Performance Agreement For Supply Chain Manager In Franklin

Description

Form popularity

FAQ

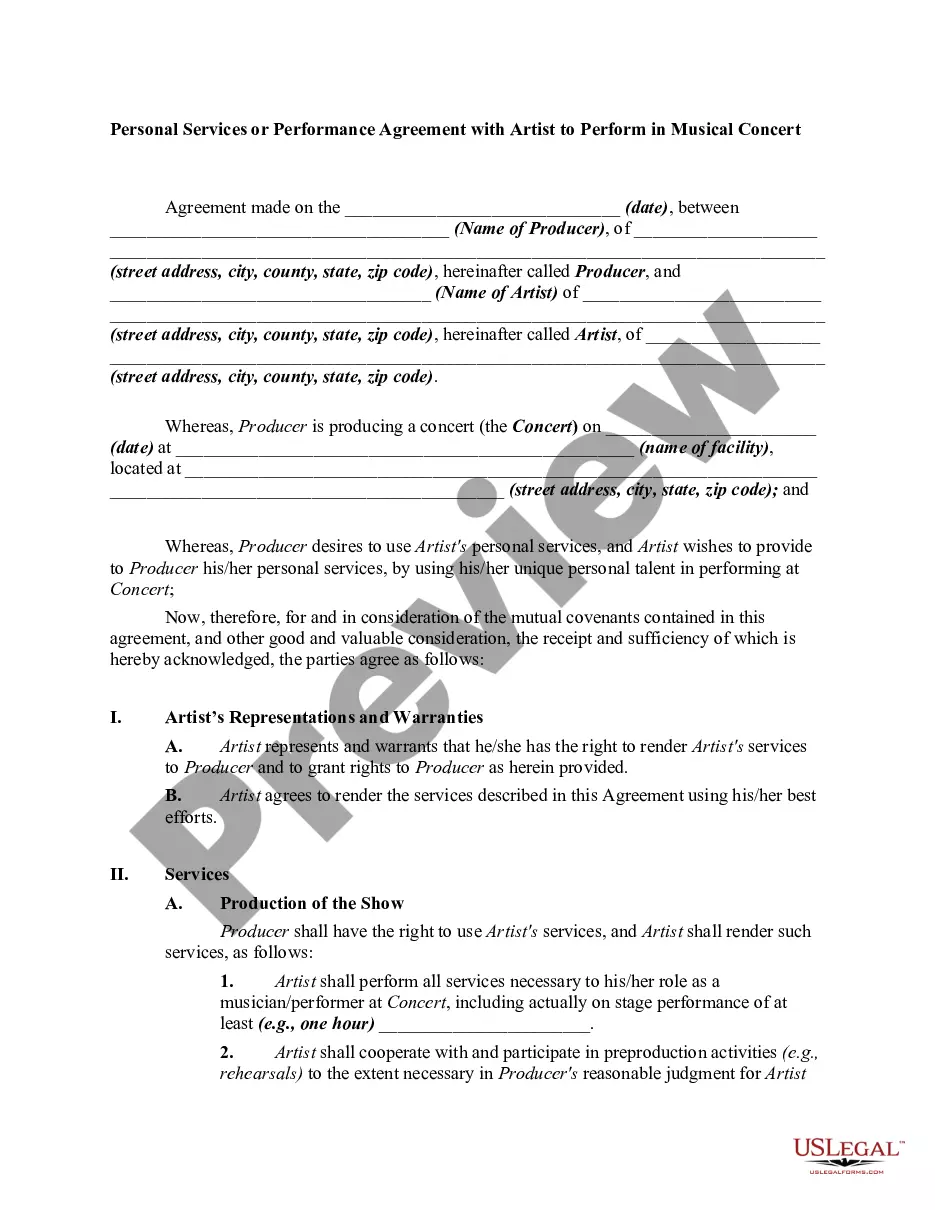

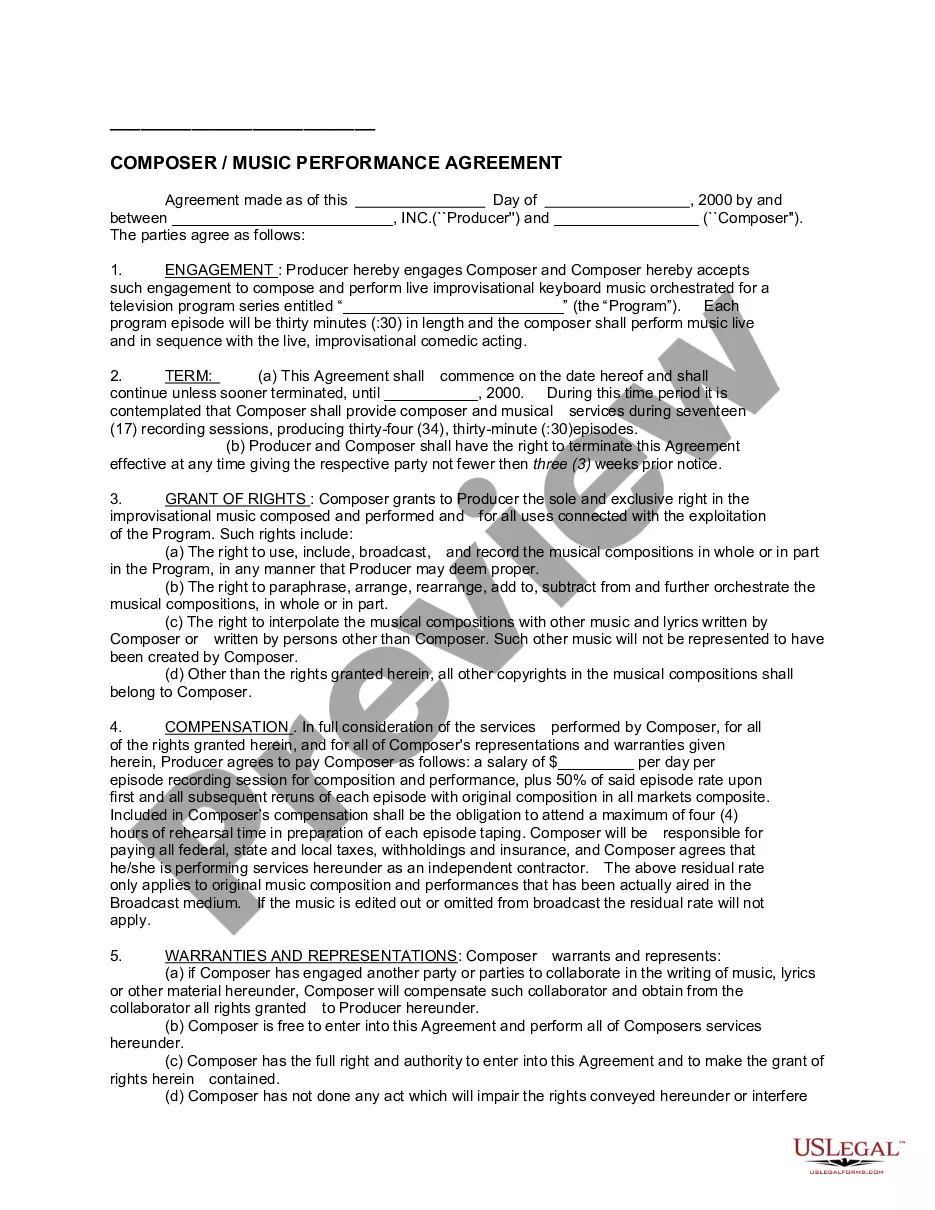

