Hvac Service Agreement Template With Warranty Coverage In Bexar

Description

Form popularity

FAQ

HVAC service agreements are designed to spot potential system weaknesses before they cause shutdowns. With a service provider regularly inspecting and servicing your HVAC equipment, potential hazards can be identified and remedied swiftly, ensuring business operations are safeguarded from HVAC-related disruptions.

How to Bid HVAC Jobs: 7 Steps Step 1: Review the Specifications. Step 2: Analyze the Drawings. Step 3: Perform a Quantity Takeoff. Step 4: Work Out Labor Costs. Step 5: Factor in Overhead and Profit Margin. Step 6: Create Your HVAC Estimate. Step 7: Review & Present Your Proposal.

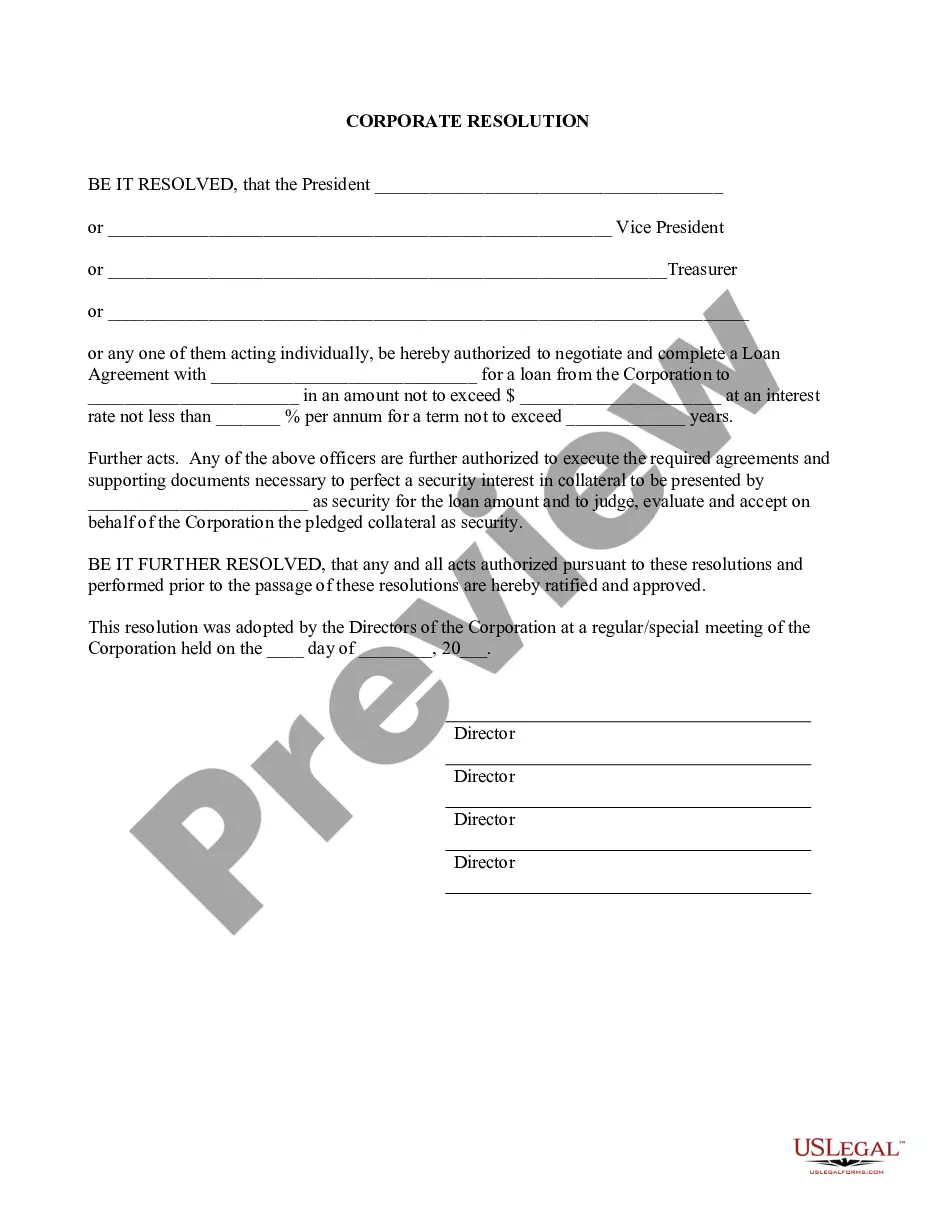

