Reclaim Cast

Description

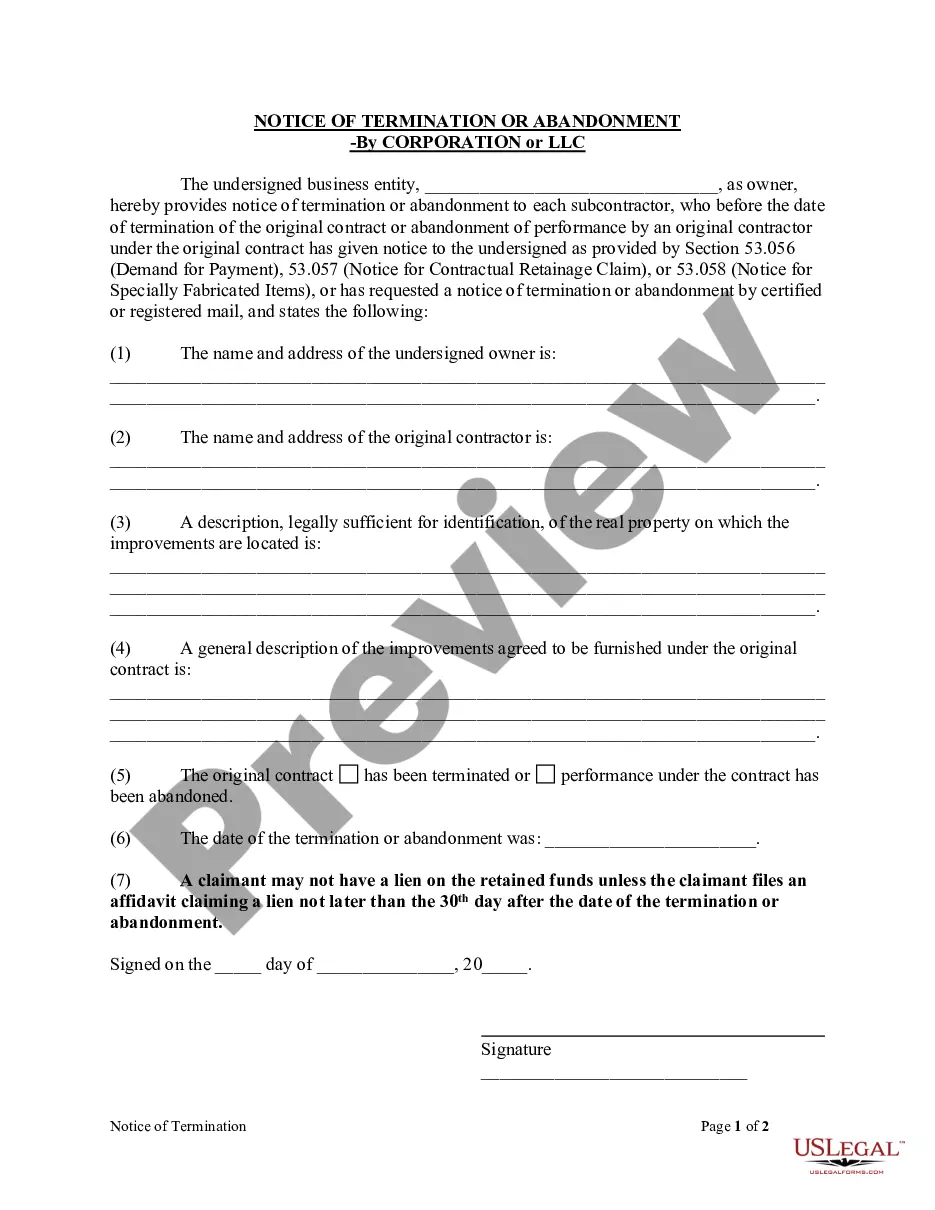

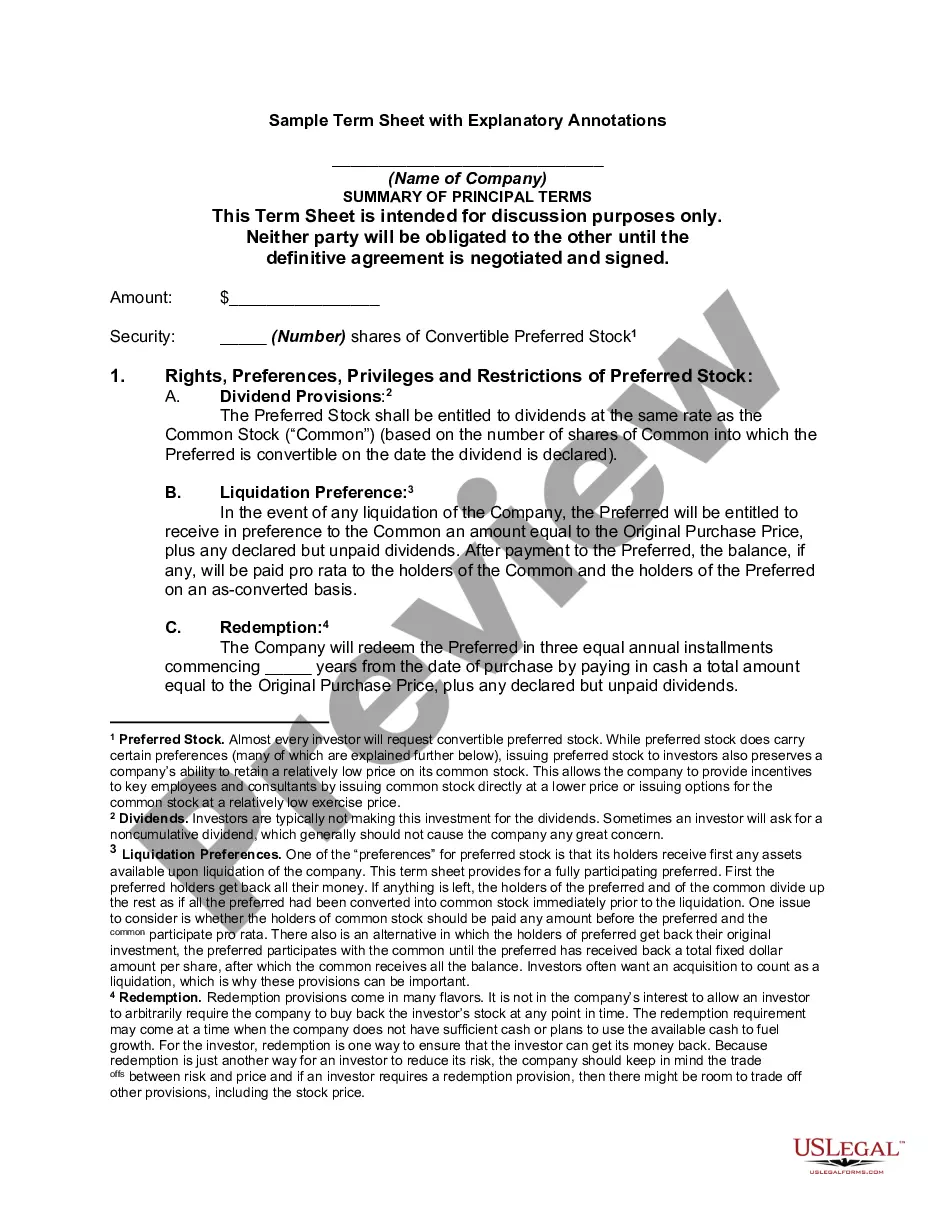

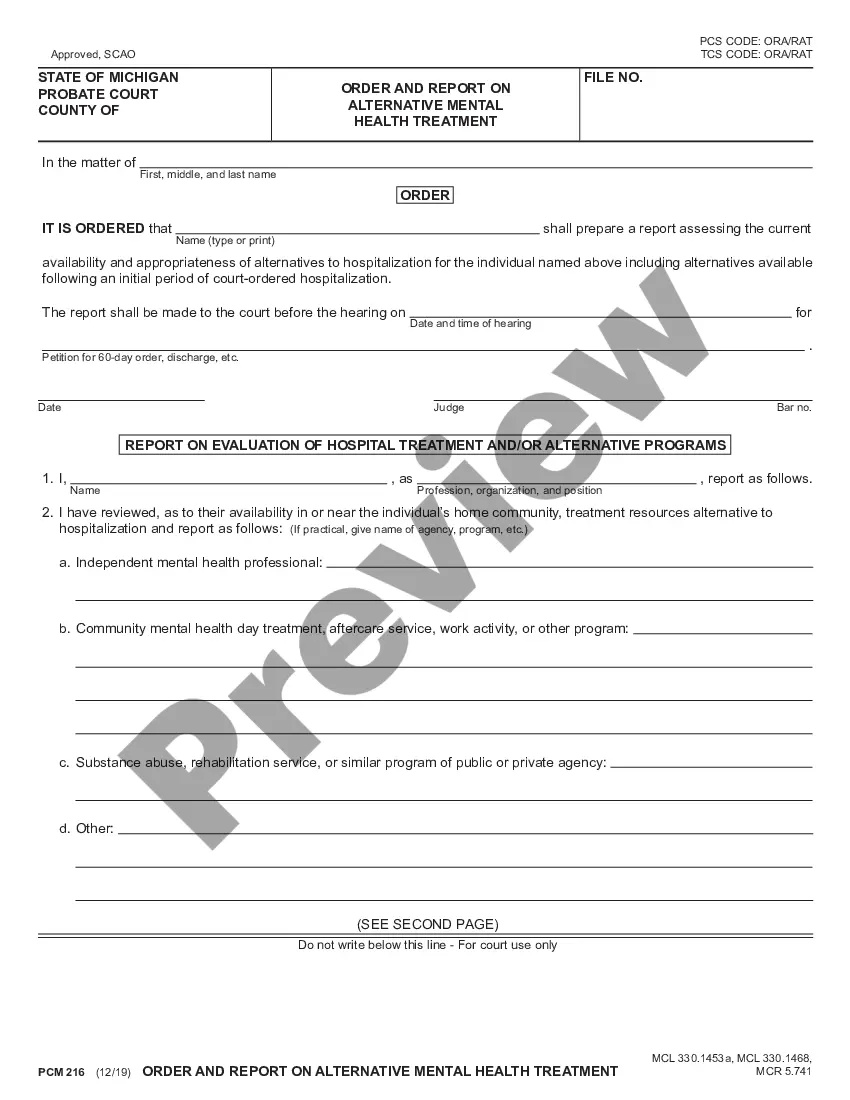

