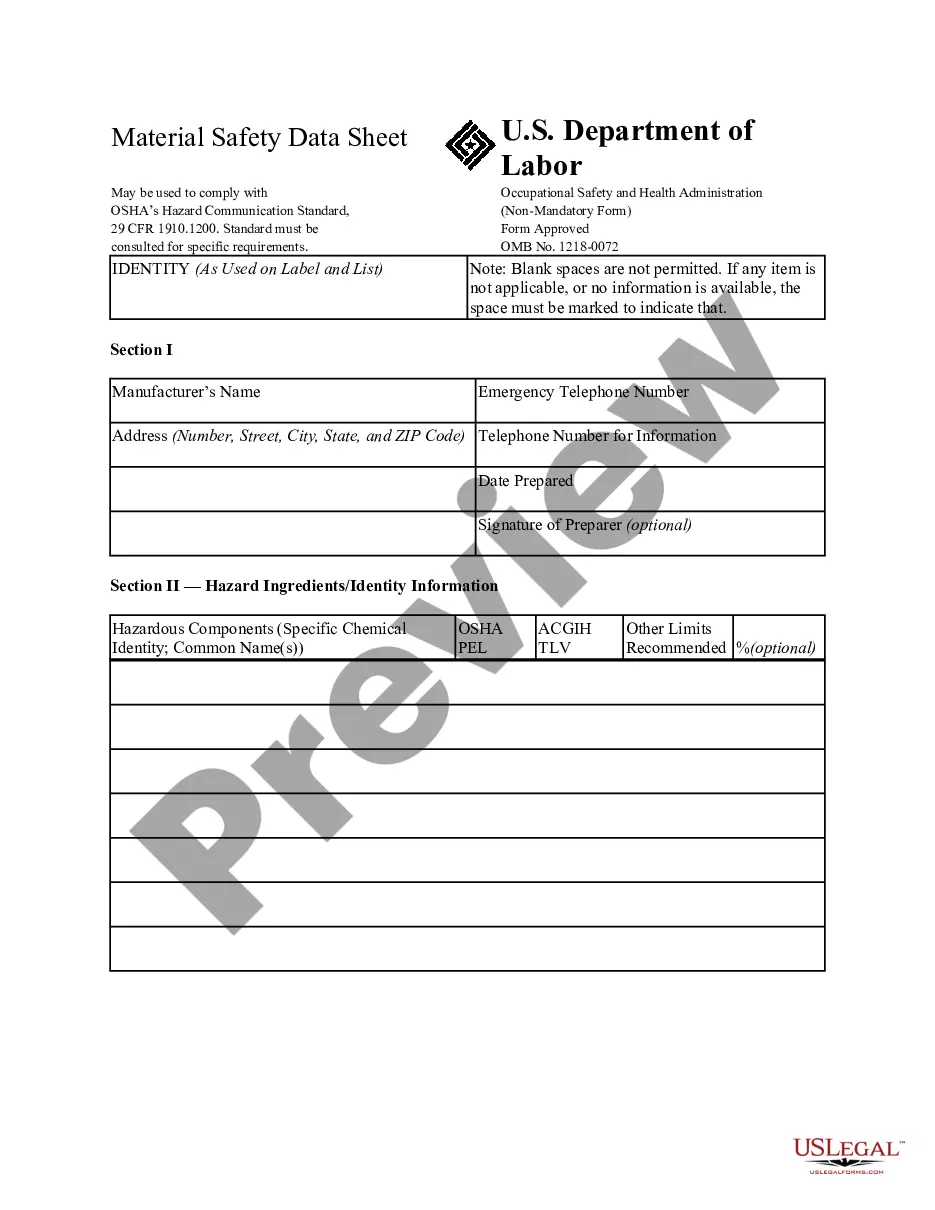

South Carolina Material Safety Data Sheet from the U.S. Dept. of Labor and OSHA

Description

How to fill out Material Safety Data Sheet From The U.S. Dept. Of Labor And OSHA?

