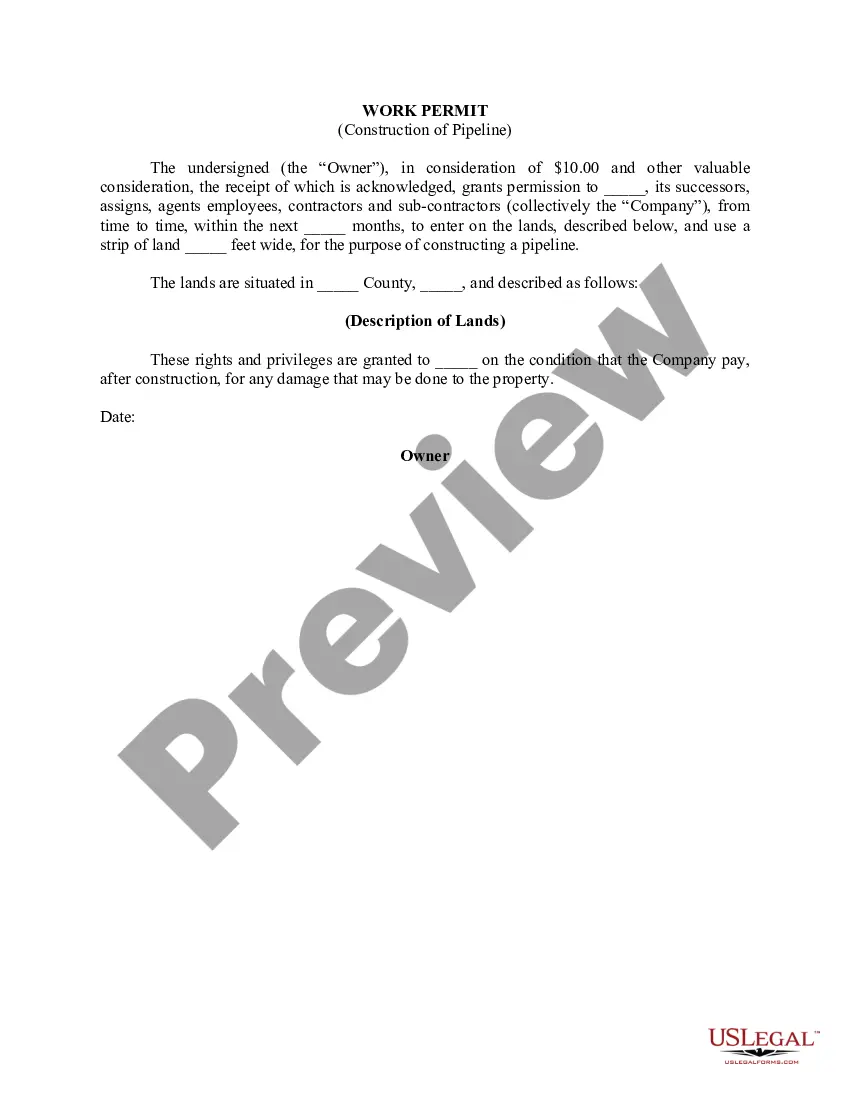

Kansas Work Permit (Construction of Pipeline)

