Contract Manufacturing Agreement Format In Florida

Description

Form popularity

FAQ

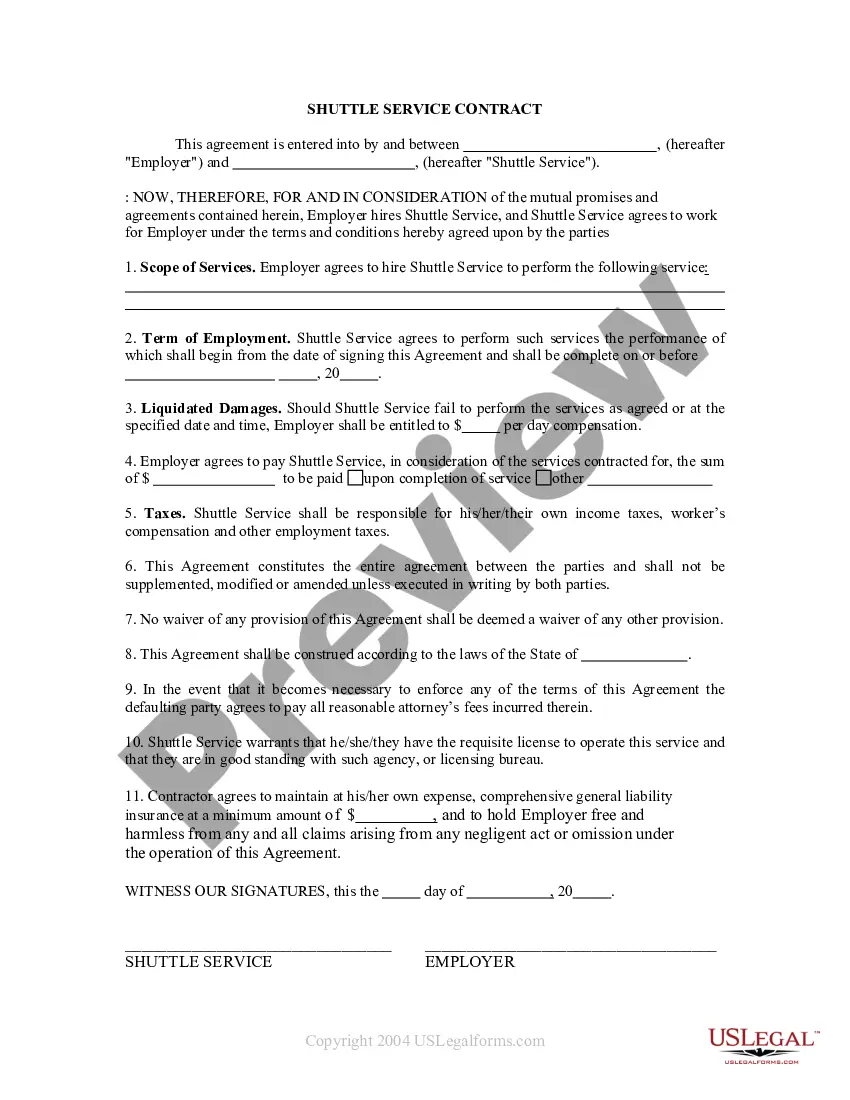

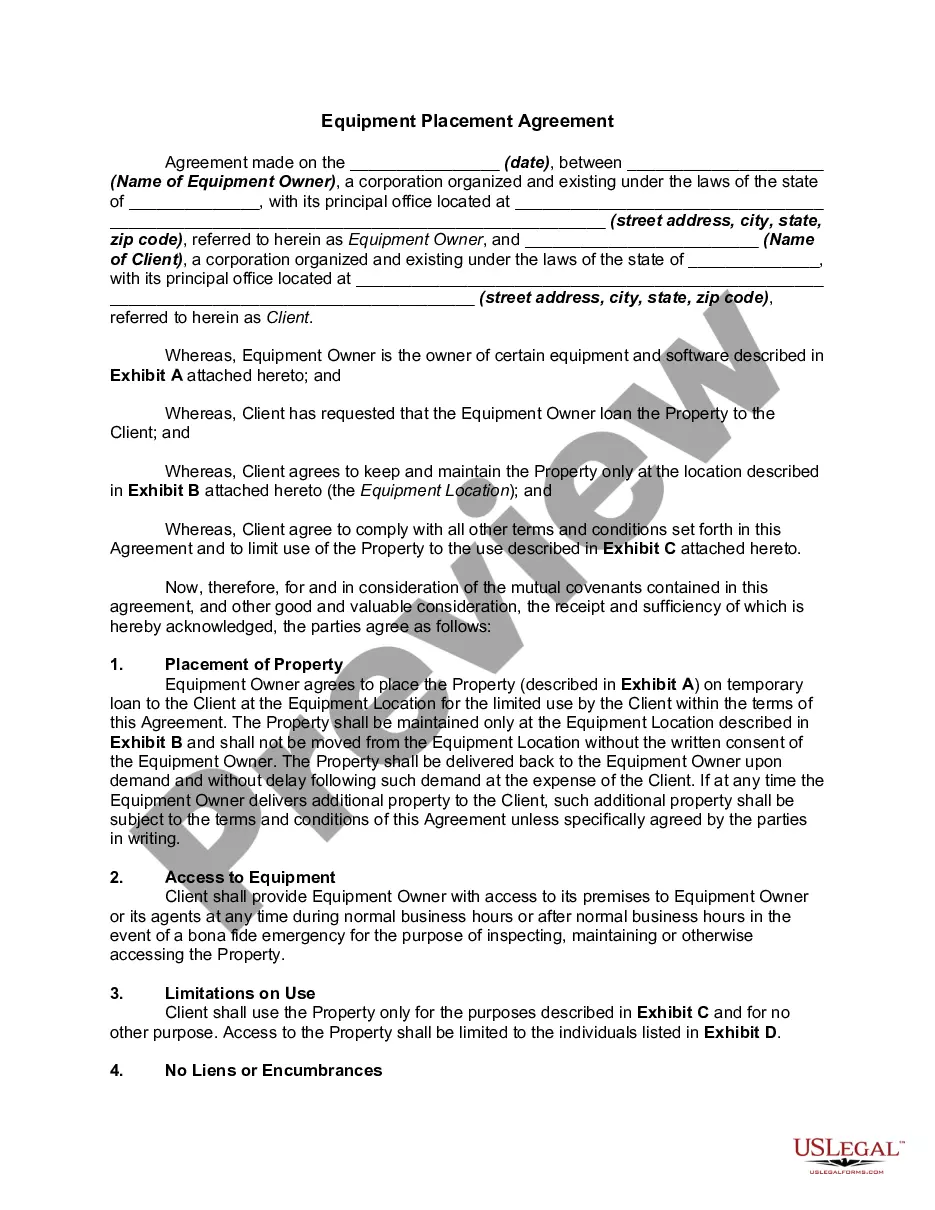

The types of contract manufacturing arrangements are component manufacturing, private label manufacturing, labor subcontracting, and contract manufacturing for the use of equipment and facilities.

Here's a look at the primary types of contract manufacturing services: End-to-End Production, Partial Production Services, and Private Label Manufacturing. End-to-End Production. Partial Production Services. Private Label Manufacturing.

One of the most prominent examples of contract manufacturing is an original equipment manufacturer called Foxconn, a Taiwanese contract manufacturer that specializes in electronics. They have work with some of the largest companies in the United States like Apple, Xbox, and Amazon.