Finding the appropriate legal document template can be quite challenging. Obviously, there are numerous themes available online, but how do you locate the specific legal form you require.

Utilize the US Legal Forms website. The service offers thousands of templates, such as the South Carolina Material Safety Data Sheet from the U.S. Department of Labor and OSHA, suitable for both business and personal needs.

All of the forms are vetted by experts and comply with federal and state regulations.

Once you are confident that the form is appropriate, click on the Purchase now option to acquire the form. Select the pricing plan you desire and enter the required information. Create your account and finalize your purchase using your PayPal account or credit card. Choose the file format and download the legal document template to your device. Complete, modify, print, and sign the received South Carolina Material Safety Data Sheet from the U.S. Department of Labor and OSHA. US Legal Forms is the largest repository of legal forms where you can find various document templates. Use the service to download well-crafted paperwork that adheres to state requirements.

- If you are already registered, Log In to your account and select the Download option to acquire the South Carolina Material Safety Data Sheet from the U.S. Department of Labor and OSHA.

- Utilize your account to search through the legal forms you have previously purchased.

- Navigate to the My documents tab of your account to obtain another copy of the document you need.

- If you are a new user of US Legal Forms, here are straightforward instructions that you can follow.

- Firstly, ensure you have chosen the correct form for your city/county. You can examine the form using the Preview option and read the form description to confirm this is indeed the right one for you.

- If the form does not meet your requirements, use the Search area to find the suitable form.

