New Hampshire Maintenance Supervisor Checklist

Category:

State:

Multi-State

Control #:

US-382EM

Format:

Word;

Rich Text

Instant download

Description

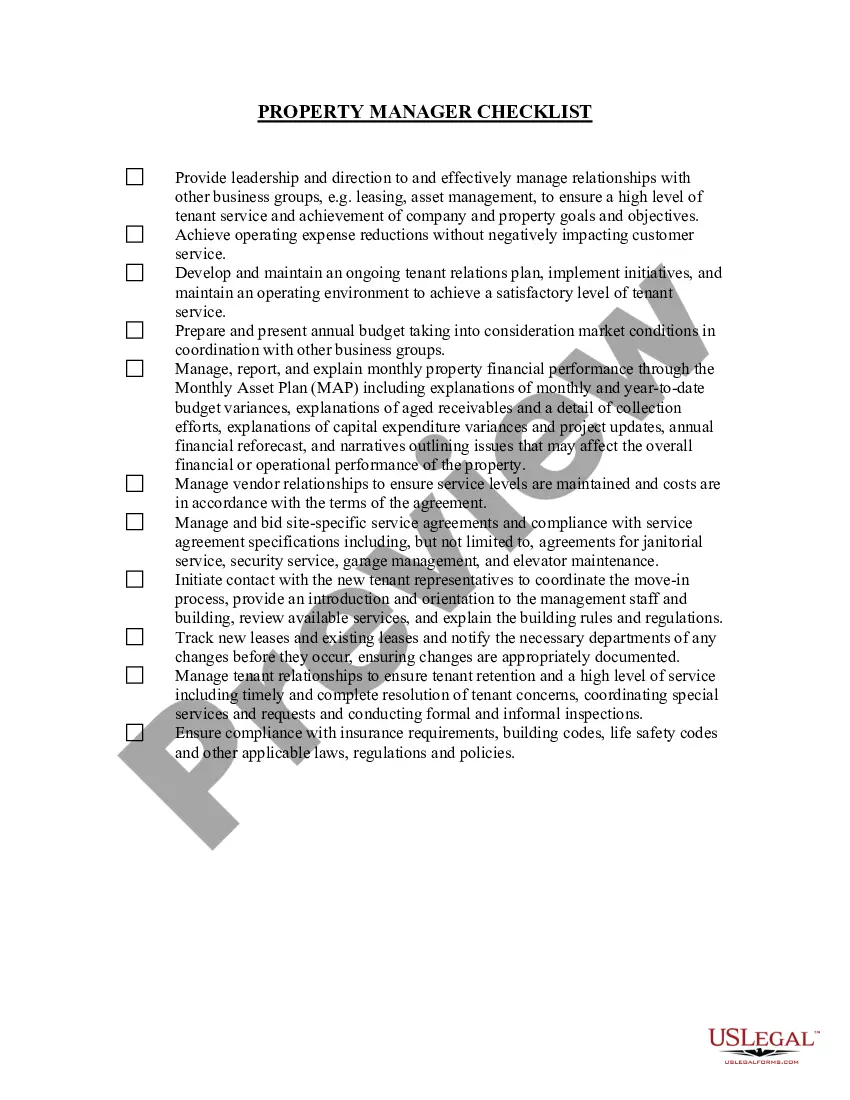

This form is used to list the potential duties of a maintenance supervisor.

How to fill out Maintenance Supervisor Checklist?

If you wish to finalize, retrieve, or print legal document templates, utilize US Legal Forms, the most extensive compilation of legal documents, accessible online.

Make use of the site's straightforward and convenient search feature to locate the files you require.

Various templates for businesses and personal purposes are organized by categories and keywords.

Step 4. Once you have found the form you need, select the Purchase now button. Choose the payment plan you prefer and enter your details to register for an account.

Step 5. Process the transaction. You may use your Visa or MasterCard or PayPal account to complete the payment.

- Employ US Legal Forms to access the New Hampshire Maintenance Supervisor Checklist with just a few clicks.

- If you are already a US Legal Forms user, sign in to your account and click the Acquire button to obtain the New Hampshire Maintenance Supervisor Checklist.

- You can also retrieve forms you previously saved in the My documents section of your account.

- For first-time users of US Legal Forms, follow the steps below.

- Step 1. Confirm you have chosen the form for the correct city/state.