Description

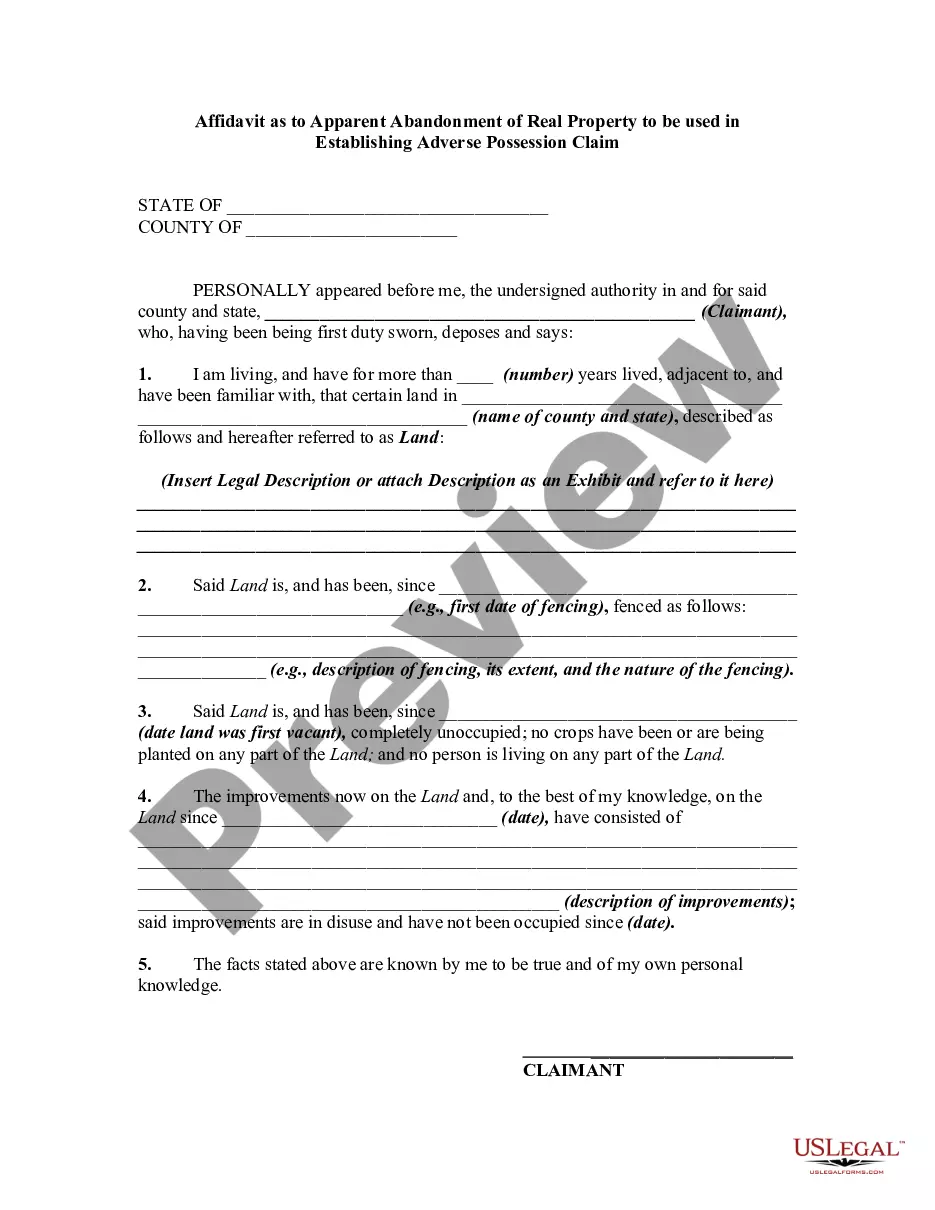

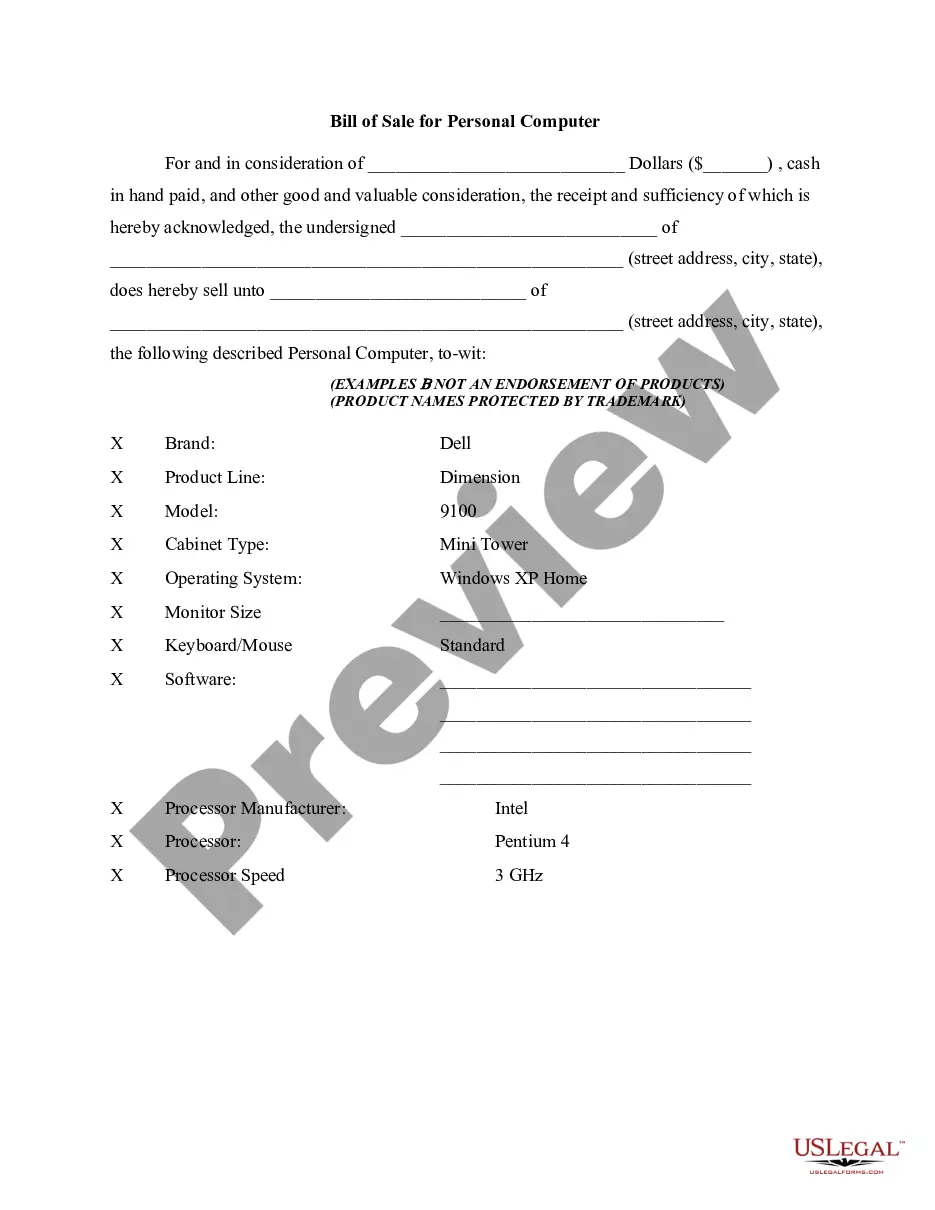

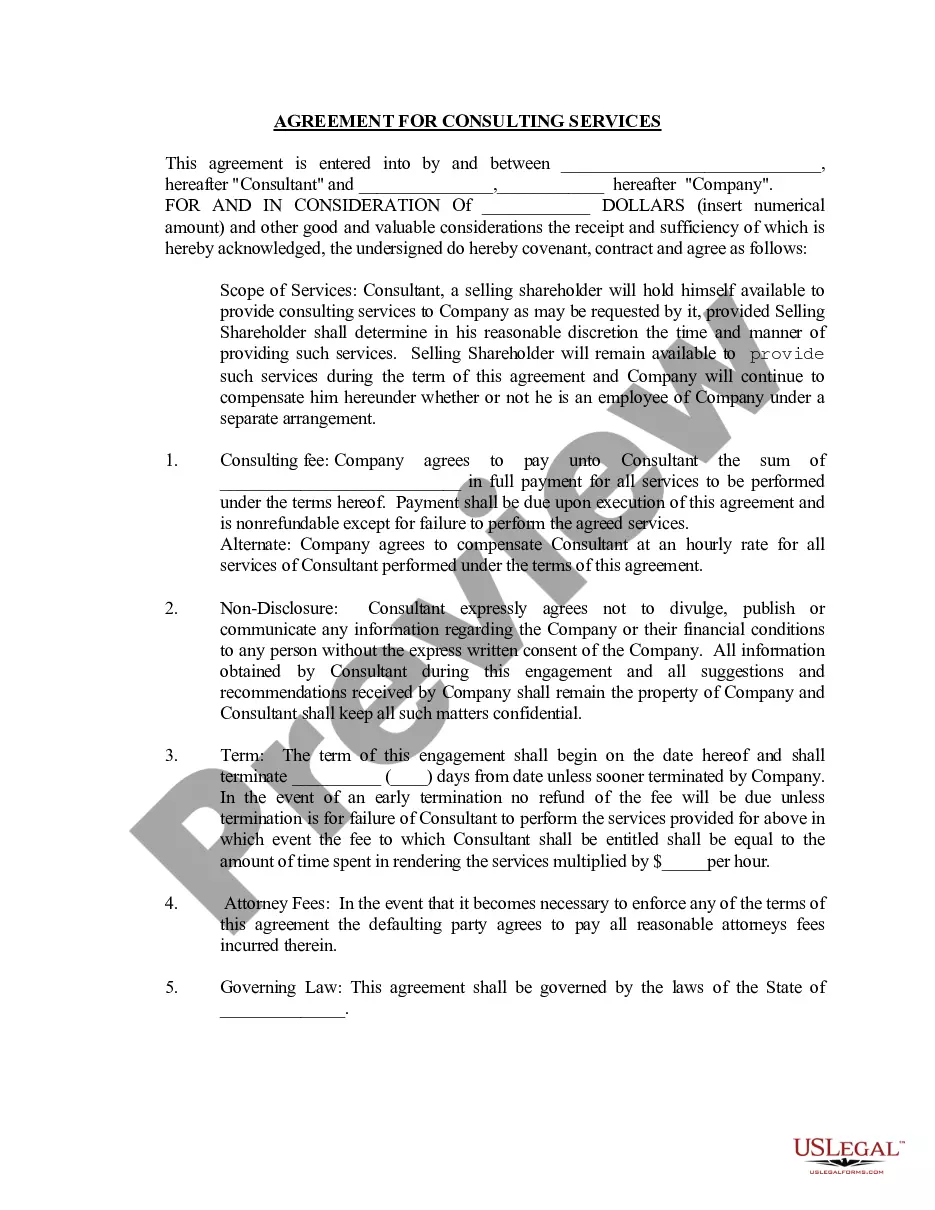

How to fill out Work Permit (Construction Of Pipeline)?

US Legal Forms - among the biggest libraries of authorized kinds in America - provides a wide array of authorized papers web templates it is possible to download or print out. While using site, you may get a large number of kinds for organization and person uses, sorted by groups, claims, or keywords and phrases.You will discover the most recent variations of kinds such as the Kansas Work Permit (Construction of Pipeline) within minutes.

If you have a subscription, log in and download Kansas Work Permit (Construction of Pipeline) in the US Legal Forms catalogue. The Obtain key will show up on every type you see. You get access to all previously acquired kinds inside the My Forms tab of the bank account.

If you would like use US Legal Forms for the first time, listed below are basic recommendations to obtain started out:

- Be sure you have selected the proper type for your city/region. Click the Preview key to analyze the form`s content material. Look at the type outline to ensure that you have chosen the correct type.

- In case the type does not suit your needs, take advantage of the Search discipline near the top of the display screen to obtain the one which does.

- If you are happy with the form, verify your choice by simply clicking the Buy now key. Then, opt for the prices program you favor and offer your references to register for an bank account.

