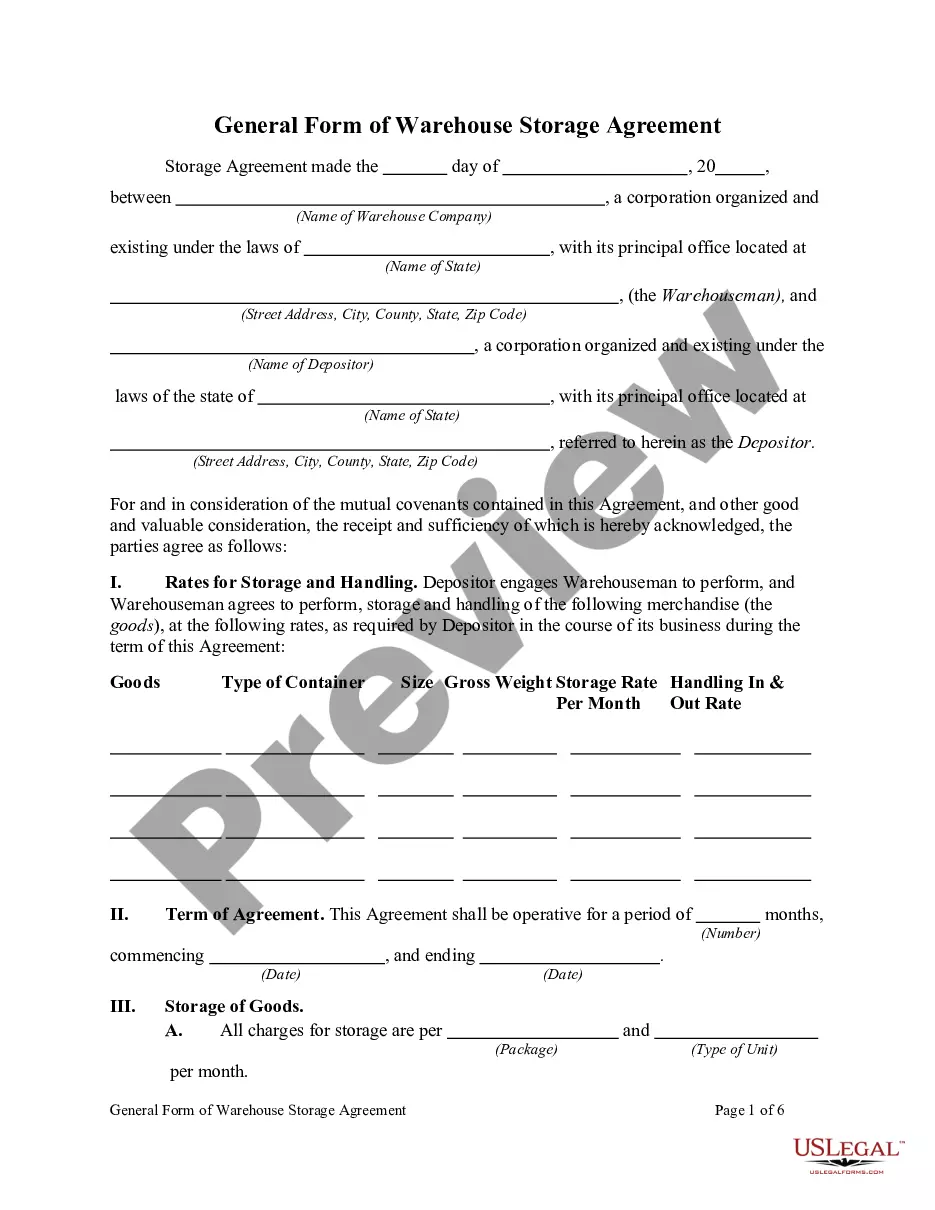

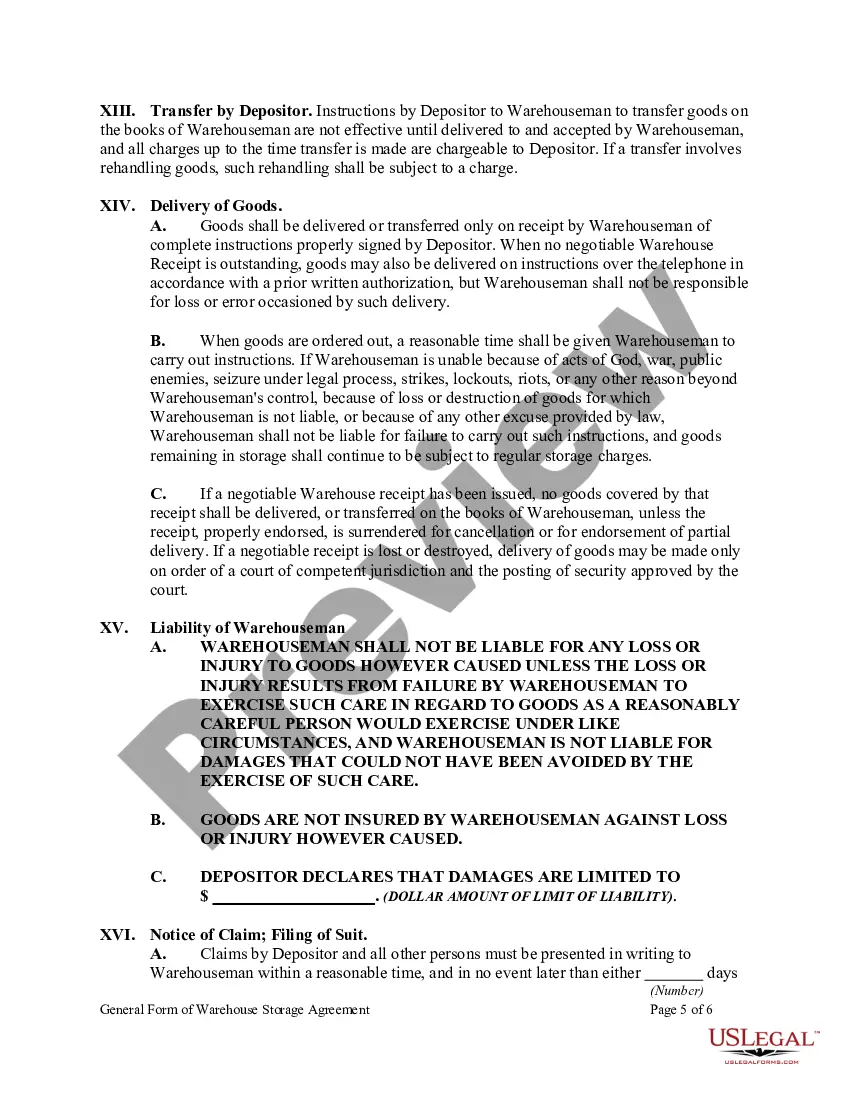

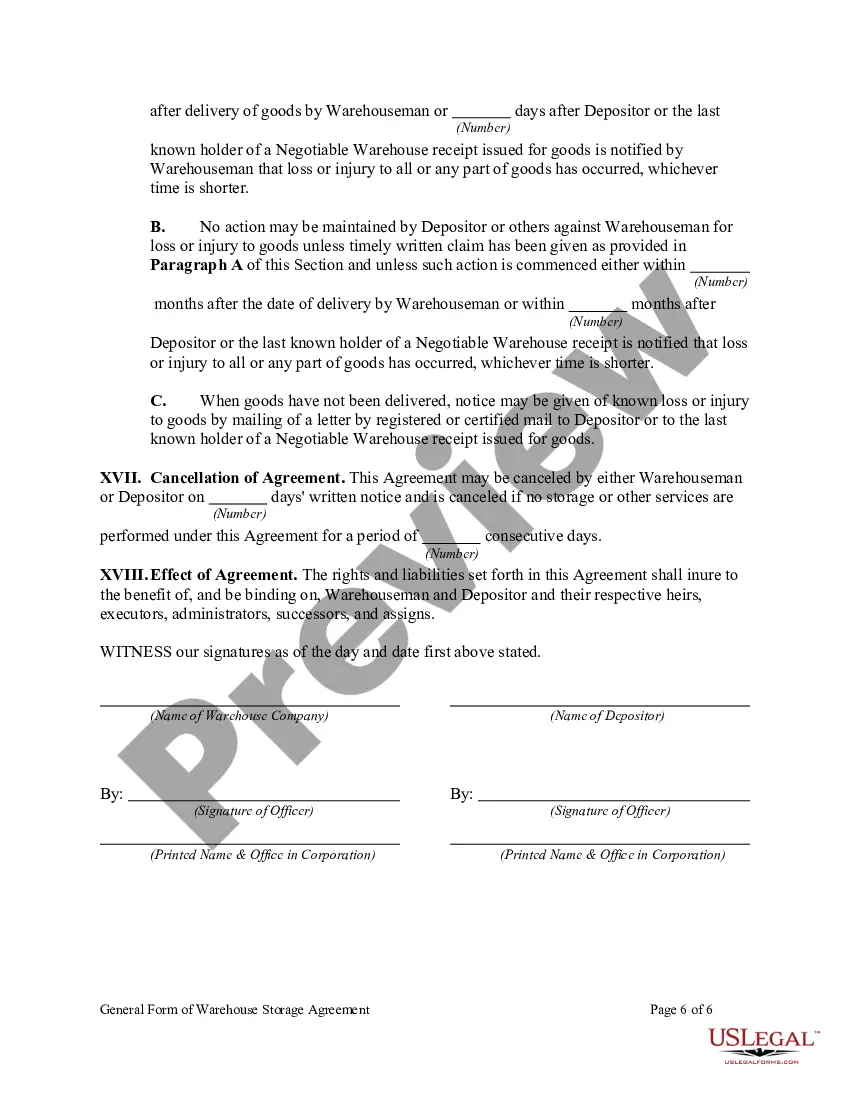

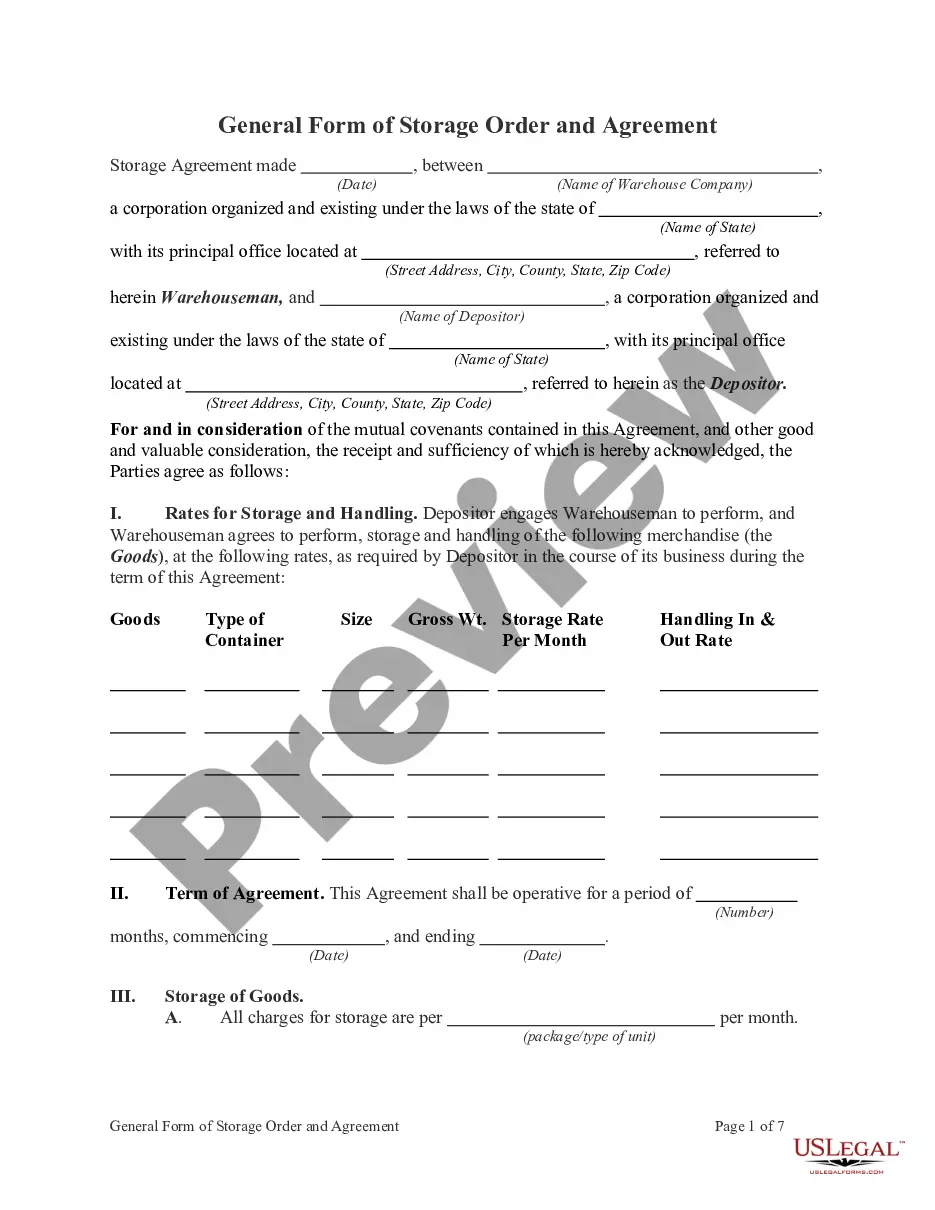

Warehouse Storage Charges

Description

How to fill out General Form Of Warehouse Storage Agreement?

Whether for business purposes or for individual affairs, everybody has to handle legal situations at some point in their life. Completing legal papers demands careful attention, beginning from choosing the correct form template. For example, if you select a wrong edition of the Warehouse Storage Charges, it will be rejected once you submit it. It is therefore important to get a reliable source of legal papers like US Legal Forms.

If you need to get a Warehouse Storage Charges template, stick to these simple steps:

- Find the sample you need by using the search field or catalog navigation.

- Look through the form’s description to make sure it matches your case, state, and county.

- Click on the form’s preview to view it.

- If it is the wrong document, get back to the search function to find the Warehouse Storage Charges sample you need.

- Get the file if it matches your needs.

- If you have a US Legal Forms profile, just click Log in to gain access to previously saved documents in My Forms.

- If you don’t have an account yet, you can download the form by clicking Buy now.

- Select the proper pricing option.

- Complete the profile registration form.

- Select your payment method: you can use a credit card or PayPal account.

- Select the document format you want and download the Warehouse Storage Charges.

- After it is saved, you can complete the form by using editing software or print it and finish it manually.

With a substantial US Legal Forms catalog at hand, you do not need to spend time searching for the appropriate sample across the internet. Make use of the library’s simple navigation to find the right form for any occasion.

