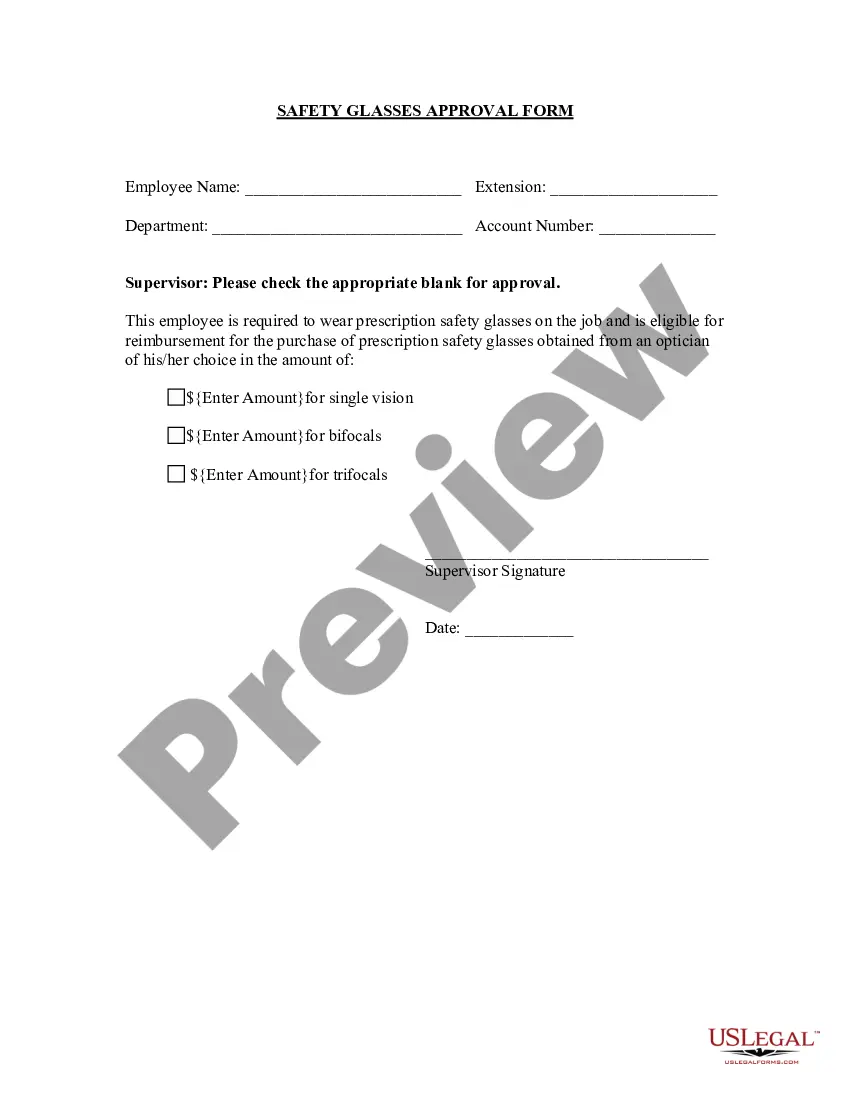

Wisconsin Safety Glasses Approval Form

Description

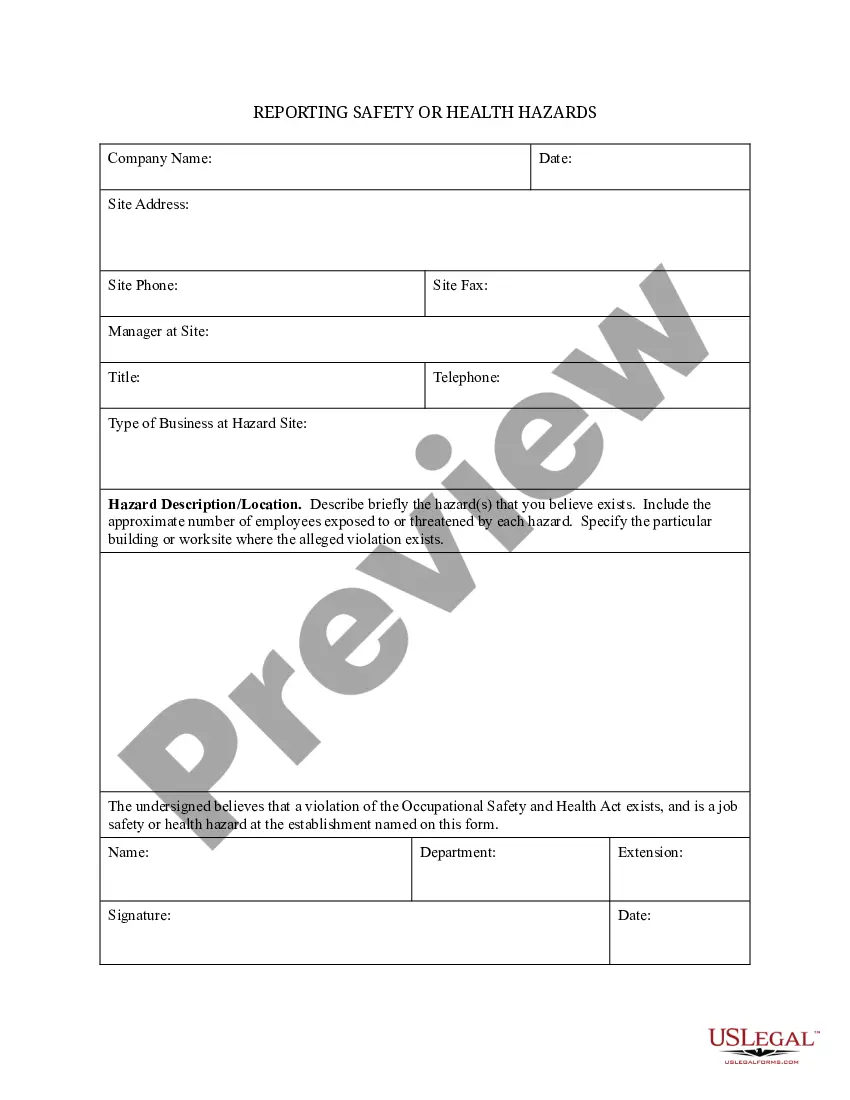

How to fill out Safety Glasses Approval Form?

You might spend hours online searching for the appropriate legal document template that satisfies the federal and state requirements you have.

US Legal Forms offers a vast array of legal forms that are evaluated by professionals.

You can easily download or print the Wisconsin Safety Glasses Approval Form from this service.

