Performance Agreement For Supply Chain Manager In Clark

Description

Form popularity

FAQ

Supply Chain Performance refers to the extended supply chain's activities in meeting end-customer requirements, including product availability, on-time delivery, and all the necessary inventory and capacity in the supply chain to deliver that performance in a responsive manner.

Understanding supplier performance management Metrics and KPIs: These are quantitative measurements that provide data on supplier performance. Examples are lead time, on-time delivery rates, defect rates, and order accuracy.

SCM's primary goal is to keep a firm afloat and ultimately to drive it to success. Other objectives of SCM include improving efficiency and quality, minimising costs, optimising delivery and distribution and providing the best possible experience to your customers.

What is Performance Management? An ongoing, continuous process of communicating and clarifying job responsibilities, priorities, performance expectations, and development planning that optimize an individual's performance and aligns with organizational strategic goals.

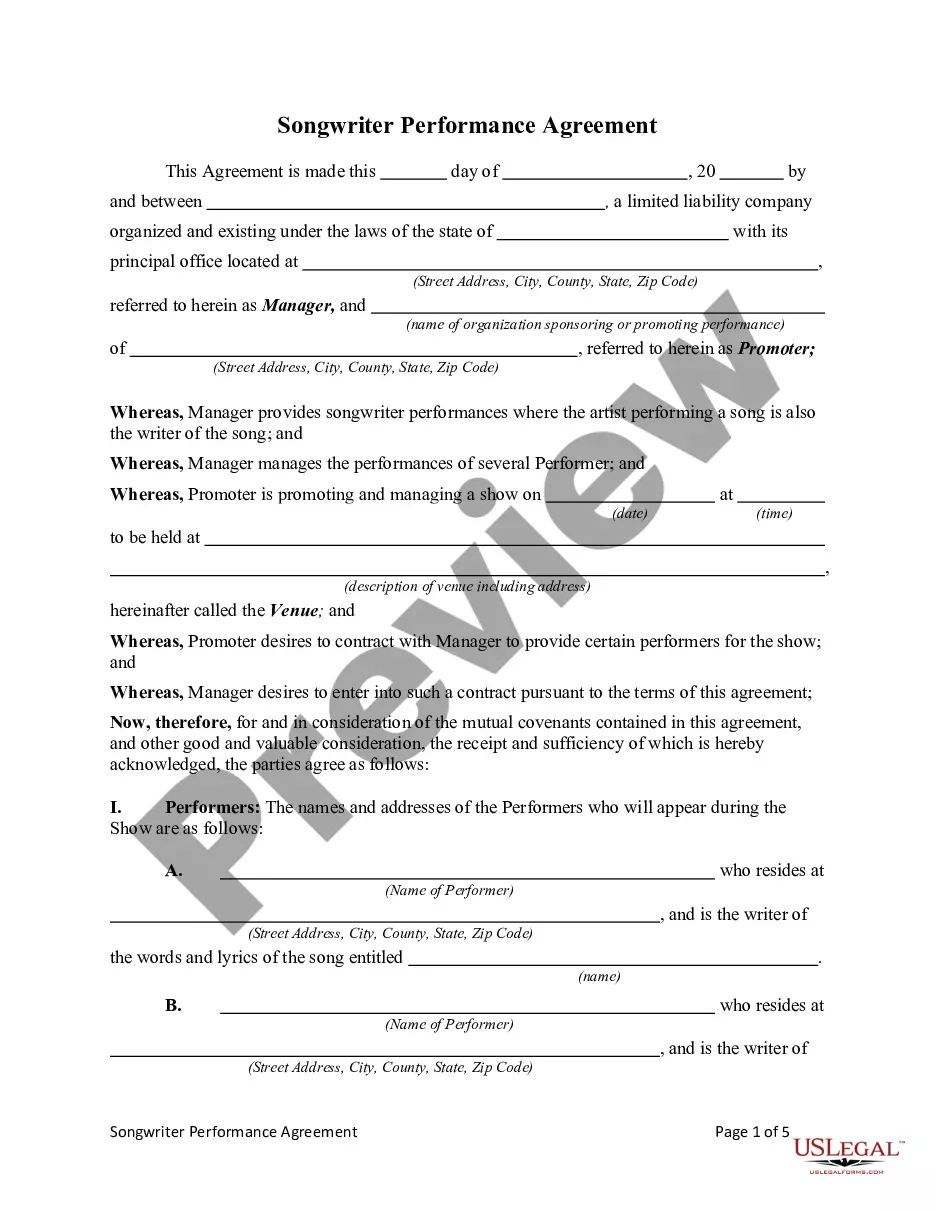

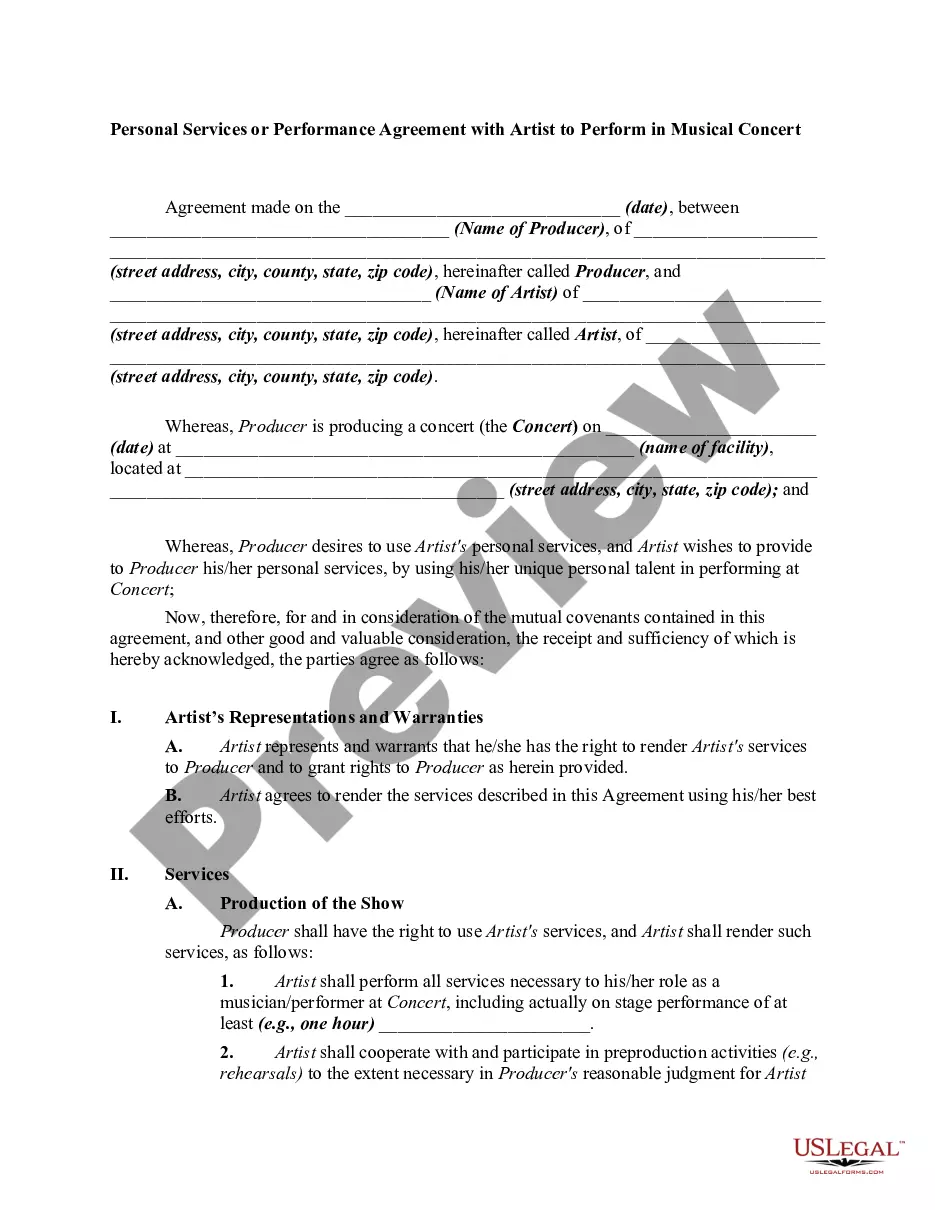

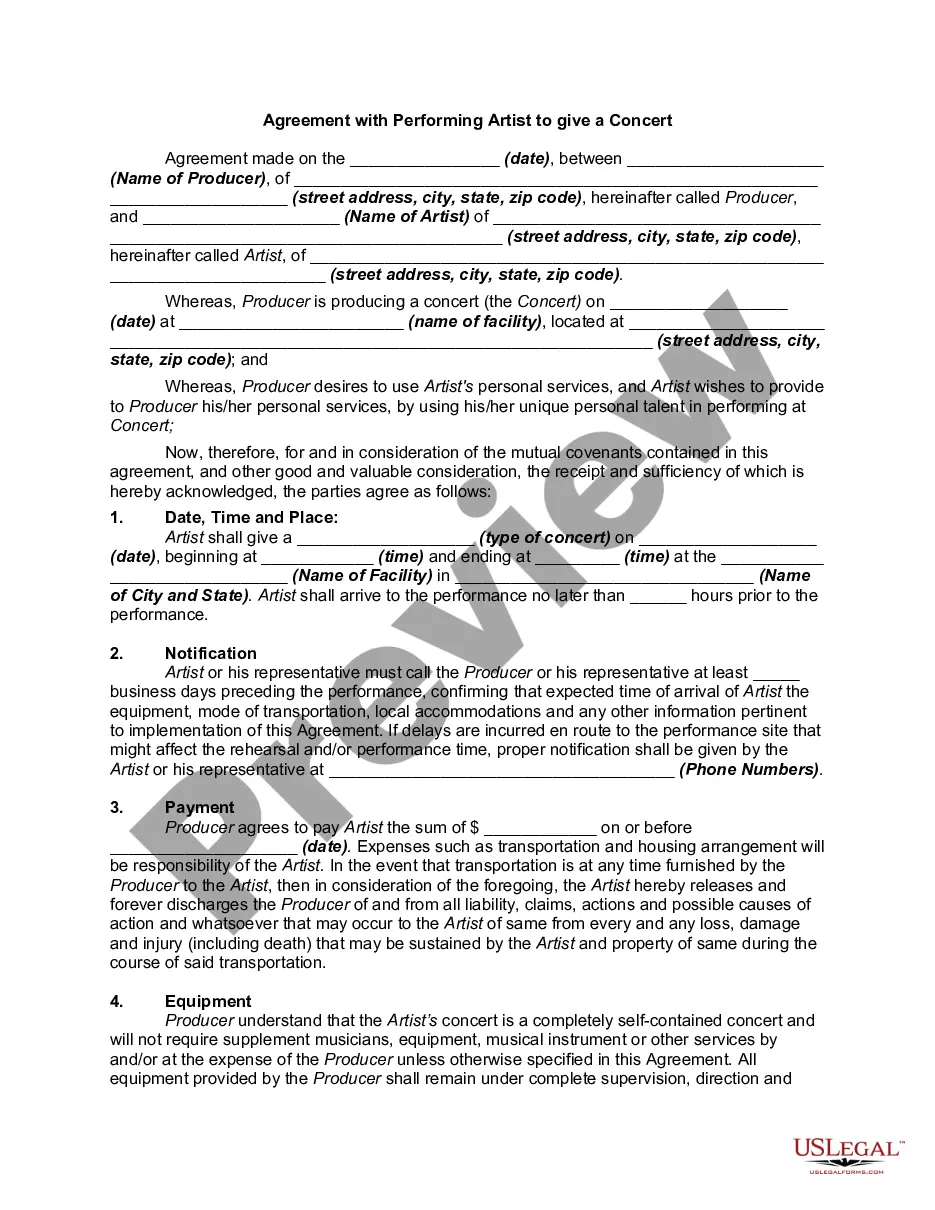

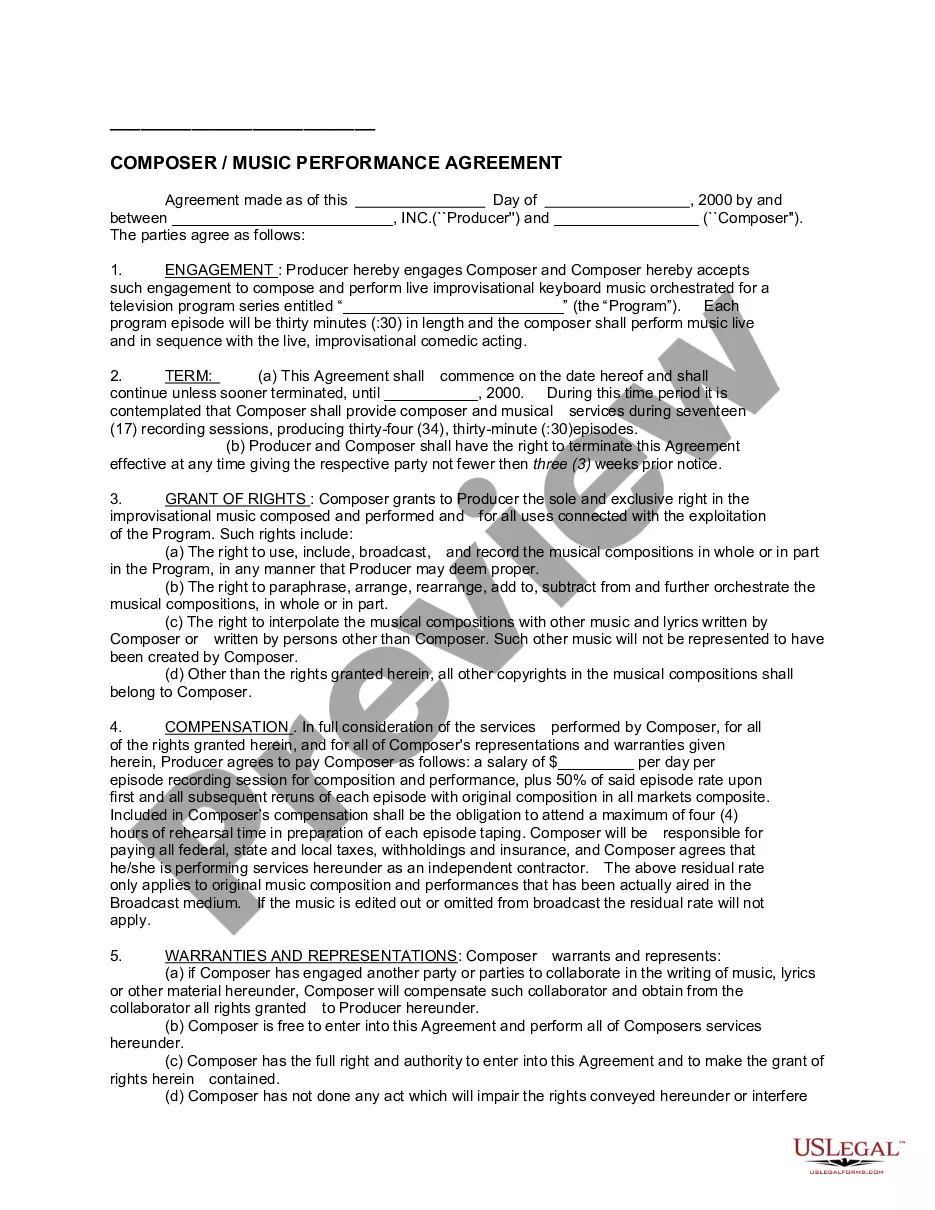

These agreements outline the terms and conditions under which the parties will collaborate and interact within the supply chain. They are important because they provide a legal framework that governs the relationships and responsibilities of the parties involved, ensuring clarity, transparency, and accountability.

The performance management system entails processes that are critical to improving supply chain effectiveness and efficiency including identifying measures and data requirements, defining targets, planning, communicating, measuring, reporting and feedback.

The performance management system entails processes that are critical to improving supply chain effectiveness and efficiency including identifying measures and data requirements, defining targets, planning, communicating, measuring, reporting and feedback.