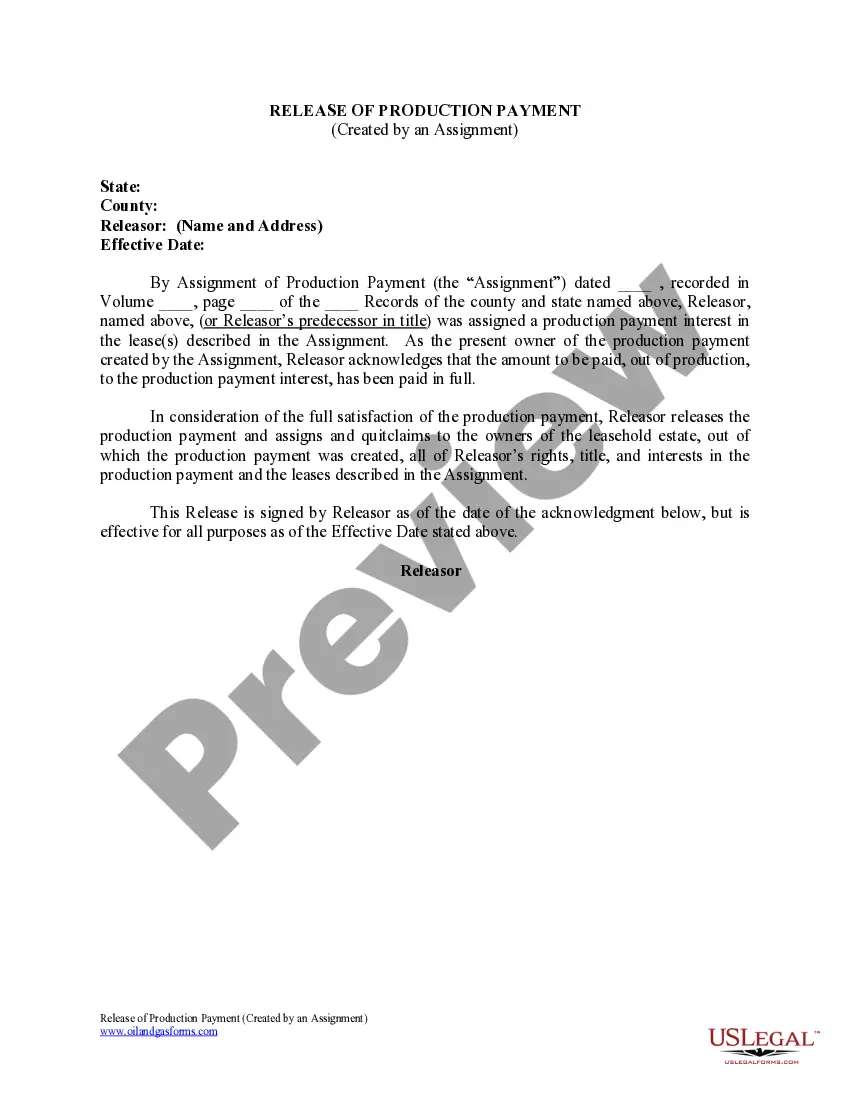

This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

New Jersey Conversion of An Oil Or Gas Well to An injection Or Water Well

Description

How to fill out Conversion Of An Oil Or Gas Well To An Injection Or Water Well?

You may spend several hours on the web looking for the legal record web template that fits the federal and state requirements you need. US Legal Forms provides a huge number of legal varieties which can be analyzed by specialists. It is possible to download or print the New Jersey Conversion of An Oil Or Gas Well to An injection Or Water Well from the assistance.

If you currently have a US Legal Forms bank account, you can log in and then click the Obtain option. After that, you can full, change, print, or indicator the New Jersey Conversion of An Oil Or Gas Well to An injection Or Water Well. Every legal record web template you purchase is yours forever. To obtain yet another backup associated with a bought develop, check out the My Forms tab and then click the related option.

If you use the US Legal Forms website initially, stick to the simple instructions listed below:

- Initially, make sure that you have chosen the proper record web template to the region/town of your choice. Browse the develop explanation to make sure you have chosen the right develop. If readily available, use the Preview option to search throughout the record web template too.

- In order to get yet another edition from the develop, use the Lookup discipline to obtain the web template that suits you and requirements.

- Upon having discovered the web template you want, simply click Buy now to proceed.

- Select the costs plan you want, enter your qualifications, and sign up for a free account on US Legal Forms.

- Full the deal. You can use your bank card or PayPal bank account to fund the legal develop.

- Select the structure from the record and download it in your product.

- Make changes in your record if needed. You may full, change and indicator and print New Jersey Conversion of An Oil Or Gas Well to An injection Or Water Well.

Obtain and print a huge number of record themes utilizing the US Legal Forms site, that provides the most important selection of legal varieties. Use specialist and condition-particular themes to take on your organization or personal requires.

Form popularity

FAQ

Injection wells utilize the earth as a filter to treat the wastewater before it reaches the aquifer. This method of wastewater disposal also serves to spread the injectate over a wide area, further decreasing environmental impacts.

Deep well injection is the process of safely storing or disposing of liquids deep underground. It involves drilling beneath drinking water aquifers (1,500 to >3,000 feet deep) to trap the liquid waste under multiple impermeable layers of rock. It requires favorable geology, so it is not suitable for all locations.

While a production well is used to extract oil or gas from the subsurface, injection wells are used to safely dispose of waste generated from those production operations or, in some cases, to increase production from nearby producing wells.

There are also some concerns as to long-lasting geologic effects of deep well injection, such as seismic activity, that have been discovered in recent years. There have also been numerous cases of deep wells failing and causing significant damage to the environment.

No fracking is permitted with deep well injections. The wells are cased, and the waste water is sent thousands of feet below the surface, usually to a sandstone, or limestone formation.

While a production well is used to extract oil or gas from the subsurface, injection wells are used to safely dispose of waste generated from those production operations or, in some cases, to increase production from nearby producing wells.

An injection well is used to place fluid underground into porous geologic formations. These underground formations may range from deep sandstone or limestone, to a shallow soil layer. Injected fluids may include water, wastewater, brine (salt water), or water mixed with chemicals.