Agreement For Contract Manufacturing

Description

How to fill out Contract Manufacturing Statement Of Work?

Whether for corporate reasons or personal affairs, everyone must deal with legal issues at some stage in their lives.

Completing legal documents requires meticulous care, beginning with selecting the correct form template.

Select the file format you wish to use and download the Agreement For Contract Manufacturing. After downloading it, you can fill out the form with editing software or print it to complete it by hand. With a comprehensive US Legal Forms catalog available, you will never have to waste time hunting for the appropriate sample online. Utilize the library's intuitive navigation to find the suitable template for any situation.

- For instance, if you choose an incorrect version of an Agreement For Contract Manufacturing, it will be rejected upon submission.

- Thus, it's vital to have a trustworthy source for legal documents like US Legal Forms.

- To obtain an Agreement For Contract Manufacturing template, follow these straightforward steps.

- Find the sample you require using the search box or by browsing the catalog.

- Review the form’s description to confirm it aligns with your situation, jurisdiction, and area.

- Click on the form’s preview to inspect it.

- If it is not the correct form, return to the search tool to discover the Agreement For Contract Manufacturing template you need.

- Download the template once it fits your requirements.

- If you already possess a US Legal Forms account, simply click Log in to access previously saved documents in My documents.

- If you don’t have an account yet, you can acquire the form by selecting Buy now.

- Choose the suitable payment option.

- Complete the profile registration form.

- Choose your payment method: either a credit card or a PayPal account.

