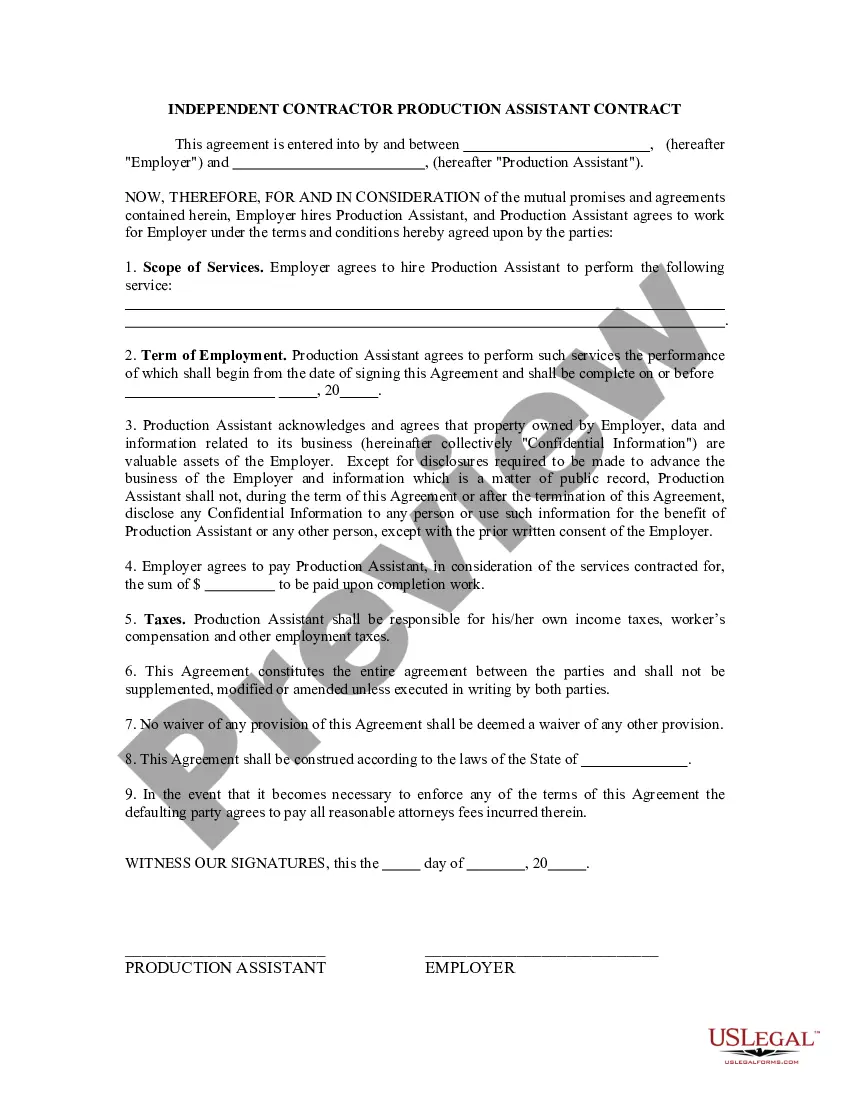

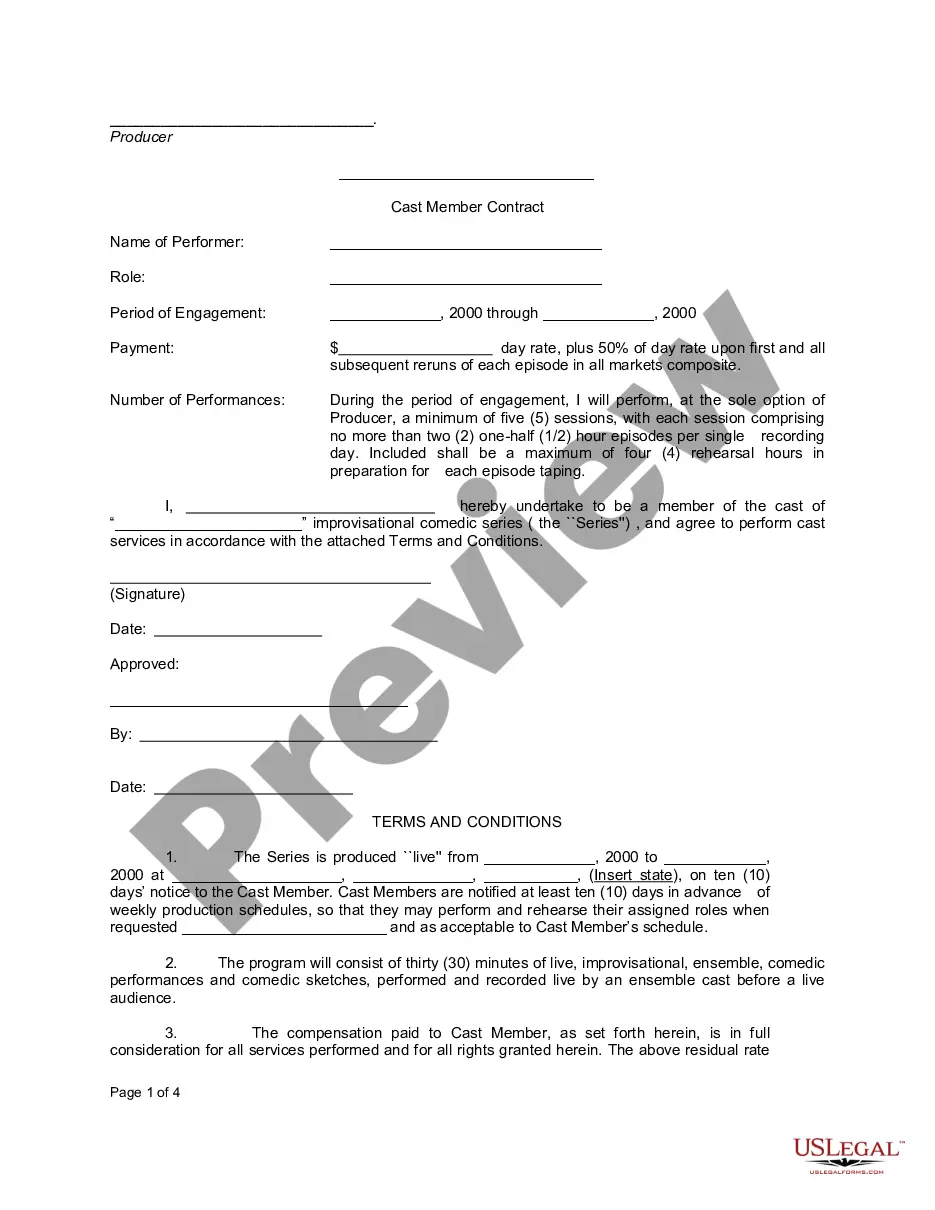

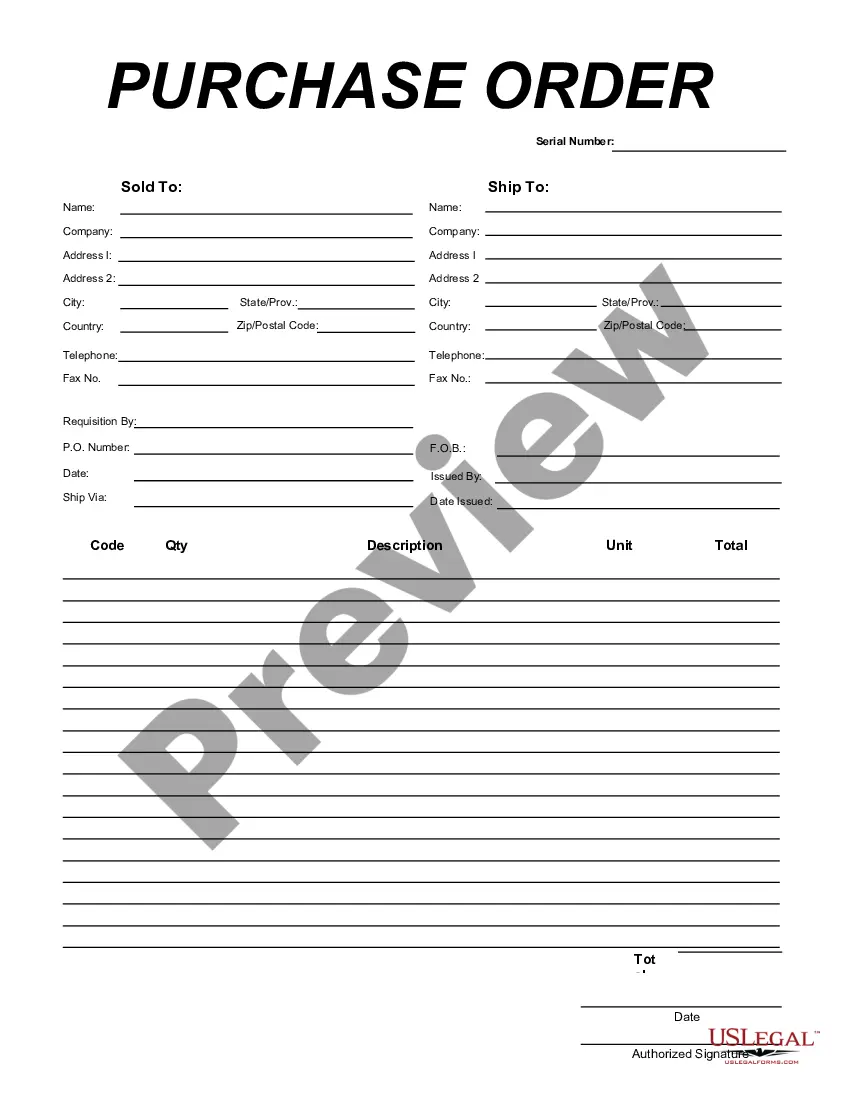

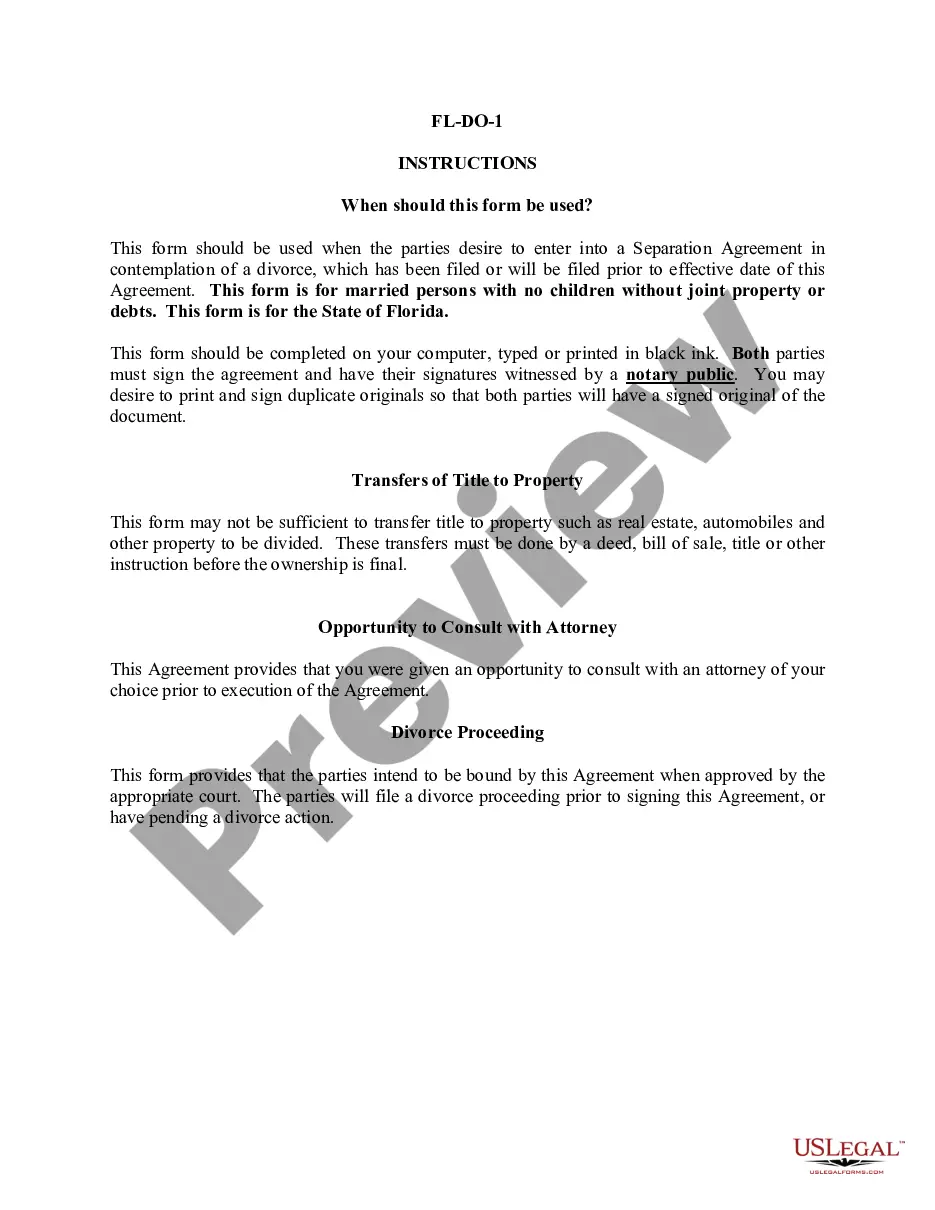

This is a tooling agreement between the buyer and vendor. The document describes the description of tooling, the replacement value of tooling, location of tooling, and the relationship of the parties in all their dealings.

Ohio Tooling Agreement

Description

How to fill out Tooling Agreement?

Discovering the right legitimate file design can be a battle. Obviously, there are plenty of themes accessible on the Internet, but how would you obtain the legitimate develop you will need? Use the US Legal Forms website. The assistance provides a large number of themes, such as the Ohio Tooling Agreement, which you can use for organization and personal needs. All of the kinds are checked out by specialists and fulfill state and federal demands.

If you are presently signed up, log in to your account and click the Obtain button to have the Ohio Tooling Agreement. Make use of account to look through the legitimate kinds you might have ordered formerly. Check out the My Forms tab of your account and get one more version in the file you will need.

If you are a new end user of US Legal Forms, listed here are easy guidelines so that you can adhere to:

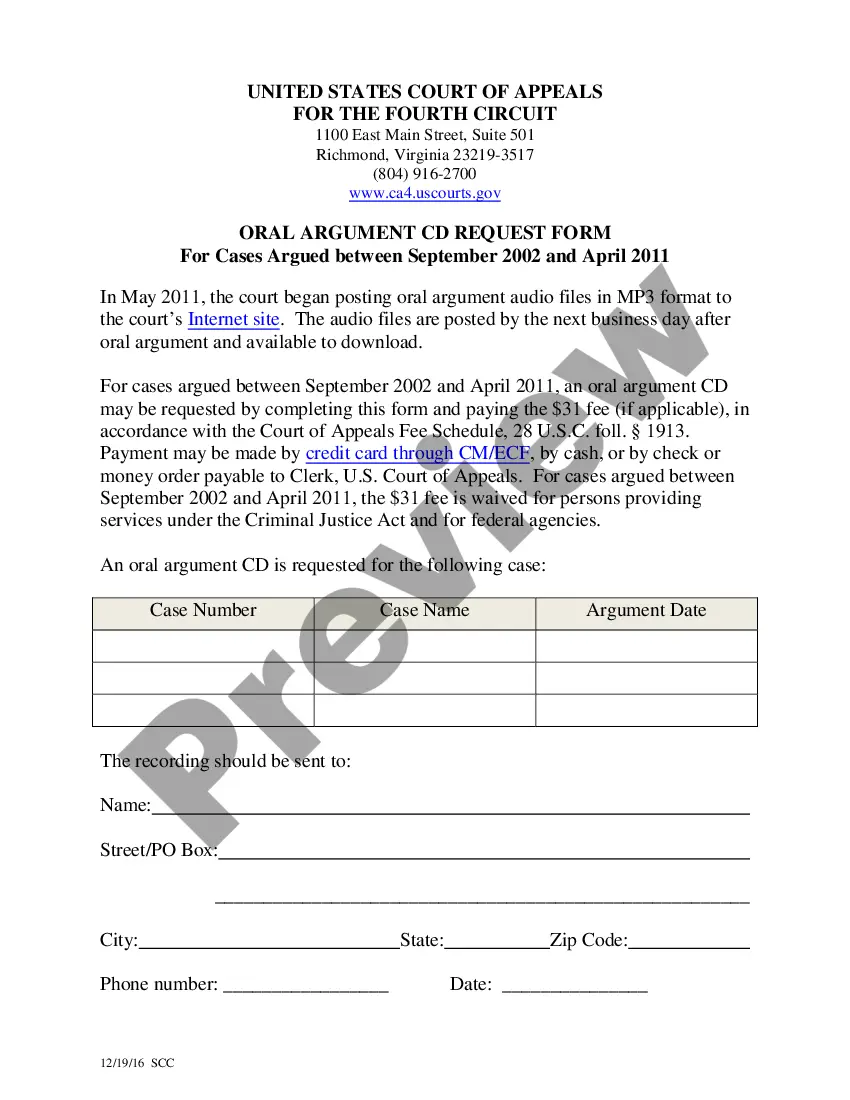

- Initially, make sure you have selected the correct develop for your metropolis/county. It is possible to look through the shape while using Preview button and read the shape explanation to ensure it will be the best for you.

- In case the develop does not fulfill your needs, use the Seach area to discover the correct develop.

- When you are certain the shape would work, go through the Acquire now button to have the develop.

- Select the pricing plan you need and enter in the needed information and facts. Build your account and pay money for your order with your PayPal account or bank card.

- Opt for the submit file format and download the legitimate file design to your product.

- Full, modify and produce and indication the acquired Ohio Tooling Agreement.

US Legal Forms will be the biggest collection of legitimate kinds for which you can discover different file themes. Use the service to download appropriately-made documents that adhere to status demands.

Form popularity

FAQ

If a manufacturer makes an item that is used in the manufacturing operation as described in this rule, such as tools, tooling, replacement parts for machinery, or consumable substances, such as acid or solvents, the raw materials and components that go into that item are not taxable.

Ohio law provides that contractors are consumers of the tangible personal property that they into real property. As the consumer, the contractor is re sponsible for paying sales or use tax on the purchase of the tangible personal property to be installed.

Placement Service ? October 1, 2021 As such, employment services and employment placement services are no longer taxable in Ohio beginning on October 1, 2021.

Tax-exempt goods Some goods are exempt from sales tax under Ohio law. Examples include most non-prepared food items, items purchased with food stamps, and prescription drugs.

Ohio law provides that contractors are consumers of the tangible personal property that they into real property. As the consumer, the contractor is re sponsible for paying sales or use tax on the purchase of the tangible personal property to be installed.

In general, repairs to tangible personal property are subject to sales tax unless the property being repaired is itself exempt from sales tax. This is also true for installation of tangible personal property.

Common exemptions from Ohio sales and use tax: Groceries and food sold for off premises consumption. Prescription medicines. Housing related utilities, such as gas, electric, water and steam.

Generally, services are not subject to sales tax in Ohio, but there's exceptions to every rule. For example, some taxable services in Ohio include: Landscaping or Lawn Care Services. Private Investigative or Security Services.