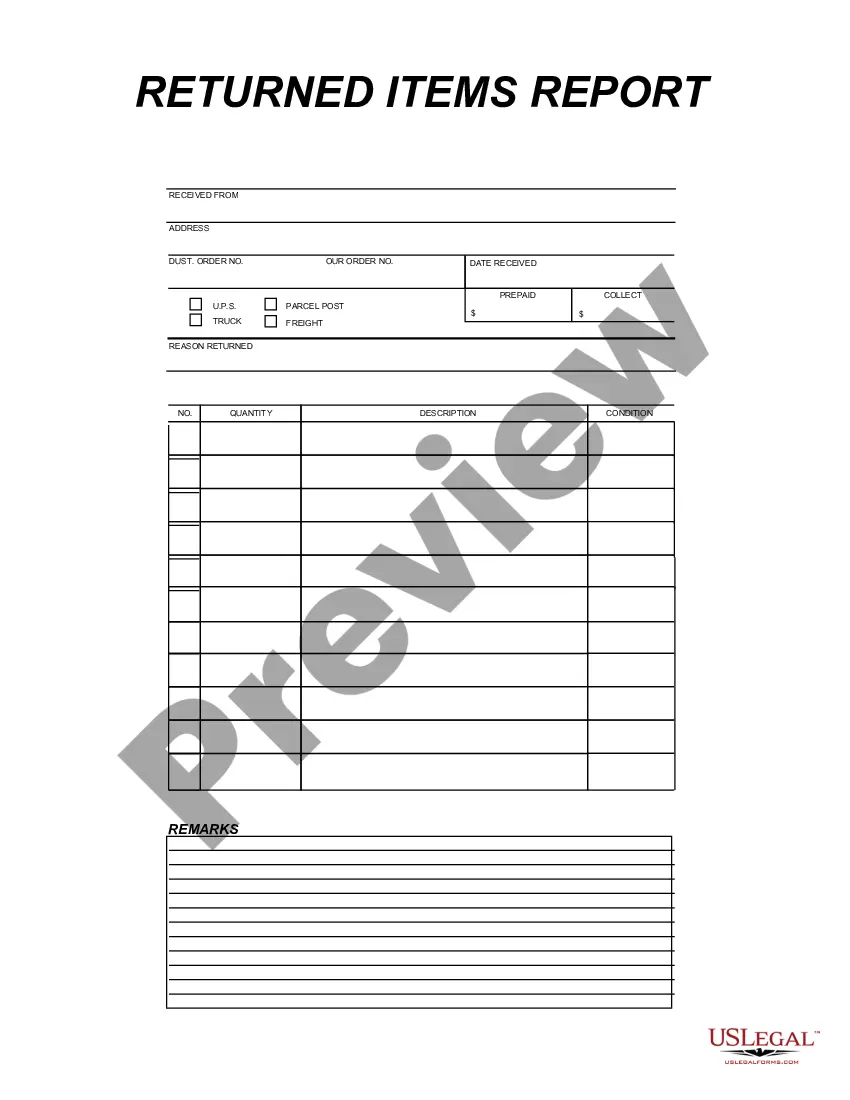

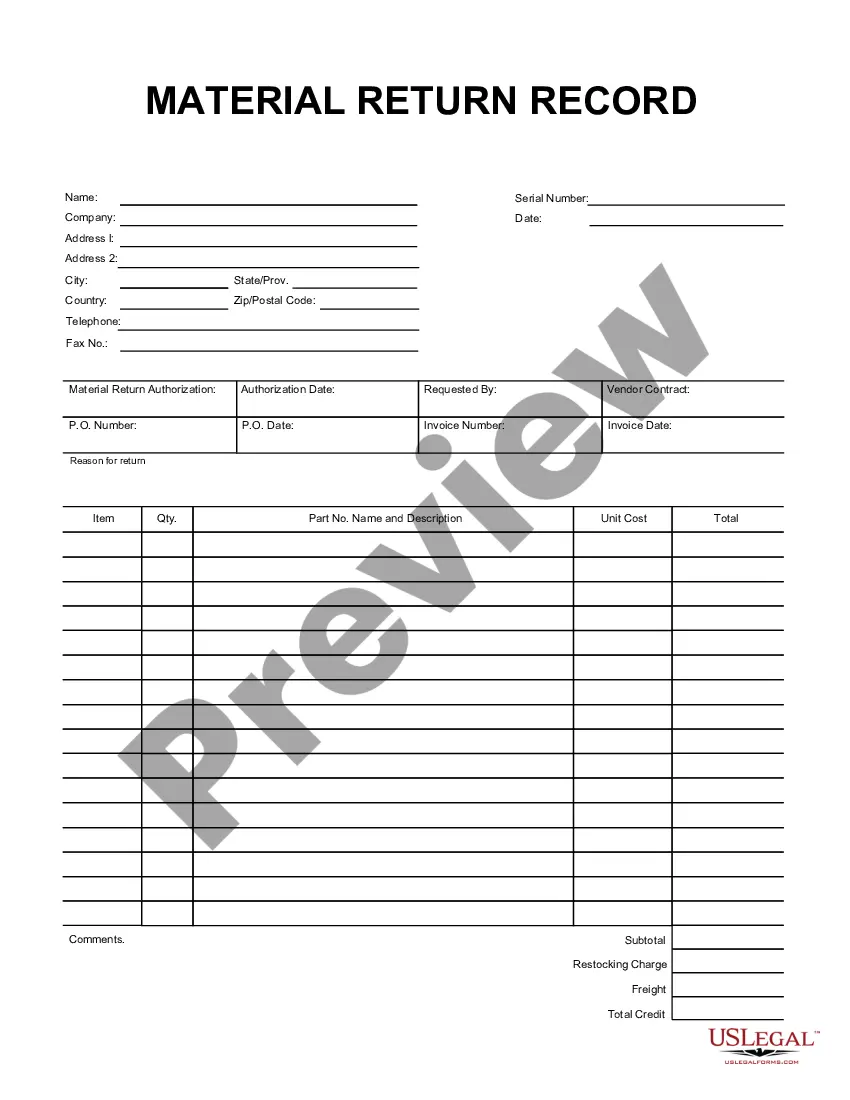

Kentucky Material Return Record

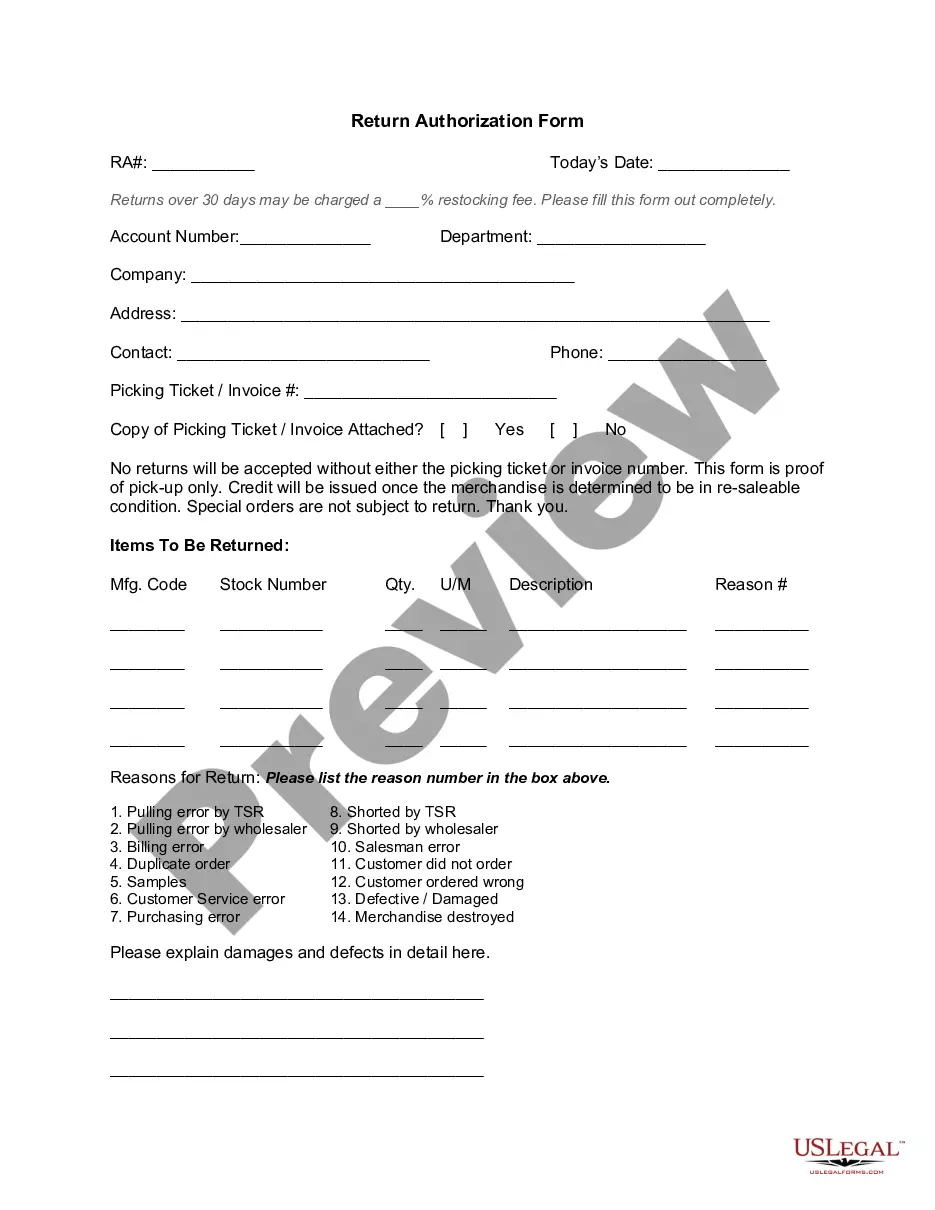

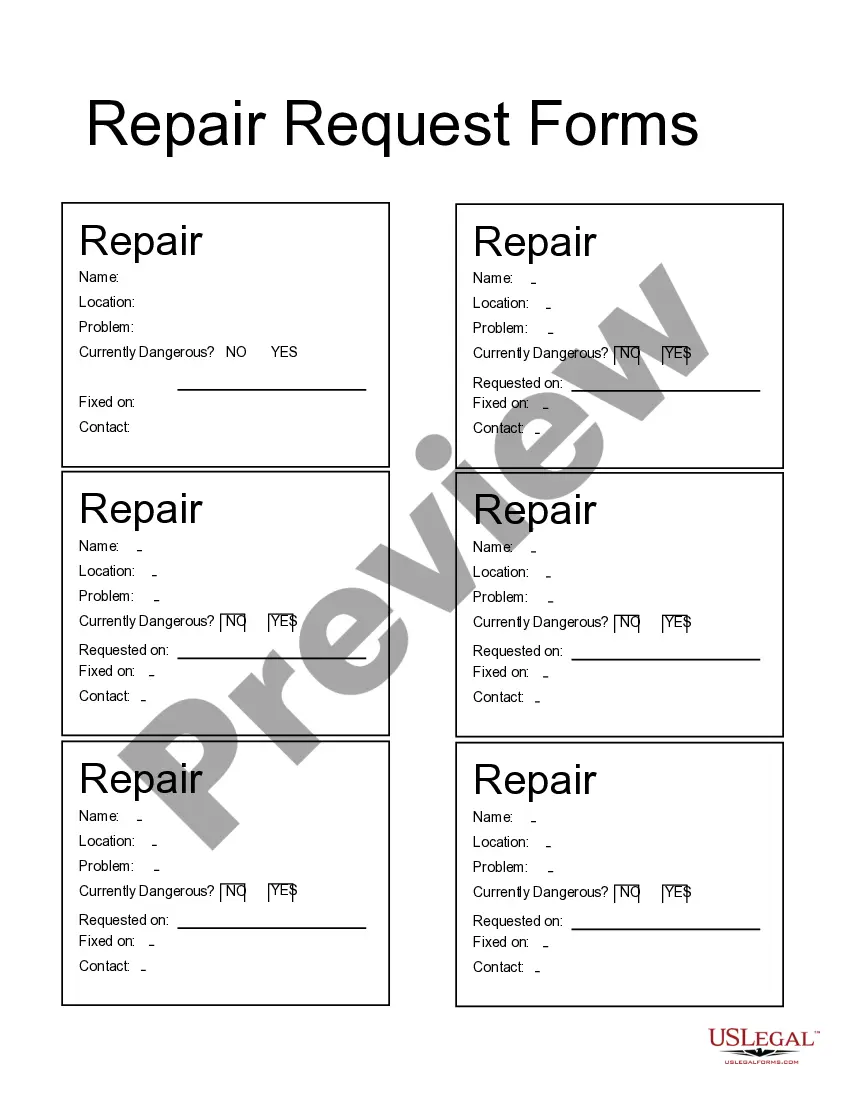

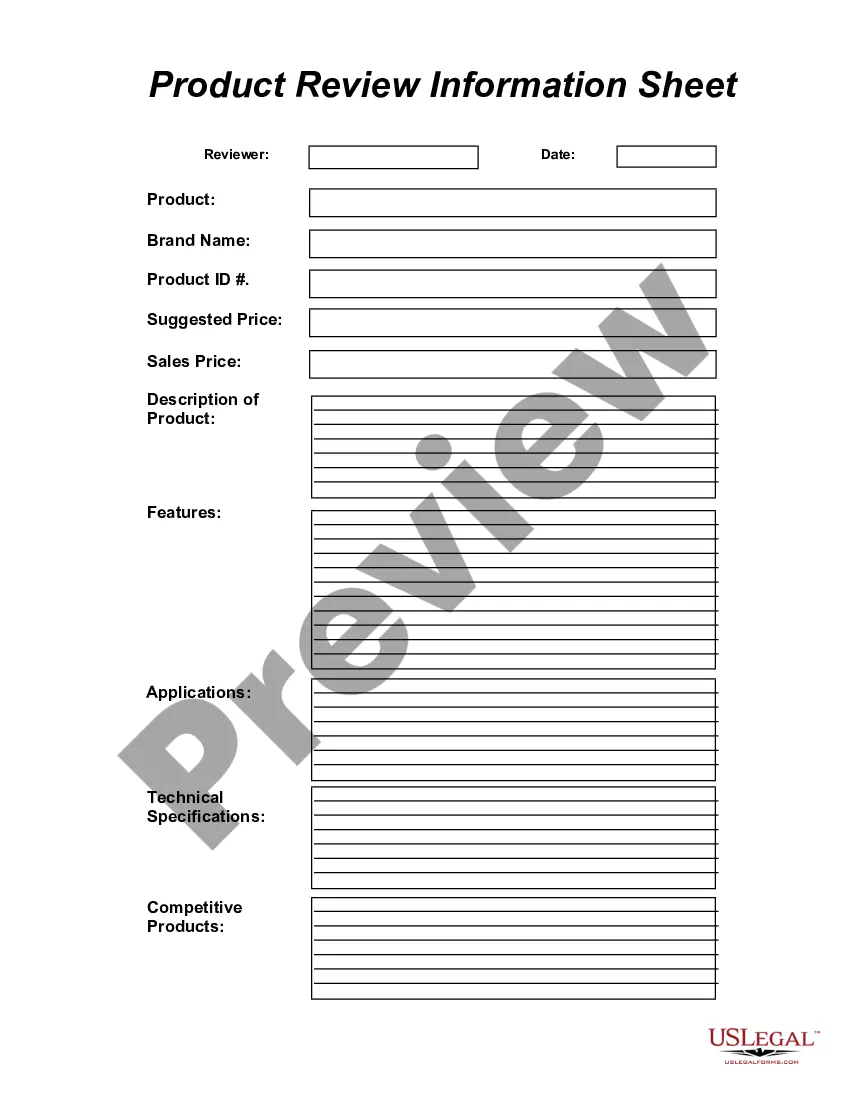

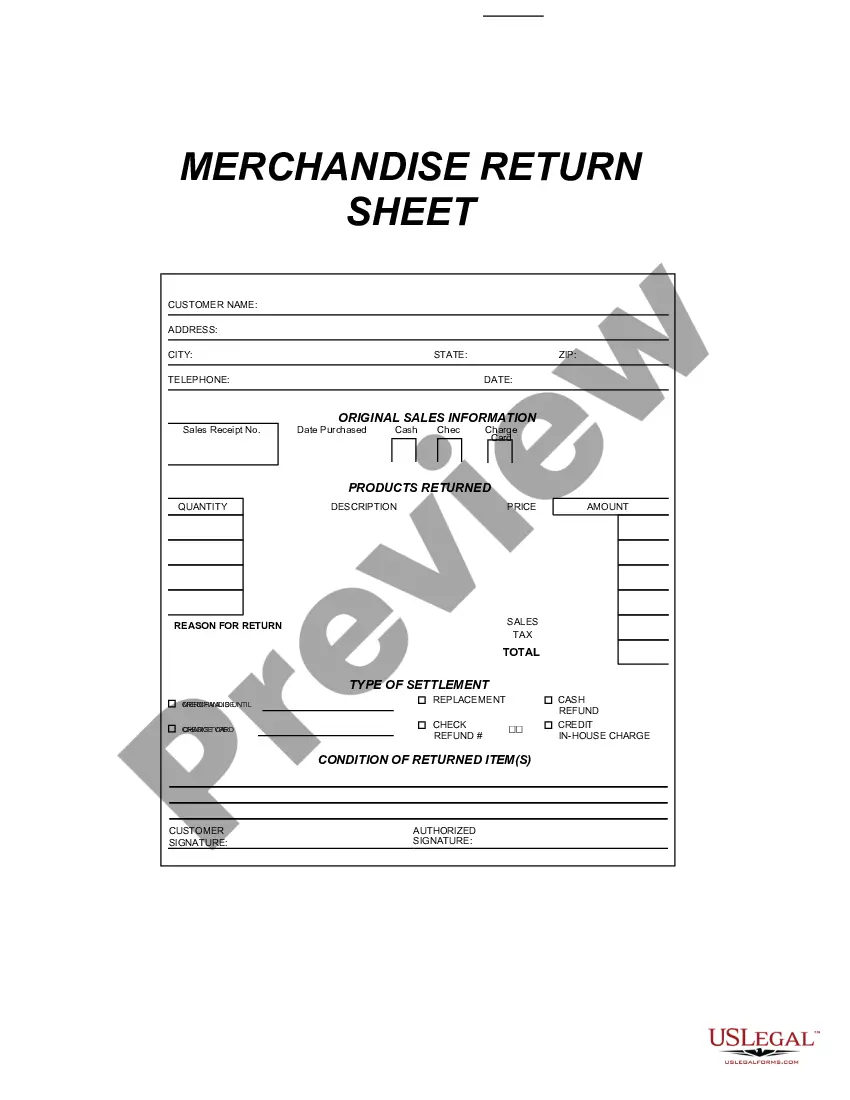

Description

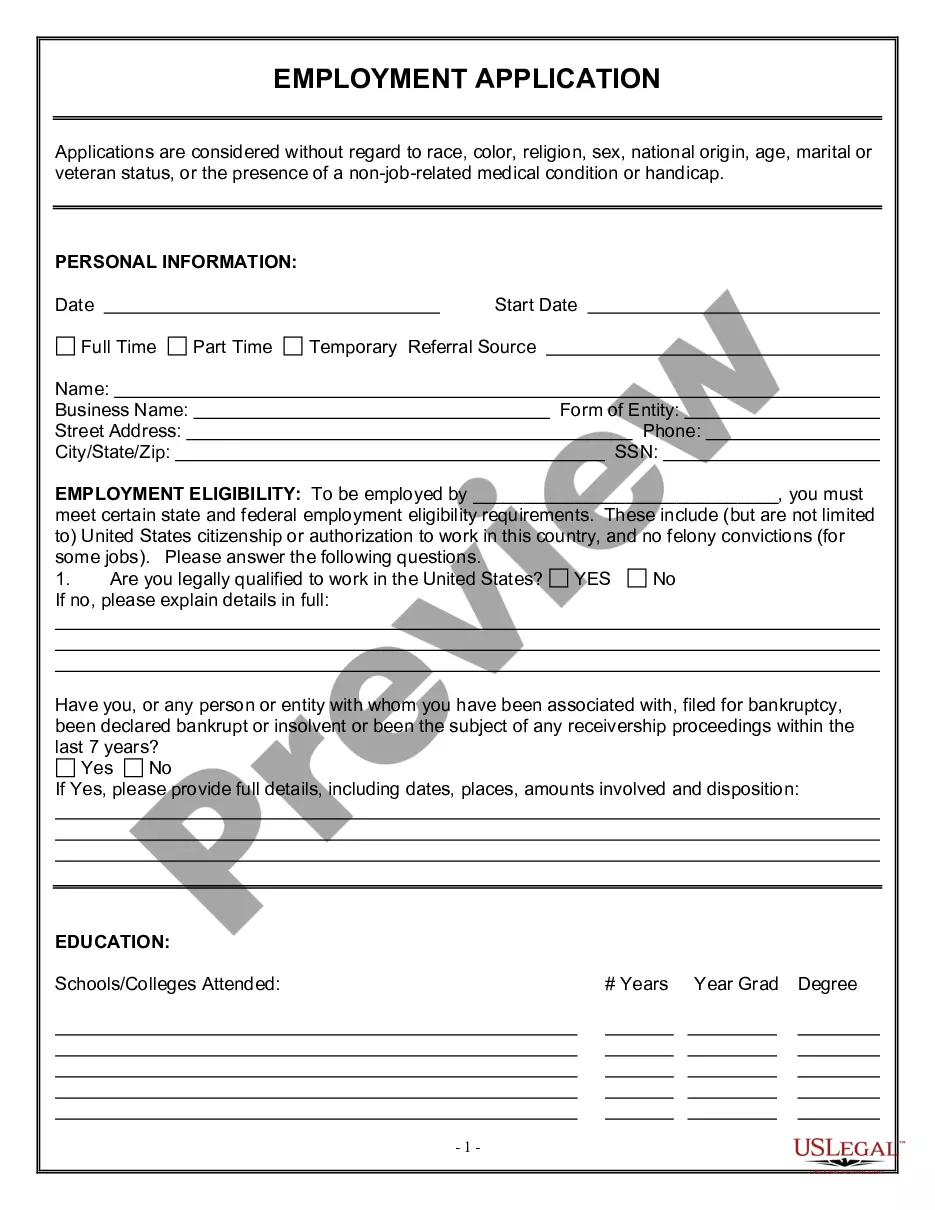

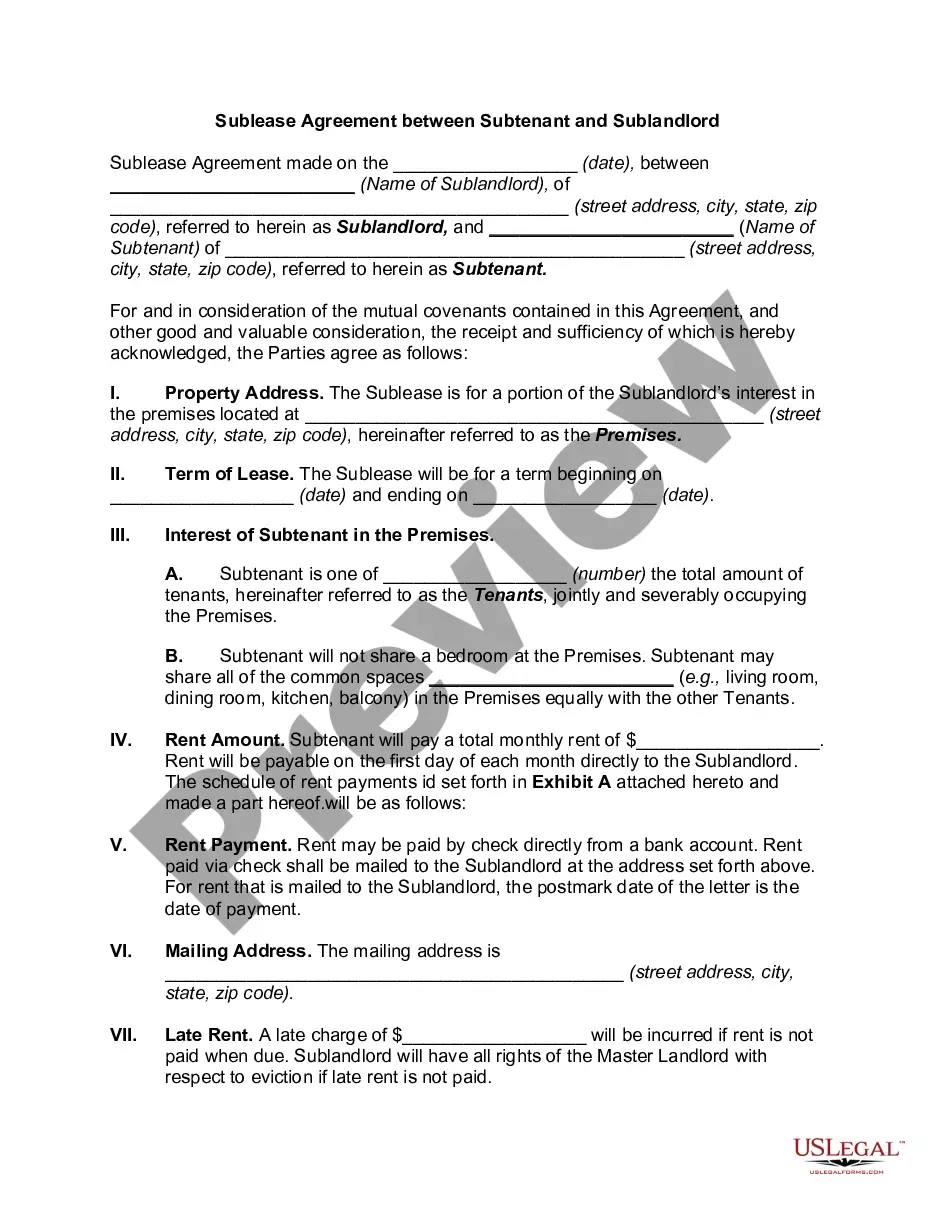

How to fill out Material Return Record?

Finding the appropriate legal document template can be quite challenging.

Undoubtedly, there are many templates available online, but how do you locate the legal form you need.

