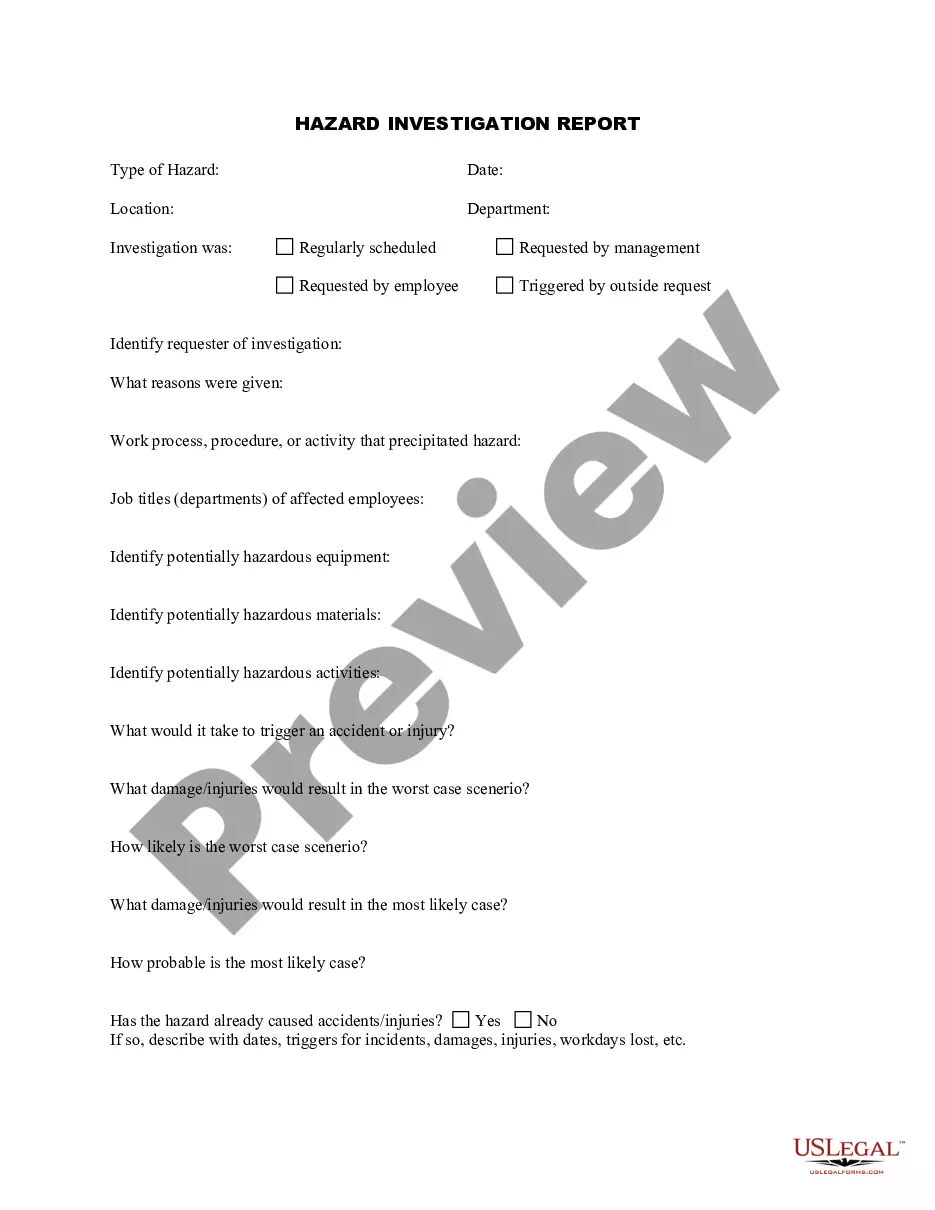

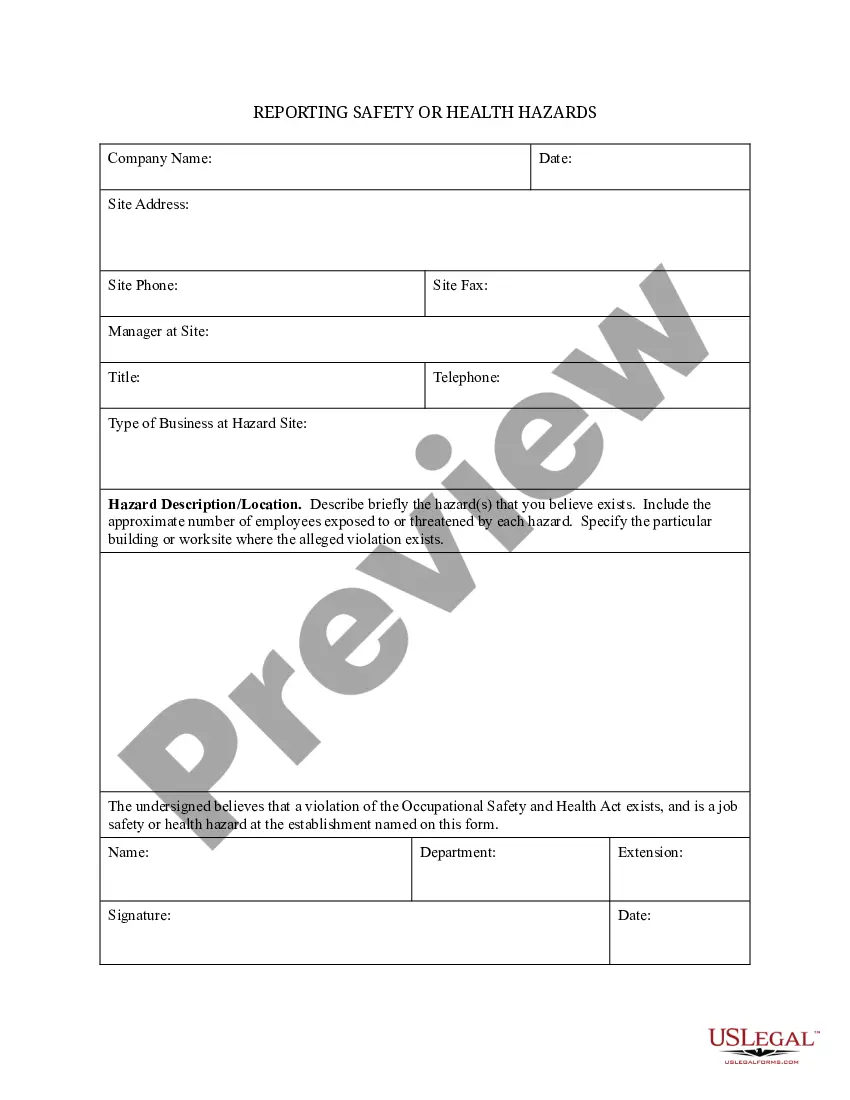

Kansas Safety or Health Hazards Report Form

Description

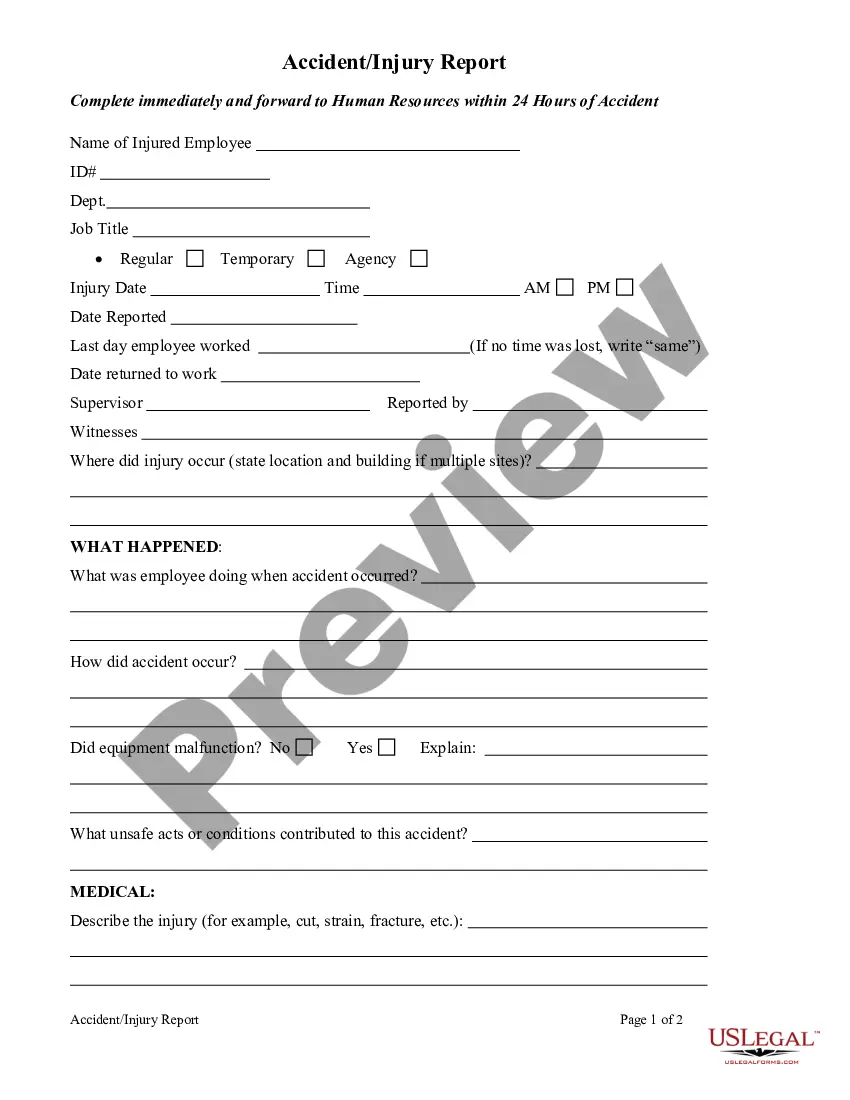