Form popularity

FAQ

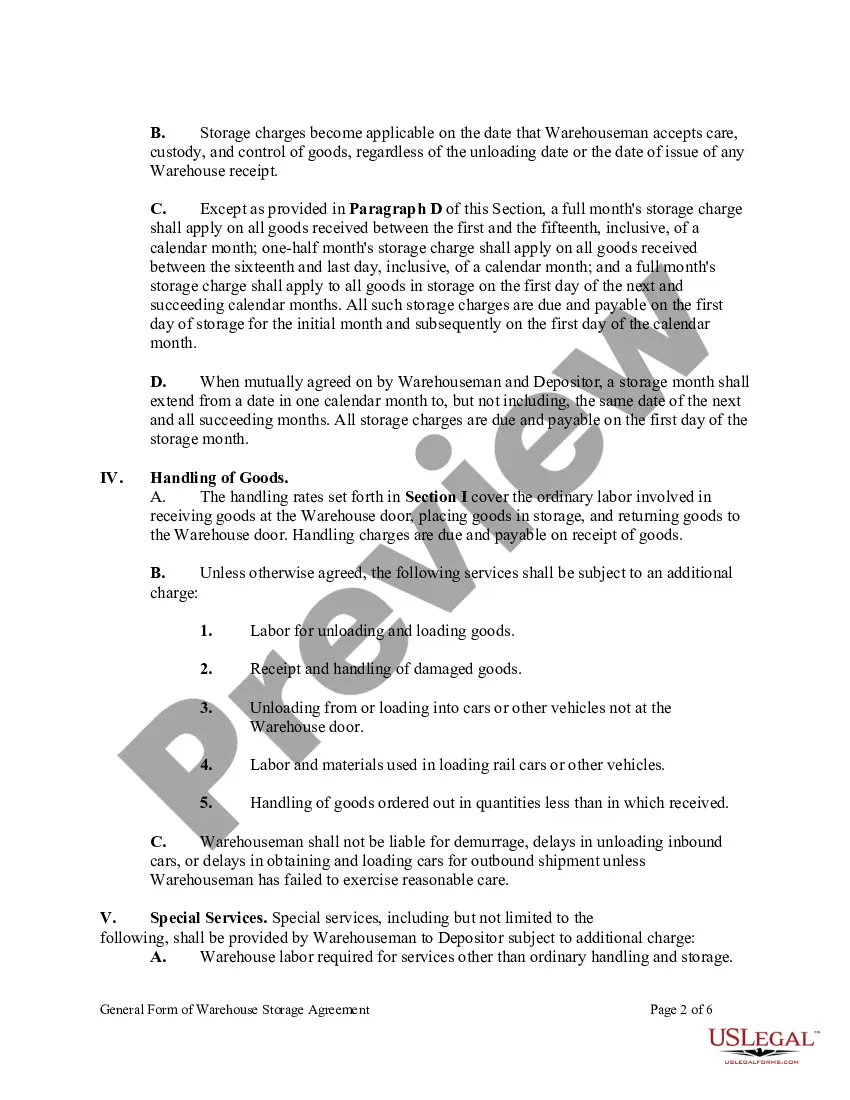

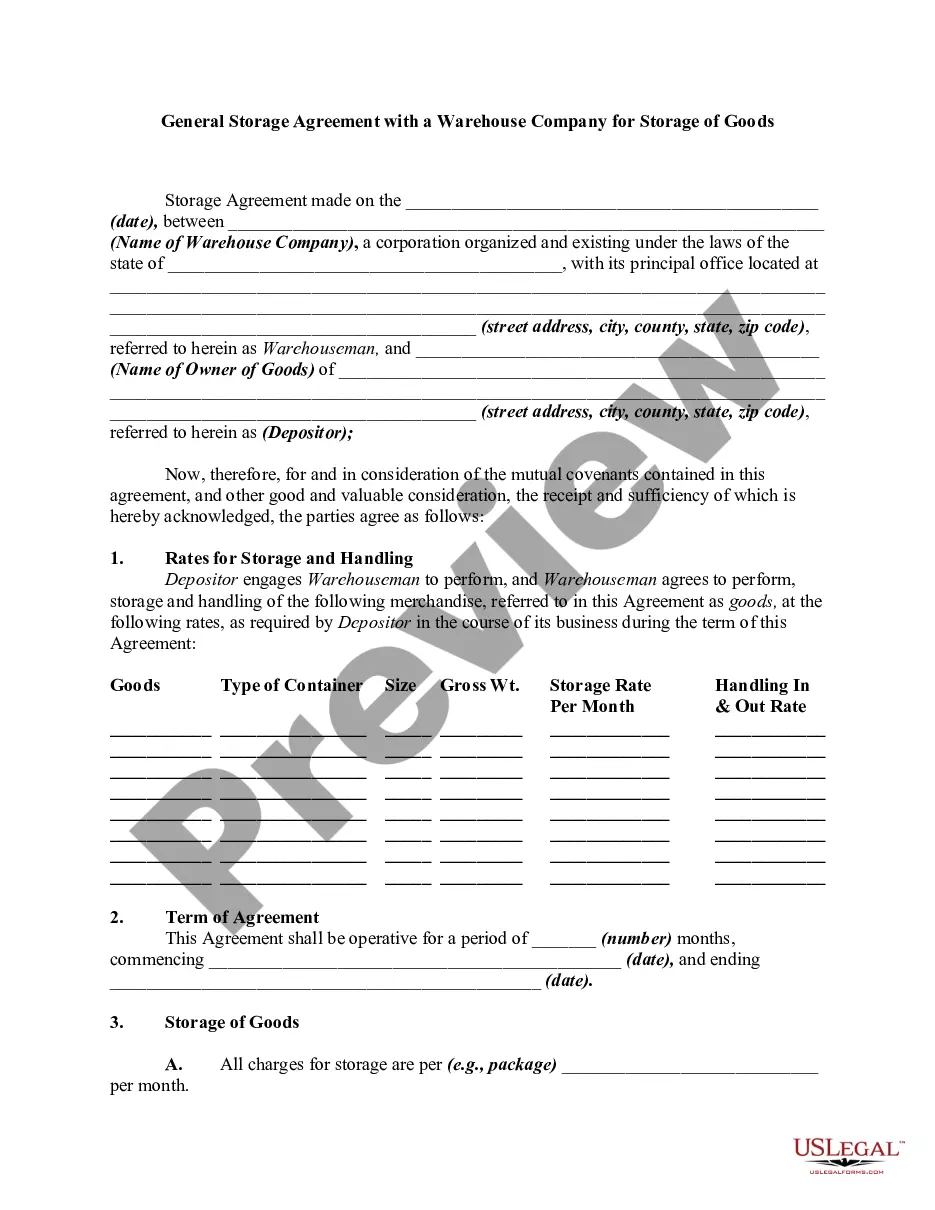

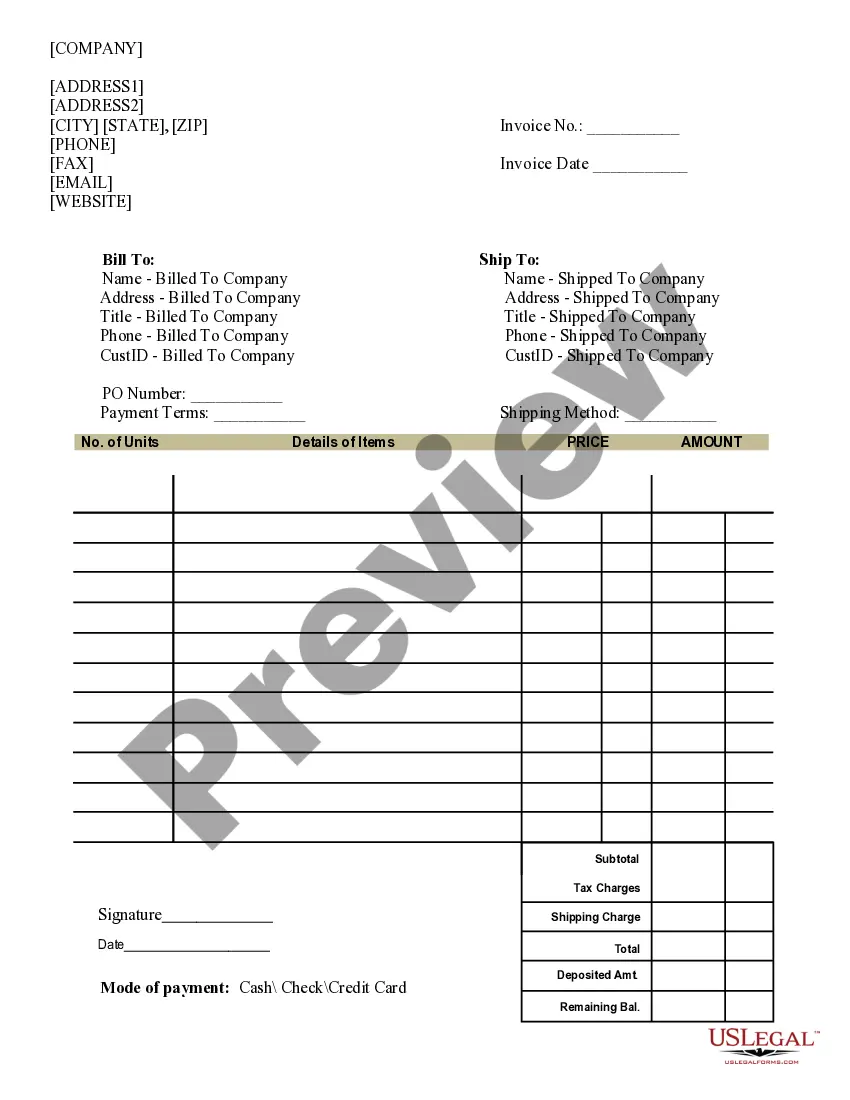

Multiply the length of your stack by the width to find the square footage of your inventory. Then multiply your square footage by the charge per square foot from the warehouse company. Multiply the square foot number (length x width) by the highest point on your stack.