Utilize the US Legal Forms website. The service offers thousands of templates, such as the Kentucky Material Return Form, which you can utilize for business and personal purposes.

You can browse the form using the Preview button and review the form description to ensure it is suitable for you.

- All forms are reviewed by experts and comply with federal and state regulations.

- If you are already registered, Log In to your account and click the Download button to access the Kentucky Material Return Form.

- Use your account to search the legal forms you have previously purchased.

- Visit the My documents tab in your account and retrieve another copy of the document you need.

- If you are a new user of US Legal Forms, here are some simple instructions to follow.

- First, ensure that you have selected the correct form for your city/state.

Form popularity

FAQ

To get a copy of last year's return, you need to request your Kentucky Material Return Record through the Kentucky Department of Revenue. You can usually do this online, by mail, or by phone, depending on your preference. Ensure you have your personal details ready to expedite the retrieval process. This will help you access the records you need quickly.

200bThe tax imposed by KRS 141.0401 is a tax imposed on those entities with limited liability in the state of Kentucky and not an income tax. Therefore, the Limited Liability Entity Tax (LLET) paid is not an add-back to determine Kentucky taxable income; it is deductible for Kentucky and federal purposes.

Kentucky is now offering KY File, a new way to file your current year return free of charge. It allows you to: Select the Kentucky income tax forms and schedules that you need. Fill in your tax information online.