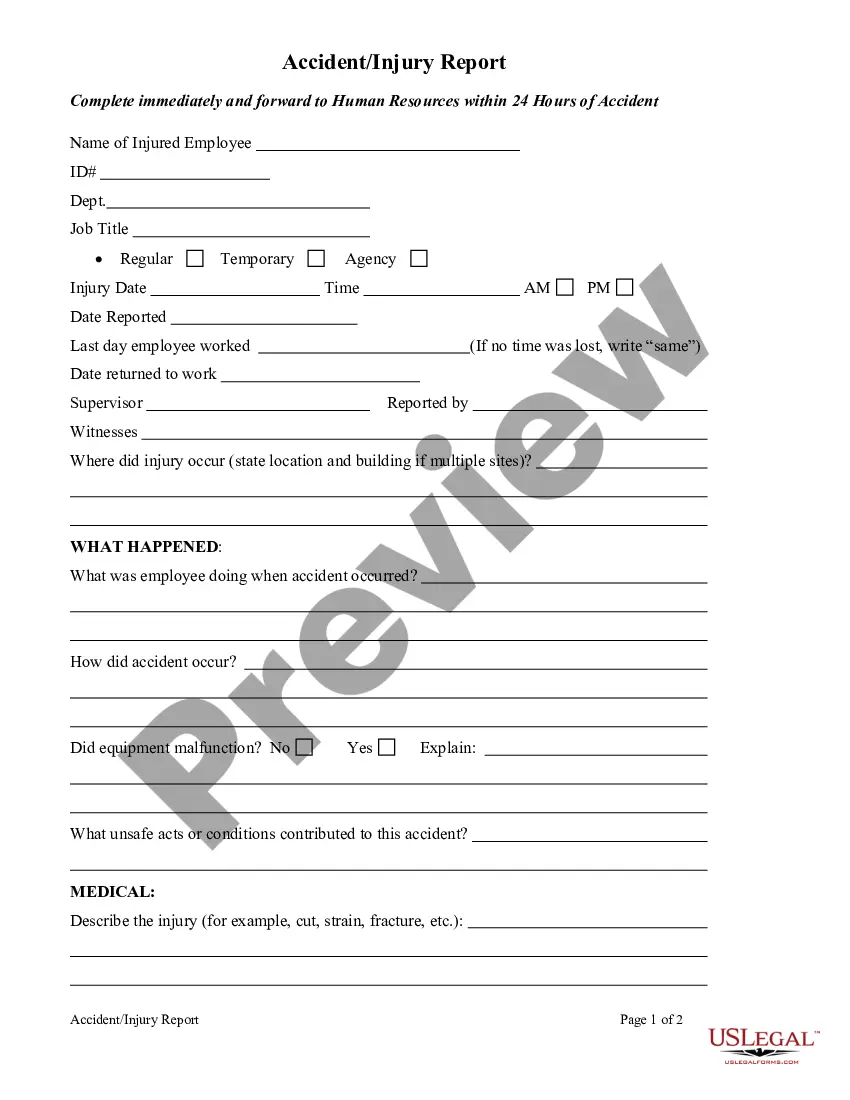

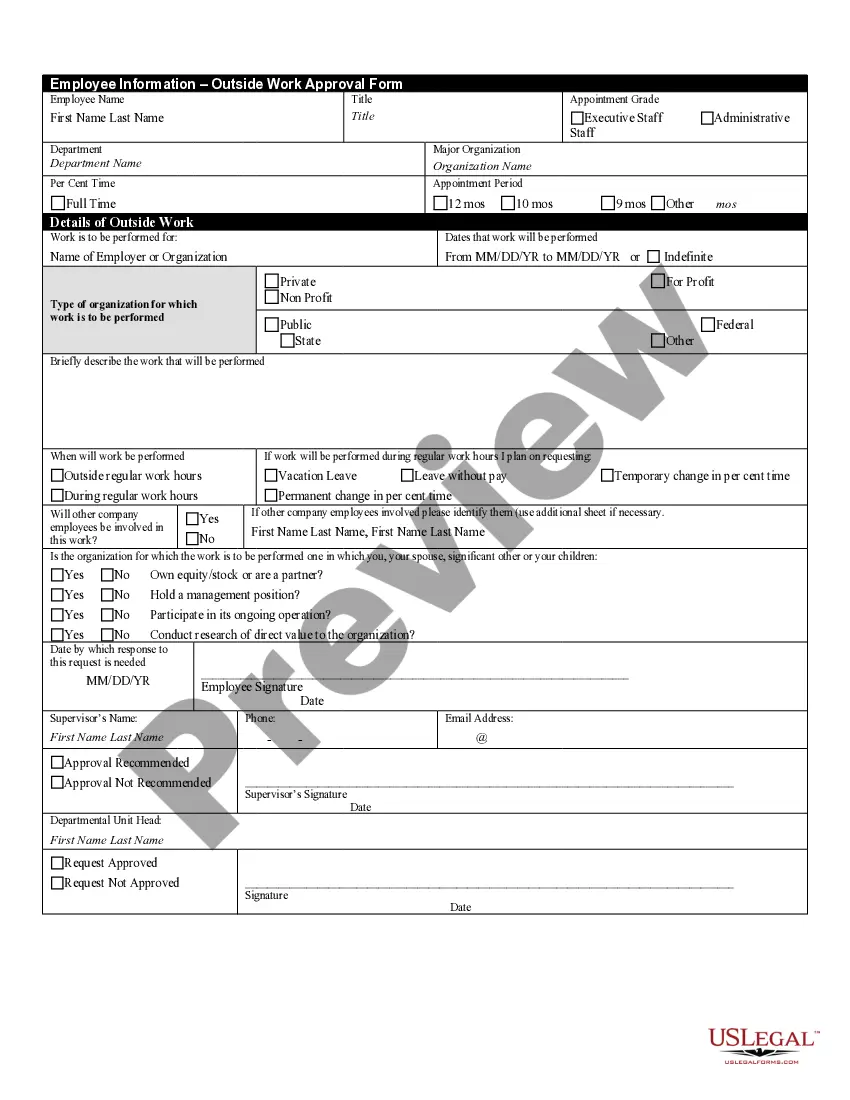

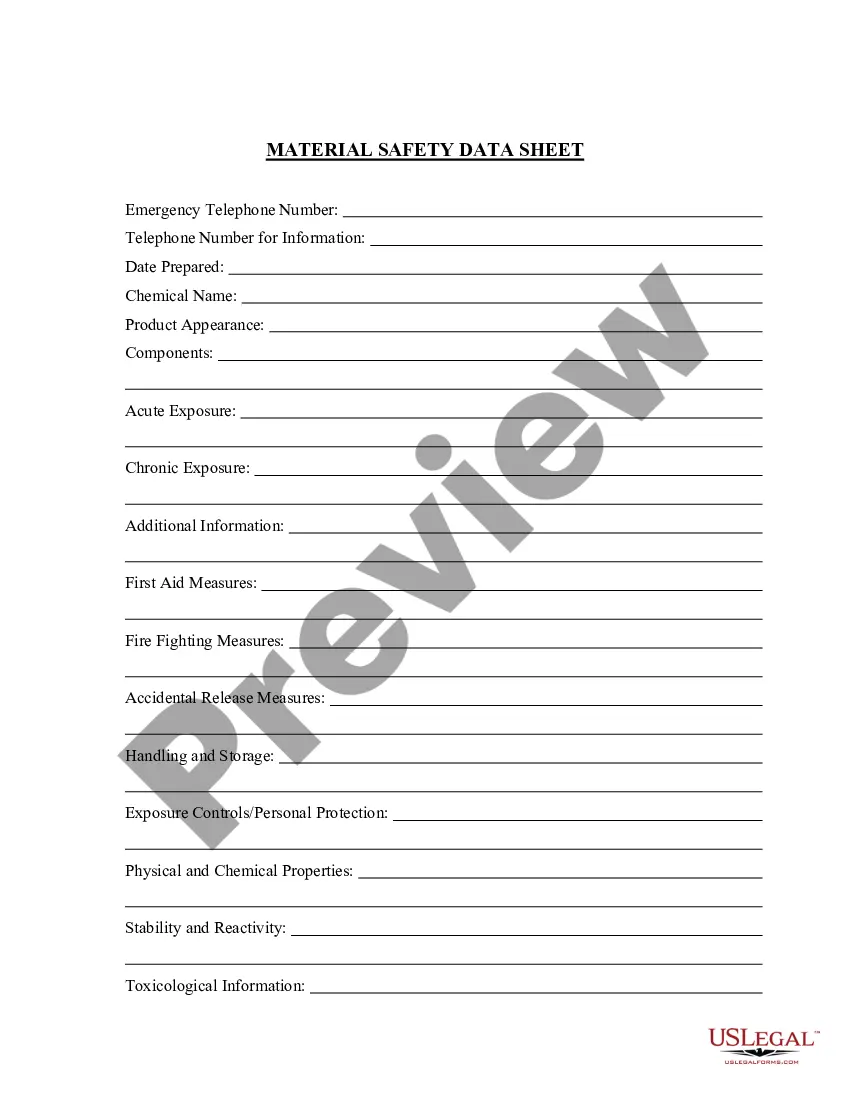

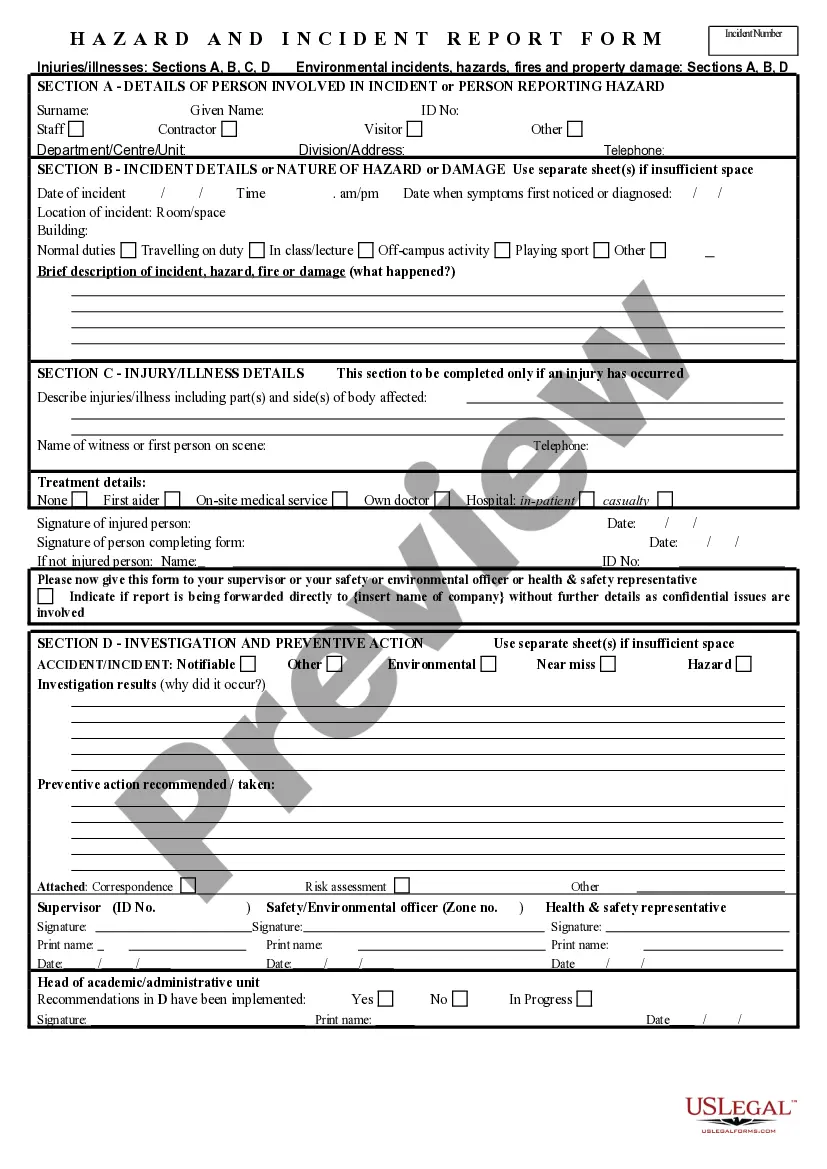

Review the form description to ensure you have selected the correct one. If available, use the Preview button to examine the document template as well.

- If you already possess a US Legal Forms account, you can Log In and hit the Obtain button.

- Then, you can complete, modify, print, or endorse the Wisconsin Safety Glasses Approval Form.

- Every legal document template you acquire is yours permanently.

- To retrieve another copy of any purchased form, visit the My documents section and click on the corresponding button.

- If it’s your first time using the US Legal Forms site, follow the basic instructions below.

- First, ensure you have selected the correct document template for your chosen state/city.

