Missouri Self-Employed Precast Concrete Contract

Description

How to fill out Self-Employed Precast Concrete Contract?

Finding the correct legal document template can be challenging. Of course, there are numerous formats accessible online, but how do you locate the legal form you require.

Utilize the US Legal Forms website. This service offers a wide array of templates, including the Missouri Self-Employed Precast Concrete Contract, suitable for both business and personal purposes. All documents are vetted by experts and comply with federal and state regulations.

If you are already a registered user, Log In to your account and click the Download button to retrieve the Missouri Self-Employed Precast Concrete Contract. Use your account to browse the legal forms you have previously purchased. Navigate to the My documents section of your account to obtain another copy of the document you require.

Complete, modify, print, and sign the acquired Missouri Self-Employed Precast Concrete Contract. US Legal Forms is the largest repository of legal forms where you will discover numerous document templates. Utilize the service to obtain well-crafted documents that comply with state regulations.

- If you are a new user of US Legal Forms, here are simple steps to follow.

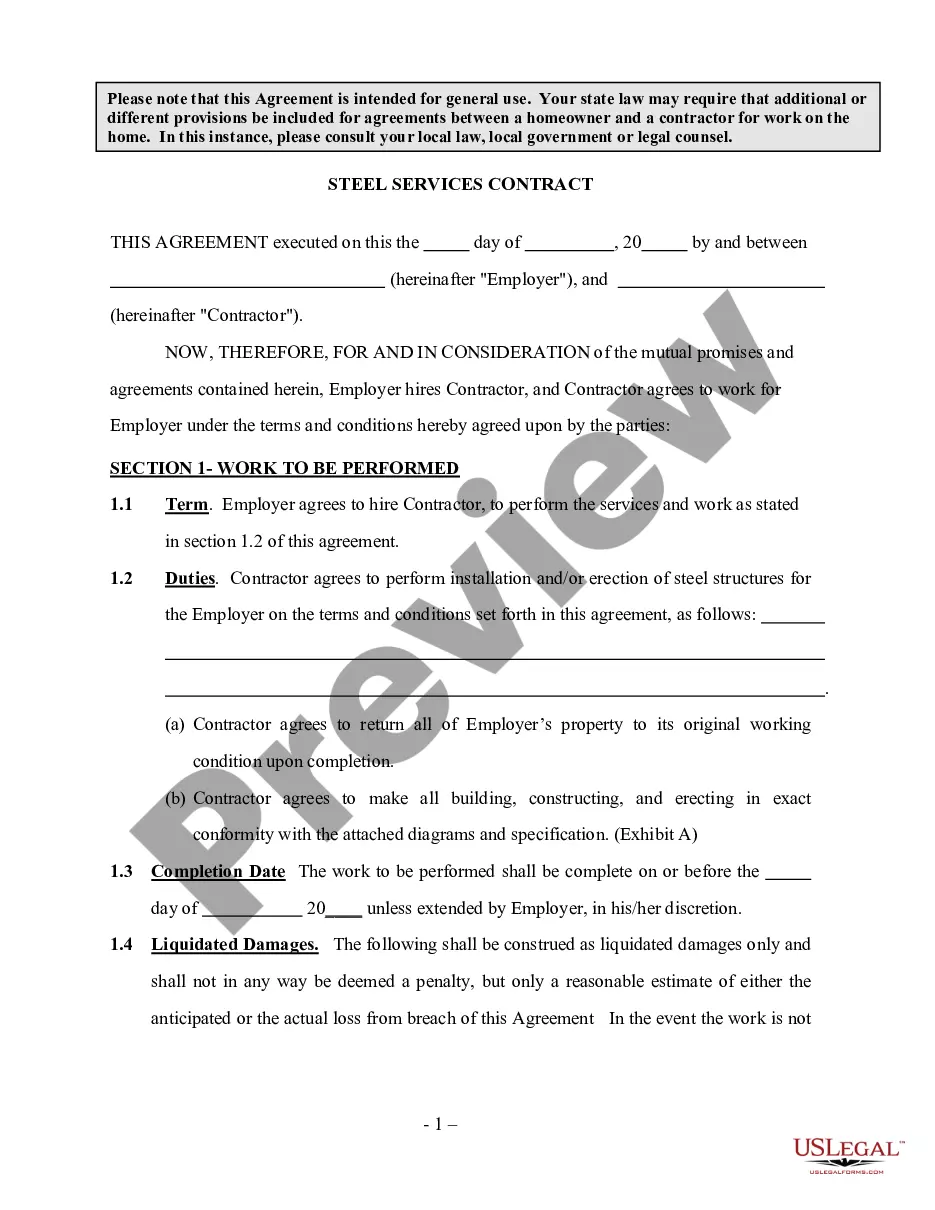

- First, ensure that you have selected the correct form for your city/state. You can review the document using the Preview button and examine the form details to confirm it meets your needs.

- If the form does not suit your requirements, use the Search box to find the appropriate document.

- Once you are confident that the form is suitable, click on the Get now button to download the form.

- Select the pricing plan you prefer and input the necessary information. Create your account and complete your purchase using your PayPal account or credit card.

- Choose the file format and download the legal document template to your device.

Form popularity

FAQ

The average concrete contractor's income can vary significantly based on location, experience, and specialization. In Missouri, contractors focusing on Missouri Self-Employed Precast Concrete Contracts can expect competitive earnings, especially as they build their reputation and client base. On average, concrete contractors earn between $40,000 and $70,000 annually, but skilled professionals with a strong portfolio can earn even more. Therefore, investing in your skills and marketing can lead to higher profits.

To become a contractor in Missouri, you must meet specific requirements. First, ensure you obtain the necessary licenses, including a Missouri Self-Employed Precast Concrete Contract if you work independently. Additionally, you should have liability insurance to protect yourself and your clients. Lastly, consider registering your business and adhering to local building codes for a successful operation.