Form popularity

FAQ

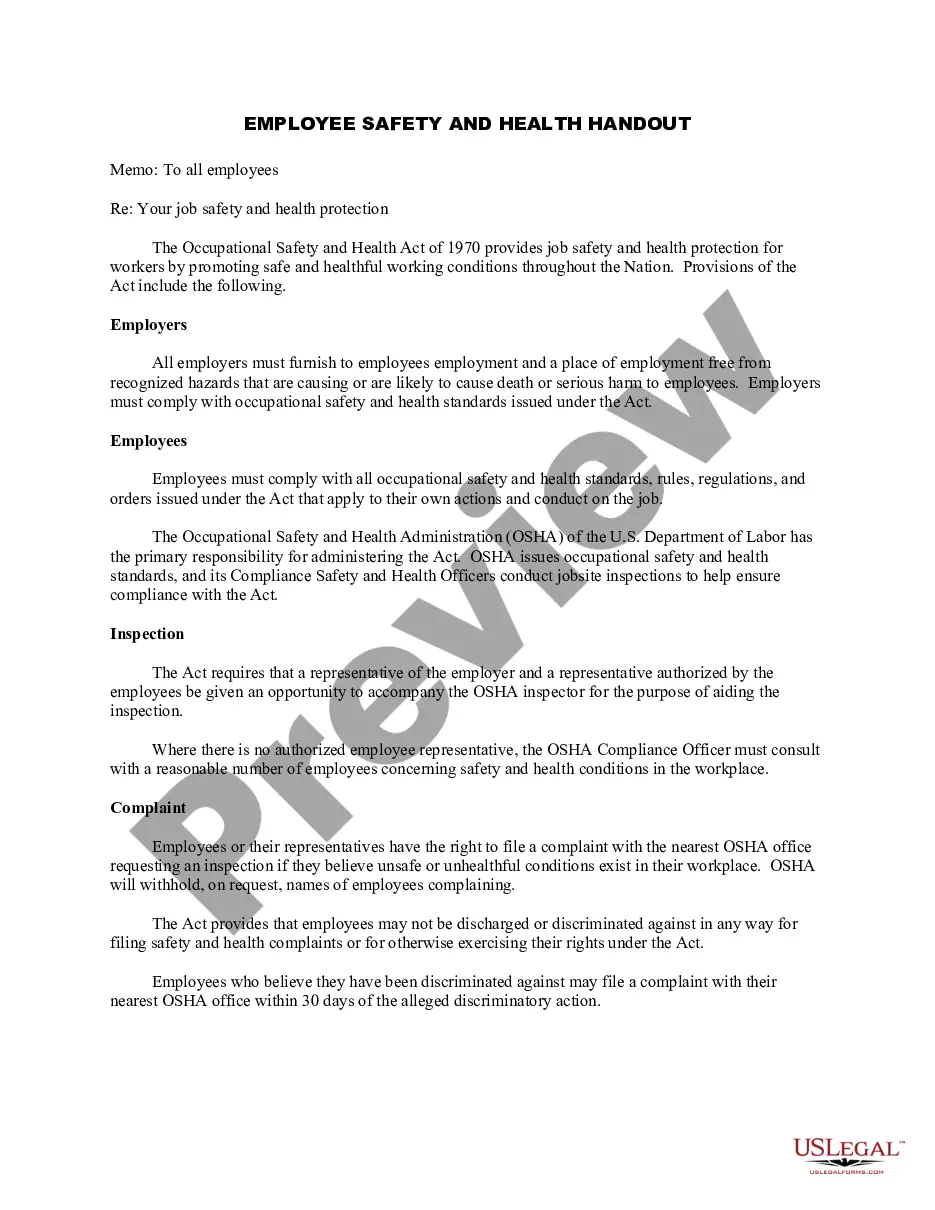

Step Five - A Periodic Review Annually, the JHAs should be reviewed by the Supervisors with all workcenter personnel. JHAs should be reviewed during a mishap, injury or illness investigation to help identify possible causes or problem areas.

Instructions for Conducting a Job Hazard AnalysisInvolve employees. Discuss what you are going to do and why.Review your company's accident/injury/illness/near miss history to determine which jobs pose the highest risk to employees.Identify the OSHA standards that apply to your jobs.Set priorities.