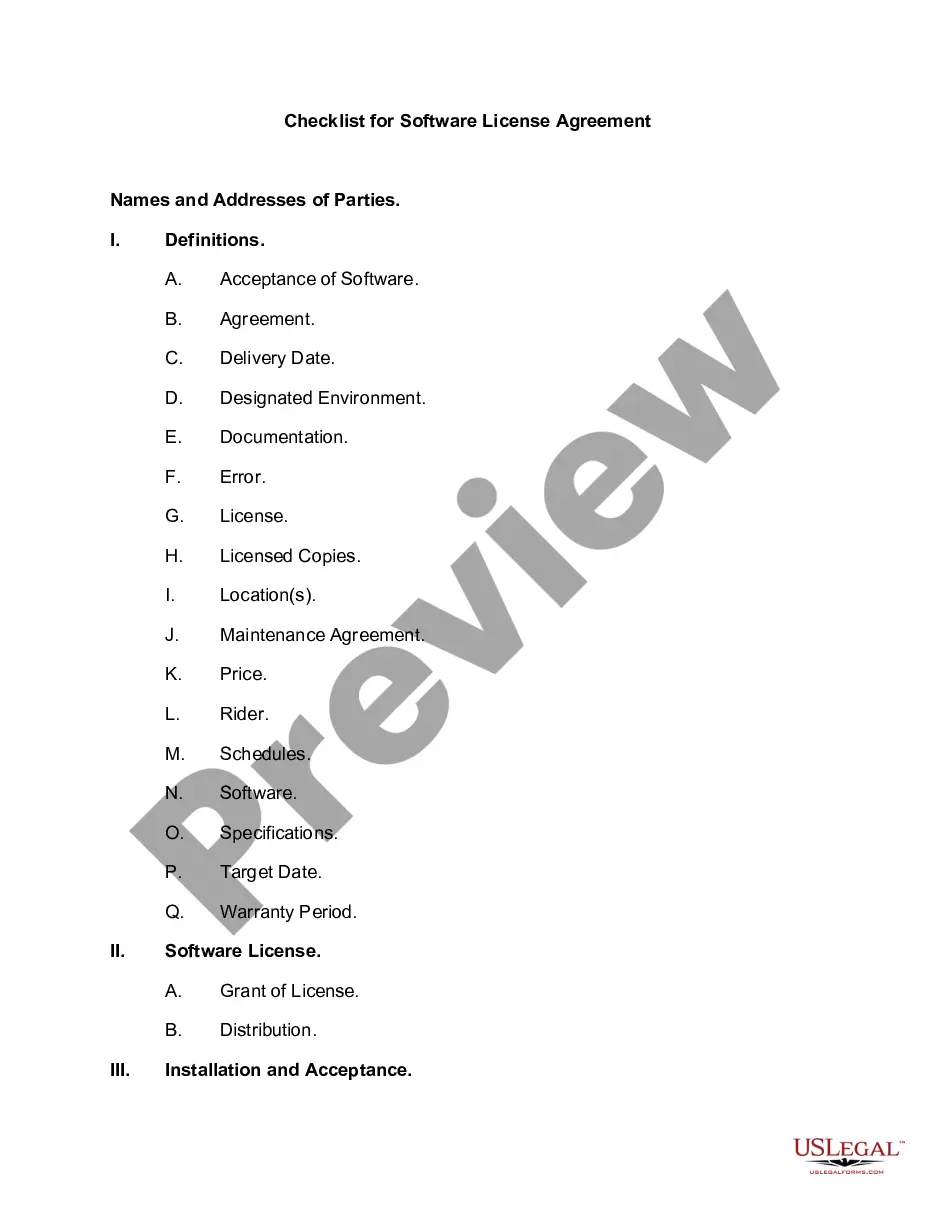

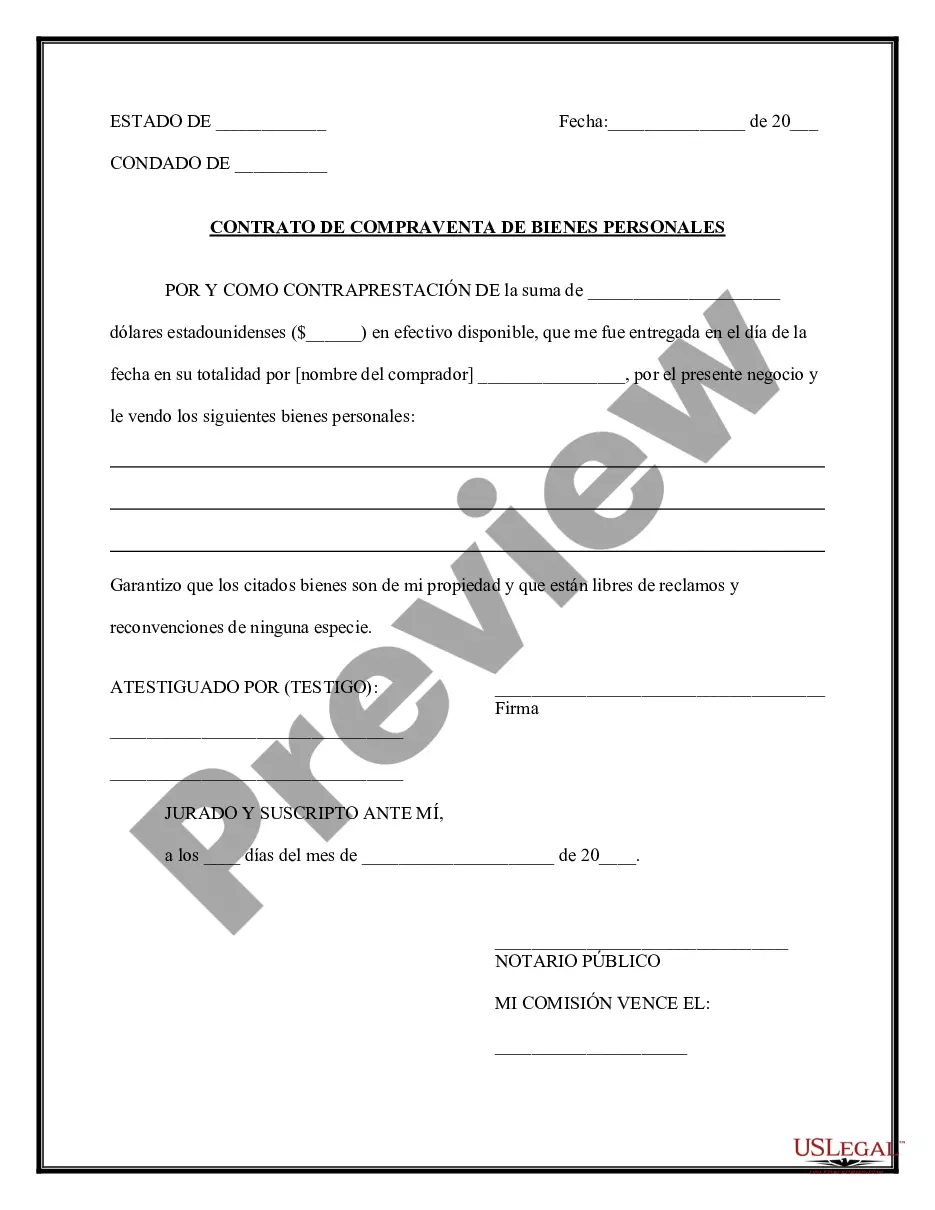

Contract management is a systematic process of managing contracts to minimize operational and functional risks and optimize vendor performance. It involves contract creation, execution, and analysis. Depending on the business operations, it also consists of termination of contracts.

Here are six steps to consider when creating your supply chain plan: Review company goals. Perform market research. Forecast consumer demand. Allocate inventory requirements. Fulfill consumer orders. Ensure planning flexibility.

