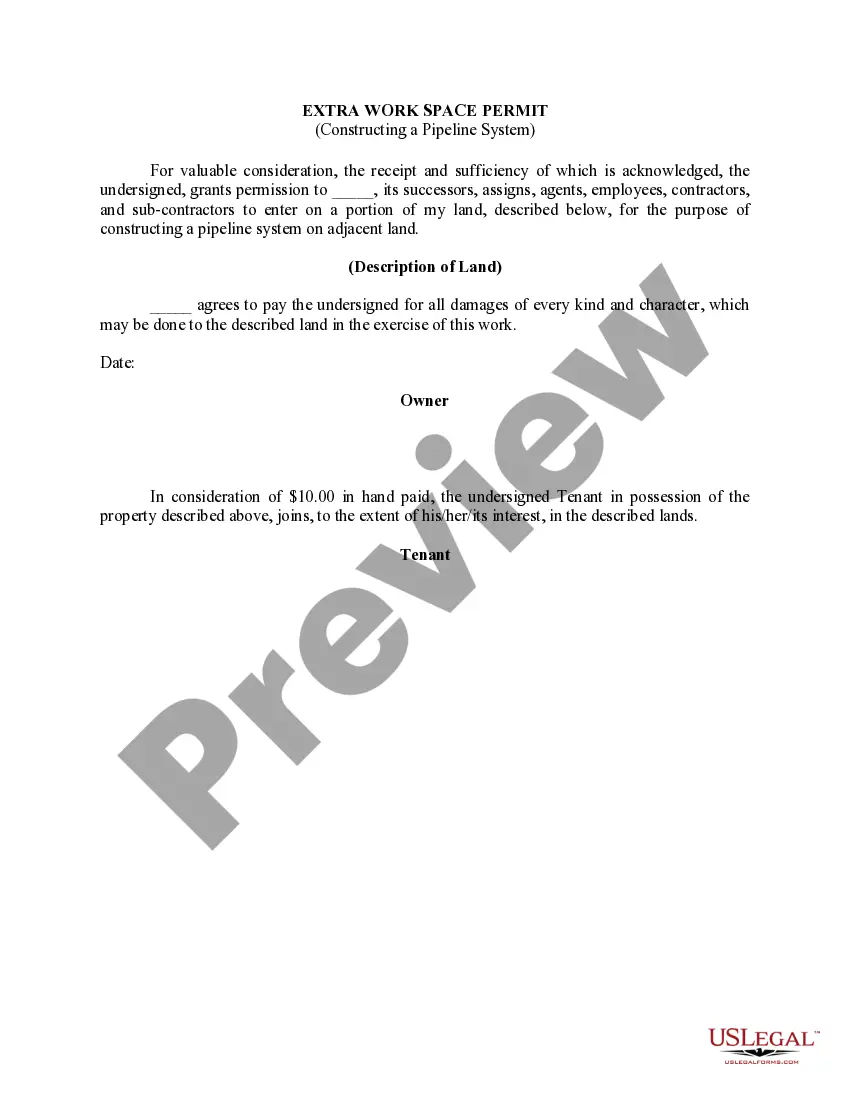

Massachusetts Extra Work Space Permit (Constructing a Pipeline System)

Description

How to fill out Extra Work Space Permit (Constructing A Pipeline System)?

It is possible to spend hours on the web searching for the legitimate document template that meets the federal and state specifications you will need. US Legal Forms gives a large number of legitimate forms that happen to be analyzed by experts. You can actually download or produce the Massachusetts Extra Work Space Permit (Constructing a Pipeline System) from the services.

If you already possess a US Legal Forms profile, you are able to log in and click the Obtain button. Next, you are able to full, revise, produce, or indicator the Massachusetts Extra Work Space Permit (Constructing a Pipeline System). Every legitimate document template you acquire is the one you have permanently. To get one more version associated with a purchased develop, proceed to the My Forms tab and click the related button.

If you are using the US Legal Forms site for the first time, stick to the simple guidelines listed below:

- Initial, make certain you have chosen the right document template for your area/town that you pick. Look at the develop explanation to make sure you have picked the proper develop. If available, take advantage of the Review button to appear from the document template too.

- In order to discover one more model from the develop, take advantage of the Research field to discover the template that suits you and specifications.

- Once you have located the template you would like, click on Acquire now to proceed.

- Pick the prices prepare you would like, key in your qualifications, and sign up for your account on US Legal Forms.

- Complete the purchase. You can utilize your credit card or PayPal profile to cover the legitimate develop.

- Pick the format from the document and download it to your gadget.

- Make modifications to your document if required. It is possible to full, revise and indicator and produce Massachusetts Extra Work Space Permit (Constructing a Pipeline System).

Obtain and produce a large number of document web templates while using US Legal Forms web site, that offers the biggest variety of legitimate forms. Use expert and condition-specific web templates to tackle your company or personal requires.

Form popularity

FAQ

Pipe laying progresses with the lay vessel moving forward on its anchors. The pipe is placed on the seabed in a controlled S-bend shape. The curvature in the upper section, or the overbend, is controlled by a supporting structure, called a stinger, that is fitted with rollers to minimize damage to the pipe.

Pipelines cross existing roads, highways, streams, rivers and wetlands. Typically, pipelines are constructed underneath these obstacles by either boring for shallow depth or using horizontal directional drilling (HDD) for deeper placement.

The process includes various stages, such as planning, excavation, pipe placement, jointing, and backfilling. Careful consideration is given to factors like pipe materials, diameter, route selection, and connectivity to ensure the longevity and effectiveness of the water supply infrastructure.

Construction includes: weld the pipe pieces together (every weld is inspected using X-ray or ultrasound); lower the welded pipe into place in the trench; valves and fittings, including remote sensors to monitor pipeline pressure, flow rate and temperature ? valves can quickly shut down a pipeline in case of ...

Constructing a process piping system typically involves: Pipe routing design and implementation. The piping system should be designed to efficiently route materials to the necessary locations. It also requires the proper implementation of pipes and components.

Massachusetts Home Repairs that Require a Permit Removal of Walls. Re-wiring of Electrical. Plumbing Updates. HVAC Replacement. Replacement of Kitchen Cabinets. Exterior Siding Work (Including Painting)

A pipeline is a system that consists of pipes, fittings (valves and joints), pumps (compressors or blowers in the case of gas pipelines), booster stations (i.e., intermediate pumping stations placed along the pipeline to house pumps or compressors), storage facilities connected to the pipe, intake and outlet structures ...

Phases of Pipeline Construction: An Overview Route Selection. Pipelines routes avoid populated areas, when possible. ... Regulatory Process. Onsite inspection occurs frequently. ... Design. ... Pipe Fabrication. ... Site Preparation. ... Pipe Stringing. ... Trenching. ... Bending.