Final Inspection Quality

Description

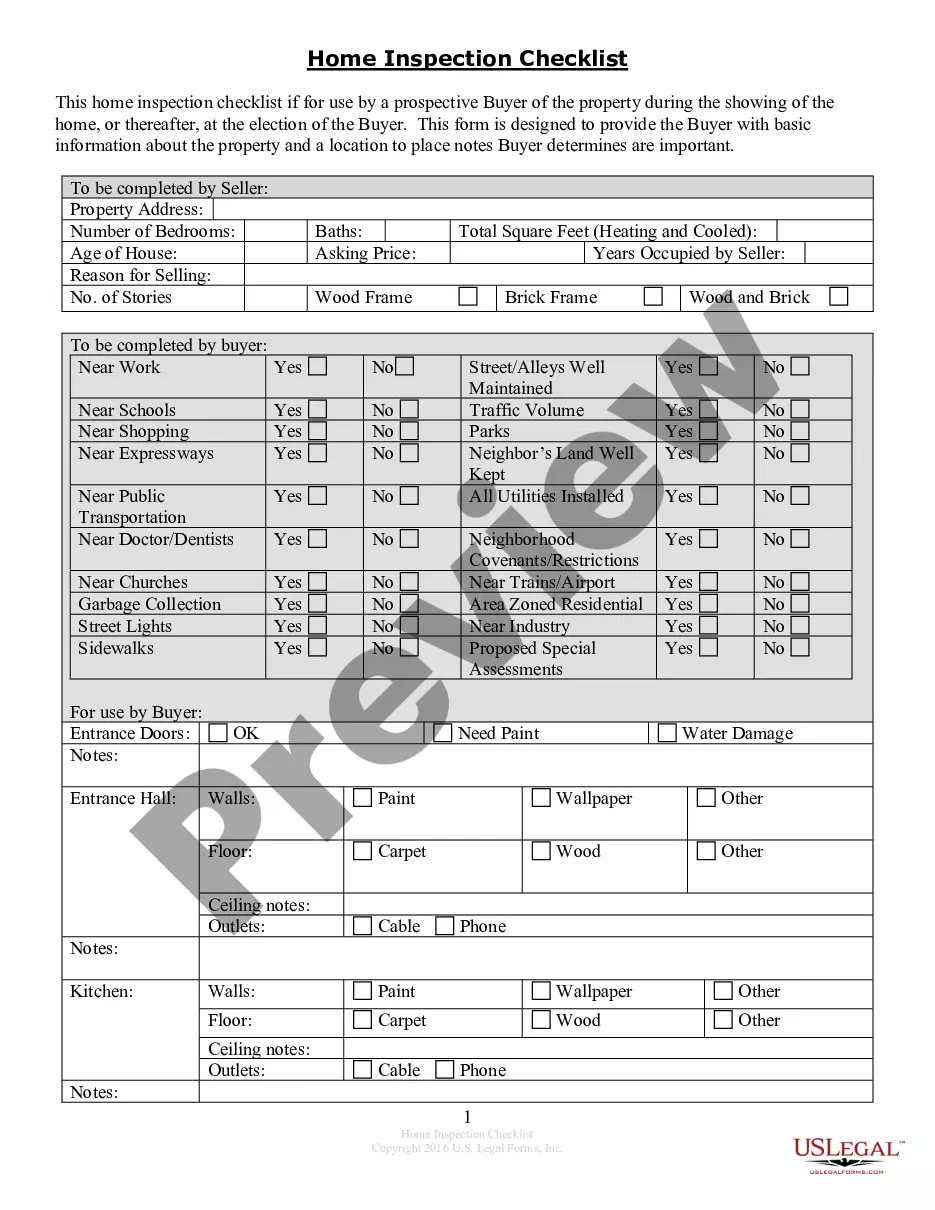

How to fill out Tennessee Buyer's Home Inspection Checklist?

- Log in to your account if you're a returning user, ensuring your subscription is active. If necessary, renew your membership as per your plan.

- For first-time users, explore the extensive collection available. Use the Preview mode to review document options, ensuring they meet your legal requirements and jurisdiction specifications.

- Utilize the search function to find alternative templates if needed. Should you encounter any discrepancies, this feature will help locate the right form quickly.

- Select your preferred plan by clicking on the Buy Now button and create an account to access the library.

- Complete your purchase process by entering your payment information via credit card or PayPal.

- Download the chosen document and save it to your device, making it accessible anytime from your My Forms section. You can now confidently complete and utilize your legal forms.

By following these steps, you'll successfully access and manage legal documents through US Legal Forms, contributing to your overall final inspection quality. Their robust library and expert assistance pave the way for efficient legal form execution.

Don't miss out on the convenience and extensive resources—visit US Legal Forms today to simplify your legal documentation!