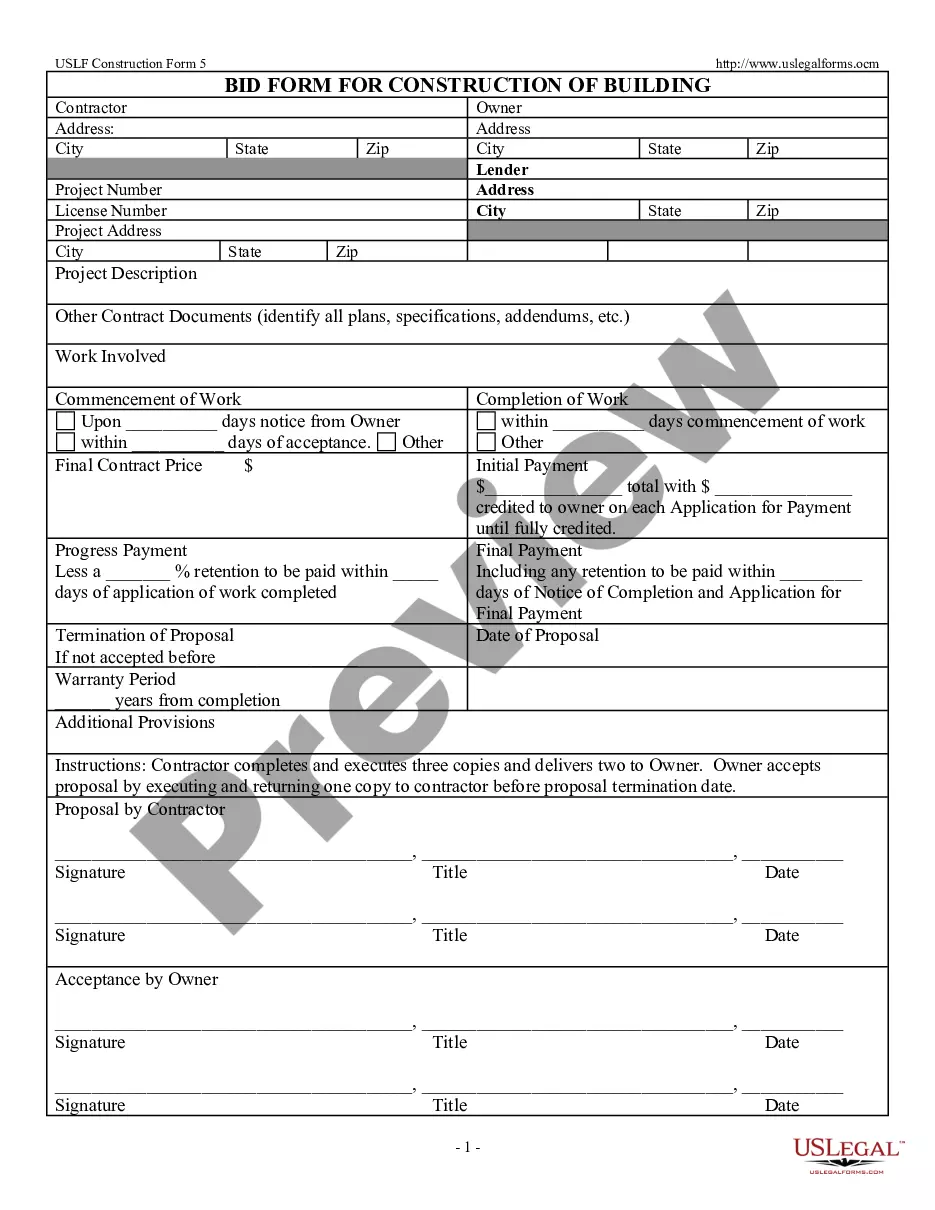

Your manufacturing contract should include: intellectual property (since the contract manufacturer(s) will be producing your proprietary creation). an assessment of manufacturing costs. clearly-written obligations of both parties. liabilities. product quality standards (if a quality control clause is included).

Contracts are made up of three basic parts – an offer, an acceptance and consideration.

