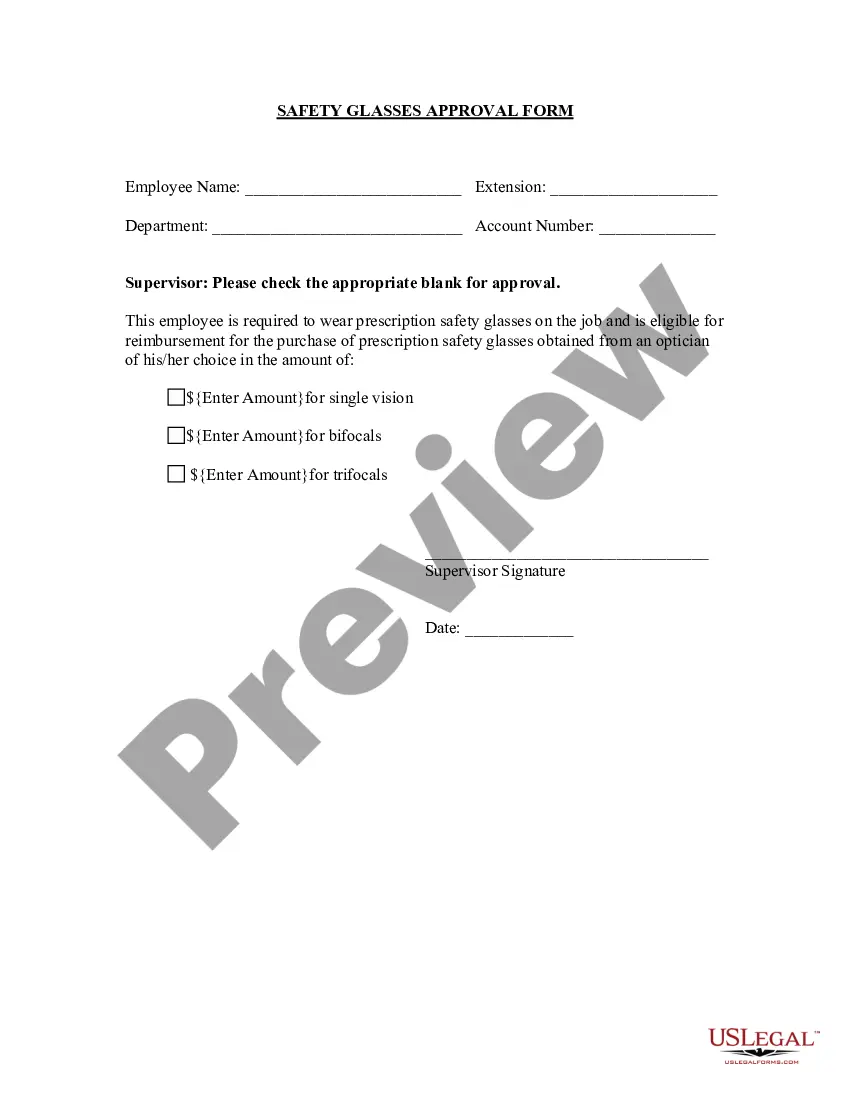

North Carolina Safety Glasses Approval Form

Description

How to fill out Safety Glasses Approval Form?

If you wish to finalize, acquire, or print authentic document templates, utilize US Legal Forms, the largest selection of legal forms available online.

Take advantage of the site’s user-friendly search feature to find the documents you need.

An assortment of templates for commercial and personal purposes are organized by categories and regions, or keywords.

- Utilize US Legal Forms to access the North Carolina Safety Glasses Approval Form with just a few clicks.

- If you are already a US Legal Forms customer, Log In to your account and click on the Download button to obtain the North Carolina Safety Glasses Approval Form.

- You can also retrieve forms you previously downloaded in the My documents section of your account.

- If this is your first time using US Legal Forms, follow the steps below.

- Step 1. Ensure you have chosen the form for the correct city/state.

