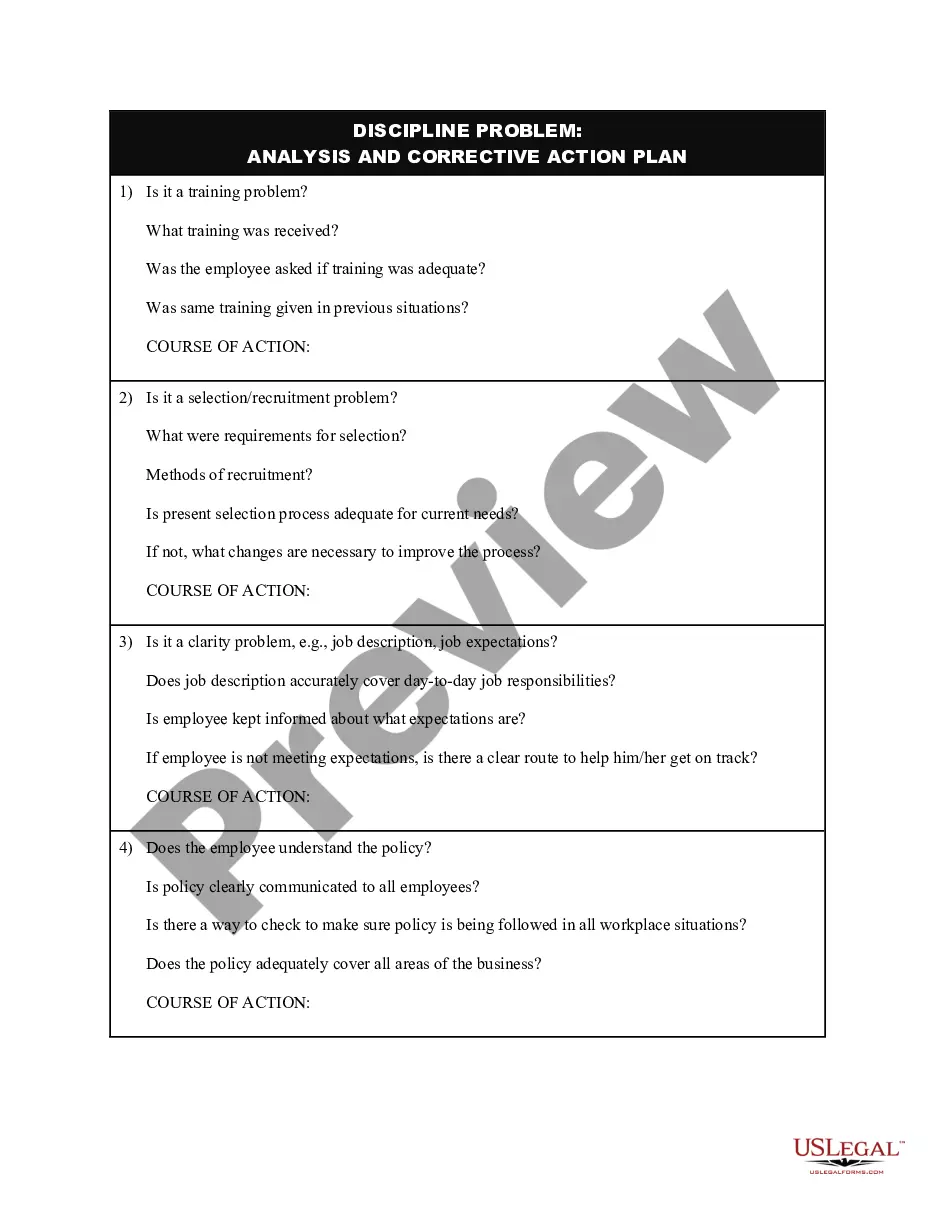

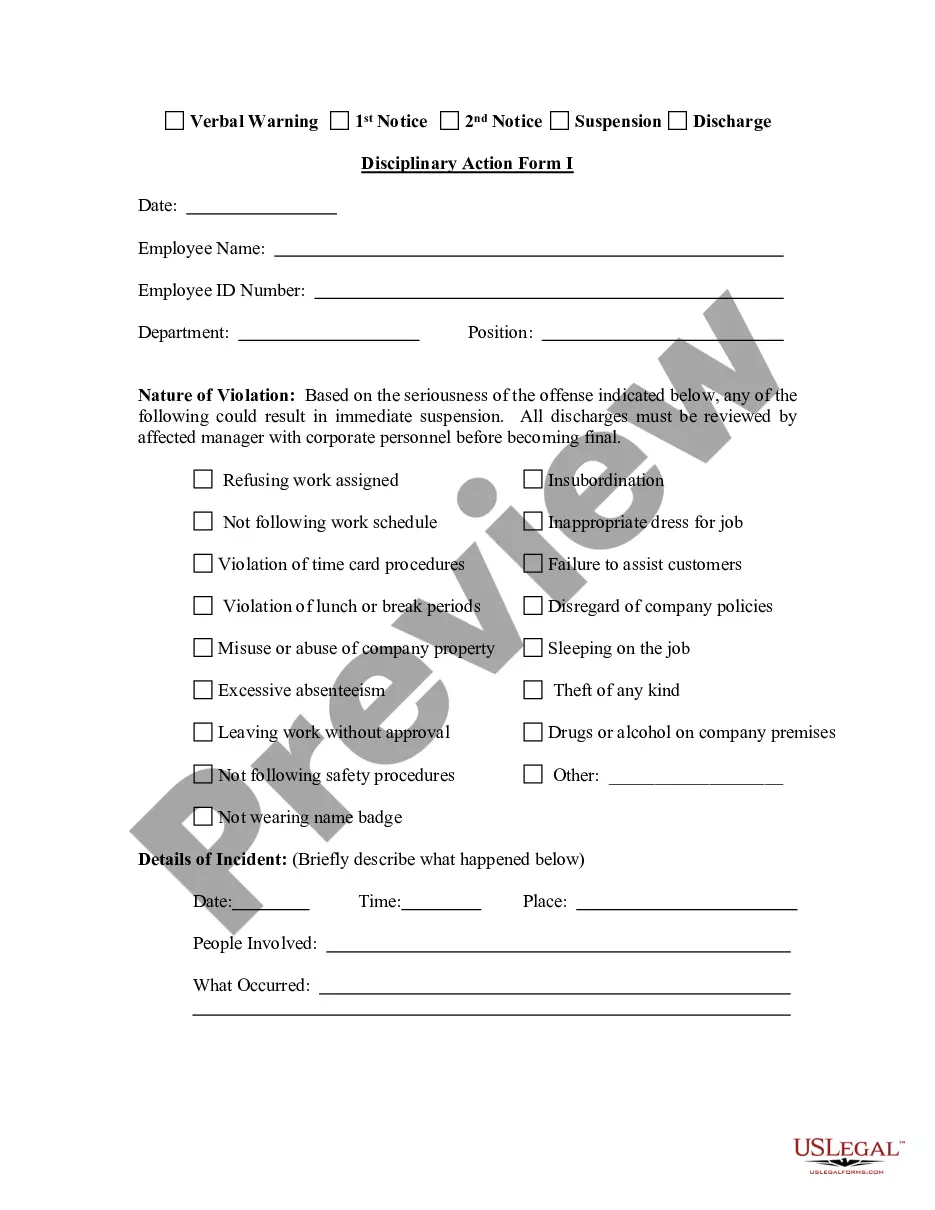

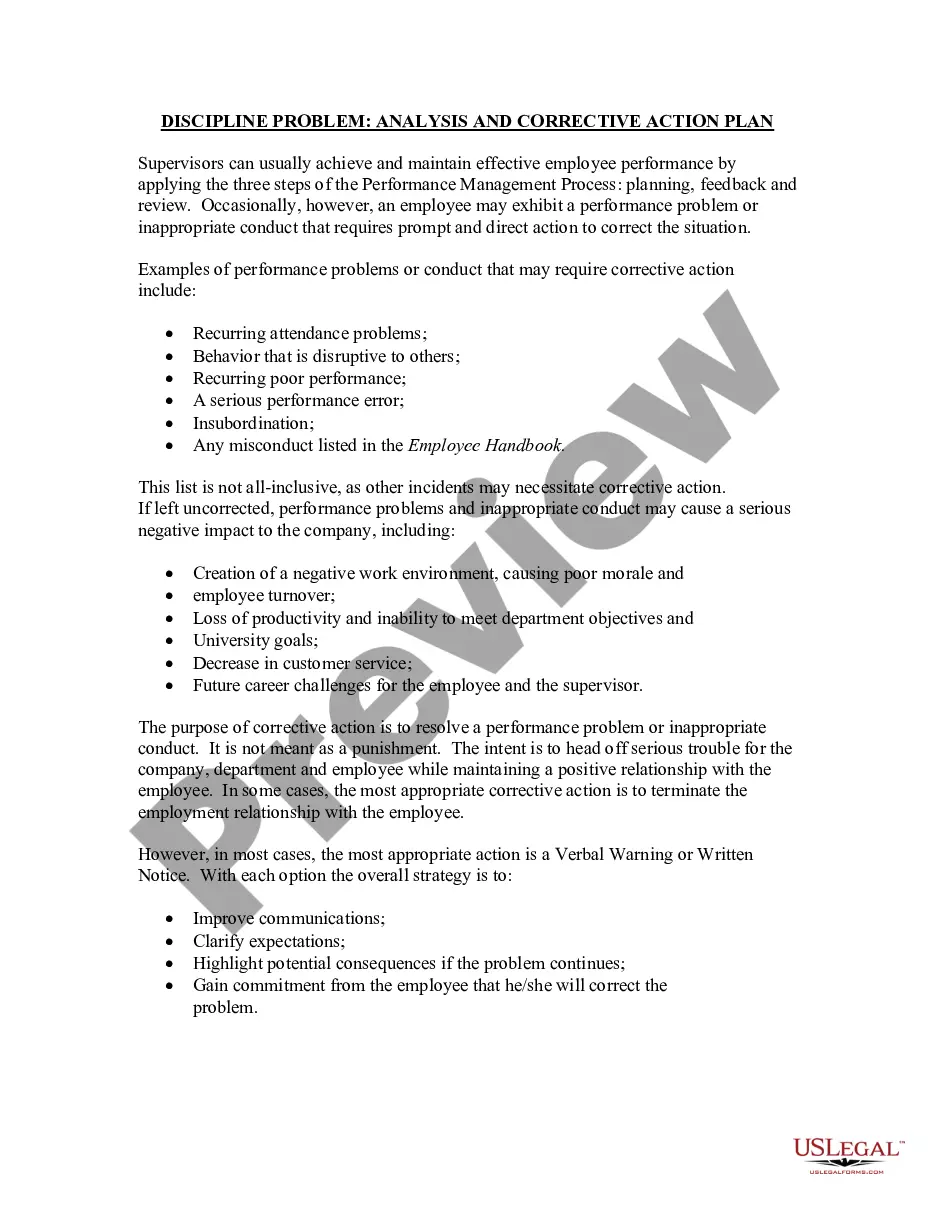

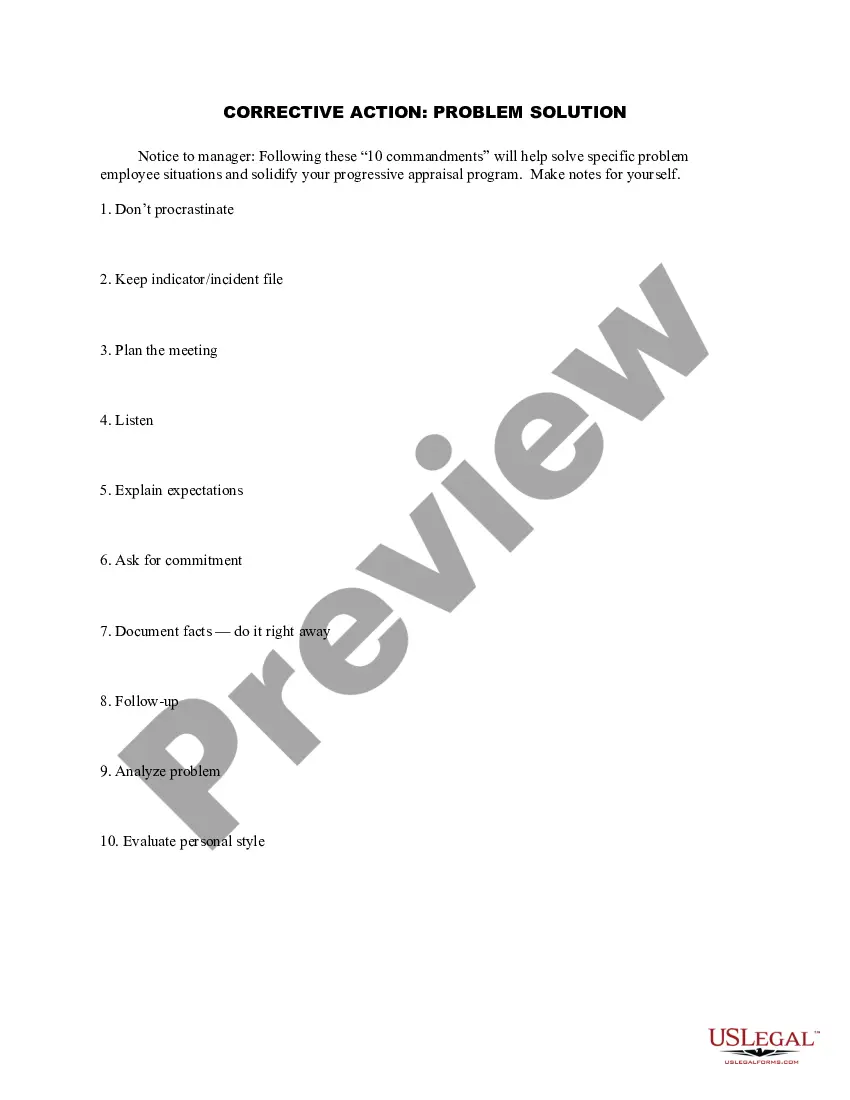

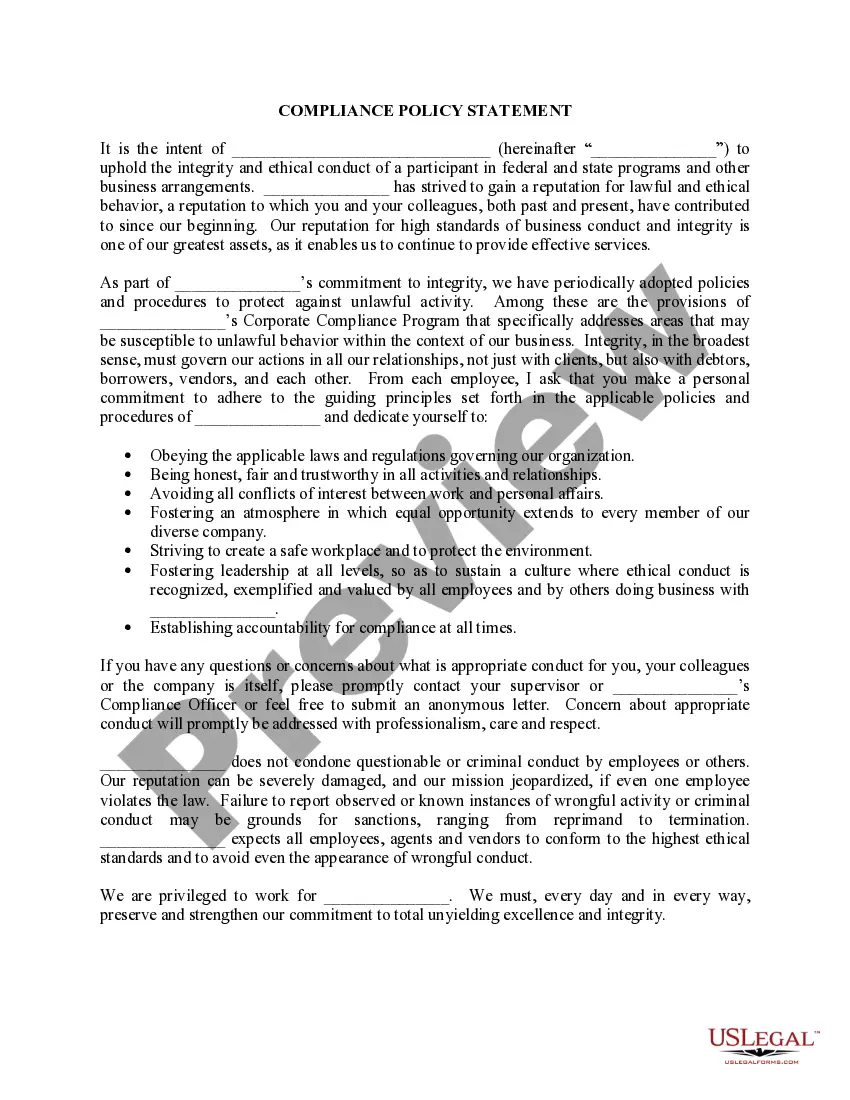

Nevada Discipline Problem - Analysis and Corrective Action Plan

Description

How to fill out Discipline Problem - Analysis And Corrective Action Plan?

You have the capability to invest time online searching for the legal document template that meets the state and federal standards you require.

US Legal Forms offers thousands of legal documents that have been reviewed by experts.

It is easy to obtain or print the Nevada Discipline Problem - Analysis and Corrective Action Plan from the service.

