This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

Indiana Conversion of An Oil Or Gas Well to An injection Or Water Well

Description

How to fill out Conversion Of An Oil Or Gas Well To An Injection Or Water Well?

US Legal Forms - one of the greatest libraries of legitimate forms in America - provides a wide array of legitimate papers themes you can acquire or print out. While using web site, you may get 1000s of forms for business and person reasons, sorted by classes, says, or search phrases.You will discover the newest versions of forms just like the Indiana Conversion of An Oil Or Gas Well to An injection Or Water Well in seconds.

If you have a membership, log in and acquire Indiana Conversion of An Oil Or Gas Well to An injection Or Water Well in the US Legal Forms collection. The Obtain key will appear on each type you perspective. You get access to all in the past saved forms from the My Forms tab of your own account.

If you wish to use US Legal Forms initially, listed below are basic recommendations to help you started:

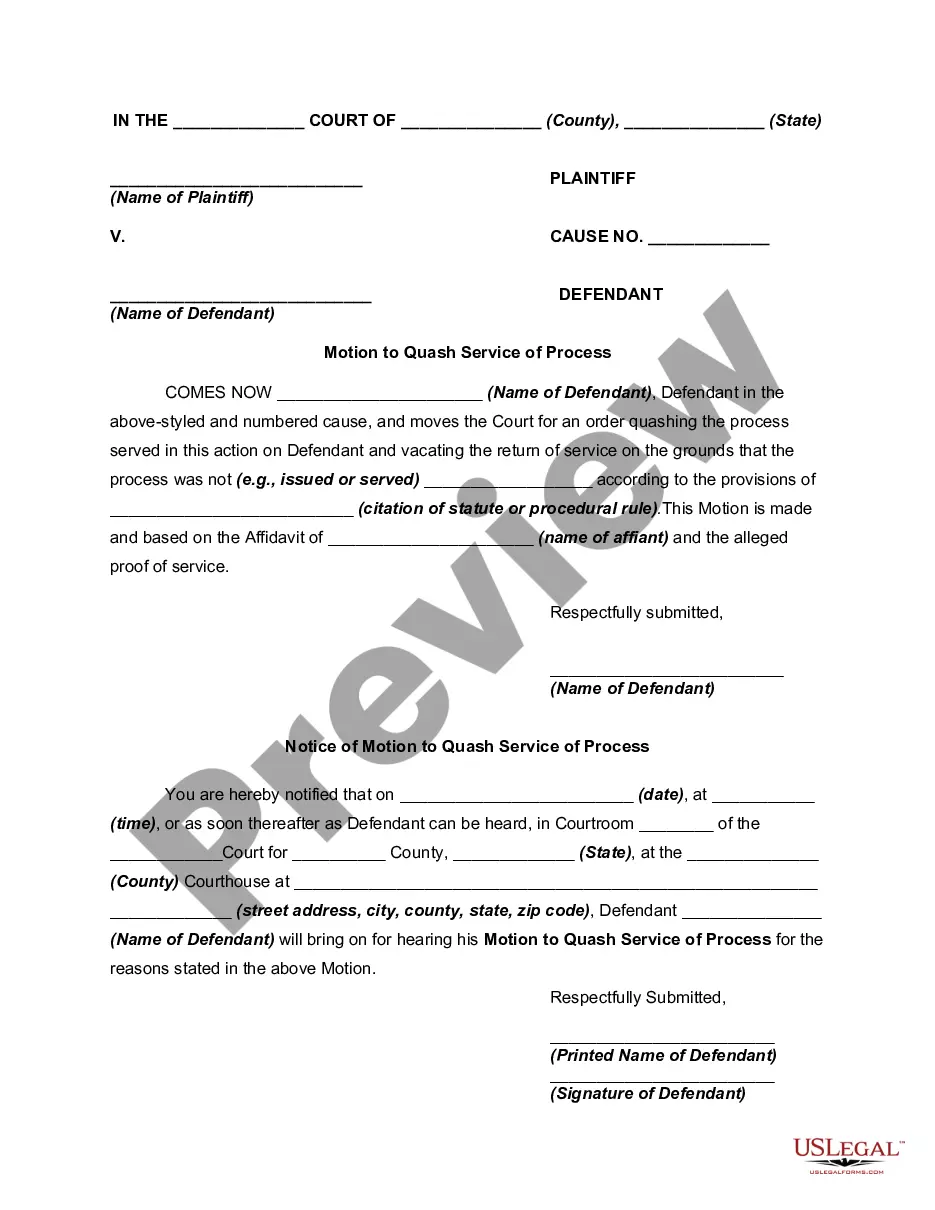

- Ensure you have picked the right type for the city/area. Select the Review key to check the form`s information. Read the type information to actually have chosen the proper type.

- In the event the type doesn`t suit your requirements, make use of the Search area on top of the display to obtain the one that does.

- Should you be content with the shape, validate your choice by clicking the Acquire now key. Then, pick the costs program you want and give your references to sign up for an account.

- Method the transaction. Utilize your Visa or Mastercard or PayPal account to accomplish the transaction.

- Select the structure and acquire the shape on the device.

- Make adjustments. Complete, edit and print out and sign the saved Indiana Conversion of An Oil Or Gas Well to An injection Or Water Well.

Each and every web template you added to your account does not have an expiration time which is yours for a long time. So, if you would like acquire or print out yet another copy, just proceed to the My Forms section and click on on the type you want.

Gain access to the Indiana Conversion of An Oil Or Gas Well to An injection Or Water Well with US Legal Forms, one of the most extensive collection of legitimate papers themes. Use 1000s of skilled and state-specific themes that meet your company or person requirements and requirements.

Form popularity

FAQ

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well.

Oil Well - You may see a wellhead, metal casing, a pumpjack, oil and/or brine tanks, and pipes/fittings. Gas Well - You may see a wellhead, metal casing, separator, brine tank, and pipes/fittings.

Source wells are used to provide water for oil and gas industry use. The source may be either shallow fresh water or deep formation water. The principle uses of this water are to supply injection wells or for hydraulic fracture stimulation.

We call crude oil and petroleum fossil fuels because they are mixtures of hydrocarbons that formed from the remains of animals and plants (diatoms) that lived millions of years ago in a marine environment before dinosaurs existed.

Shallow, deep and ultra-deep wells Oil and gas wells are commonly classified based on their total vertical depth (TVD), which is broadly divided into three main categories: (i) shallow, (ii) deep, and (iii) ultra-deep (Fig. 15.1). Shallow wells represent the conventional oil and gas reserves that are now scarce.

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas may be termed a gas well.