Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements refer to the design requirements set by the state of Washington for the installation and maintenance of hydraulic and roped hydraulic elevators. These requirements ensure that elevators are installed and operated in a manner that is both safe and reliable. There are two main types of Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements: 1. Hydraulic Elevator Layout Requirements: These requirements cover the details of the installation and servicing of hydraulic elevators, including the installation of the power unit, the hydraulic cylinders, the control valves, the safety devices, the counterweight, and the emergency stop switch. 2. Roped Hydraulic Elevator Layout Requirements: These requirements cover the details of the installation and servicing of roped hydraulic elevators, including the installation of the power unit, the elevator motor, the control valves, the safety devices, the counterweight, and the emergency stop switch. In addition to these two main types, Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements also cover a wide range of other topics, including the installation of the elevator shaft, the elevator car, the emergency stop switch, the fire safety systems, and the maintenance and inspection of the elevator system.

Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements

Description

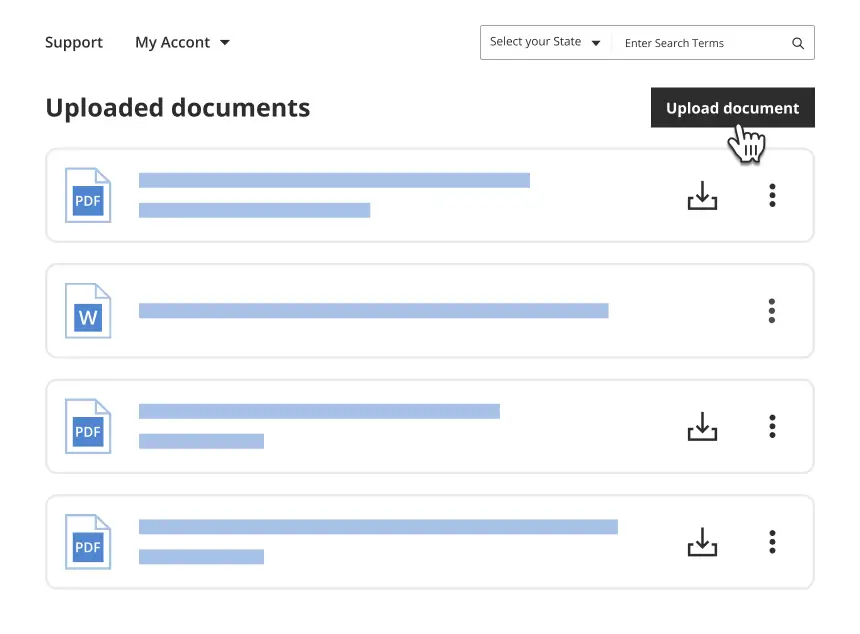

Get your form ready online

Our built-in tools help you complete, sign, share, and store your documents in one place.

Make edits, fill in missing information, and update formatting in US Legal Forms—just like you would in MS Word.

Download a copy, print it, send it by email, or mail it via USPS—whatever works best for your next step.

Sign and collect signatures with our SignNow integration. Send to multiple recipients, set reminders, and more. Go Premium to unlock E-Sign.

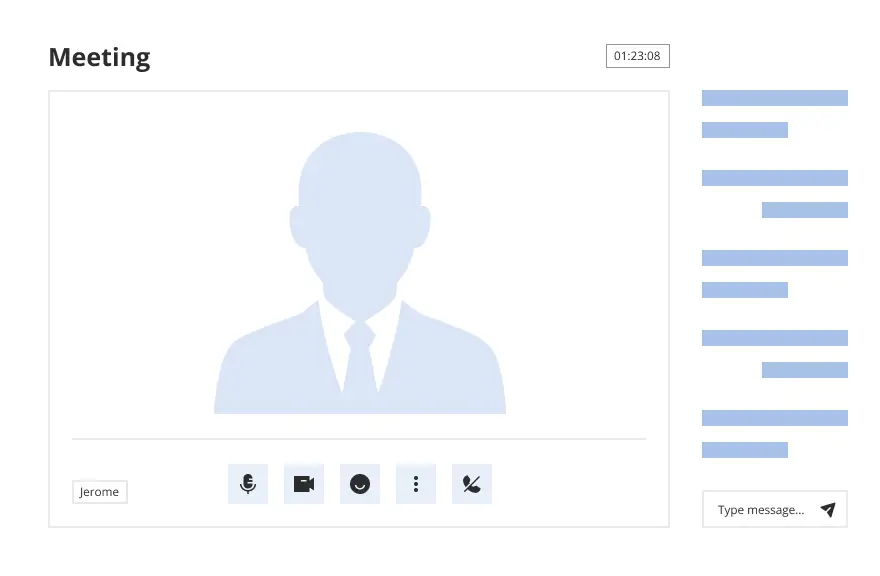

If this form requires notarization, complete it online through a secure video call—no need to meet a notary in person or wait for an appointment.