If available, use the Preview option to review the document template as well.

- If you already possess a US Legal Forms account, you can sign in and select the Download option.

- Then, you can complete, modify, print, or sign the Nevada Discipline Problem - Analysis and Corrective Action Plan.

- Each legal document template you buy is yours to keep for a long time.

- To get another copy of any purchased form, go to the My documents section and select the corresponding option.

- If you are using the US Legal Forms website for the first time, follow the simple instructions outlined below.

- First, ensure that you have selected the correct document template for your chosen county/area.

- Check the form description to confirm that you have chosen the right form.

Form popularity

FAQ

Your 8D report documents the below steps.Team approach.Describe the Problem.Containment Action.Root Cause Verification.Implement Corrective Action.Verify Corrective Action.Prevent Recurrence.Congratulate the Team.

8D methodology uses a structured eight step approach to problem solving. The objective is to face the problem and discover the weaknesses in the management systems that permitted the problem to occur in the first place. The output of an 8D process is an 8D report.

Ford Motor Company developed this problem solving methodology, then known as Team Oriented Problem Solving (TOPS), in the 1980s. The early usage of 8D proved so effective that it was adopted by Ford as the primary method of documenting problem solving efforts, and the company continues to use 8D today.

In the Loop (Quality Progress) An 8D report is a quality report suppliers use to inform a customer about the status of complaint-related actions. Use this refresher to help track the status of customer complaints. Adapted from Modular Kaizen: Continuous and Breakthrough Improvement, ASQ Quality Press.

The 8D methodology is a structured and systematic approach to problem-solving. From an 8D problem-solving example it's clear that it not only identifies a problem but also recognizes the weaknesses in the system. Analysis of an 8D report example prevents future occurrences of similar issues.

The Eight Steps of the 8D MethodologyD0 Plan.D1 Put Together A Team.D2 Define the Problem.D3 Implement a Temporary Fix.D4 Identify Root Causes and Chose a Solution.D5 Confirm The Solution Resolves The Problem.D6 Fully Implement the Solution.D7 Prevent Recurrence.More items...

The purpose of 8D problem solving method is to identify, correct and prevent problems affecting customers and operational efficiency. It is a problem solving approach similar to PDCA cycle (Plan Do Check Act). 8D stands for 8 Disciplines.

The 8D problem solving process is a detailed, team oriented approach to solving critical problems in the production process. The goals of this method are to find the root cause of a problem, develop containment actions to protect customers and take corrective action to prevent similar problems in the future.