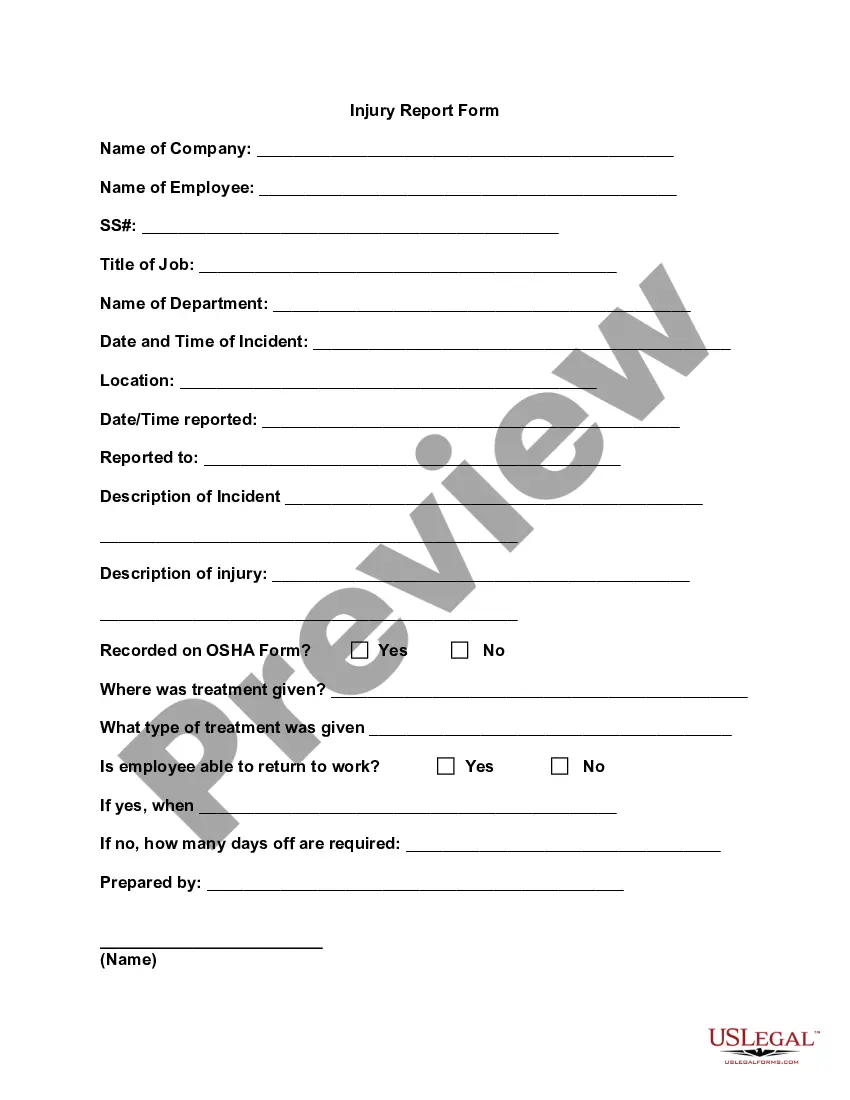

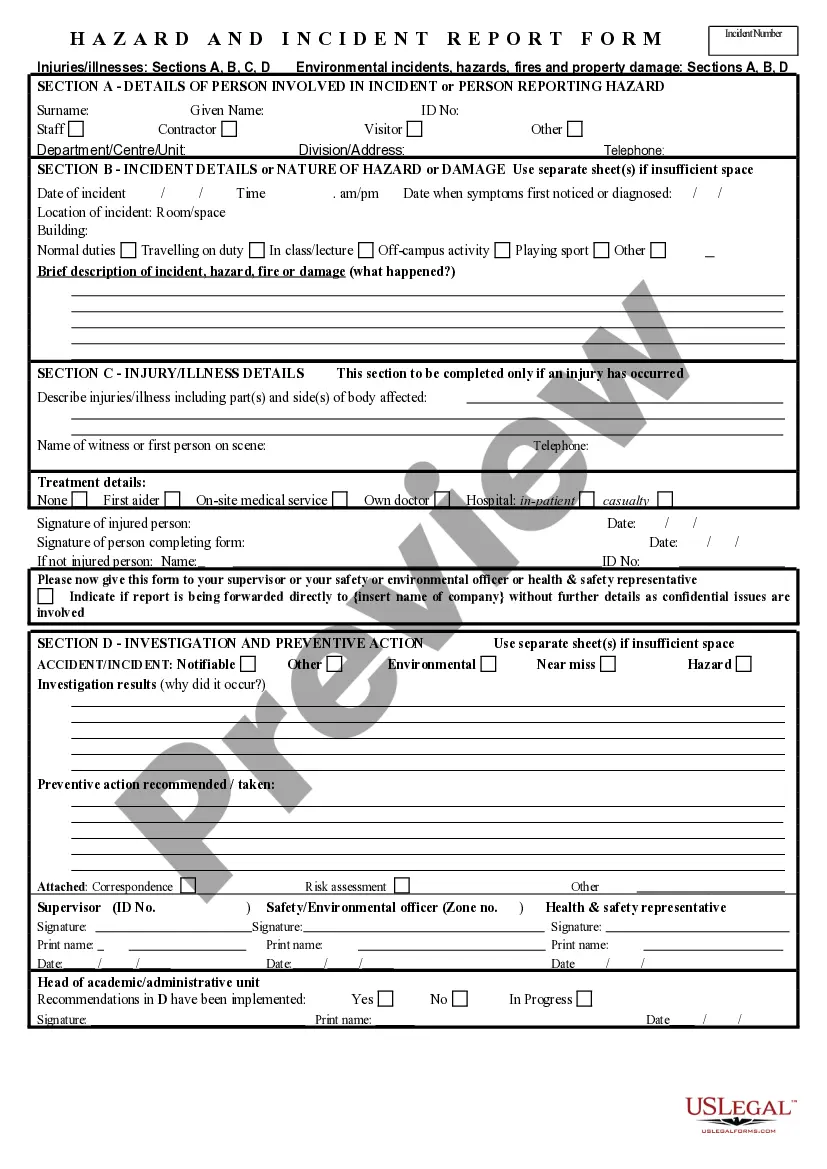

How to fill out Safety Or Health Hazards Report Form?

Locating the correct authentic document template can be challenging.

It goes without saying, there are numerous templates available on the web, but how do you find the authentic form you require.

Utilize the US Legal Forms website. The service offers thousands of templates, such as the Kansas Safety or Health Hazards Report Form, which you can utilize for both business and personal purposes.