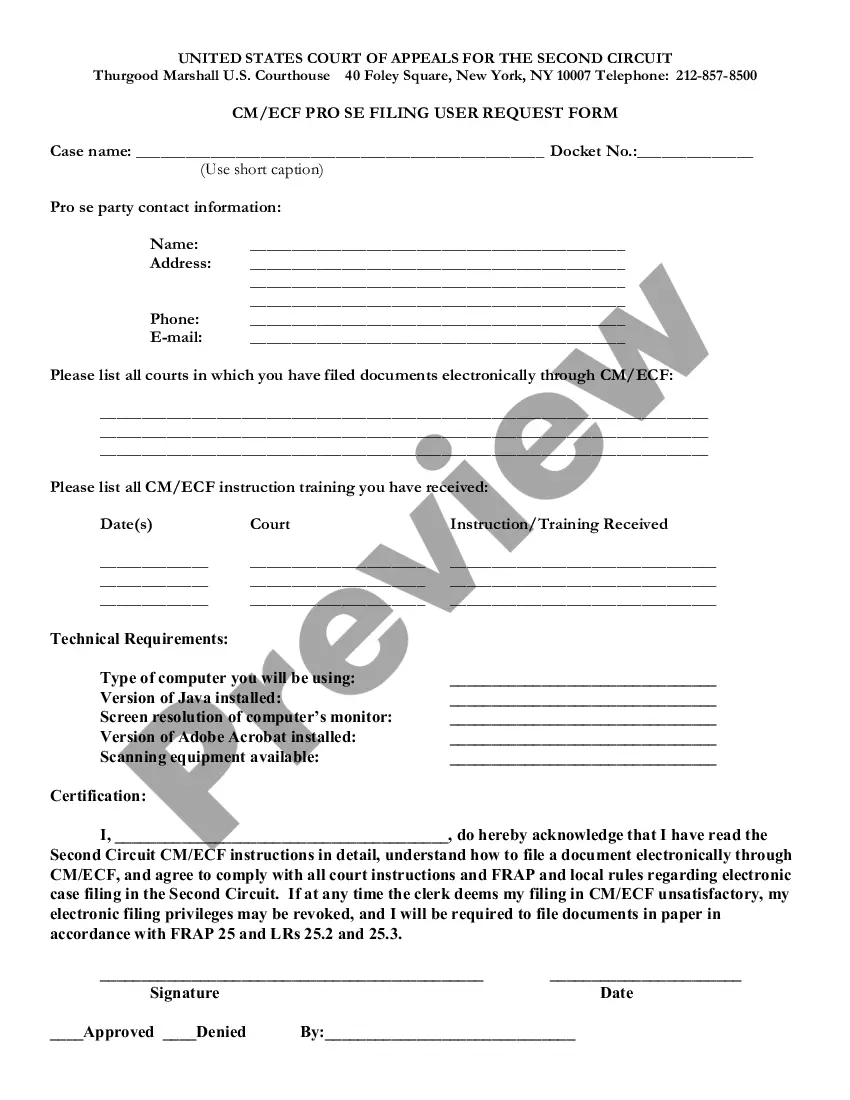

Write the contract in six steps Start with a contract template. Open with the basic information. Describe in detail what you have agreed to. Include a description of how the contract will be ended. Write into the contract which laws apply and how disputes will be resolved. Include space for signatures.

A contract has three distinct stages: preparation, perfection, and consummation. Preparation or negotiation begins when the prospective contracting parties manifest their interest in the contract and ends at the moment of their agreement.

Contract manufacturing typically falls into three categories: component manufacturing, which involves producing individual parts; sub-assembly manufacturing, which focuses on creating semi-finished components; and complete product manufacturing, where the manufacturer produces a fully finished product ready for the ...

Contract manufacturing is a manufacturing-as-service approach: the customer provides all designs and specifications, and the supplier simply build to the drawing, while in OEM, the customer is providing a portion of the design (external, internal, some specs), and the supplier is incorporating their existing components ...

In its most basic form, contract manufacturing is when one business agrees to assist in the production of goods for another business. The arrangement could be limited to producing certain components, such as equipment faceplates or control panel overlays, or it could entail complete start-to-finish manufacturing.