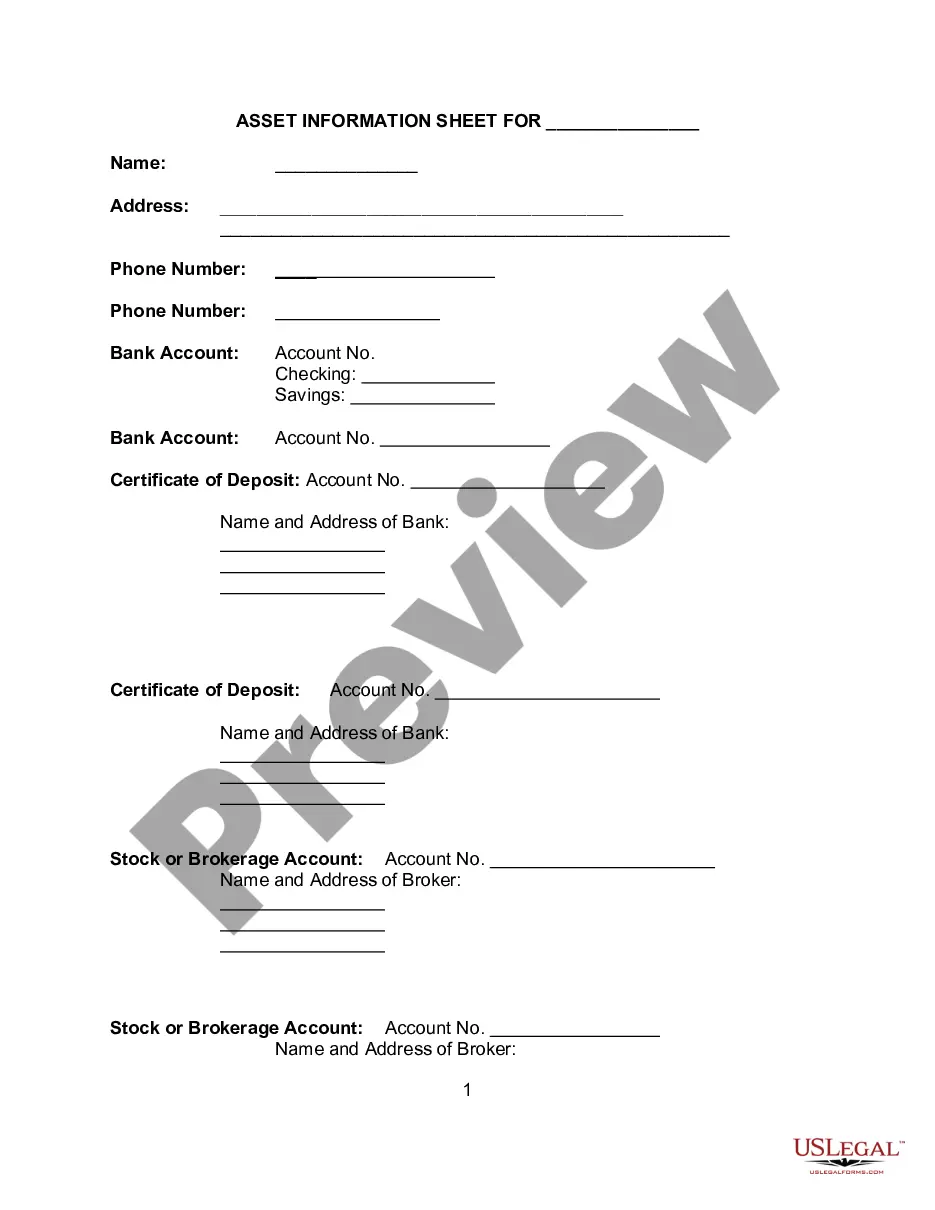

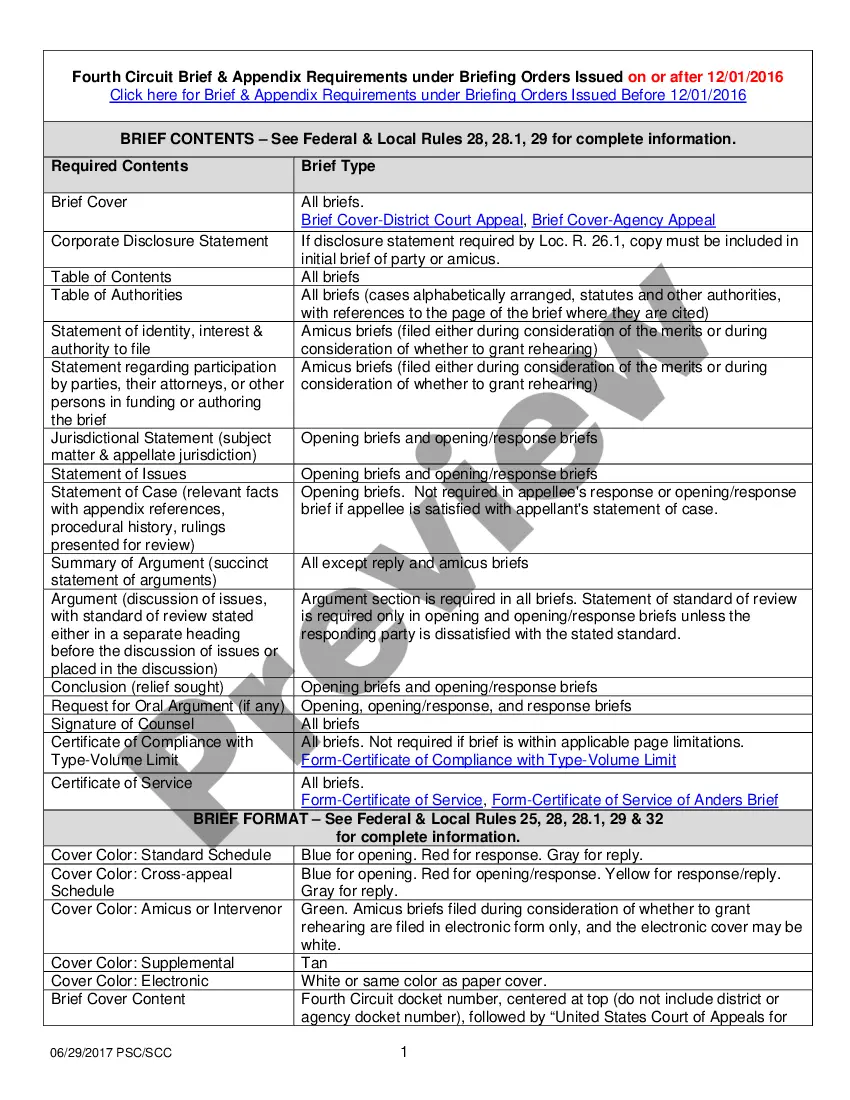

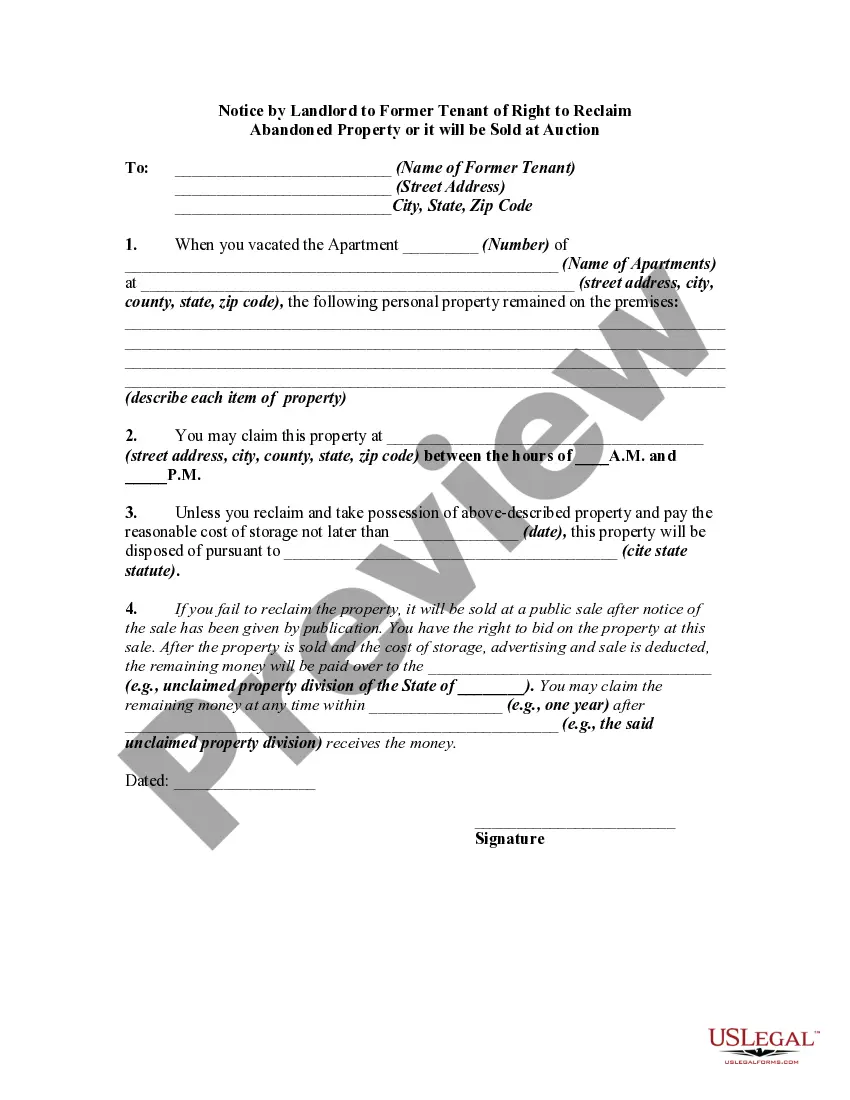

How to fill out Notice By Landlord To Former Tenant Of Right To Reclaim Abandoned Property Or It Will Be Sold At Auction - Abandonment?

Managing legal documents can be perplexing, even for the most seasoned experts.

When searching for a Reclaim Cast and lacking the time to find the suitable and current version, the tasks can be stressful.

US Legal Forms addresses all your requirements, ranging from personal to business documents, all in one platform.

Employ advanced tools to fulfill and handle your Reclaim Cast efficiently.

