South Dakota Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

US Legal Forms - among the largest collections of legal documents in the United States - offers a variety of legal paper templates that you can download or print.

By using the site, you can access thousands of forms for business and personal purposes, organized by categories, states, or keywords.

You can find the most recent versions of forms such as the South Dakota Aseptic Techniques within minutes.

Review the form description to ensure that you've selected the correct form.

If the form does not meet your needs, use the Search section at the top of the screen to find one that does.

- If you currently hold a subscription, Log In to access South Dakota Aseptic Techniques from the US Legal Forms library.

- The Download button will be visible on each form you view.

- You can find all previously downloaded forms in the My documents tab of your account.

- If you are a first-time user of US Legal Forms, here are some simple steps to get you started.

- Ensure you have chosen the correct form for your city/state.

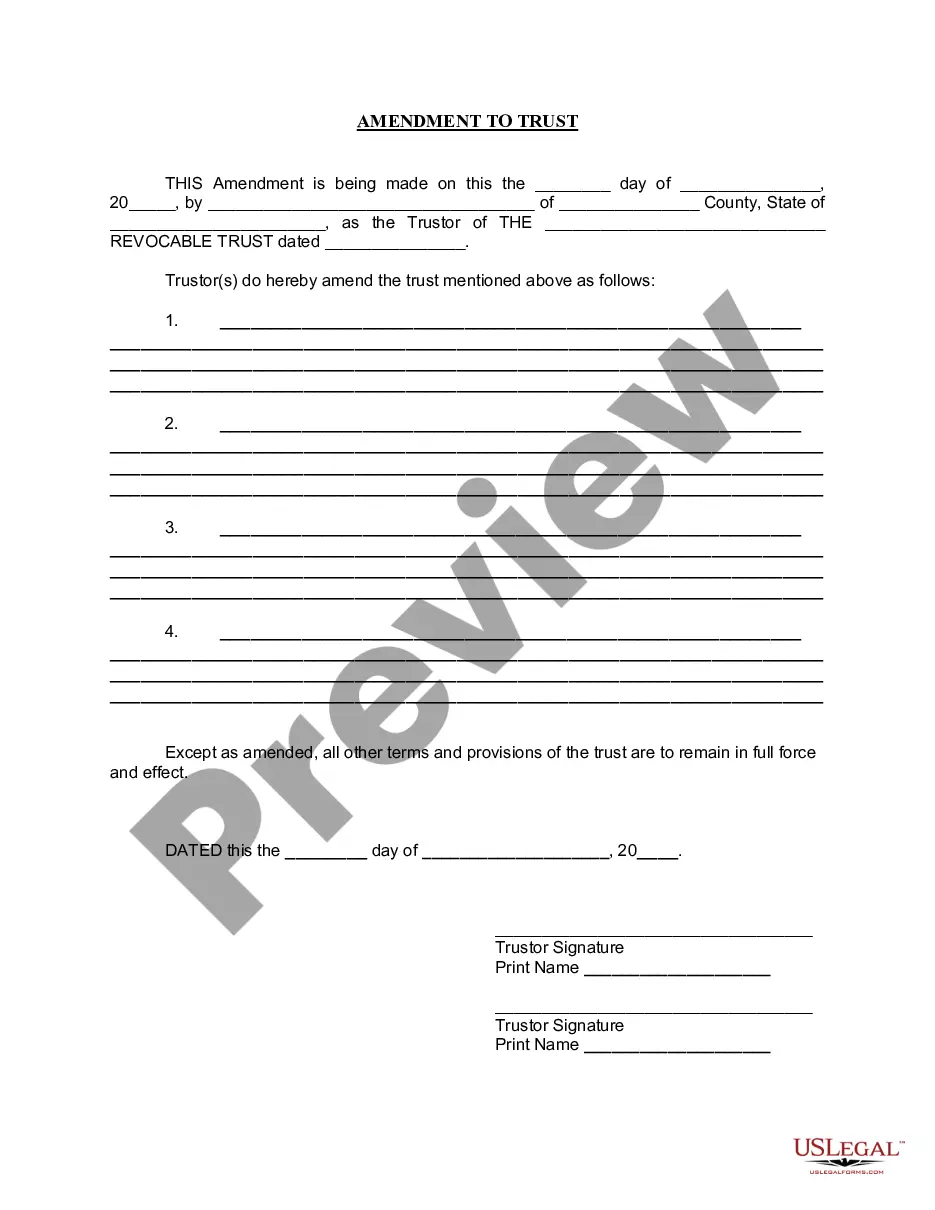

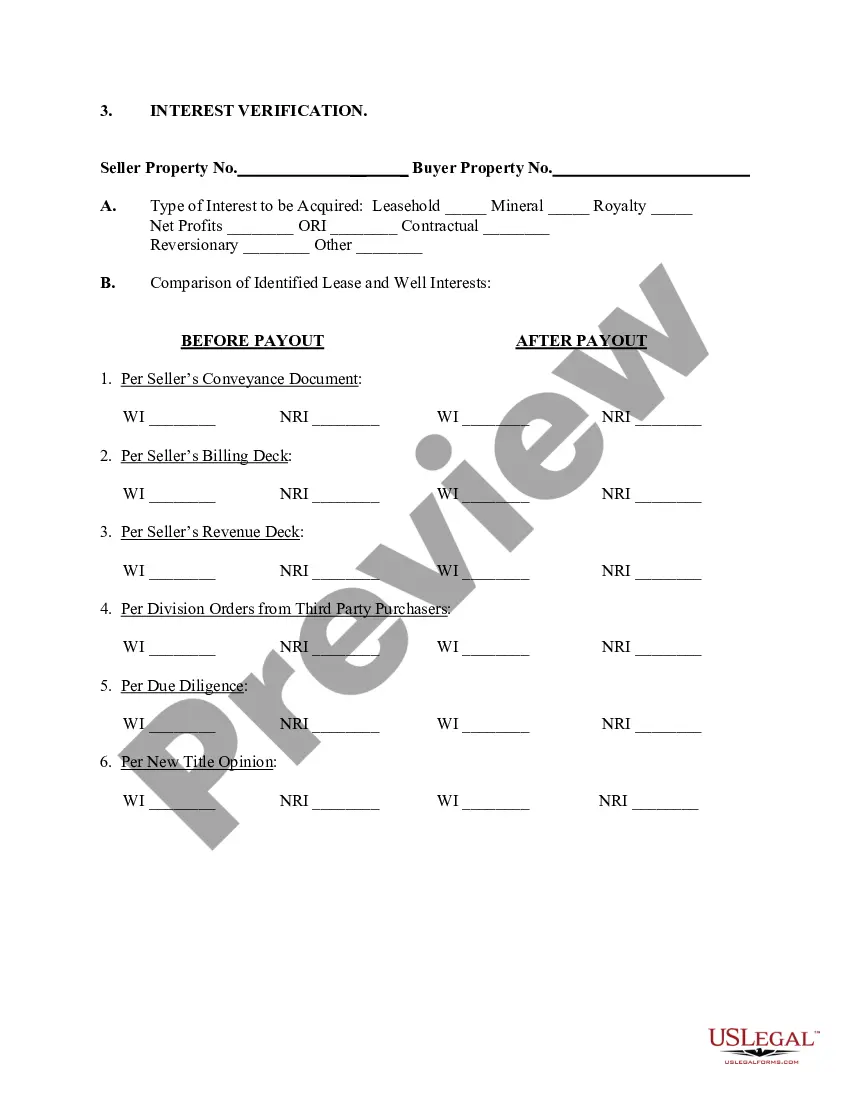

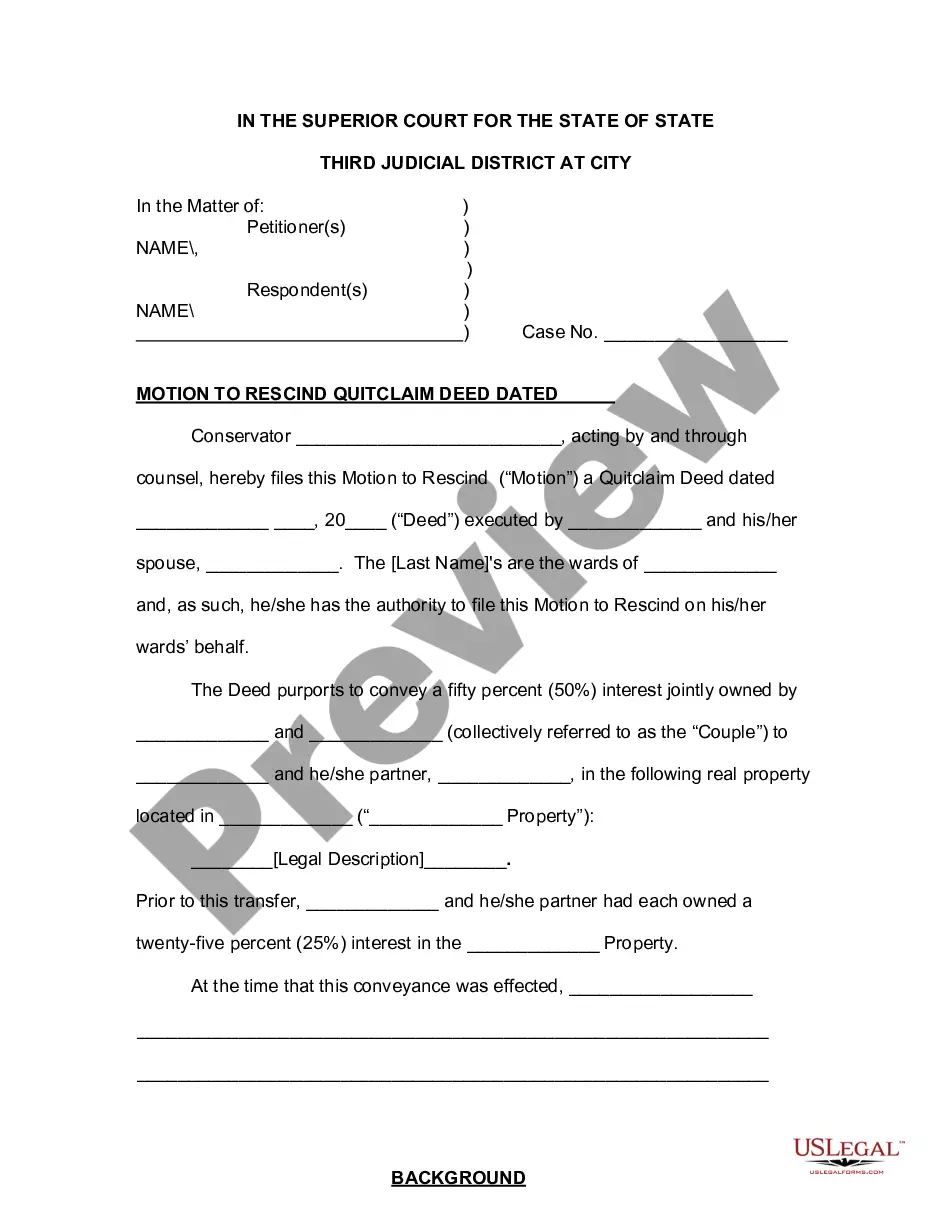

- Click the Preview button to view the form’s content.