Multiply the square foot number (length x width) by the highest point on your stack. This number is the cubic feet of storage required. If the warehouse charges by cubic foot, multiply this number by the charge per cubic foot. Divide the total size in square or cubic feet by the size or the storage bay or locker.

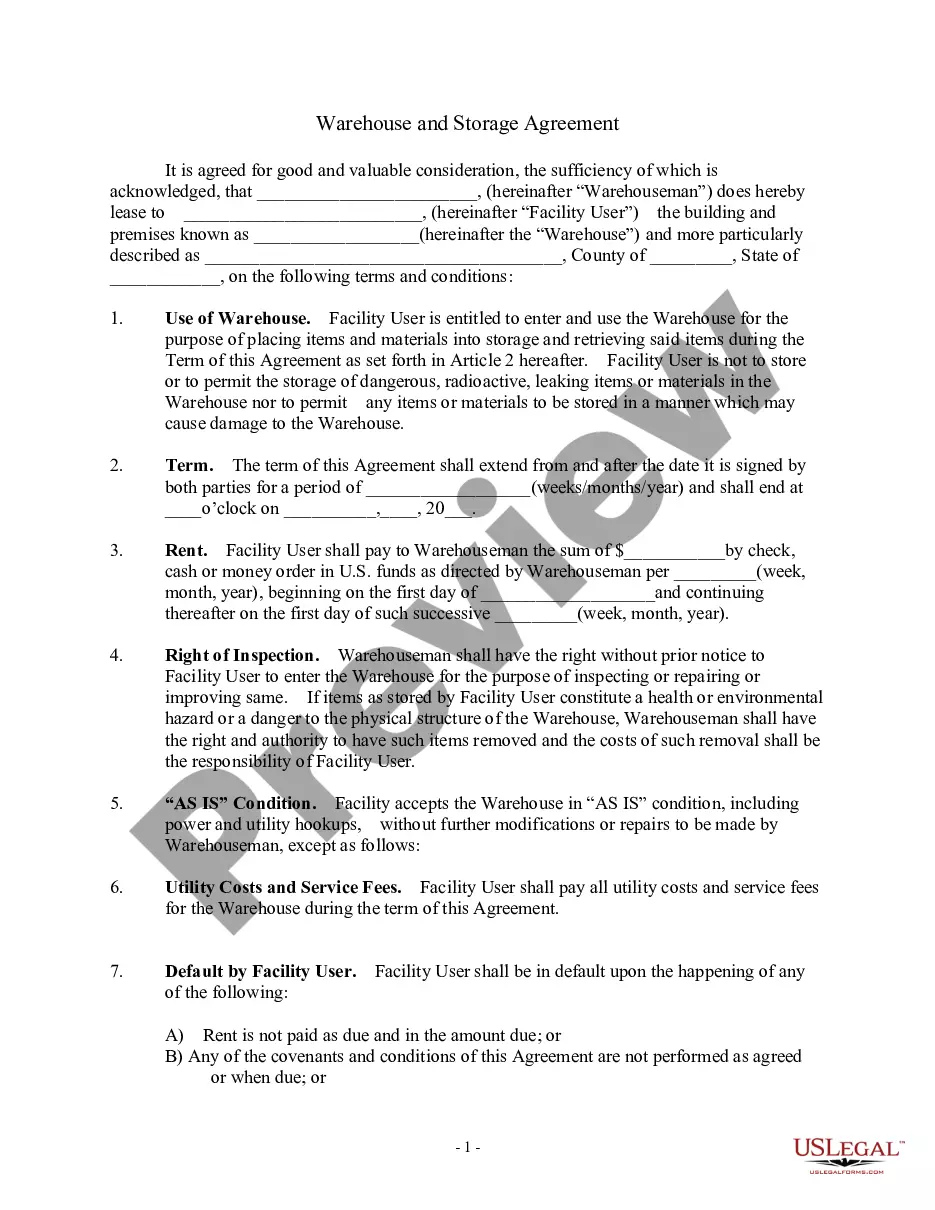

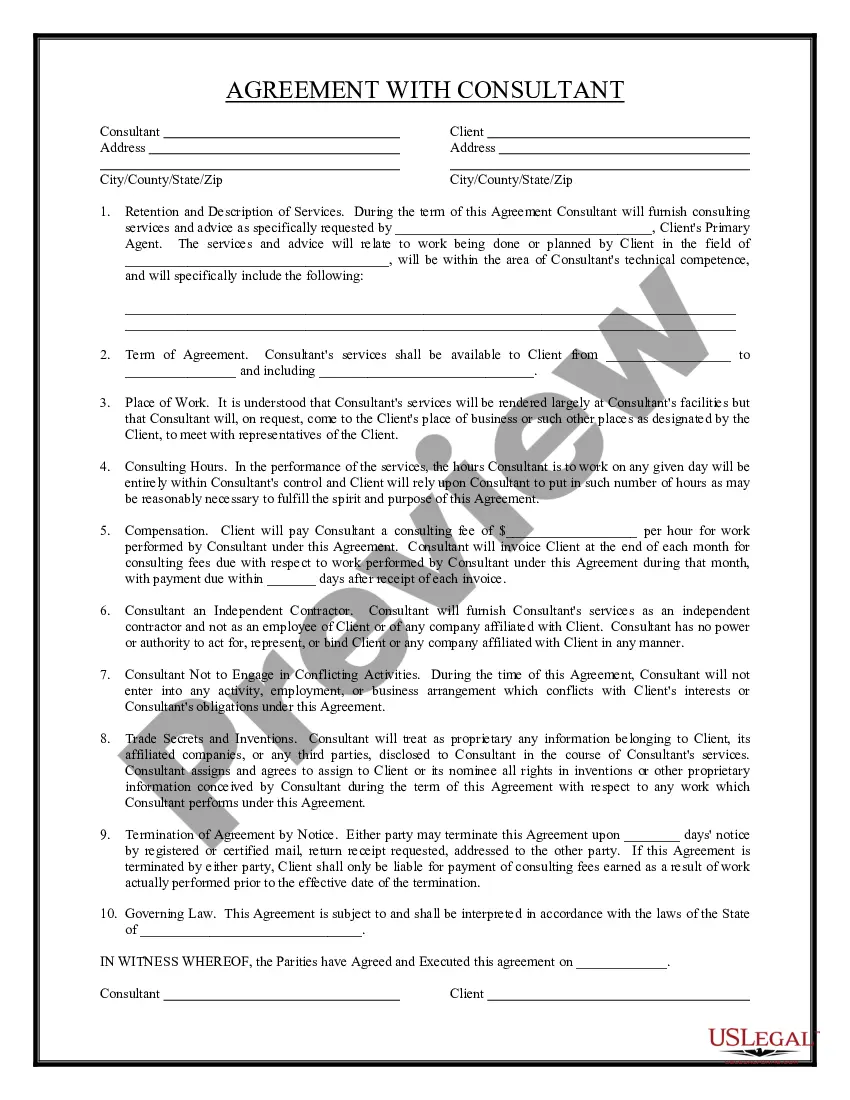

A suitable example of storage cost is storing items in a warehouse. A company that manufactures and sells products may have to pay a certain fee to keep the products in a warehouse. Storage costs can also include the cost of labor for the employees who manage and maintain the warehouse.

Storage costs are the amount of money incurred as a result of storing inventory. The costs could be direct or indirect money spent on the storage of goods. The storage costs may include costs for space, rent, electricity, software, depreciation and warehouse personnel.

How to Maximize Warehouse Space Utilization Extend your racking up vertically. a mezzanine above a floor-level process. Reduce aisle width in the racking area. Change your storage medium. Add half-pallet storage locations. Leverage your warehouse management system for directed put-away. Use underutilized space.