We protect your documents and personal data by following strict security and privacy standards.

Make edits, fill in missing information, and update formatting in US Legal Forms—just like you would in MS Word.

Download a copy, print it, send it by email, or mail it via USPS—whatever works best for your next step.

Sign and collect signatures with our SignNow integration. Send to multiple recipients, set reminders, and more. Go Premium to unlock E-Sign.

If this form requires notarization, complete it online through a secure video call—no need to meet a notary in person or wait for an appointment.

We protect your documents and personal data by following strict security and privacy standards.

Looking for another form?

How to fill out Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements?

Preparing official paperwork can be a real stress if you don’t have ready-to-use fillable templates. With the US Legal Forms online library of formal documentation, you can be confident in the blanks you obtain, as all of them correspond with federal and state laws and are verified by our experts. So if you need to fill out Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements, our service is the best place to download it.

Obtaining your Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements from our catalog is as simple as ABC. Previously registered users with a valid subscription need only log in and click the Download button once they find the proper template. Afterwards, if they need to, users can take the same document from the My Forms tab of their profile. However, even if you are new to our service, registering with a valid subscription will take only a few moments. Here’s a brief guideline for you:

- Document compliance check. You should attentively examine the content of the form you want and ensure whether it suits your needs and complies with your state law requirements. Previewing your document and looking through its general description will help you do just that.

- Alternative search (optional). If there are any inconsistencies, browse the library using the Search tab on the top of the page until you find an appropriate blank, and click Buy Now when you see the one you need.

- Account registration and form purchase. Create an account with US Legal Forms. After account verification, log in and choose your preferred subscription plan. Make a payment to continue (PayPal and credit card options are available).

- Template download and further usage. Select the file format for your Washington Hydraulic/ Roped Hydraulic Elevator Layout Requirements and click Download to save it on your device. Print it to fill out your papers manually, or take advantage of a multi-featured online editor to prepare an electronic version faster and more efficiently.

Haven’t you tried US Legal Forms yet? Sign up for our service now to obtain any formal document quickly and easily whenever you need to, and keep your paperwork in order!

Form popularity

FAQ

Roped hydraulic elevators use a combination of a hydraulic jack and cables to lift the elevator car. This provides the smooth ride of a hydraulic elevator without the need to dig a deep hole in the ground. The hydraulic jack resides in the hoistway between the rails. A pulley is attached to the top of the jack.

The industry-standard model is a 3? wide by 4? deep cab interior cab size with a 750 lb capacity and will travel 20-25 feet per minute. When planning for the required space, figure using around a 5'x5? area on each floor to accommodate the elevator and shaft-way enclosure.

In contrast to traction elevators, hydraulic elevators (like endura MRL from TK Elevator) don't use belts or ropes. Instead, they use an electronic pump to push hydraulic fluid into a cylinder, using pressure. This pressure pushes a piston and causes the elevator to rise.

Hydraulic elevators are only recommended for low to mid-rise buildings with a maximum of 5 to 7 storeys. There are two reasons for this limit. Firstly, the system requires a lot of energy to lift the cab, making it unsuitable for skyscrapers and other similar tall buildings. Speed is the other major reason.

These systems also operate at speeds of 150 ft./min. or less, making them slower than other types of elevators. Because of these factors, hydraulic elevators are only intended for buildings that are up to seven stories.

Hydraulic elevators are used extensively in buildings up to five or six stories high. Sometimes, but rarely, up to 8 stories high. These elevators, which can operate at speeds up to 61 meters (200 ft) per minute, do not use the large overhead hoisting machinery the way geared and gearless traction systems do.

There are two types of drive systems for these elevators: the direct type, where a plunger that extends or retracts through hydraulic pressure directly connects to a car to make it ascend or descend; and the indirect type, where the extending or retracting of the plunger pulls a rope that makes the car ascend or

In contrast to traction elevators, hydraulic elevators (like endura MRL from TK Elevator) don't use belts or ropes. Instead, they use an electronic pump to push hydraulic fluid into a cylinder, using pressure. This pressure pushes a piston and causes the elevator to rise.