Maine Toll Manufacturing Agreement

Description

How to fill out Toll Manufacturing Agreement?

You can dedicate time online searching for the legal document template that meets both federal and state requirements you will require.

US Legal Forms offers a wide range of legal forms which are reviewed by experts.

It is possible to download or print the Maine Toll Manufacturing Agreement from the service.

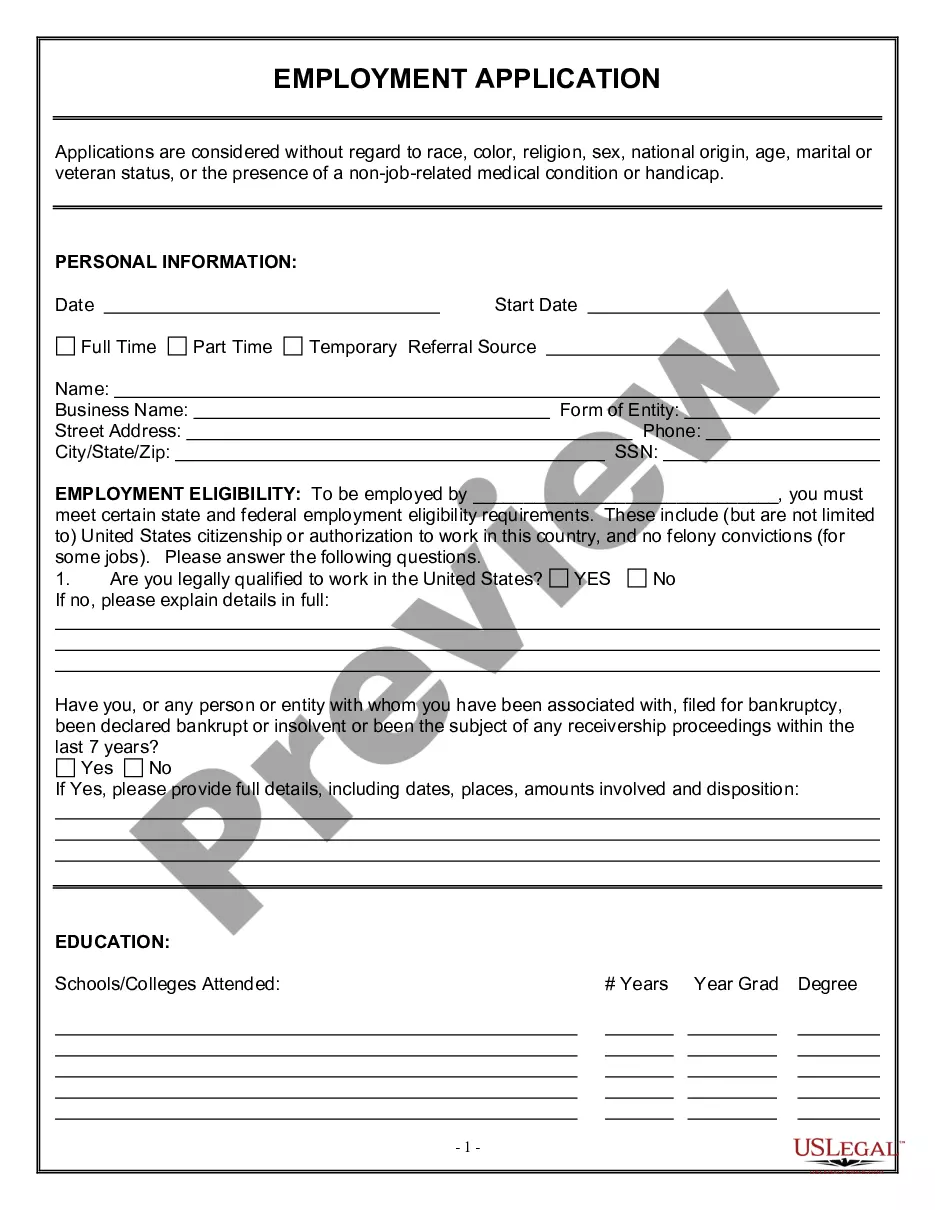