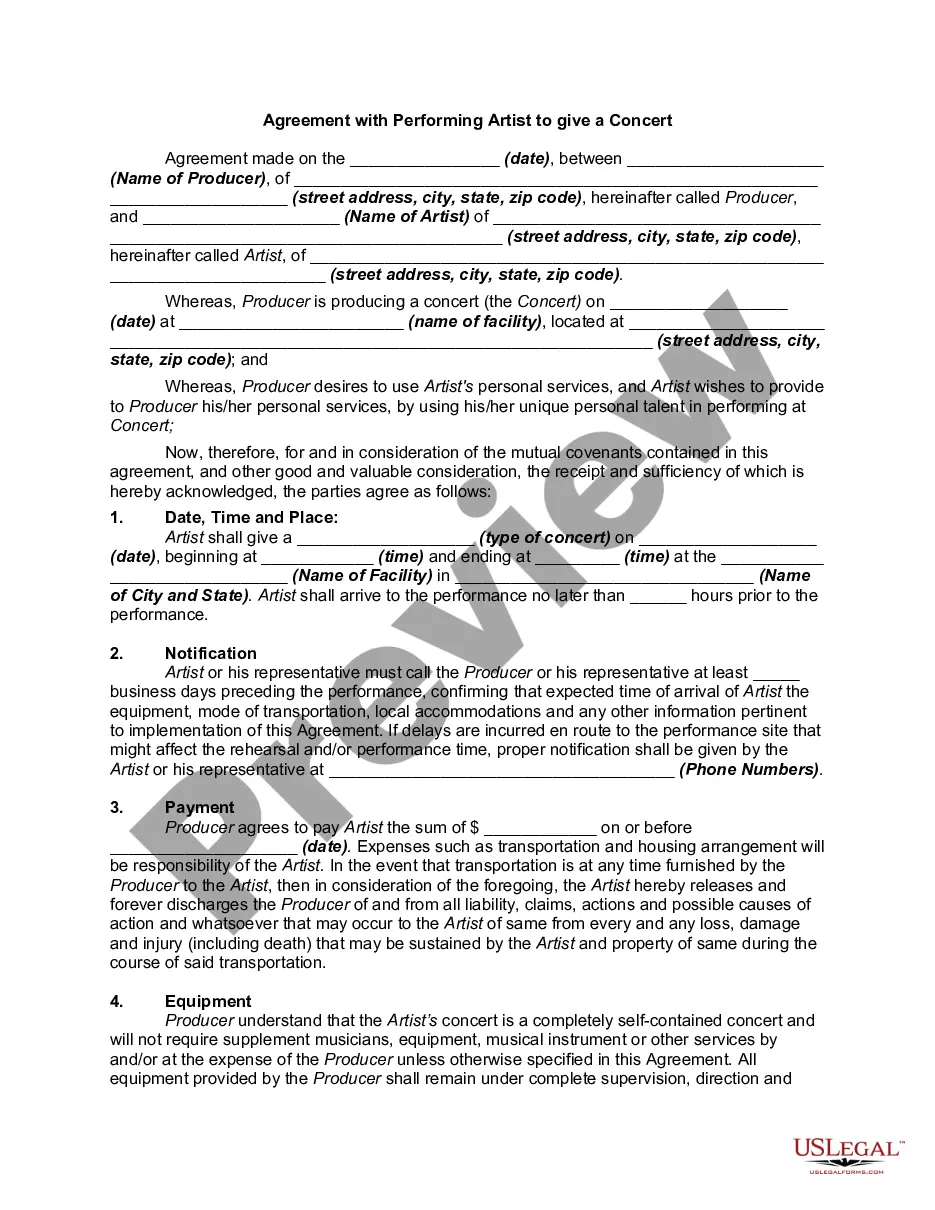

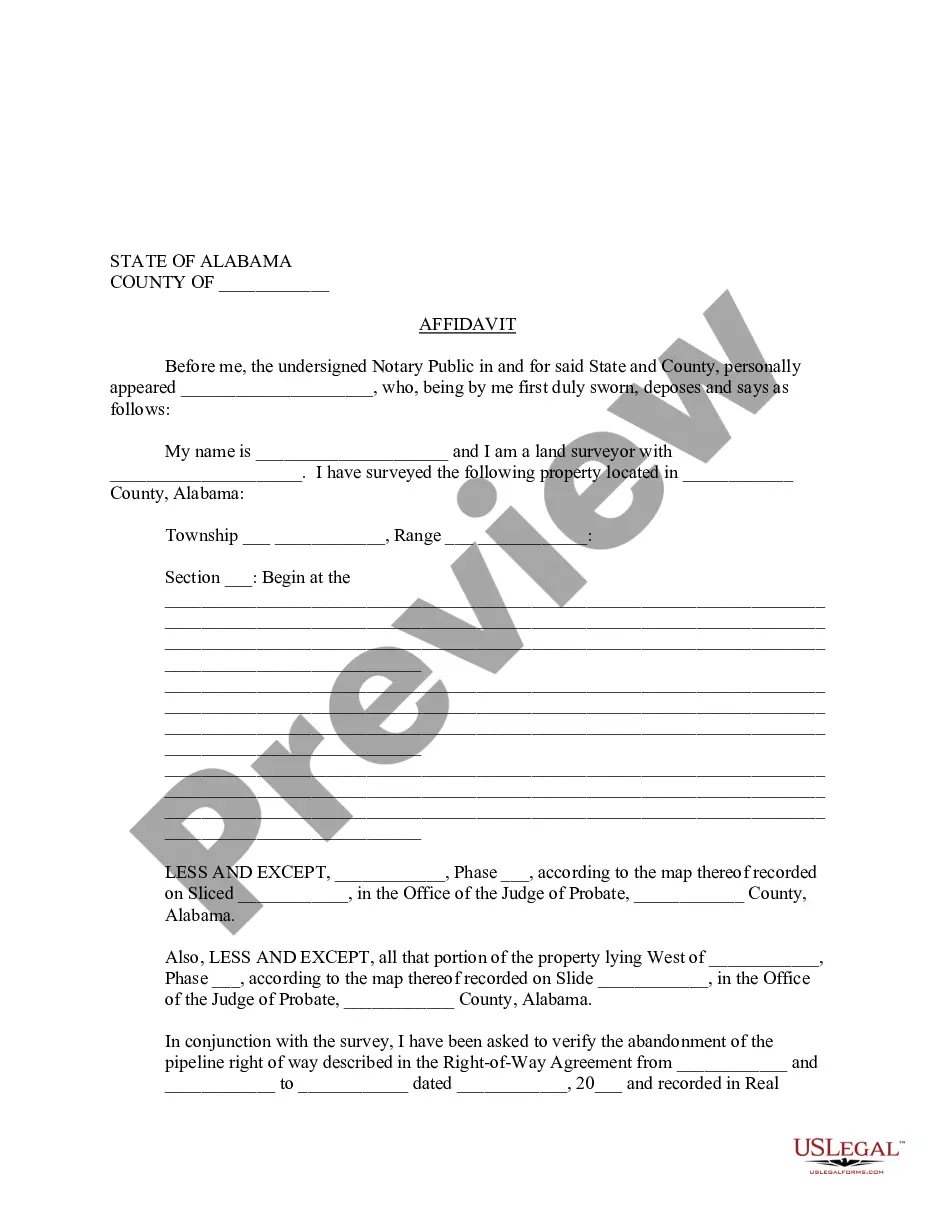

Force majeure clauses in supplier contracts allow parties to renegotiate terms, adjust delivery schedules, or seek alternative sources of supply in response to unforeseen events.

How to measure Supply Chain Performance Inventory Investment. Inventory Efficiency. On-Time Supplier Delivery. Forecasting Accuracy. Lead Time. Unplanned Orders. Schedule Changes. Overdue Backlog.

The performance management system entails processes that are critical to improving supply chain effectiveness and efficiency including identifying measures and data requirements, defining targets, planning, communicating, measuring, reporting and feedback.

Supply Chain Performance refers to the extended supply chain's activities in meeting end-customer requirements, including product availability, on-time delivery, and all the necessary inventory and capacity in the supply chain to deliver that performance in a responsive manner.

Supply Chain Performance refers to the extended supply chain's activities in meeting end-customer requirements, including product availability, on-time delivery, and all the necessary inventory and capacity in the supply chain to deliver that performance in a responsive manner.