Form popularity

FAQ

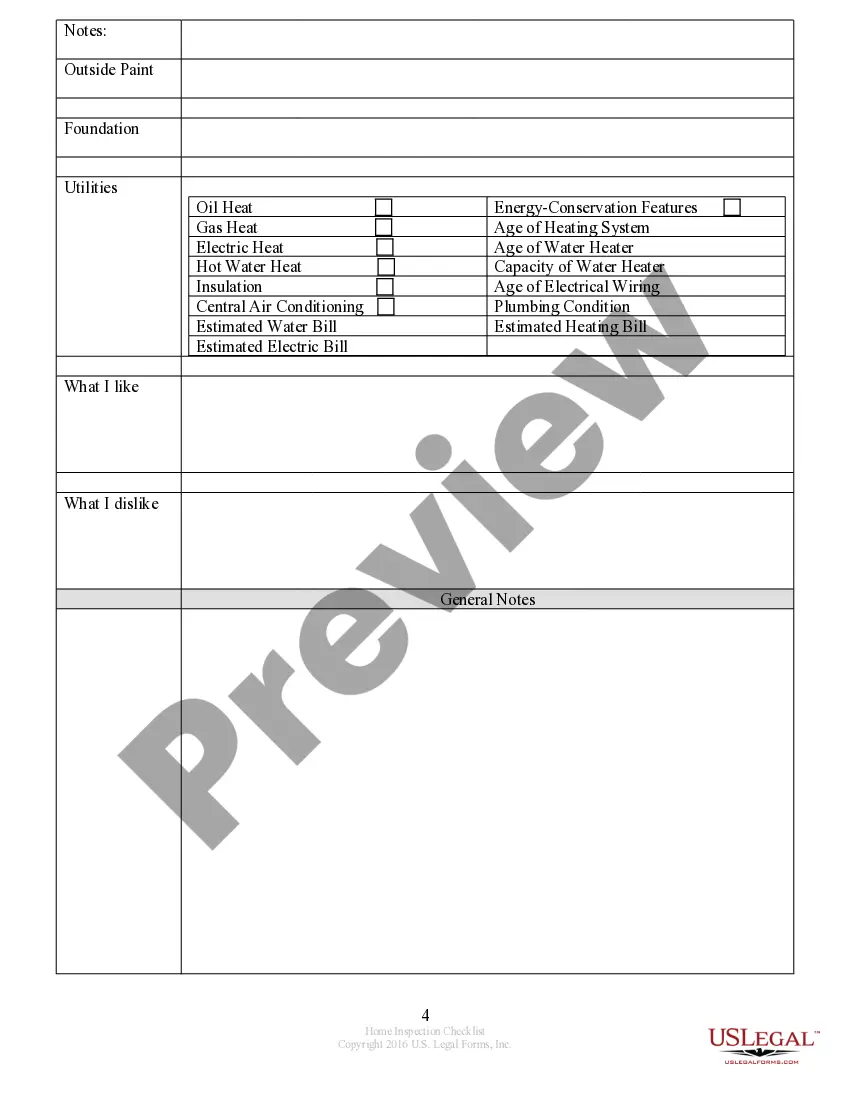

After a final inspection quality assessment, you can typically move in if the property meets all necessary standards and regulations. It is crucial to ensure that any outstanding issues have been resolved before taking possession. Consult with your local authorities or the inspection team to confirm that the property is compliant. This step will give you peace of mind knowing that your new home is safe and ready for you to enjoy.

To conduct a quality inspection, you first need to establish clear criteria based on the standards of final inspection quality. Next, you should systematically evaluate each aspect of the property, including structural integrity, safety features, and compliance with local regulations. Gathering data during this process is essential, so using checklists can help ensure no detail is overlooked. Finally, documenting your findings provides a clear picture of the property's condition, which aids you in making informed decisions.

The process of final inspection involves several key stages that ensure the property meets necessary criteria. First, an inspector will arrive on site to conduct a thorough evaluation of the property’s condition. This includes reviewing systems such as electrical, plumbing, and HVAC, as well as checking for any structural issues. Following the inspection, a detailed report will summarize the findings, promoting informed decisions regarding the final inspection quality.

The final quality check is an essential step in the inspection process that confirms the property aligns with all specified standards. It involves assessing the condition and functionality of all systems, ensuring that the final inspection quality meets or exceeds industry norms. Inspectors will document their findings, which can help identify any lingering issues that need resolution before closing. This check is vital for buyer confidence and long-term satisfaction.

A final inspection consists of a comprehensive review of the property to ensure it meets all standards and regulations. Inspectors evaluate elements like structure, systems, and finishes to verify the final inspection quality. This process not only involves checking existing features but also confirming any required corrections from previous inspections are addressed. Essential documents should be available to complete the final inspection efficiently.

Typically, a house does not need to be completely empty for a final inspection. However, clear access to key areas is crucial to ensure the inspector can thoroughly evaluate the final inspection quality. It's best to remove personal items that may obstruct views or access to necessary spaces. Ensuring a clean and orderly environment can lead to a more efficient inspection process.

The riskiest part of a home inspection often involves evaluating the roof and foundation, where hidden problems can significantly impact final inspection quality. Issues here can lead to costly repairs if not identified early. Inspectors may use specialized tools to uncover these hidden concerns. a thorough inspection could save you from unexpected expenses down the line.

A deal breaker in a home inspection typically refers to significant problems that could change your buying decision. These can include severe structural damage, major electrical issues, or signs of mold. If a home has deal breakers, it often affects the final inspection quality and your willingness to invest in the property. Always prioritize finding a home without such major concerns.

A red flag on a house indicates potential issues that may arise during a final inspection quality assessment. These issues could range from structural concerns to safety hazards. If you notice red flags, consider seeking a professional evaluation before proceeding. By addressing these concerns early, you can protect your investment.

An example of a quality check is testing finished electrical equipment to ensure it meets safety and performance standards. Inspectors may check wiring, functionality, and compliance with regulations, ensuring the manufacturer's specifications have been met. This step is integral to achieving final inspection quality.