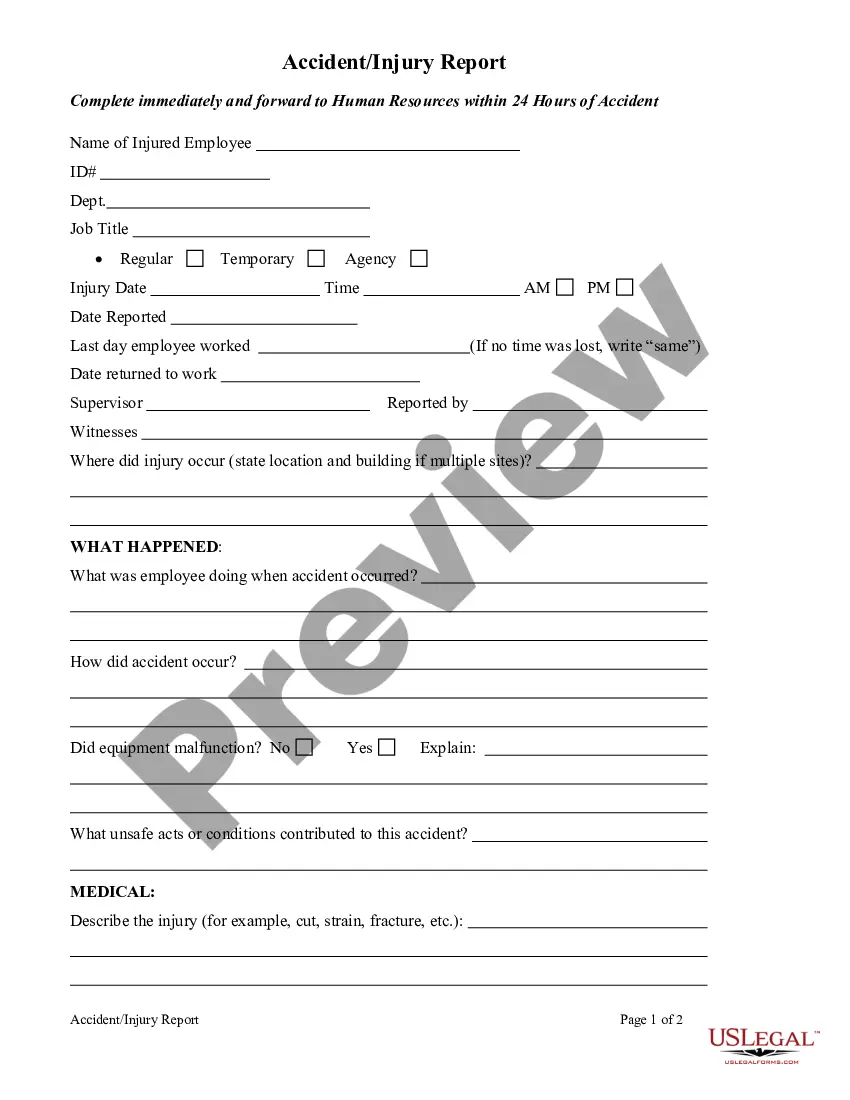

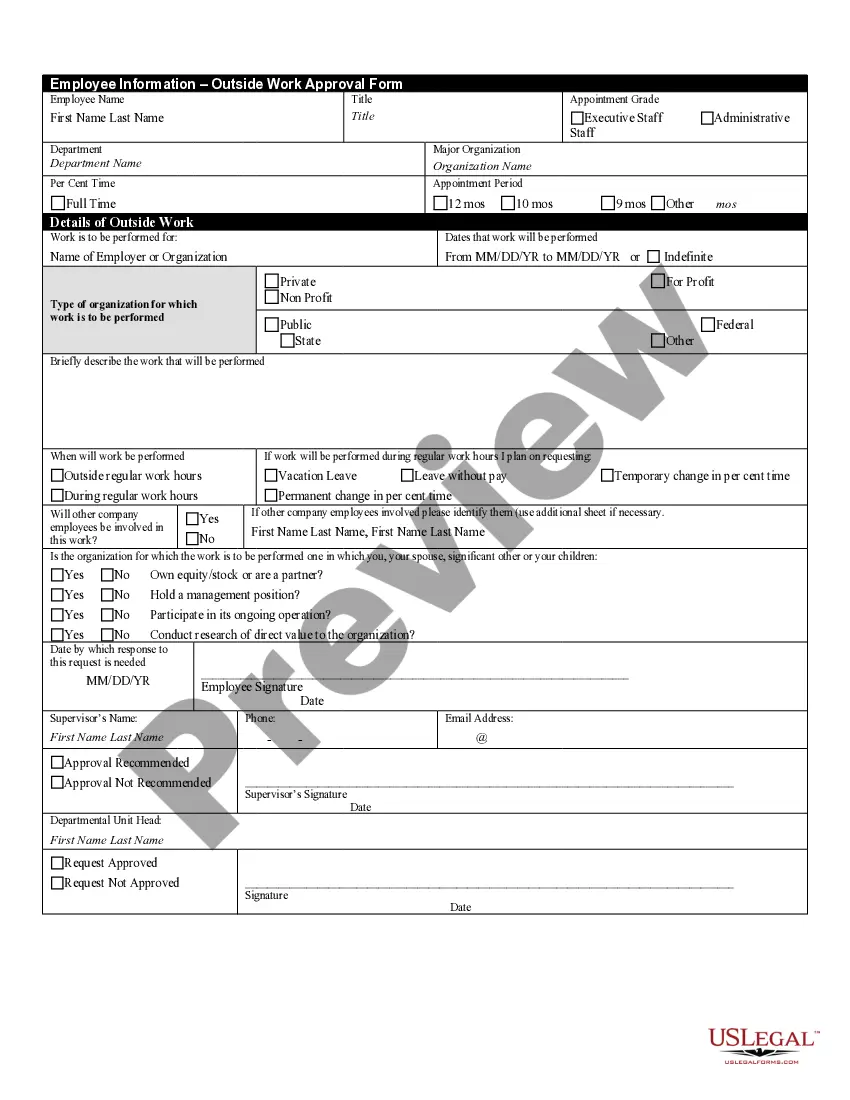

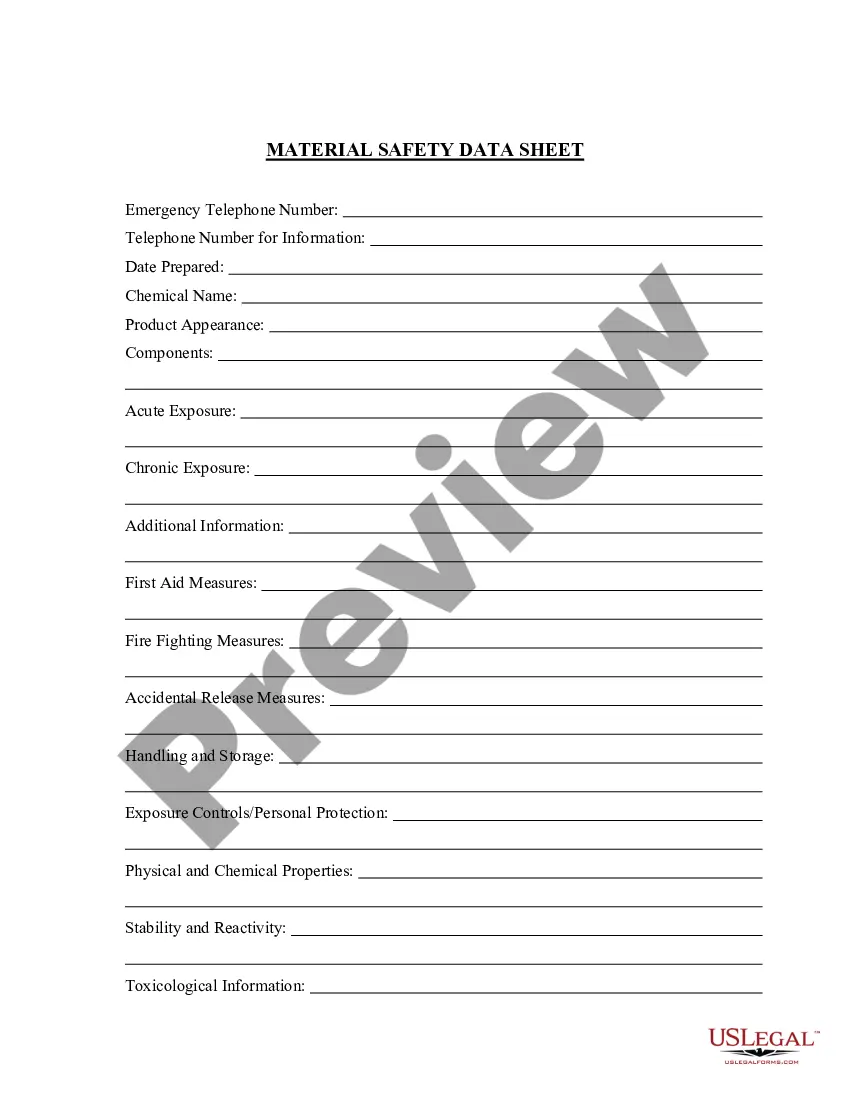

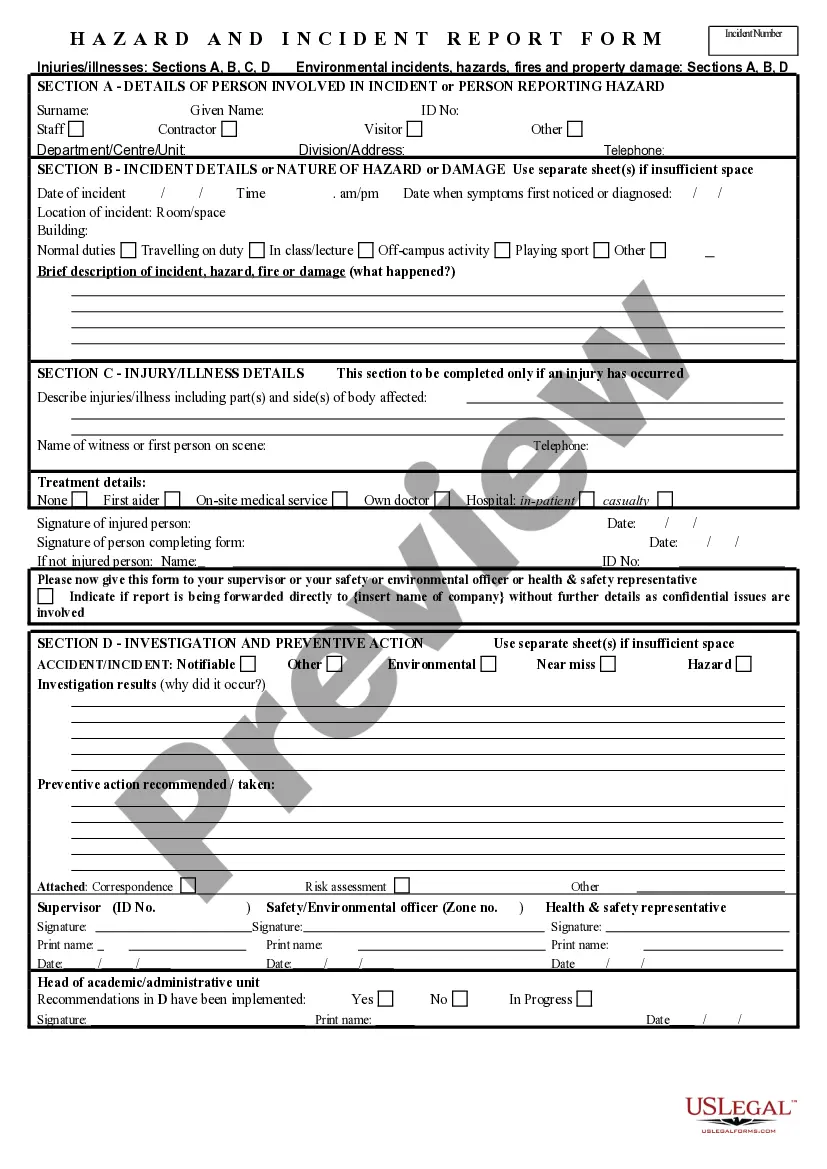

- Step 2. Use the Preview option to review the form’s content. Be sure to read the description.

- Step 3. If you are dissatisfied with the form, use the Search box at the top of the screen to find alternative forms in your desired legal form category.

- Step 4. Once you have located the form you need, click on the Buy now button. Choose the pricing plan you prefer and provide your details to register for an account.

- Step 5. Process the transaction. You can use your Visa or MasterCard or PayPal account to complete the purchase.

- Step 6. Select the format of your legal form and download it to your device.

- Step 7. Complete, edit, and print or sign the North Carolina Safety Glasses Approval Form.