Form popularity

FAQ

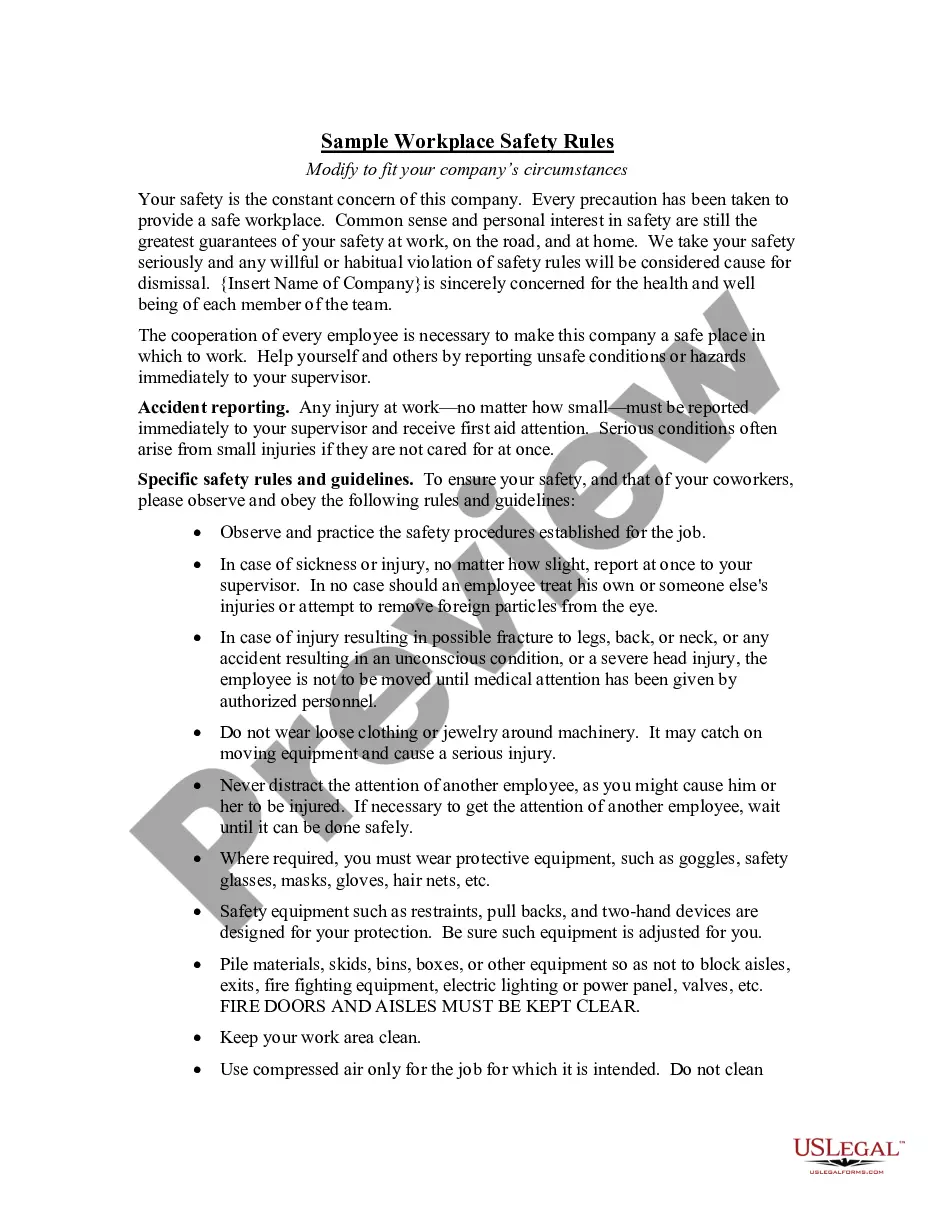

PRINCIPLES OF THE ASEPTIC TECHNIQUECreating a microorganism-free environment (sterile field)Use of sterilized instruments and dressings.Maintaining sterility of sterile field and instruments by preventing microbial contaminationby contact with non-sterile objects; such as:More items...