With a comprehensive annual maintenance contract, you can control and account for all maintenance costs on a long-term, fixed basis. By reducing variability in your maintenance budget, you can reliably allocate funds throughout the rest of the business without fear of overruns in maintenance or shortfalls elsewhere.

There are multiple types of HVAC systems, including split systems and ductless systems. Split systems are most common but require ductwork, which can be expensive to . To find the right system for your home, consider your climate, budget, and current HVAC setup.

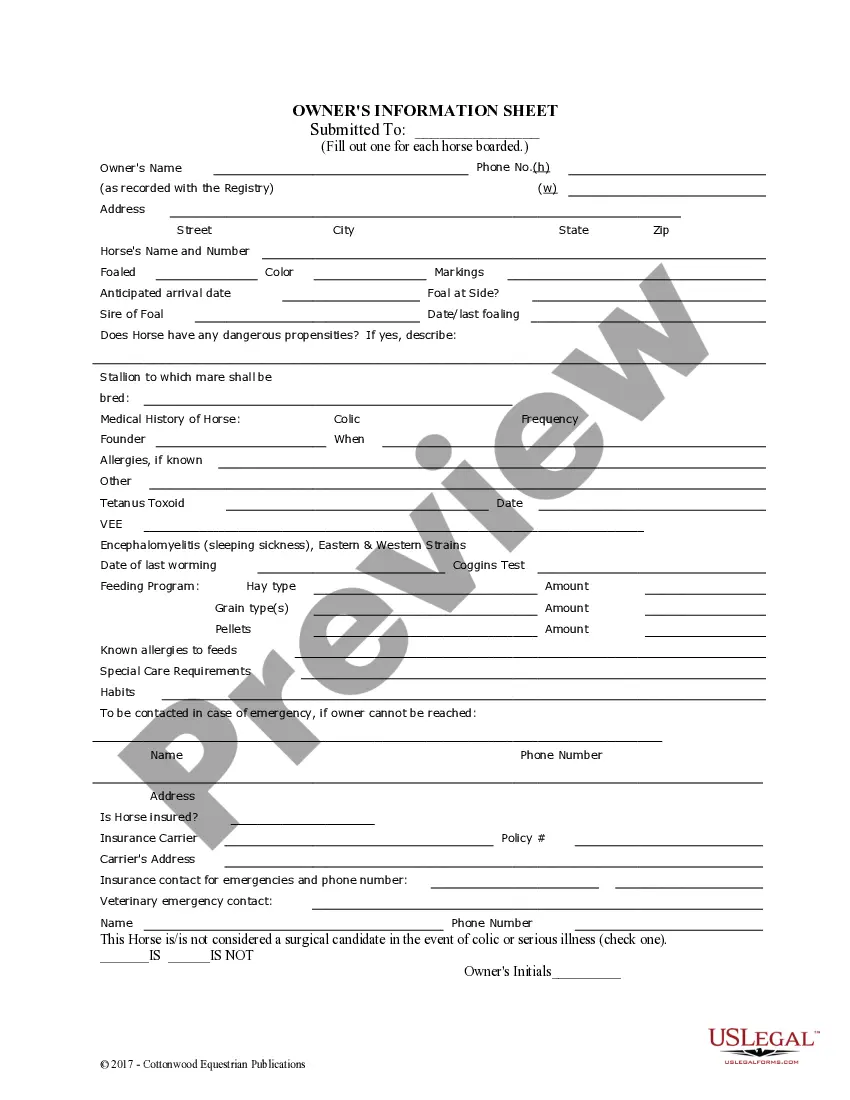

In any event, some of the most important elements of a maintenance contract include: Business and customer name and contact information. Details of equipment being serviced or repaired. Contractor response and service completion time.