- Every legal document template you acquire is yours indefinitely. You have access to every form you downloaded within your account. Navigate to the My documents section and select a form for printing or redownloading.

- Compete and download, and print the North Carolina Safety Glasses Approval Form with US Legal Forms. There are millions of professional and state-specific forms available for your commercial or personal needs.

Form popularity

FAQ

The first marking you'll likely see on your eyewear is Z87 or Z87+. This is the ANSI standard for impact which helps ensure safety eyewear provides workers with the needed protection from impact hazards. For safety eyewear to pass the basic Z87 standard, it must pass the ball drop test.

§1910.133(a)(3), OSHA requires that eye protection must comply with either of two consensus standards incorporated by reference in OSHA's eye protection standard at A§1910.133(b). These are Occupational and Educational Personal Eye and Face Protection Devices, ANSI Z87. 1-. 1989 and ANSI Z87.

CSA Z94. 3-15 covers Eye and Face Protectors including safety glasses, safety goggles, welding helmets and face shields.

The ANSI Z87. 1 certified safety glasses are tested extensively according to these hazards to assess their safety and performance in the workplace. Testing can involve primary and high impact tests for lenses and frames, exposure to non-ionizing radiation and chemicals, and durability to flame and corrosion.

ANSI, the American National Standards Institute creates the standard that safety eyewear must live up to. One of the most important classifications consumers look for in their safety glasses is the ANSI Z87 certification rating.

Do I Need OSHA Prescription Safety Glasses? If you are working in an environment that may be hazardous to your eyes, you are required to have OSHA approved safety glasses or goggles. Additionally, if you need corrective lenses, you must be wearing some form of prescription lenses.

If eye protection is required at a work site and a worker wishes to use prescription eyewear, subsection 229(2) of the OHS Code requires that the eyewear be approved to (a) CSA Standard Z94.

To be compliant with ANSI Z87. 1 standards, safety glasses must be tested for non-impact-rated or impact-rated lenses and frames, as well as exposure to non-ionizing radiation and chemicals. Safety glasses are also tested for ignition and corrosion.

If the glasses are safety-approved according to ANSI or other standards, they will be stamped. By stamped, we mean that you will see on the frame or lens whether it meets certain safety standards. Looking at the Wiley X Gravity glasses, for instance, you will note that they are ANSI Z87. 2 safety approved.

Part of OSHA's rules is that the glasses need to be clearly indicated whether they are approved or not. You can check the lens to determine if they meet Z87. 1 or not. Keep in mind that the standard is complex and covers protection from impacts, dust particles and more.