California Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

Have you found yourself in a situation where you need documents for either business or personal purposes every day.

There are many legal document templates available online, but finding reliable ones can be challenging.

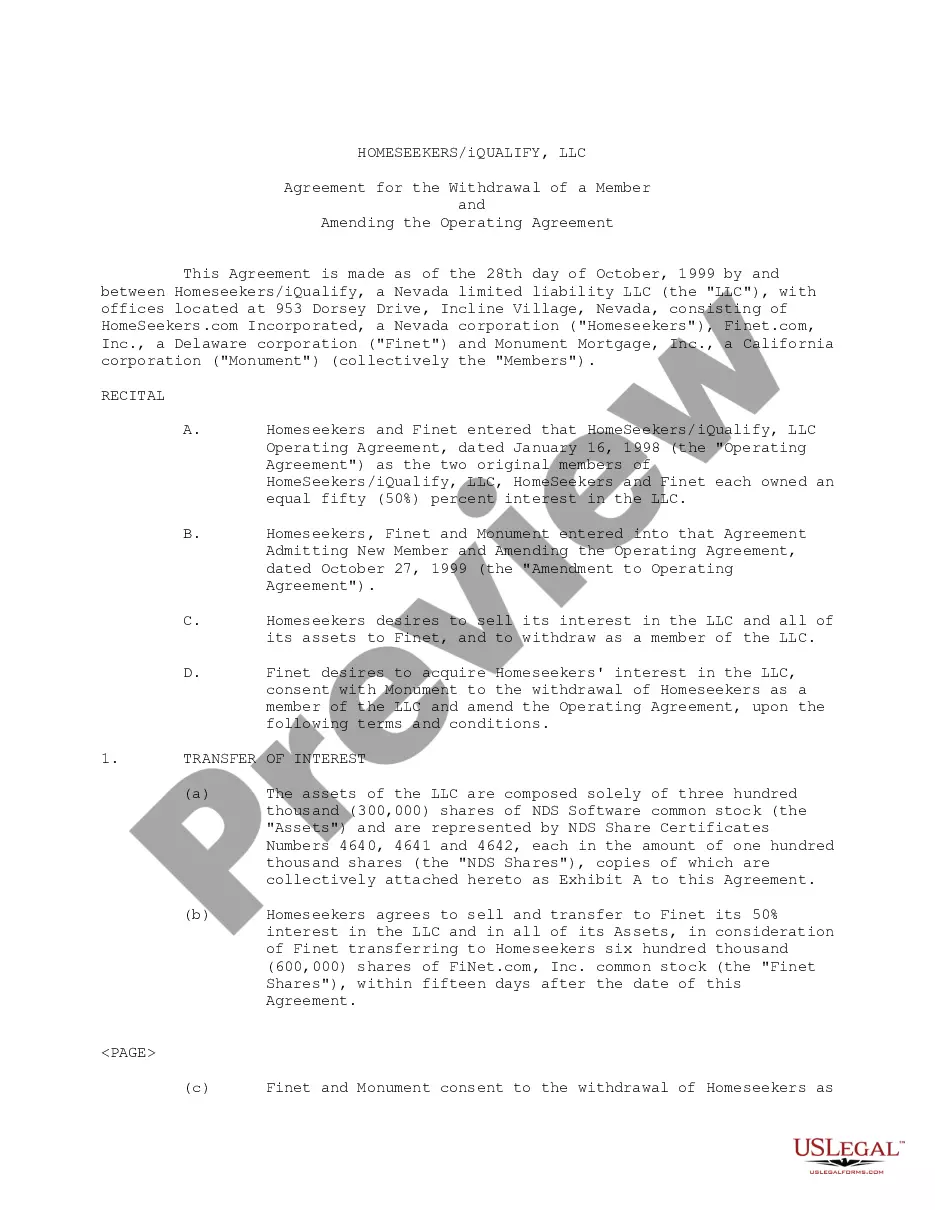

US Legal Forms provides a vast array of form templates, like the California Aseptic Techniques, designed to comply with federal and state regulations.

Once you have the right form, click Download now.

Choose your desired pricing plan, fill out the required information to create your account, and complete the purchase using your PayPal or credit card. Select a convenient document format and download your copy. You can access all the document templates you have purchased in the My documents section. You can acquire another copy of California Aseptic Techniques at any time if needed. Click on the desired form to download or print the document template. Use US Legal Forms, the most extensive collection of legal forms, to save time and avoid mistakes. The service offers properly crafted legal document templates for various purposes. Create an account on US Legal Forms and start simplifying your life.