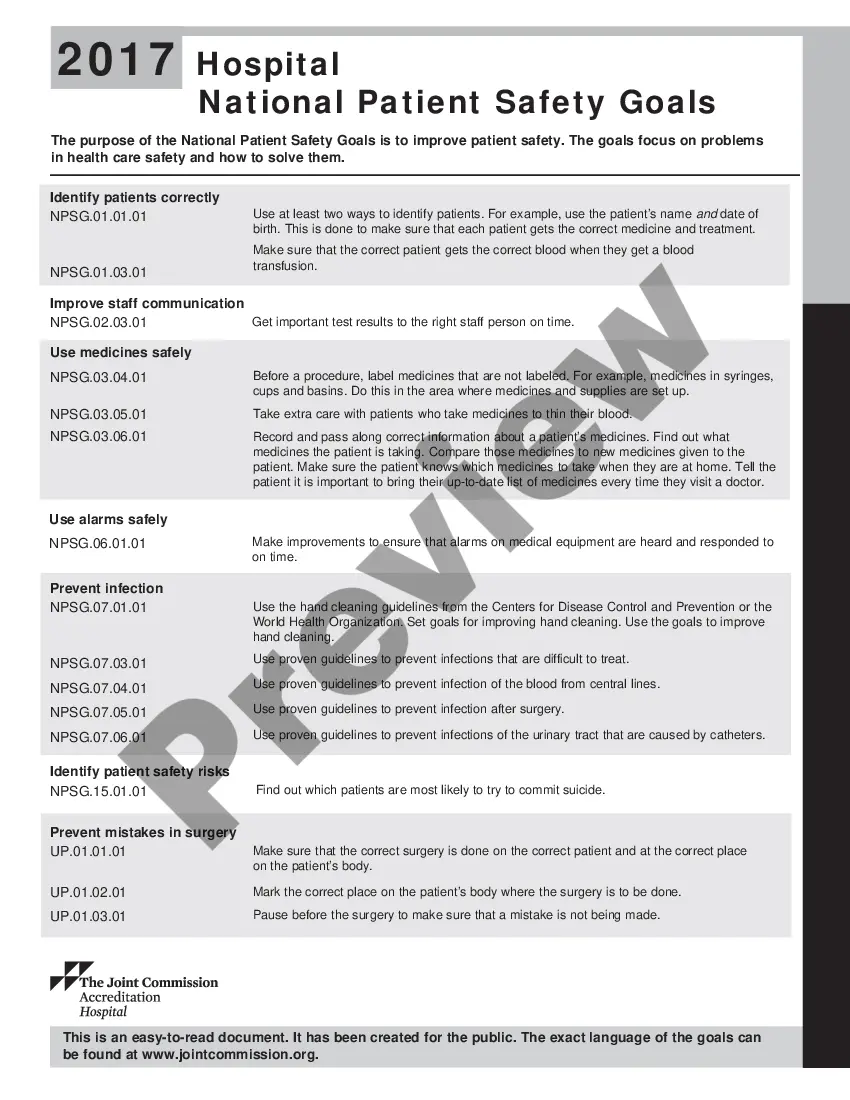

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

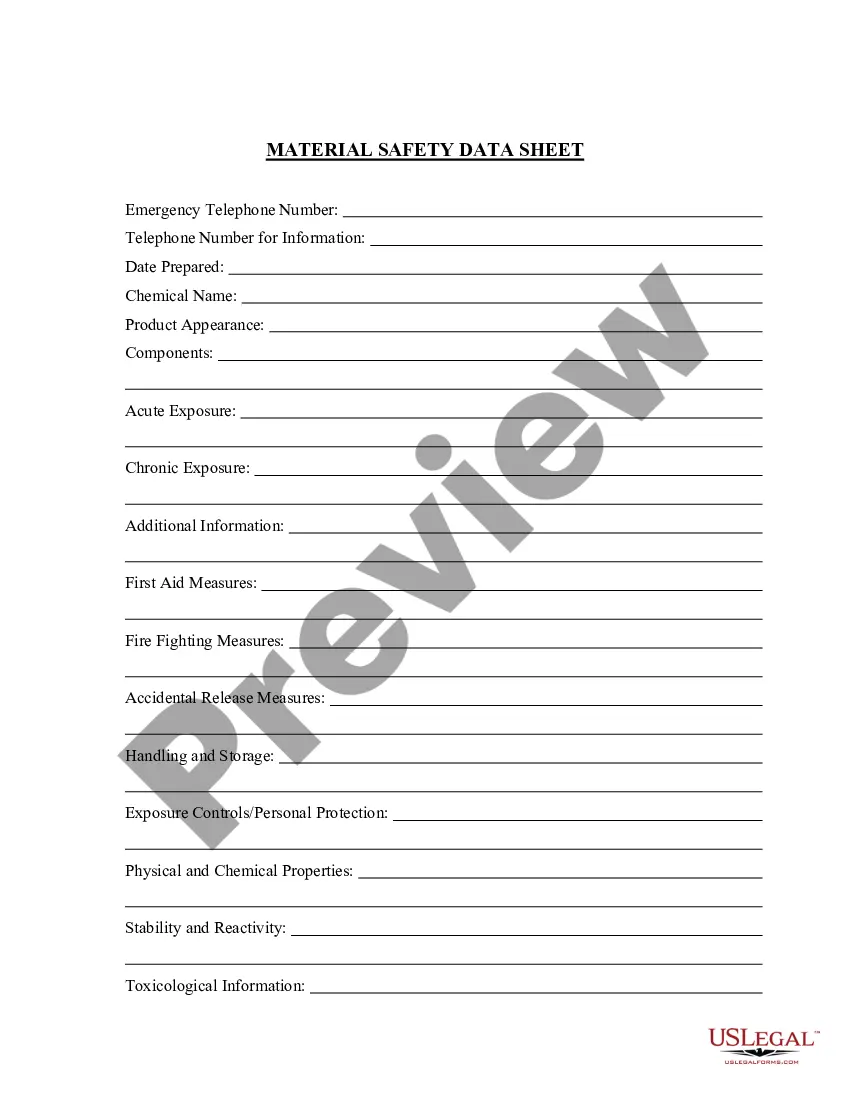

Aseptic technique is a method that involves target-specific practices and procedures under suitably controlled conditions to reduce the contamination from microbes. It is a compulsory laboratory skill to conduct research related in the field of microbiology.

Aseptic technique is classified into two different categories: standard aseptic technique and surgical aseptic technique.