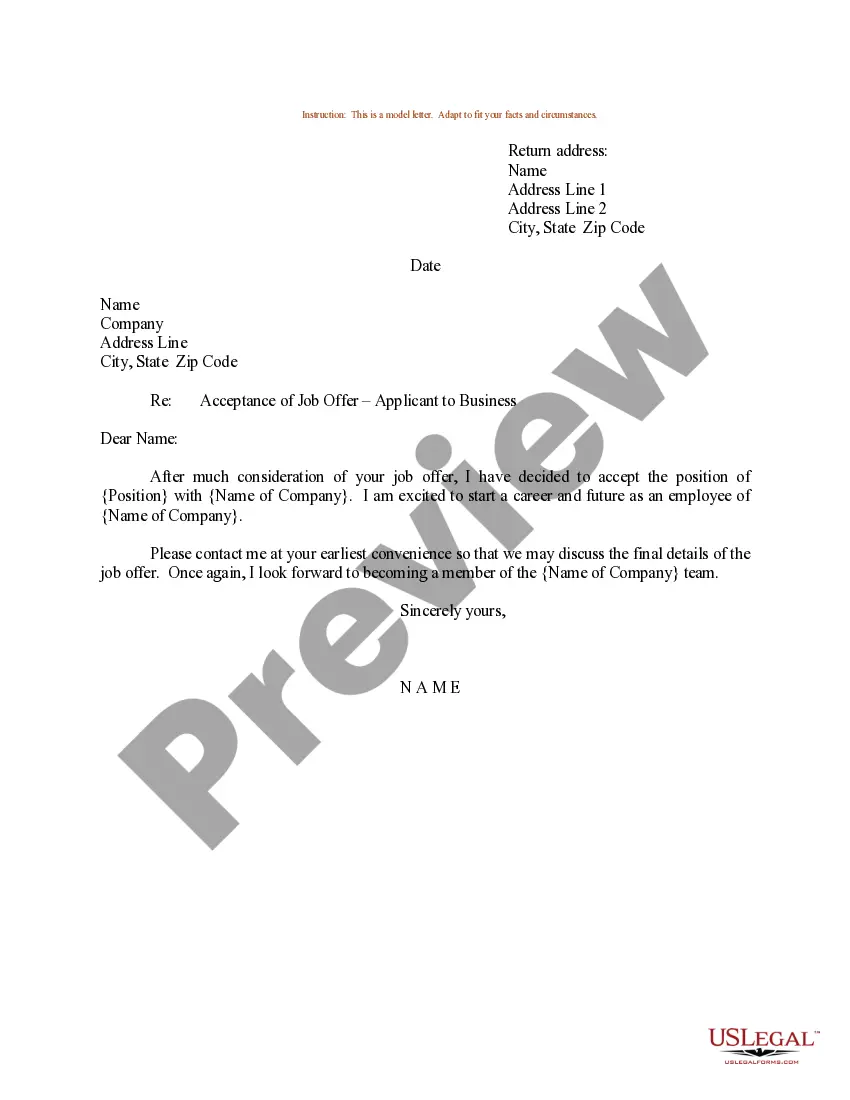

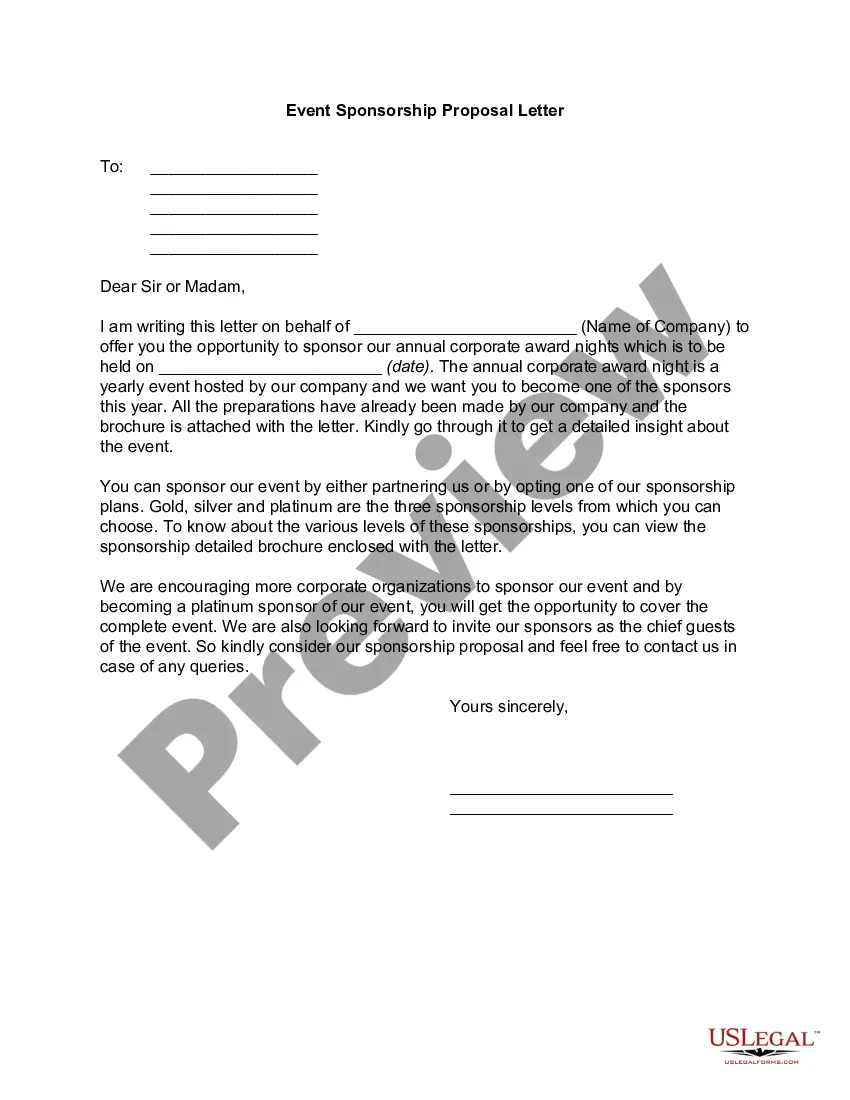

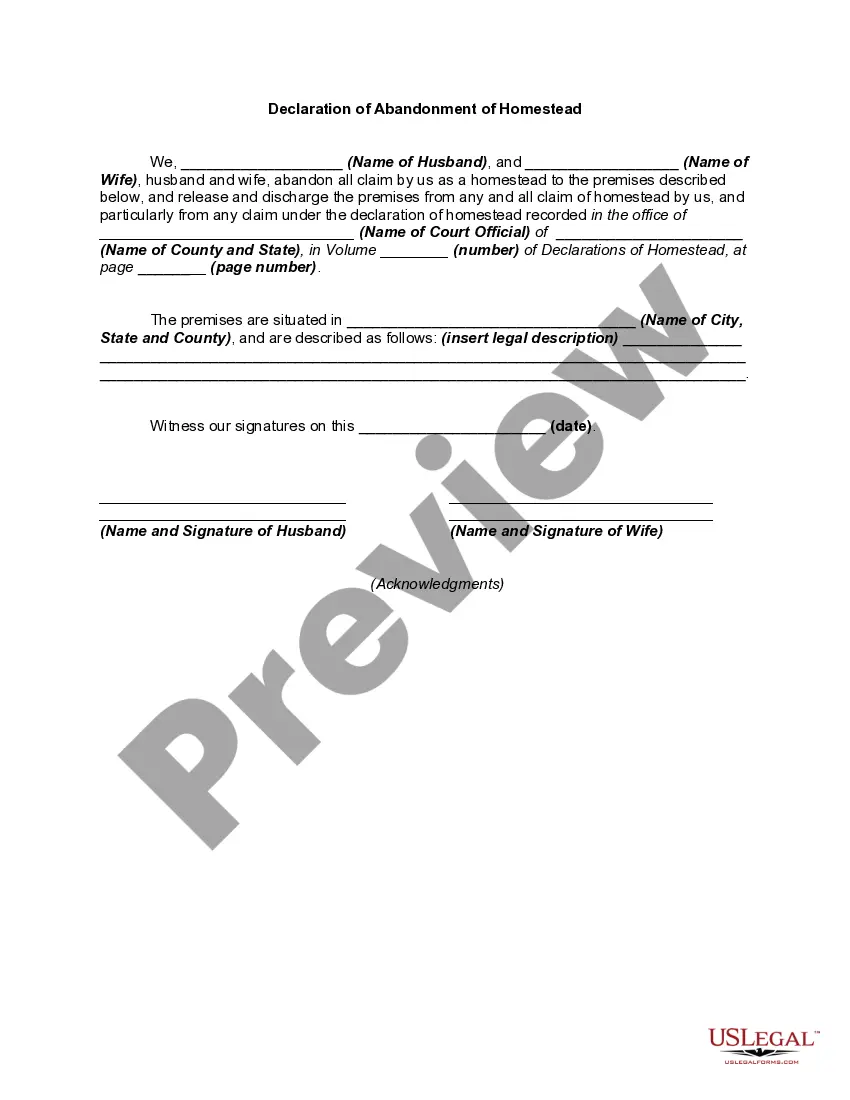

If available, utilize the Preview key to review the document template as well.