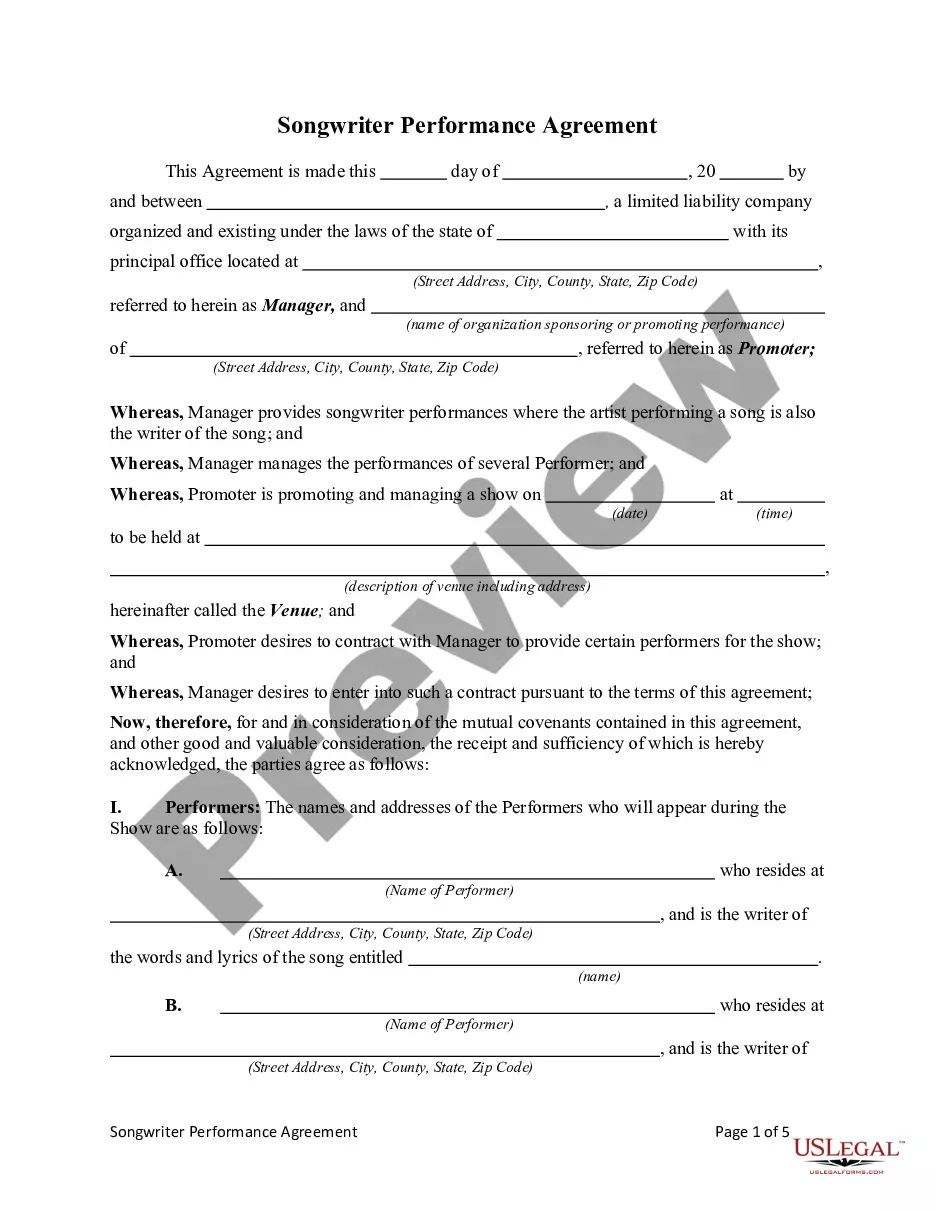

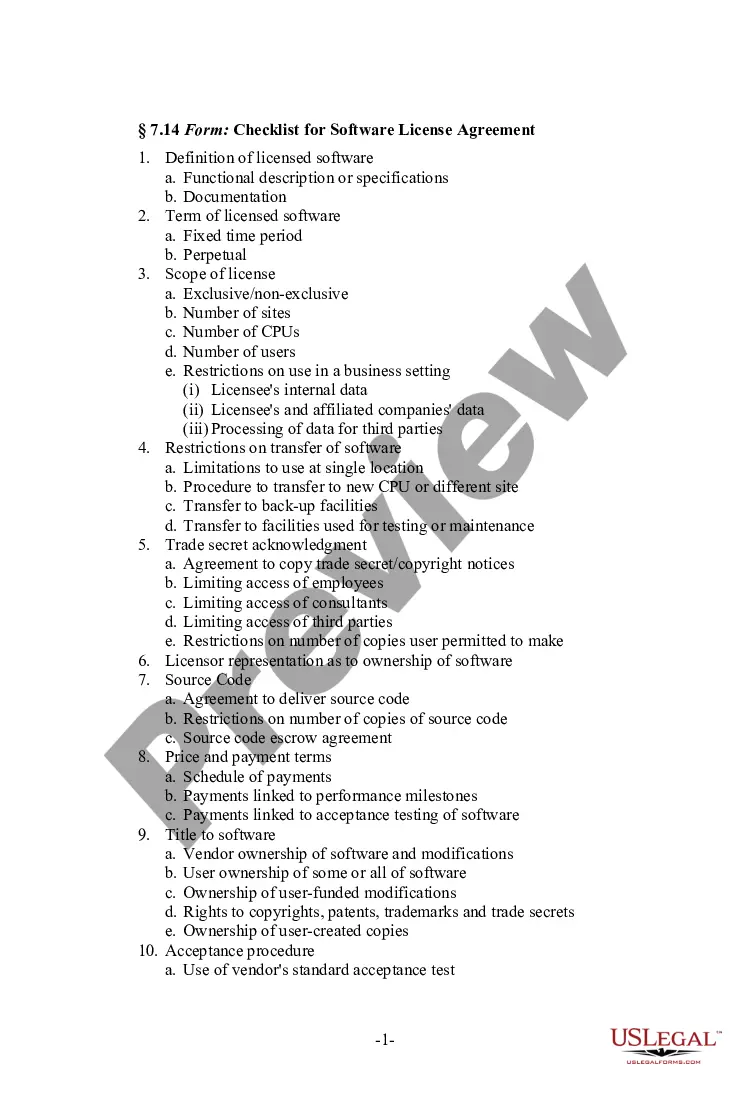

In the intricate web of supply chain management, contracts serve as the backbone, providing structure, clarity, and protection for all parties involved. From procurement to distribution, every step in the supply chain journey relies on well-drafted contracts to ensure seamless operations and mitigate potential risks.