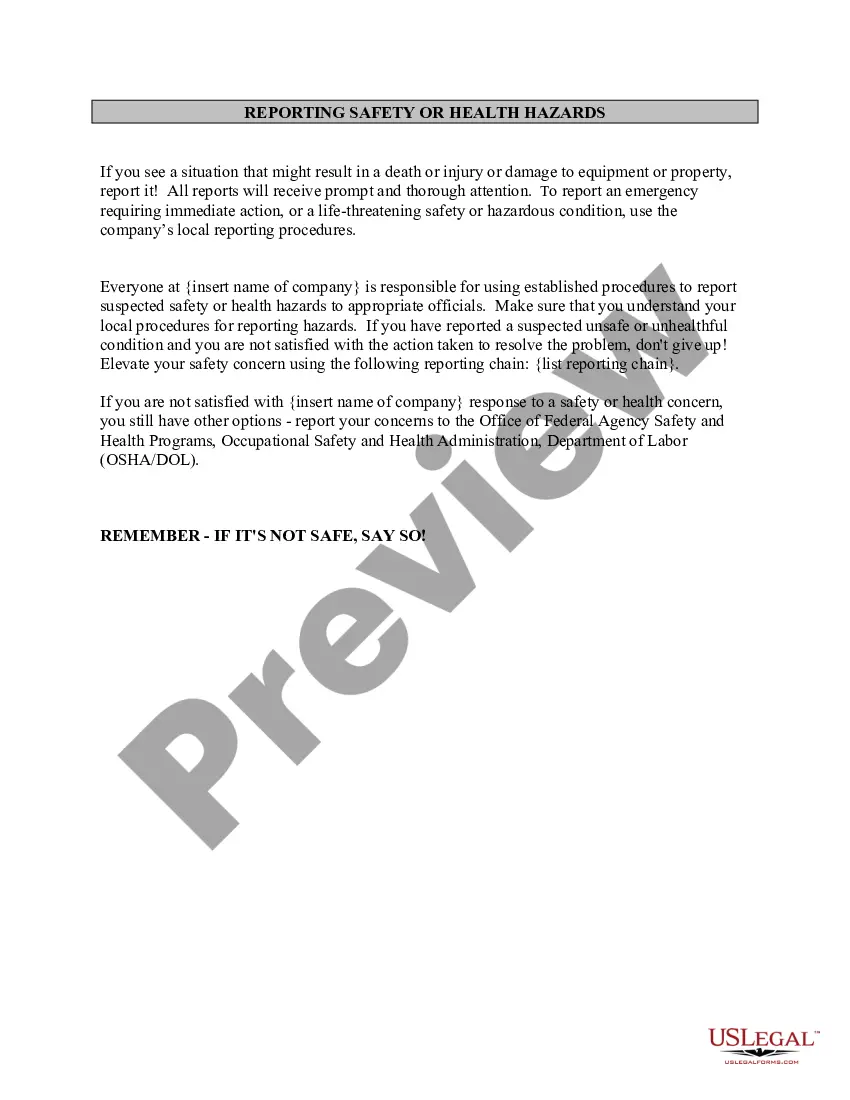

If the form does not meet your requirements, use the Search field to find the correct form. Once you are confident that the document is suitable, choose the Purchase now option to acquire the form. Select the pricing plan you want and enter the necessary information. Create your account and complete your purchase using your PayPal account or Visa or Mastercard. Choose the document format and download the legitimate document template to your device. Complete, edit, print, and sign the acquired Kansas Safety or Health Hazards Report Form. US Legal Forms is the largest repository of legal forms where you can discover various document templates. Take advantage of the service to download professionally crafted documents that comply with state regulations.

- All the forms are reviewed by professionals and meet state and federal requirements.

- If you are already registered, Log In to your account and click on the Download option to obtain the Kansas Safety or Health Hazards Report Form.

- Use your account to search through the legal forms you may have purchased previously.

- Visit the My documents tab of your account and retrieve another version of the document you require.

- If you are a new user of US Legal Forms, here are straightforward instructions for you to follow.