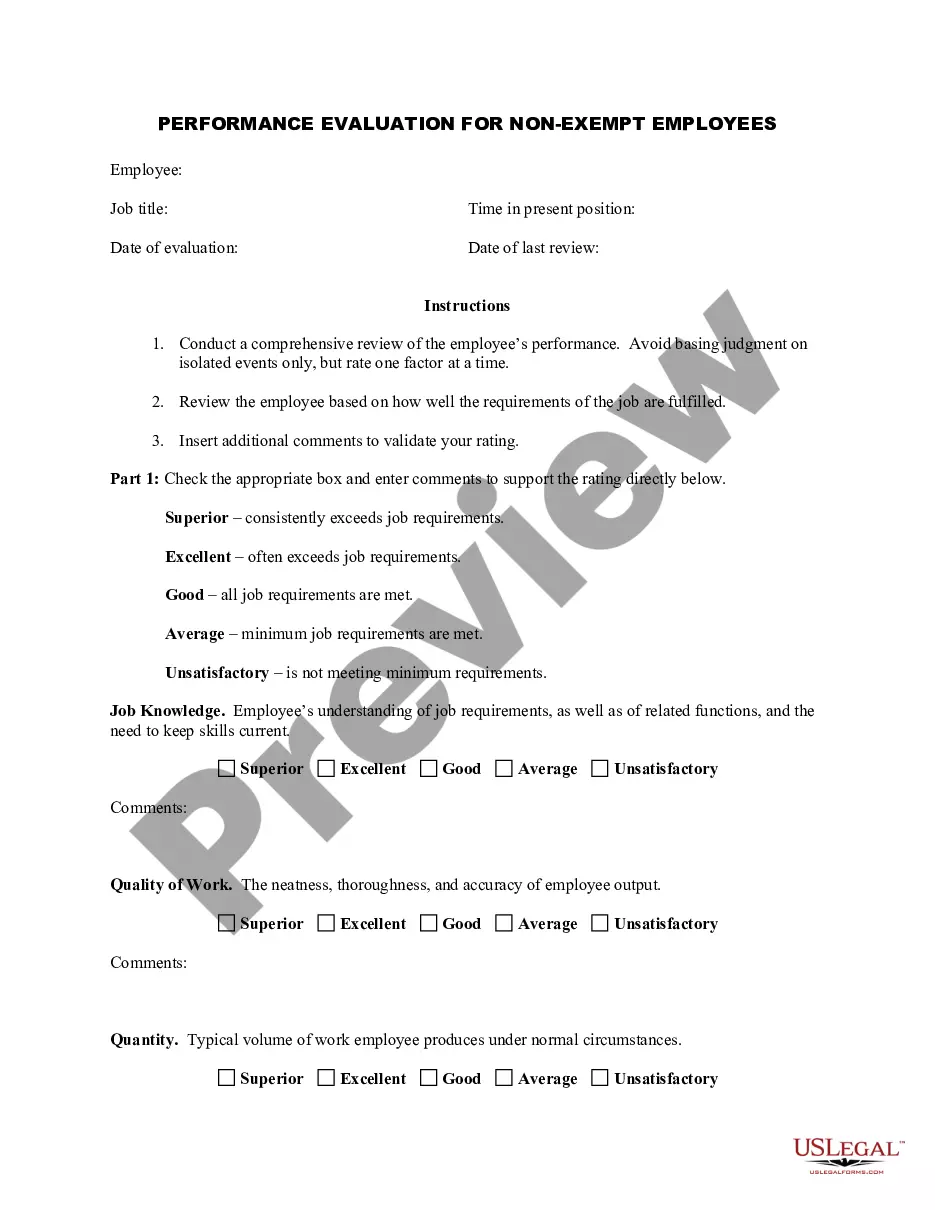

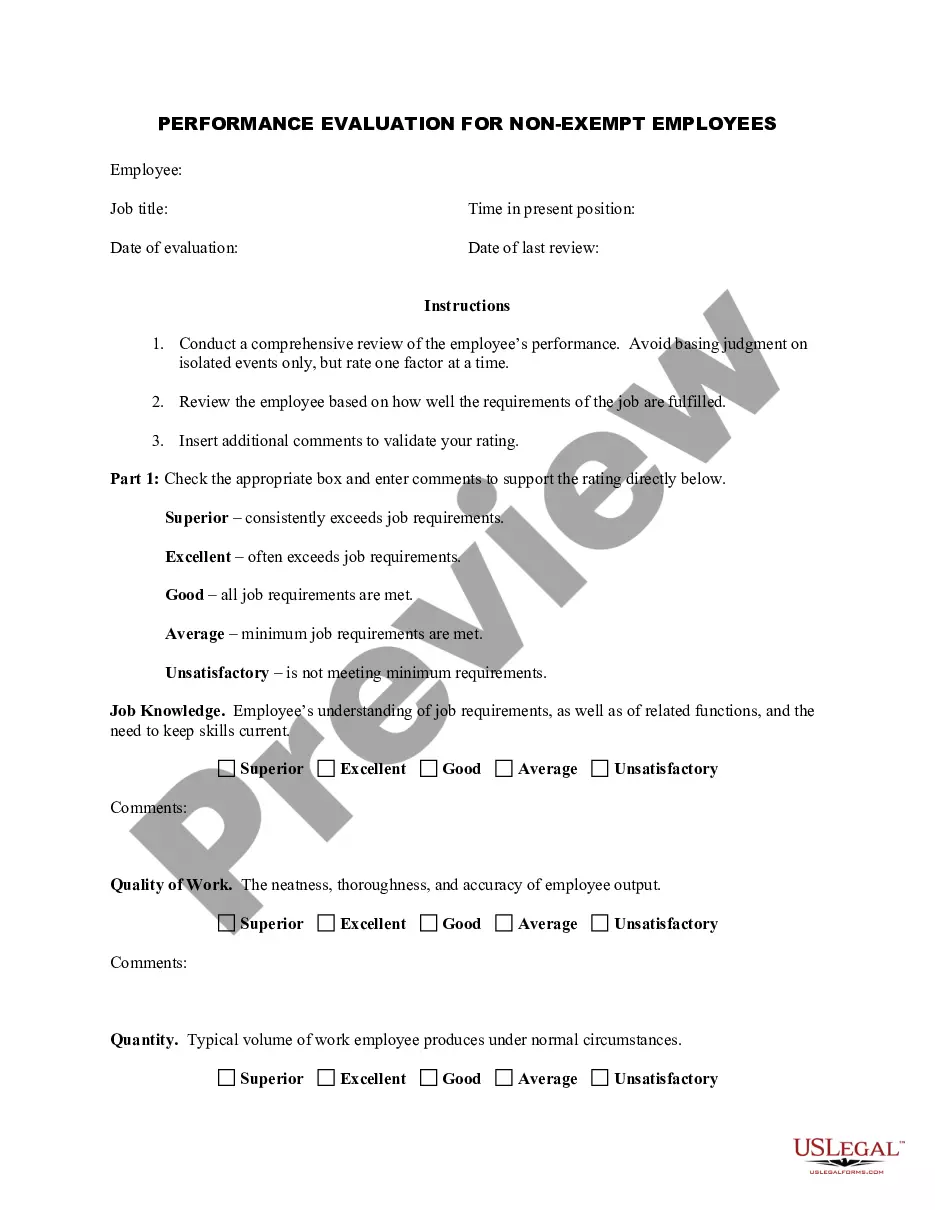

A service-level agreement (SLA) defines the level of service expected from a vendor, laying out metrics by which service is measured, as well as remedies should service levels not be achieved. It is a critical component of any technology vendor contract.

A service level agreement (SLA) is a contract between a service provider and a customer that defines the service to be provided and the level of performance to be expected. An SLA also describes how performance will be measured and approved, and what happens if performance levels are not met.

It can be gauged from the above discussion that not only are warranty and service contracts different, they also have different uses and purposes. One usually provides for coverage of manufacturing and workmanship defects, while the other provides for wide ranging defects and sometimes even for damage to the device.