- If you hold a US Legal Forms account, you can Log In and click on the Acquire key.

- Subsequently, you can complete, modify, print, or sign the Maine Toll Manufacturing Agreement.

- Every legal document template you purchase becomes yours permanently.

- To obtain another copy of a purchased form, visit the My documents tab and click on the corresponding key.

- If you are using the US Legal Forms website for the first time, follow these easy instructions.

- First, ensure that you have chosen the correct document template for your selected state/city.

- Check the form description to confirm that you have selected the right form.

Form popularity

FAQ

Subcontract manufacturing involves outsourcing production processes to third-party manufacturers, who handle the fabrication of products based on the specifications provided by the contracting company. This practice allows businesses to expand their product lines or enter new markets without the need for extensive capital investment. A Maine Toll Manufacturing Agreement can serve as an efficient solution for companies exploring subcontract manufacturing while ensuring quality and compliance.

Toll manufacturing refers to a business arrangement where a company pays another company to produce goods using its materials. This method allows businesses to maximize manufacturing capabilities without the overhead costs associated with owning production facilities. Through a Maine Toll Manufacturing Agreement, companies can effectively scale their production while maintaining quality control over the final products. It’s a strategic approach that benefits various industries.

Subcontractors are typically hired to complete specific tasks or projects, while manufacturers are responsible for converting raw materials into finished products. In the context of a Maine Toll Manufacturing Agreement, manufacturers carry out the production process, often under specific agreements with the company providing the materials. Understanding this distinction is essential for effective collaboration and ensuring clarity in business operations.

The opposite of toll manufacturing is in-house manufacturing, where a company conducts all production activities using its own resources, equipment, and workforce. This approach offers full control over the manufacturing process but often requires significant investment in facilities and equipment. In contrast, utilizing a Maine Toll Manufacturing Agreement can help businesses reduce costs and improve efficiency by outsourcing specific tasks while still retaining oversight of their final products.

Toll manufacturing is a contractual arrangement where a business hires a third party to produce goods using its raw materials. This setup enables companies to expand their production capabilities without investing in new facilities or equipment. With a Maine Toll Manufacturing Agreement, businesses can leverage existing production capacity, benefit from lower costs, and maintain quality control over their products.

Toll manufacturing refers to outsourcing specific parts of the production process to a third party, who uses your materials to create the final product. In contrast, traditional manufacturing typically means that a company handles all aspects of production internally. A Maine Toll Manufacturing Agreement allows businesses to capitalize on specialized expertise without the need for large capital investments, making it a smart choice for many manufacturers aiming to optimize their production operations.

Tolling involves paying a third party to perform specific processes on your materials, while turnkey manufacturing refers to a provider who handles the entire manufacturing process from start to finish. In a Maine Toll Manufacturing Agreement, companies often choose tolling when they want to retain control over their materials and production parameters, allowing for flexibility and customization. Turnkey solutions, on the other hand, offer convenience as the service provider manages everything, including sourcing materials and production.

Contract manufacturing comes with certain risks, such as quality control issues, supply chain disruptions, and potential legal disputes. It is vital to choose a reliable manufacturer and clearly outline terms in a contract. By using a Maine Toll Manufacturing Agreement, you can limit risks by establishing clear expectations regarding quality standards, delivery timelines, and dispute resolution.

An example of contract manufacturing is a clothing brand partnering with a factory to produce its garments. The factory receives the specifications, materials, and design from the brand and handles the production. This relationship can be formalized in a Maine Toll Manufacturing Agreement to ensure clarity and protection for both the brand and the manufacturer.

Toll manufacturing focuses on processing materials for another company, with no ownership of the final products. Subcontracting, on the other hand, involves hiring another company to perform part of the manufacturing process and usually entails transferring some responsibility for the outcome. When engaging in these practices, a Maine Toll Manufacturing Agreement can clarify the specific terms and responsibilities.