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)

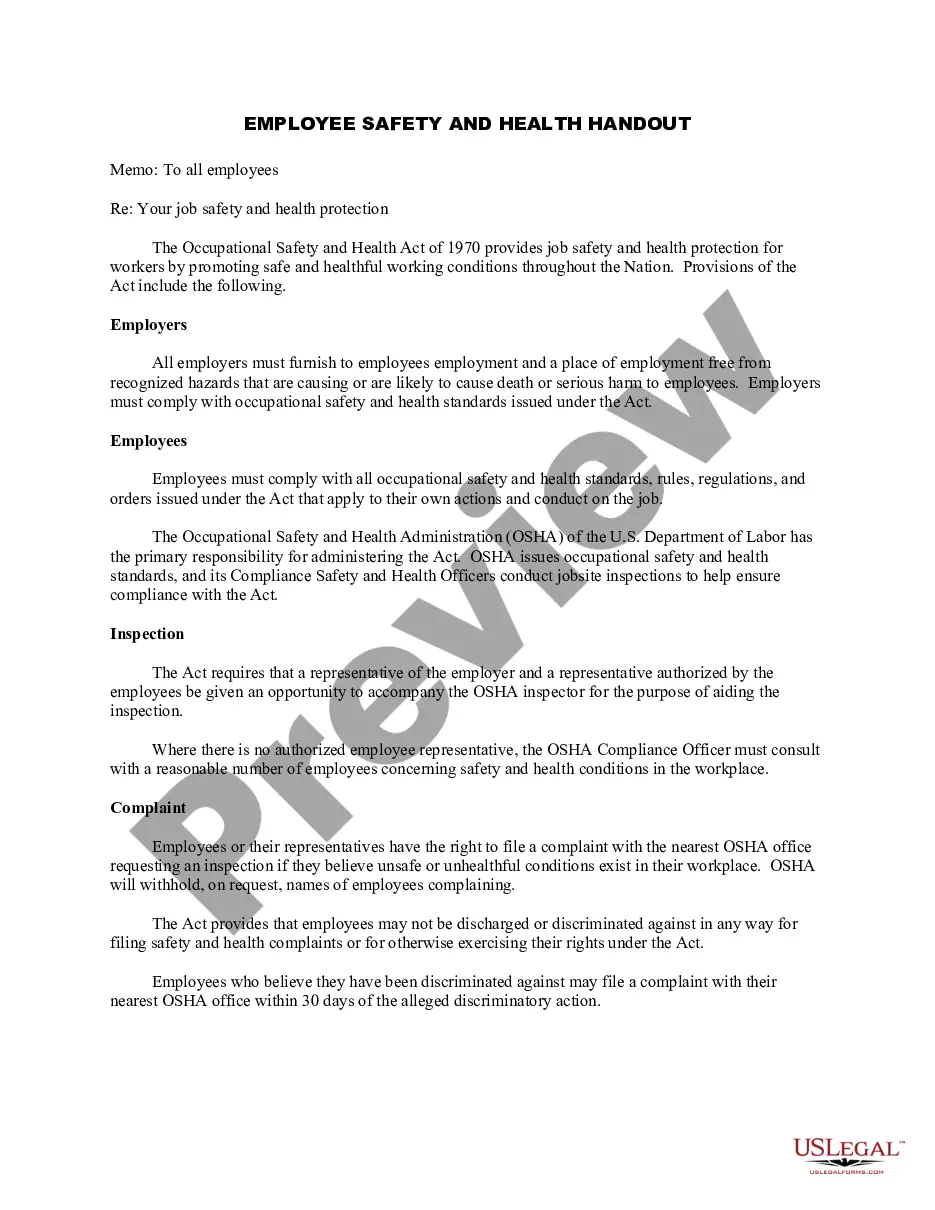

Healthcare professionals use aseptic technique when they are:performing surgical procedures.performing biopsies.dressing surgical wounds or burns.suturing wounds.inserting a urinary catheter, wound drain, intravenous line, or chest tube.administering injections.using instruments to conduct a vaginal examination.More items...?

Aseptic techniques include:Wiping bench with disinfectant/alcohol. Not growing microorganisms at body temperature. Using sterile loops when transferring cultures . Flaming culture bottle necks to prevent contamination. Sterilising (using an autoclave ) or disposing of all used equipment.

Procedures that involve aseptic technique include:200cInserting PICC lines.200cPerforming dialysis.200cInserting catheters.200cRunning IVs.200cInserting chest tubes.200cPerforming surgeries.200cDressing wounds.