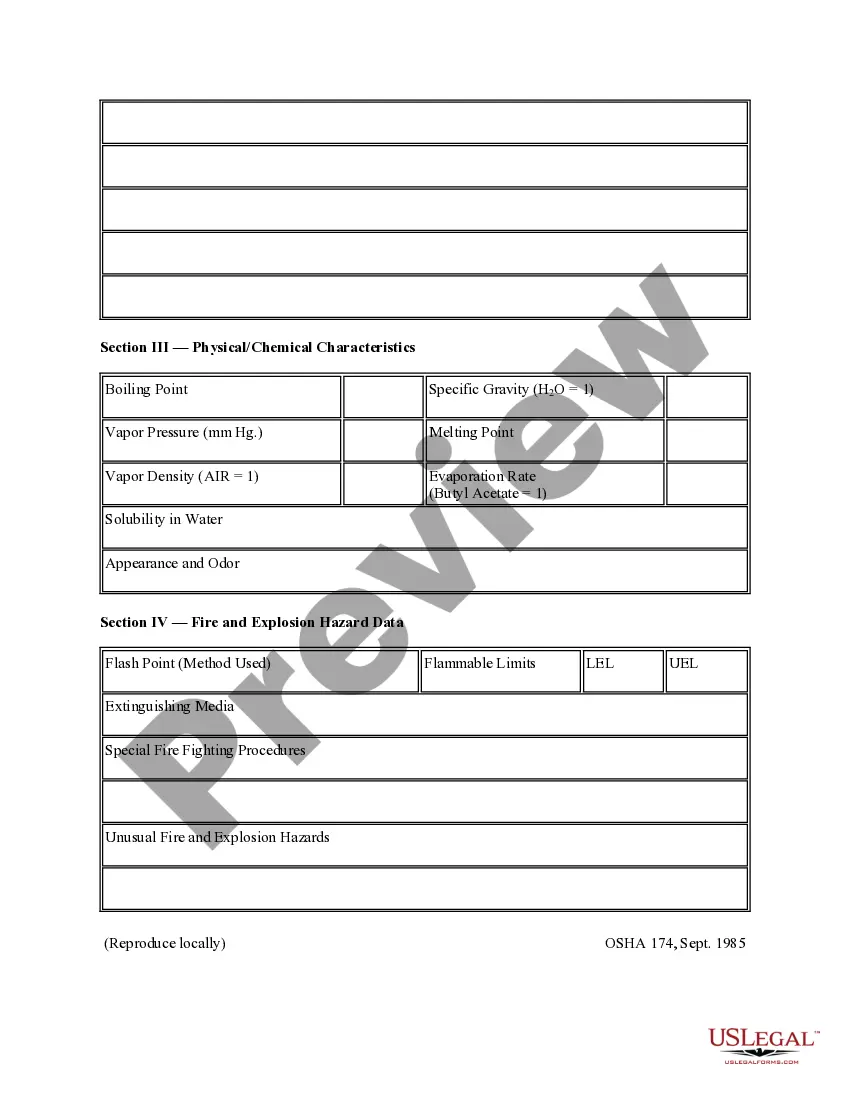

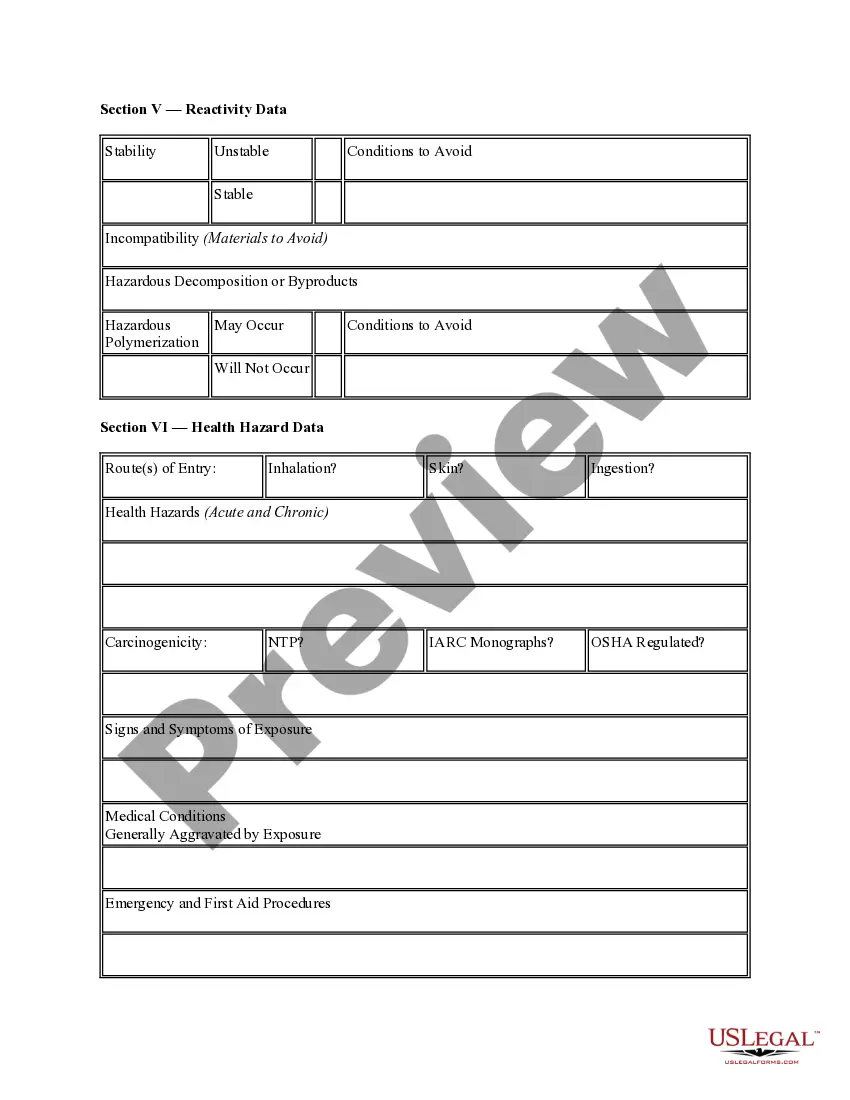

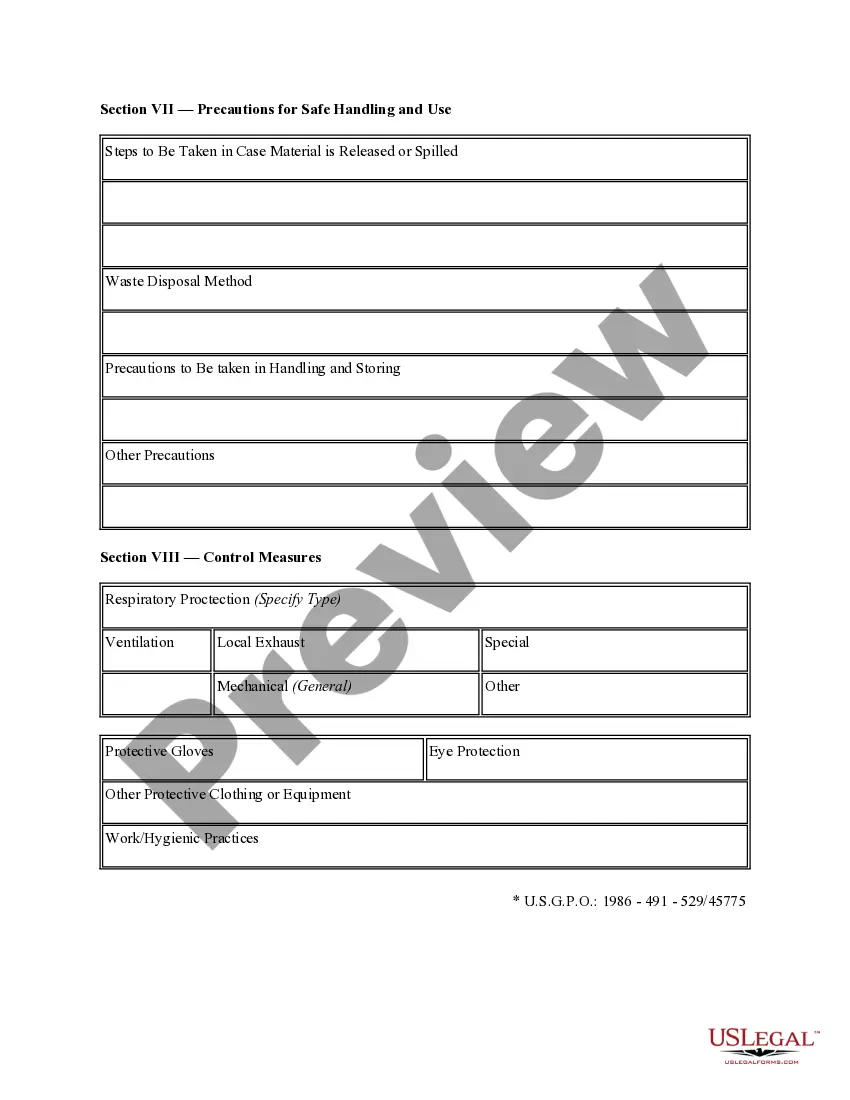

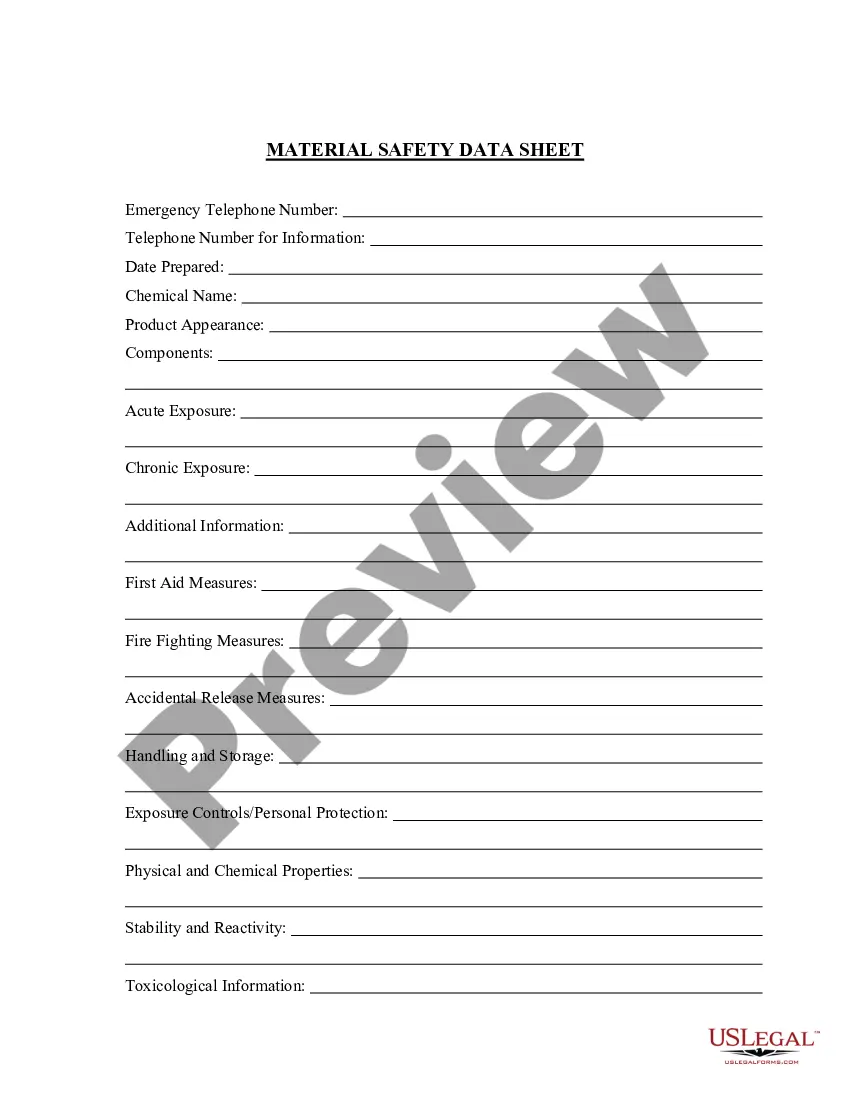

What information is on the MSDS?Product Information: product identifier (name), manufacturer and suppliers names, addresses, and emergency phone numbers.Hazardous Ingredients.Physical Data.Fire or Explosion Hazard Data.More items...

MSDSs must be developed for hazardous chemicals used in the workplace, and must list the hazardous chemicals that are found in a product in quantities of 1% or greater, or 0.1% or greater if the chemical is a carcinogen. The MSDS does not have to list the amount that the hazardous chemical occurs in the product.

How to Complete the OSHA Form 300Step 1: Determine the Establishment Locations.Step 2: Identify Required Recordings.Step 3: Determine Work-Relatedness.Step 4: Complete the OSHA Form 300.Step 5: Complete and Post the OSHA 300A Annual Summary.Step 6: Submit Electronic Reports to OSHA.Step 7: Retain the Log and Summary.

How to Fill Out a JHA: Step by StepStep 1: Choose a job from your list (according to priority) and break it down into tasks or steps.Step 2: Identify all hazards for each task.Step 3: Create hazard descriptions.Step 4: Create a plan for hazard control.Step 5: Control hazards and repeat.More items...?

All employees on the payroll are covered. The employer is required to record on the OSHA 300 Log the recordable injuries and illnesses for all employees on its payroll, including hourly, salaried, executive, part-time, seasonal, or migrant workers.

An SDS (formerly known as MSDS) includes information such as the properties of each chemical; the physical, health, and environmental health hazards; protective measures; and safety precautions for handling, storing, and transporting the chemical.

Requirementsthe name of the chemical (same as on the label)the chemical and common names of the substance.a listing of the ingredients.a statement of the ingredients that are known carcinogens or that present other known hazards.any specific hazards.