legal papers like US Legal Forms.

If you need to get a Cost For Failure template, stick to these simple steps:

- Get the template you need using the search field or catalog navigation.

- Examine the form’s information to make sure it matches your case, state, and region.

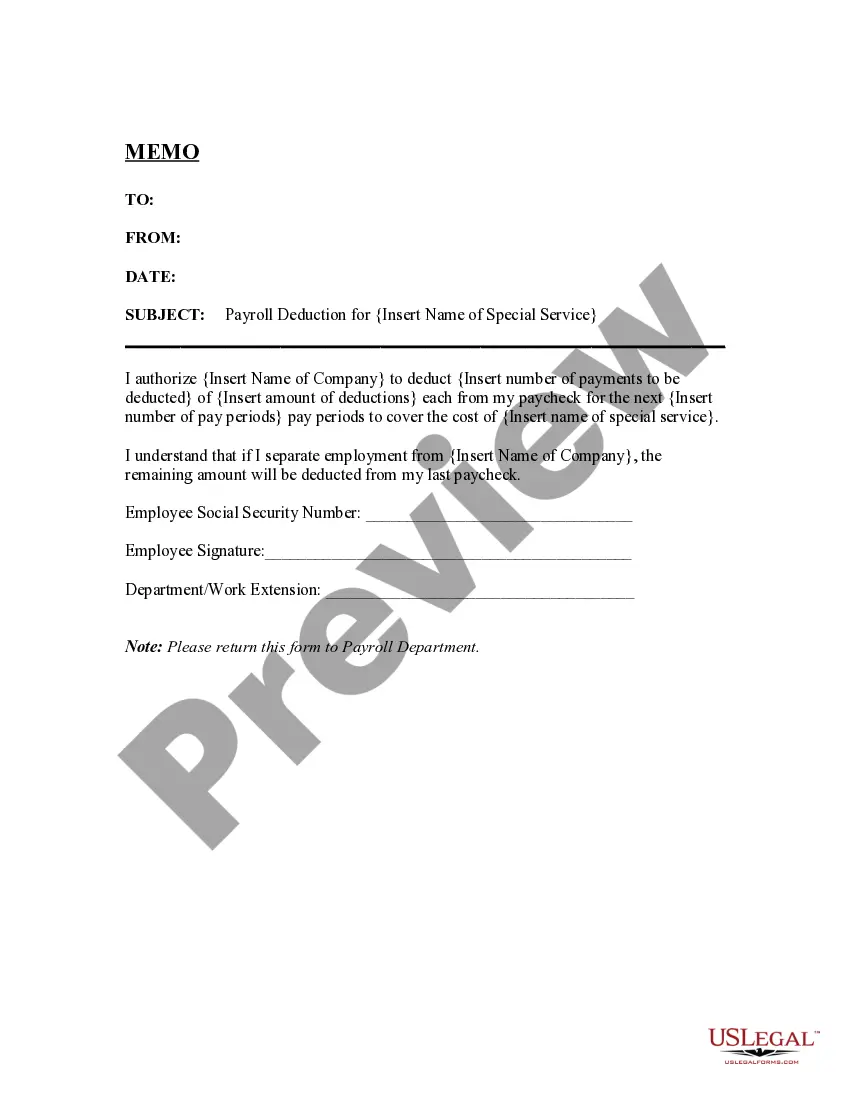

- Click on the form’s preview to see it.

- If it is the wrong form, get back to the search function to locate the Cost For Failure sample you need.

- Get the file when it meets your needs.

- If you already have a US Legal Forms profile, click Log in to access previously saved documents in My Forms.

- In the event you don’t have an account yet, you can obtain the form by clicking Buy now.

- Choose the correct pricing option.

- Complete the profile registration form.

- Pick your transaction method: use a credit card or PayPal account.

- Choose the document format you want and download the Cost For Failure.

- After it is saved, you are able to fill out the form by using editing applications or print it and finish it manually.

With a substantial US Legal Forms catalog at hand, you don’t need to spend time looking for the right template across the web. Take advantage of the library’s straightforward navigation to get the right form for any situation.

Form popularity

FAQ

Internal failure costs are a third category of quality costs. This cost occurs when quality defects are discovered before they reach the customer. Examples of internal failure costs include scrapping a product, reworking the product, and lost productivity due to machine breakdowns or labor errors.

Internal Failure Costs They are identified within the scope of the project. These costs include rejected products, reworking of defective units, and downtime caused by quality problems. It also includes any costs involved if the company has to reject and throw parts of their project work, which is also called ?scrap?.

How do you calculate the cost of poor quality in manufacturing? Poor Quality = Internal Failure Costs + External Failure Costs. COPQ = (Waste + Defects ) * Time Spent Fixing. COPQ = $2 million + $200k = $2.2 million.

Failure Costs. Failure costs are those associated with correcting nonconforming material, including scrap, rework, repair, warranty actions, and others related to the correction of nonconformances. Many organizations further subdivide this category into internal and external failure costs.

Failure costs are those incurred by a manufacturer when it produces defective goods. There are two types of failure costs, which are internal and external. Internal failure costs occur before goods are shipped to customers, while external failure costs arise subsequent to shipment.