Form popularity

FAQ

To do so, you simply need to take a look at the glasses themselves. If the glasses are safety-approved according to ANSI or other standards, they will be stamped. By stamped, we mean that you will see on the frame or lens whether it meets certain safety standards.

The first marking you'll likely see on your eyewear is Z87 or Z87+. This is the ANSI standard for impact which helps ensure safety eyewear provides workers with the needed protection from impact hazards. For safety eyewear to pass the basic Z87 standard, it must pass the ball drop test.

Do I Need OSHA Prescription Safety Glasses? If you are working in an environment that may be hazardous to your eyes, you are required to have OSHA approved safety glasses or goggles. Additionally, if you need corrective lenses, you must be wearing some form of prescription lenses.

§1910.133(a)(3), OSHA requires that eye protection must comply with either of two consensus standards incorporated by reference in OSHA's eye protection standard at A§1910.133(b). These are Occupational and Educational Personal Eye and Face Protection Devices, ANSI Z87. 1-. 1989 and ANSI Z87.

OSHA's standard for eye protection, adopted in 2015 by the American National Standards Institute for personal eye and face protectors, is more commonly referred to as ANSI Z87. 1.

To be compliant with ANSI Z87. 1 standards, safety glasses must be tested for non-impact-rated or impact-rated lenses and frames, as well as exposure to non-ionizing radiation and chemicals. Safety glasses are also tested for ignition and corrosion.

The ANSI Z87. 1 certified safety glasses are tested extensively according to these hazards to assess their safety and performance in the workplace. Testing can involve primary and high impact tests for lenses and frames, exposure to non-ionizing radiation and chemicals, and durability to flame and corrosion.

If the glasses are safety-approved according to ANSI or other standards, they will be stamped. By stamped, we mean that you will see on the frame or lens whether it meets certain safety standards. Looking at the Wiley X Gravity glasses, for instance, you will note that they are ANSI Z87. 2 safety approved.

Z87 Impact Testing:Z87 or Z87+ marking is the most common marking that you'll see on your safety glasses. This is the standard set by ANSI for impact, which ensures that workers wearing safety eyewear with this marking will get required protection against impact hazards.

If eye protection is required at a work site and a worker wishes to use prescription eyewear, subsection 229(2) of the OHS Code requires that the eyewear be approved to (a) CSA Standard Z94.