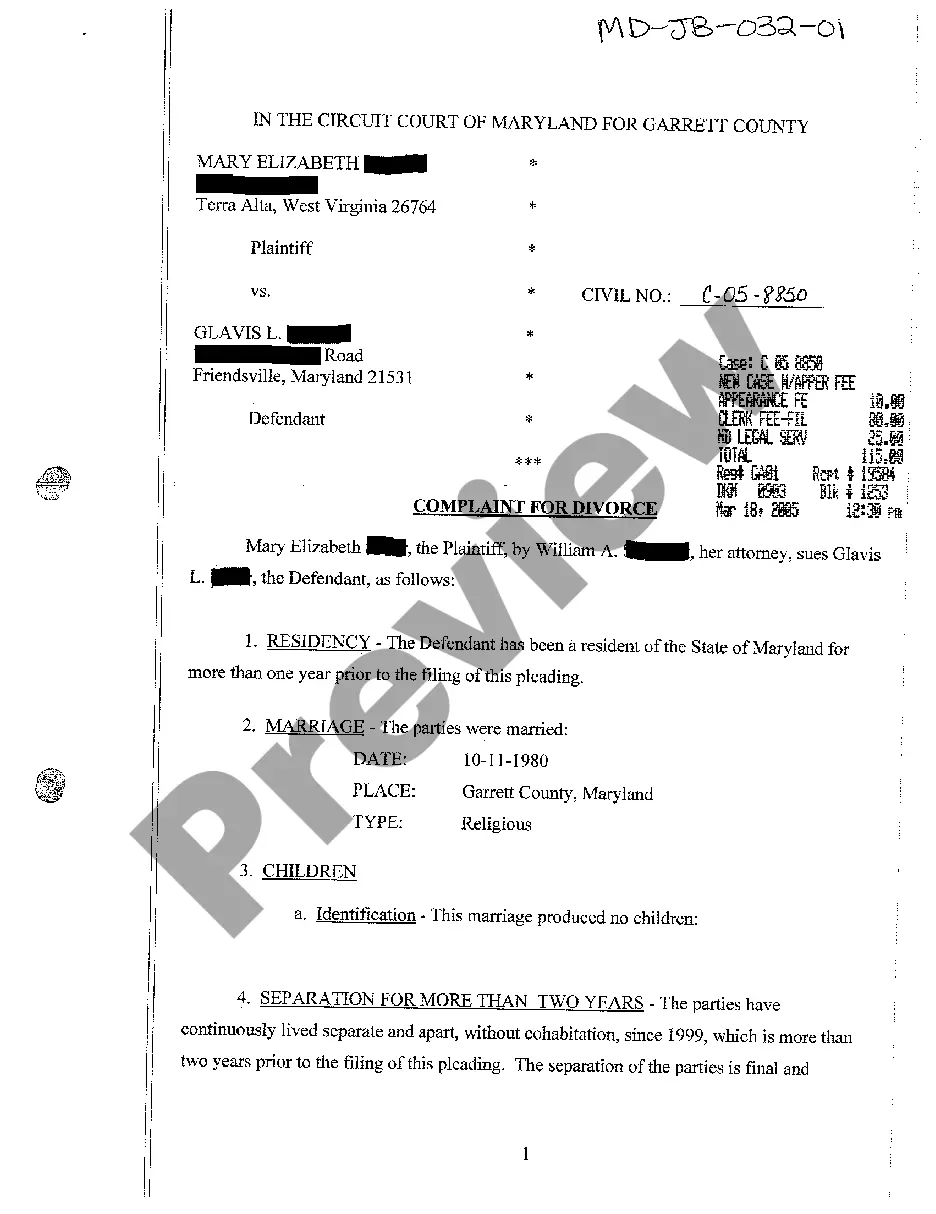

You can write your own legally binding contract as long as you include the necessary elements: offer, acceptance, consideration, and legal purpose. Make sure both parties understand and agree to the terms outlined in the contract. Using U.S. Legal Forms can help you craft a well-structured Missouri Self-Employed Precast Concrete Contract to ensure clarity and enforceability.

To make a contract for concrete work, identify the project scope, specify the materials and labor involved, and outline payment terms. Establish clear expectations for both parties, including timelines and responsibilities. For an effective Missouri Self-Employed Precast Concrete Contract, consider utilizing U.S. Legal Forms to access professional templates that fit your needs.

When writing a contract for a concrete job, detail the specific work to be done, including the type of concrete, project timelines, and payment terms. Clearly outline any special requirements or standards that need to be met. A Missouri Self-Employed Precast Concrete Contract should also include provisions for changes or delays, which can be easily managed with a template from U.S. Legal Forms.

To fill out a contractor agreement, start by entering the parties' names and addresses. Next, specify the services to be performed, payment structure, and project timelines. For a Missouri Self-Employed Precast Concrete Contract, using a U.S. Legal Forms template can guide you through the required sections and ensure completeness.

Writing a simple construction contract involves outlining the scope of work, payment details, and timelines. Be sure to include information about materials and labor, as well as any warranties or guarantees. For a comprehensive Missouri Self-Employed Precast Concrete Contract, consider using a template from U.S. Legal Forms to streamline the process.

Yes, you can make your own contract, but it is essential to follow legal guidelines to ensure its validity. Your contract should include all necessary components and be clear in its terms. Utilizing resources from U.S. Legal Forms can provide helpful templates for crafting a solid Missouri Self-Employed Precast Concrete Contract.

A contract is legally binding in Missouri when it includes an offer, acceptance, consideration, and the intention to create legal relations. Both parties must have the capacity to enter into the contract, and it should not involve illegal activities. For a Missouri Self-Employed Precast Concrete Contract, ensure all these elements are present to protect your interests.

To write a simple contract agreement, start by clearly stating the purpose of the contract and the parties involved. Include specific details such as the services to be provided, payment terms, and deadlines. Using a template, like those available on the U.S. Legal Forms platform, can help ensure you cover all necessary elements for a Missouri Self-Employed Precast Concrete Contract.