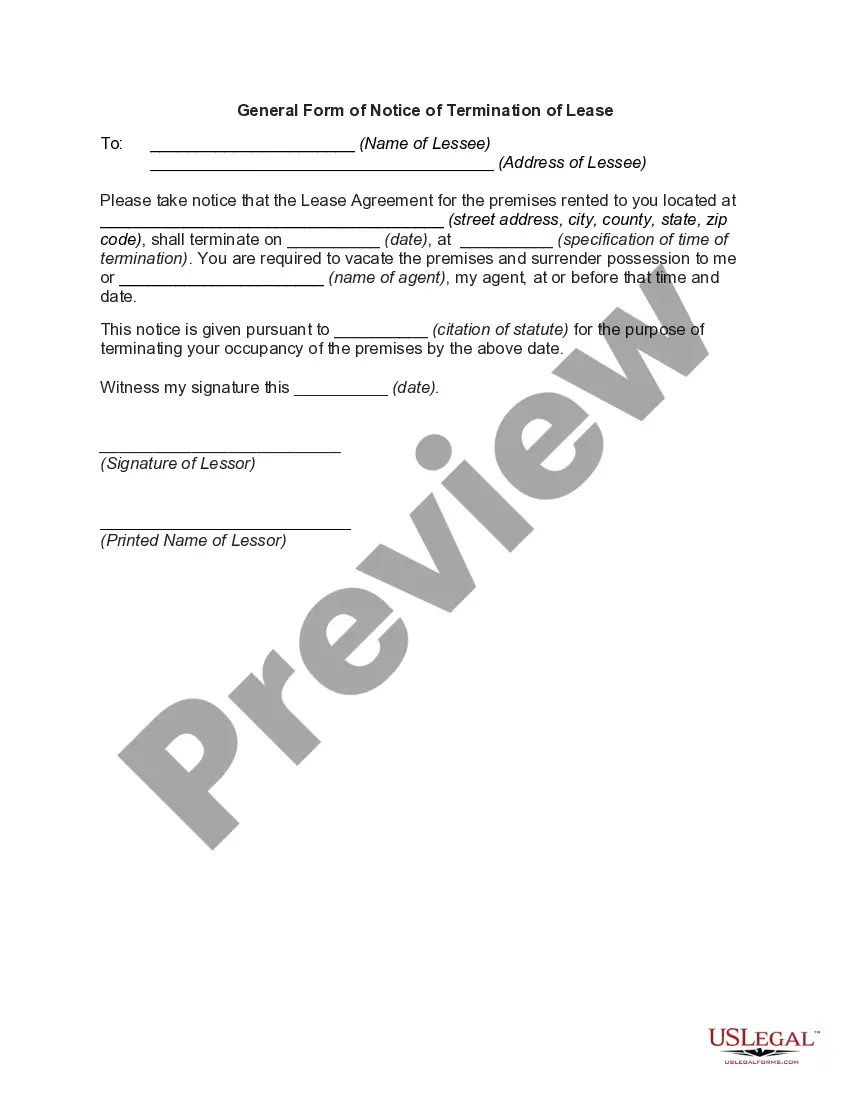

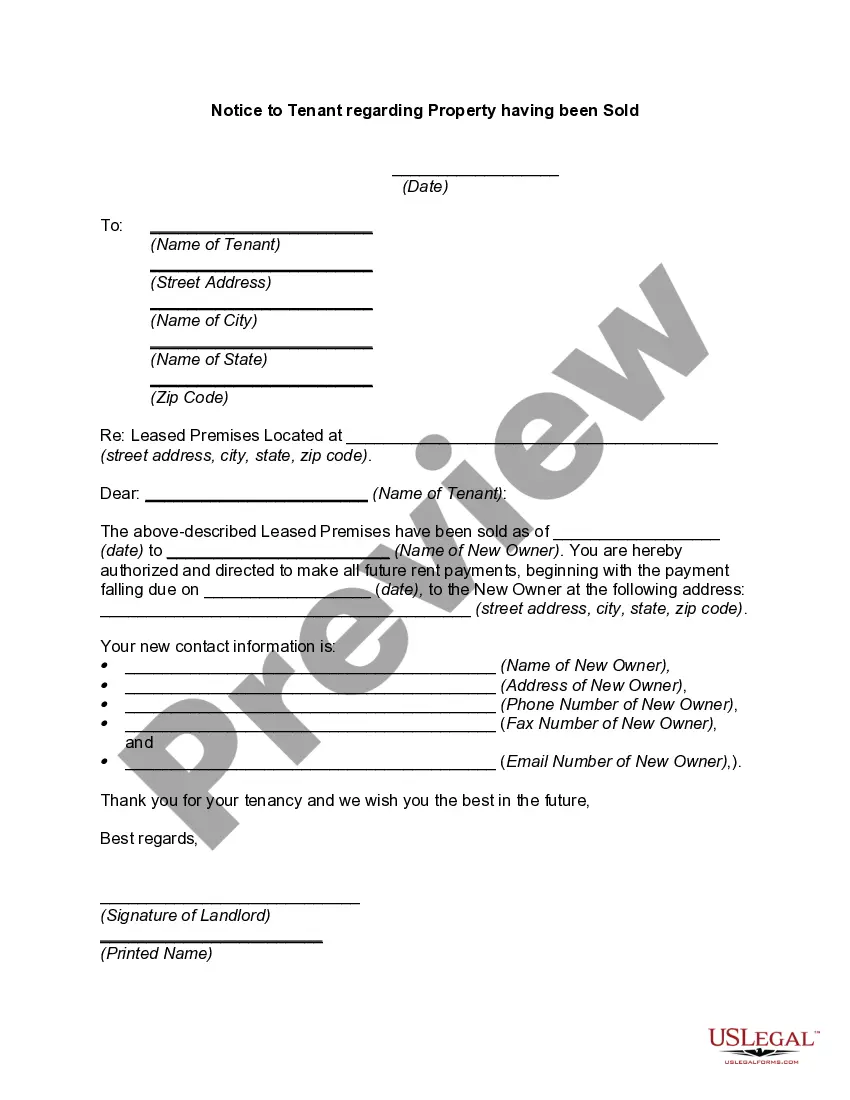

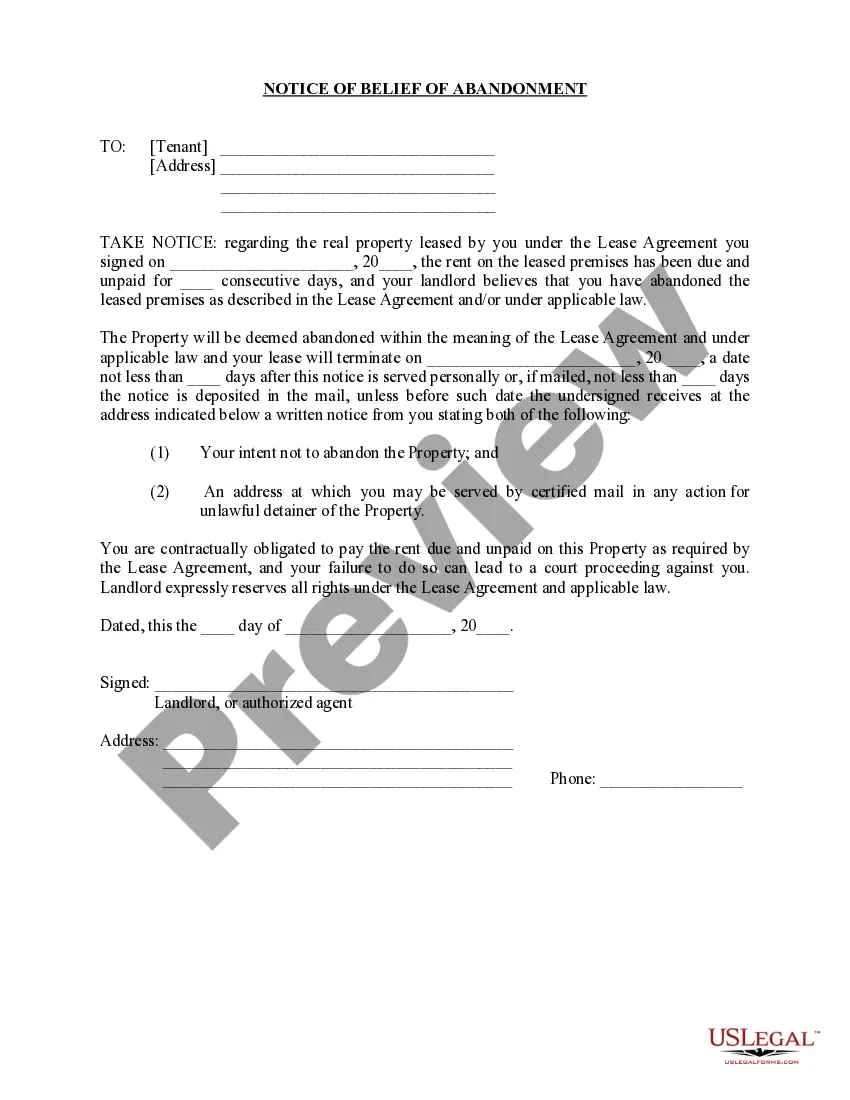

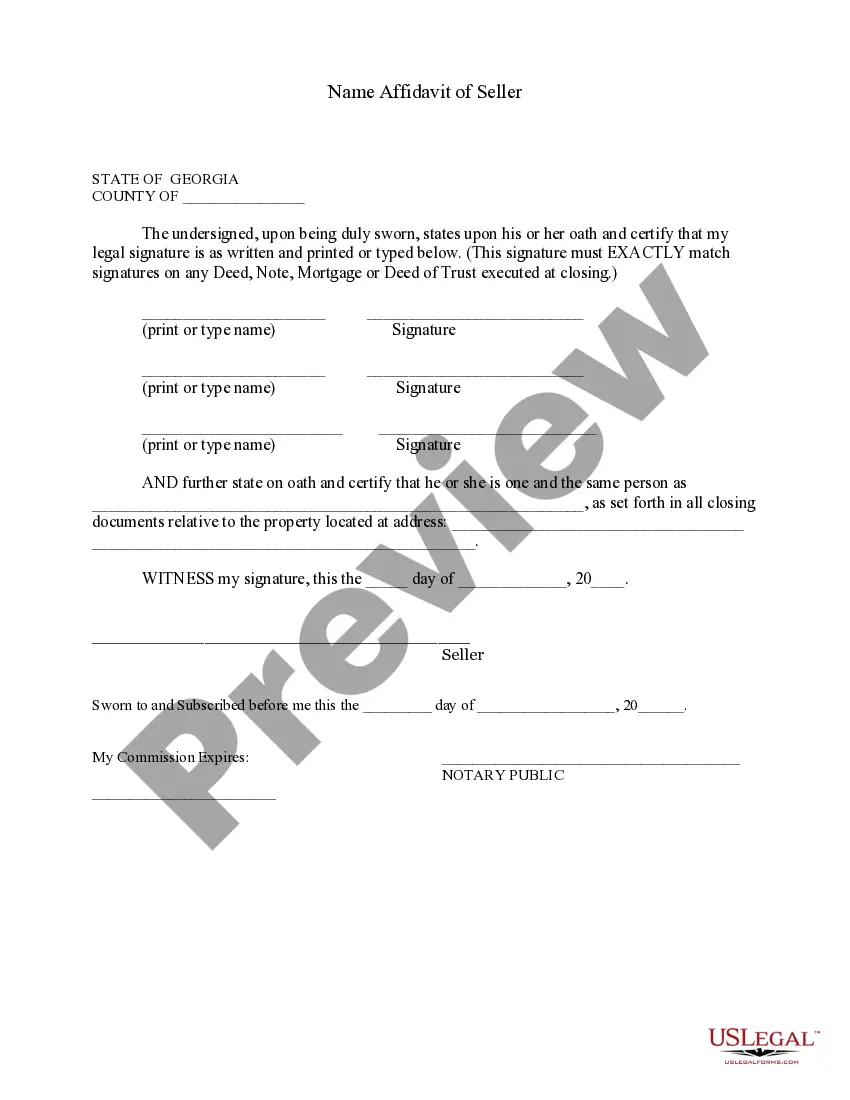

Here are the steps to follow after acquiring the form you need: Verify that it is the correct document by previewing and reviewing its description.

- Access a library of articles, guides, and materials pertinent to your situation and needs.

- Save time and energy while searching for the documents you require by using US Legal Forms' sophisticated search and Review tool.

- If you possess a subscription, Log In to your US Legal Forms account to locate the form and retrieve it.

- Check your My documents tab to see the documents you have previously downloaded and manage your files according to your preferences.

- If it's your first time using US Legal Forms, create an account to enjoy unlimited access to all the library's features.