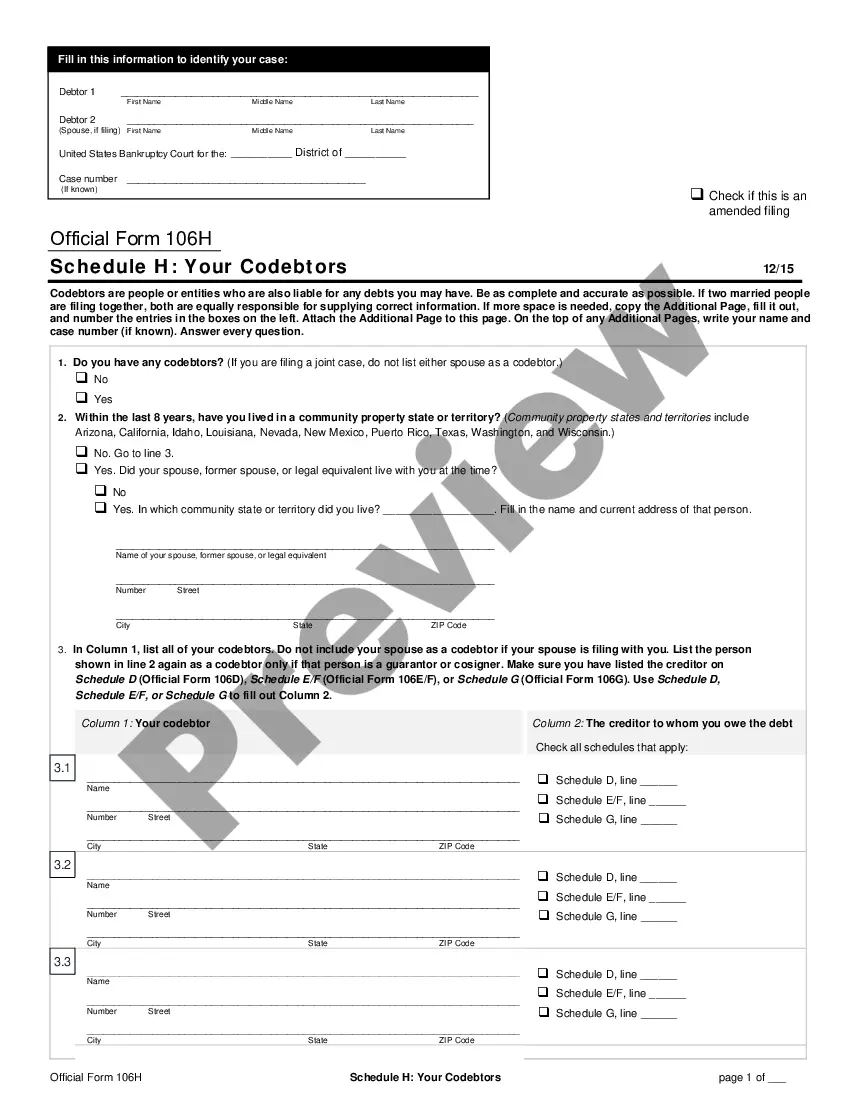

- First, ensure you have selected the appropriate form for your city/state. You can review the document using the Preview option and read the document details to ensure it’s suitable for you.

Form popularity

FAQ

Step by Step Guide to Job Safety and Job Hazard AnalysisStep 1: Choose the Procedure. The first step in performing a JSA is to identify which procedures you'll focus on.Step 2: Break the Job Into Steps.Step 3: Identify Hazards.Step 4: Implement Solutions.Step 5: Communicate the Findings.Step 6: Review and Update.15-Sept-2017

Steps of the JHA ProcessStep 1: Begin the JHA for a specific job by breaking the job down into the steps or tasks performed while doing the job.Step 2: Identify and list the hazards associated with each task (do one task first, then another, etc.)Step 3: Write a hazard description (also called a hazard scenario)More items...

OSHA requires employers to post a citation near the site of the violation for 3 days for employers who receive citations for violations.

Lab supervisors and PI's are responsible for ensuring the hazard assessment is accurately completed, up to date, and personnel are trained on the assessment. Departments are responsible for ensuring PPE is available to employees and is being used appropriately.

Three factors impact hazard inspections:frequency.documentation.inspection areas.

The 2017 OSHA Top 10 Citations provide another insight into the causes of worker injuries and fatalities.Fall Protection General Requirements (1926.501): 6,072 violations.Hazard Communication (1910.1200): 4,176 violations.Scaffolding (1926.451): 3,288 violations.Respiratory Protection (1910.134): 3,097 violations.More items...?01-May-2019

Periodic evaluations include a site inspection and evaluation of IC implementation, effectiveness, and stakeholder roles and accountabilities.

When should a formal hazard assessment or inspection be performed? When a new hazard is uncovered. Three factors impact hazard inspections: Frequency, documentation, and the inspection areas.

A process hazard analysis cannot be done by just anyone. According to OSHA, PHAs must be performed by a team with process and engineering knowledge and include at least one employee experienced in running the process. Also, one member of the team must have experience with the PHA method being used.

Managers and Supervisors are usually the ones who implement the administrative procedures, and operational policies that control chemical risks and hazards. And like all workers, they have a responsibility to follow those same procedures (leading by example).