Form popularity

FAQ

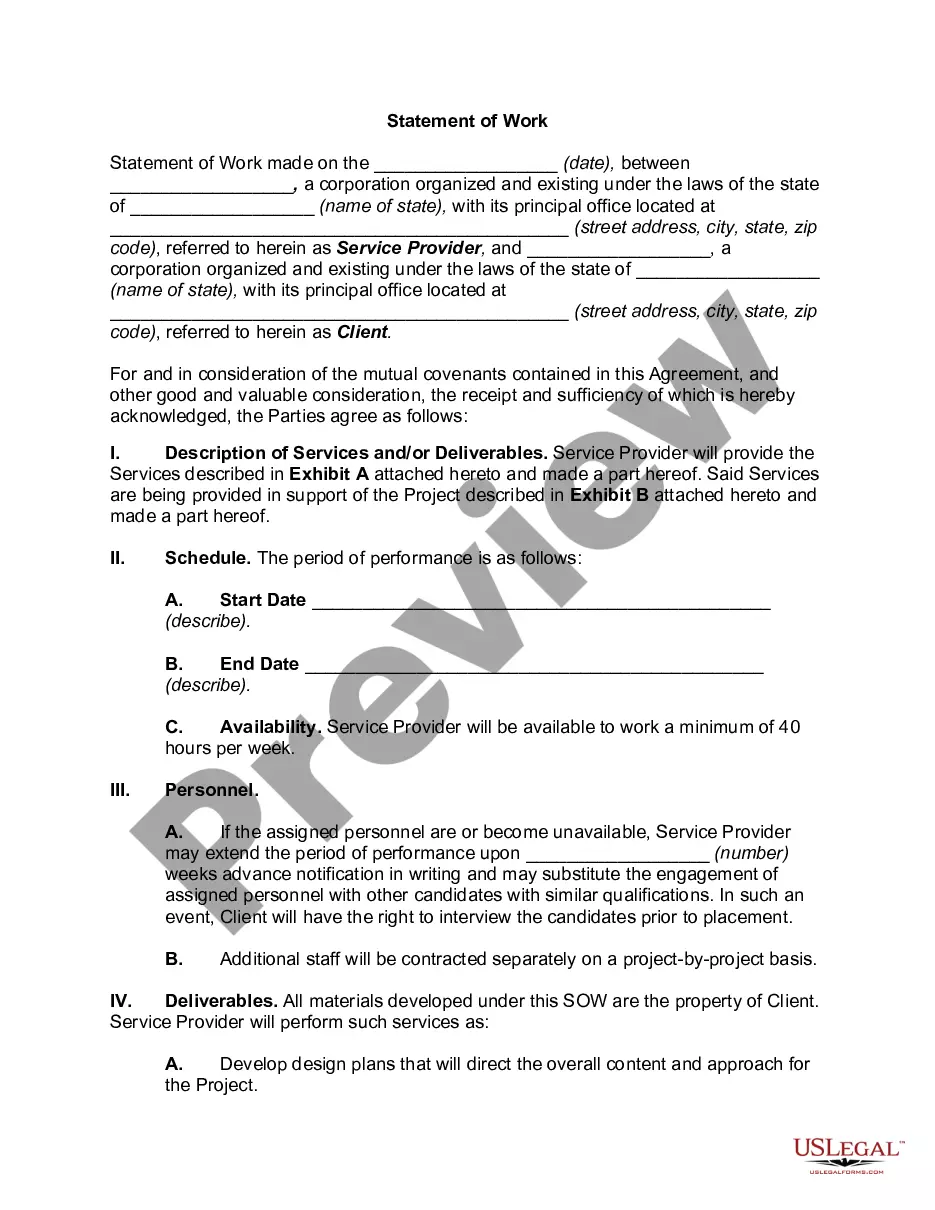

A manufacturing agreement is a contract that outlines the terms between a manufacturer and a company seeking to produce goods. It includes specific details such as production timelines, costs, and quality standards. This document is critical for establishing a clear agreement for contract manufacturing, fostering trust and cooperation between the parties involved.

To make a contract agreement, start by gathering all relevant information about the parties involved and the terms of the arrangement. Write down your expectations clearly, ensuring inclusion of key aspects like payment, delivery timelines, and product specifications. A well-structured agreement for contract manufacturing protects both parties and promotes a successful partnership.

Yes, you can write your own contract agreement, but it's crucial to ensure it covers all necessary elements. Include important details like roles, timelines, and payment terms to provide clarity. Utilizing a template or guidance from a professional service like uslegalforms can help you create a robust agreement for contract manufacturing, ensuring all legal bases are covered.

A contract manufacturing agreement is a formal document that outlines the terms of the manufacturing relationship between two parties. It specifies details such as production processes, timelines, quality standards, and payment terms. This agreement for contract manufacturing serves as a safeguard for both parties, ensuring everyone is clear on their obligations.

Contract manufacturing involves certain risks, but understanding them can minimize potential issues. Risks include quality control, supply chain disruptions, and intellectual property concerns. By establishing clear communication and a solid agreement for contract manufacturing, you can mitigate these risks and foster a successful partnership.

A contract manufacturing arrangement is a partnership where a company hires another firm to produce its products. In this setup, the contracting party provides specifications and oversees the product development process. This arrangement often includes an agreement for contract manufacturing that outlines roles, responsibilities, and deliverables, ensuring a smooth collaboration.

To get started with contract manufacturing, you first need to identify potential manufacturing partners. Next, clearly outline your product specifications and quality requirements. Once you find suitable manufacturers, engage in discussions to negotiate terms, and finalize an agreement for contract manufacturing. This process helps ensure both parties are aligned in expectations.

Starting an Agreement for contract manufacturing involves identifying the key parties and defining the agreement's objectives. Initiate the process by gathering all relevant information regarding your needs and expectations. Utilize a reliable platform like US Legal Forms to access templates that guide you through crafting a precise and effective agreement. This approach can save time and minimize potential conflicts.

To draft an Agreement for contract manufacturing, start by clearly outlining the purpose and scope of the contract. Include essential details such as parties involved, specific roles, responsibilities, and timelines. Using standardized templates can help ensure that you cover all necessary elements. Lastly, review and revise the document for clarity and legal compliance.

The three primary forms of contract manufacturing are dedicated contract manufacturing, non-dedicated contract manufacturing, and toll manufacturing. In dedicated contract manufacturing, a facility exclusively produces for one client. Non-dedicated models offer flexibility, serving multiple clients simultaneously. Toll manufacturing involves a client providing raw materials, while the manufacturer assists in the production process. Each form can be beneficial, depending on your needs, and having a clear agreement for contract manufacturing is crucial.