- If you are already familiar with the US Legal Forms website and have an account, simply Log In.

- After that, you can download the California Aseptic Techniques template.

- If you do not have an account and wish to start using US Legal Forms, follow these steps.

- Select the form you need and ensure it's for the correct city/state.

- Use the Preview button to view the form.

- Read the description to confirm you have selected the right form.

- If the form is not what you're looking for, utilize the Search field to find the form that meets your needs.

Form popularity

FAQ

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)

Healthcare professionals use aseptic technique when they are:performing surgical procedures.performing biopsies.dressing surgical wounds or burns.suturing wounds.inserting a urinary catheter, wound drain, intravenous line, or chest tube.administering injections.using instruments to conduct a vaginal examination.More items...?08-Nov-2018

Procedures that involve aseptic technique include:200cInserting PICC lines.200cPerforming dialysis.200cInserting catheters.200cRunning IVs.200cInserting chest tubes.200cPerforming surgeries.200cDressing wounds.

Aseptic techniques include:Wiping bench with disinfectant/alcohol. Not growing microorganisms at body temperature. Using sterile loops when transferring cultures . Flaming culture bottle necks to prevent contamination. Sterilising (using an autoclave ) or disposing of all used equipment.

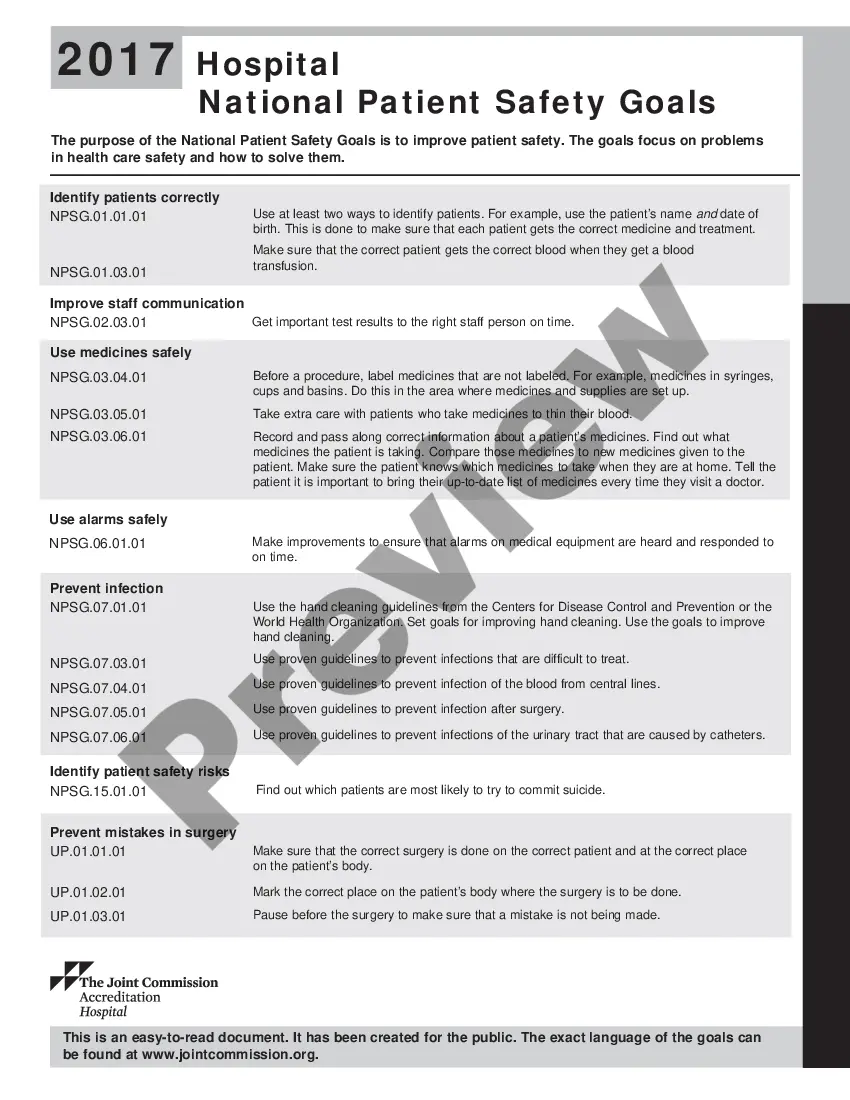

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.