- Utilize a comprehensive web form repository that can transform the experience for anyone wishing to manage these circumstances efficiently.

- US Legal Forms stands as a frontrunner in online legal documents, featuring over 85,000 state-specific legal forms accessible at any moment.

- With US Legal Forms, you can obtain specific legal and business forms tailored to your state or county.

Form popularity

FAQ

To get reclaim wax out of your rig, you can heat the rig gently with a hairdryer or heat gun. This will soften the reclaim, making it easier to collect. Next, use a dab tool to scrape the softened wax. Regular cleaning prevents buildup and ensures smooth performance.

Experience will teach you which weight is most appropriate for your casting conditions, and most casting slips work best between 1.72 and 1.80 Specific Gravity.

The generally accepted solids content of a Vitreous China sanitaryware casting slip ranges between 72 and 75% by weight, which corresponds to slip densities of 1.80?1.85 g/cm3.

In general, a dipping glaze should have a specific gravity of 1.40 - 1.70. Each glaze is different and each person will have different preferences as to how thick they like the glaze. So, testing and adjusting the glaze ing to your preferences is necessary.

Water Water content will vary depending on the materials used. In general, to mix a 10 pound batch of casting slip, the amount of water will be between 28-45% of the dry weight. A good starting point for using Darvan products for deflocculation would be 0.35%.

Typical slip viscosities range from 100 to 1000 mPa·s. High solids loading slips contain less water to remove into the mold, but they are also very viscous and possibly difficult to work with. Therefore, most slips contain 40?50 vol% particles.