- Process the purchase. Utilize your credit card or PayPal bank account to perform the purchase.

- Select the format and download the form on your own gadget.

- Make adjustments. Load, modify and print out and signal the acquired Kansas Work Permit (Construction of Pipeline).

Every single format you included with your account lacks an expiration particular date and is also your own property forever. So, in order to download or print out yet another backup, just proceed to the My Forms portion and click on on the type you will need.

Obtain access to the Kansas Work Permit (Construction of Pipeline) with US Legal Forms, probably the most comprehensive catalogue of authorized papers web templates. Use a large number of professional and express-certain web templates that meet up with your company or person needs and needs.

Form popularity

FAQ

Pipe laying progresses with the lay vessel moving forward on its anchors. The pipe is placed on the seabed in a controlled S-bend shape. The curvature in the upper section, or the overbend, is controlled by a supporting structure, called a stinger, that is fitted with rollers to minimize damage to the pipe.

Phases of Pipeline Construction: An Overview Route Selection. Pipelines routes avoid populated areas, when possible. ... Regulatory Process. Onsite inspection occurs frequently. ... Design. ... Pipe Fabrication. ... Site Preparation. ... Pipe Stringing. ... Trenching. ... Bending.

STRINGING: Pipe is transported into the easement and laid end to end next to where the trench will be dug. 5. BENDING: Where required, specialized machinery is used to bend the pipe to conform with the contours of the land and the pipeline route.

A pipeline is a system that consists of pipes, fittings (valves and joints), pumps (compressors or blowers in the case of gas pipelines), booster stations (i.e., intermediate pumping stations placed along the pipeline to house pumps or compressors), storage facilities connected to the pipe, intake and outlet structures ...

Construction includes: weld the pipe pieces together (every weld is inspected using X-ray or ultrasound); lower the welded pipe into place in the trench; valves and fittings, including remote sensors to monitor pipeline pressure, flow rate and temperature ? valves can quickly shut down a pipeline in case of ...

Pipelines have pumps, valves, and control systems that allow people to manipulate the flow of the substances that are being transported. In early history, pipes were made of materials such as lead or stone. Today, pipes are typically made of steel, iron, aluminum, plastic, or clay.

Common duties include unloading and loading materials, equipment, and tools from and onto trucks by hand, digging trenches, and laying concrete. You assist with the construction of pipe sites, ensuring the proper fittings, digging drainage ditches, and cleaning feeder pipes.