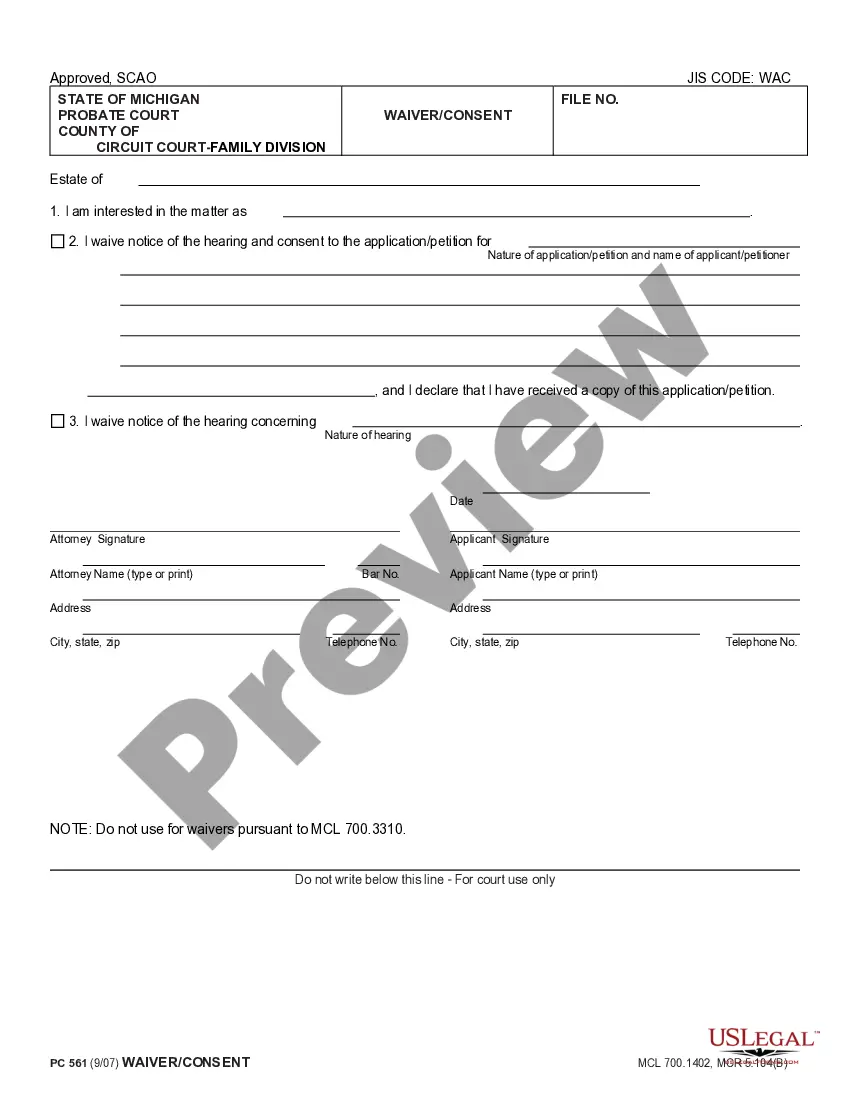

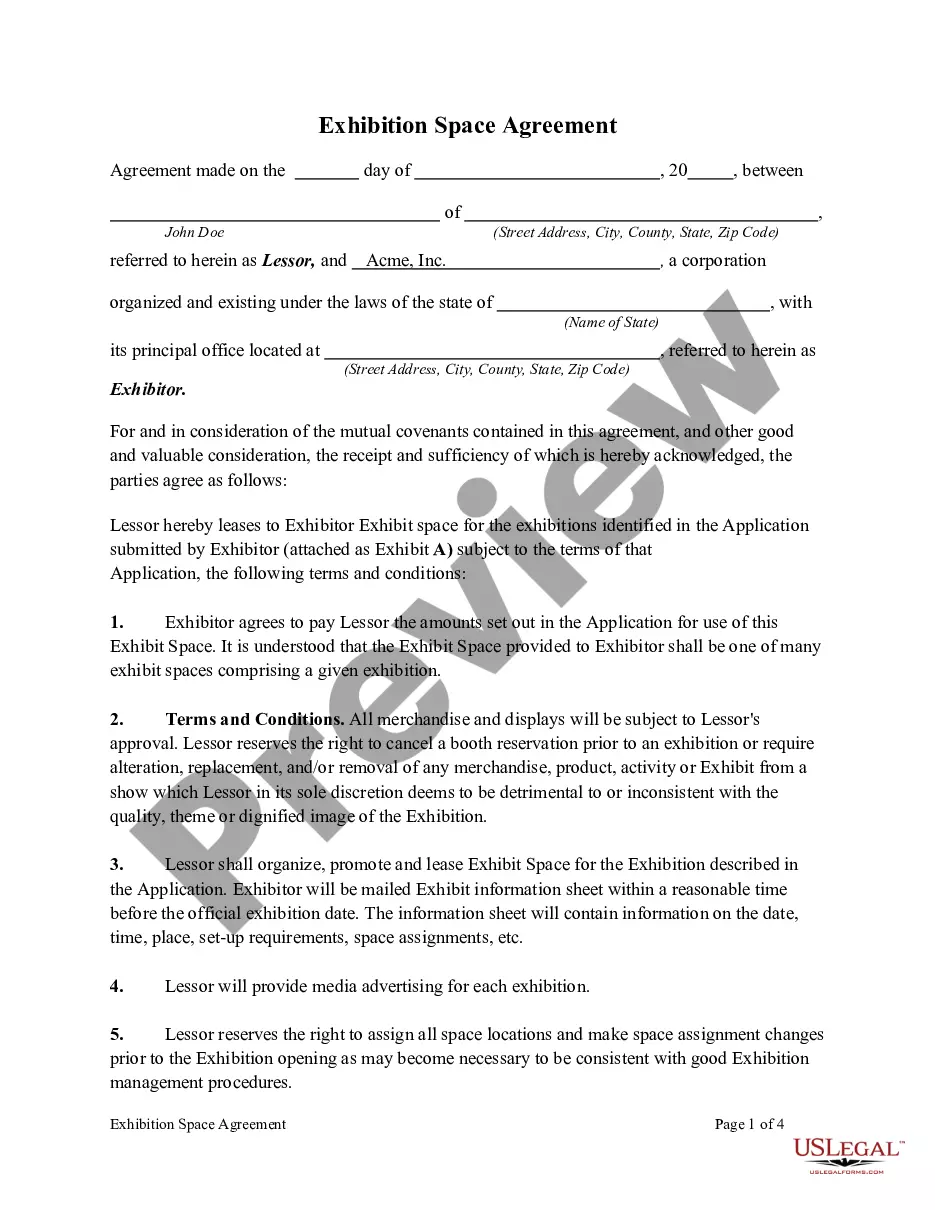

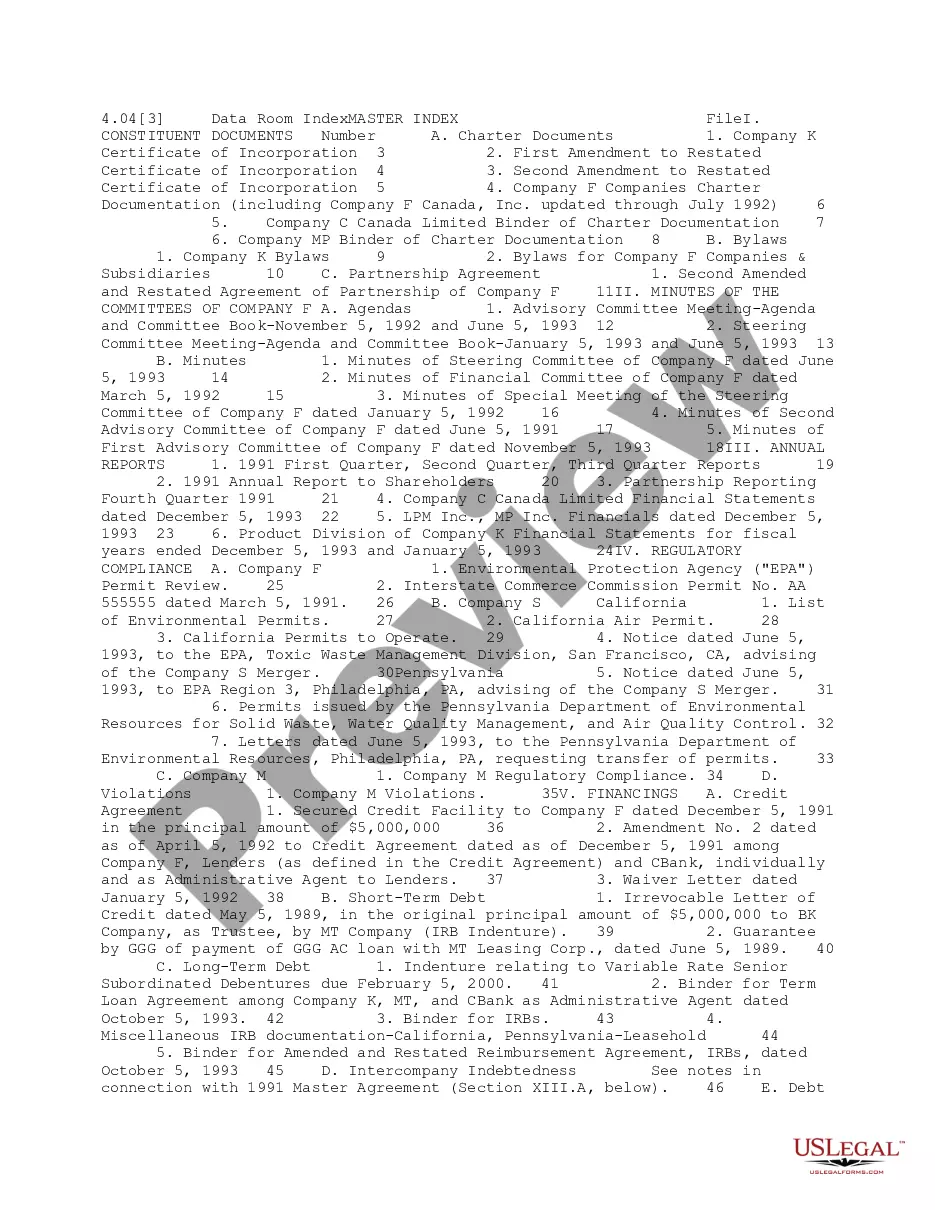

- Step 2. Use the Review option to examine the contents of the form. Be sure to read the description.

- Step 3. If you are not satisfied with the form, take advantage of the Search field at the top of the screen to discover alternative versions of the legal form template.