A Kentucky Online Gateway (KOG) user account (email address and password) is required to file Form K-5. If you use WRAPS to file your withholding tax returns, or you use eFile to file your sales tax or other returns, you will use your most current login information to file Form K-5.

The LLET may be calculated using the lesser of $0.095/$100 of Kentucky gross receipts or $0.75/$100 of Kentucky gross profits. A minimum tax of $175 applies regardless of the method used. Sole proprietorships and pass-through entities are exempt from state corporate income taxes.

Kentucky Department of Revenue P. O. Box 856905 Louisville, KY 40285-6905 Kentucky Department of Revenue Frankfort, KYReturn (Form 725).

Kentucky Adjusted Gross IncomeKentucky adjusted gross income consists of your federal adjusted gross income plus any additions and subtractions from Kentucky Schedule M (Modifications to Federal Adjusted Gross Income).

Verify that the purchaser has a Kentucky (or other state) resale certificate and Tax ID Verify the validity of your buyer's sales tax ID on the Kentucky Department of Revenue website or with the issuing state's department of revenue. You can find links to verify resale certificates in every state here.

You may use the DOR Open Records Request Form found on this web page or you may submit a letter identifying the records sought and your preferred method of receiving those records (i.e., email, postal mail, or pick up in person from the Department of Revenue in Frankfort, KY).

Your tax liability isn't based on your overall earnings but on your taxable income after you take deductions and claim tax credits. Your current year's federal tax liability appears on line 37 of Form 1040. Your total liability would also include any balances still owed from previous years.