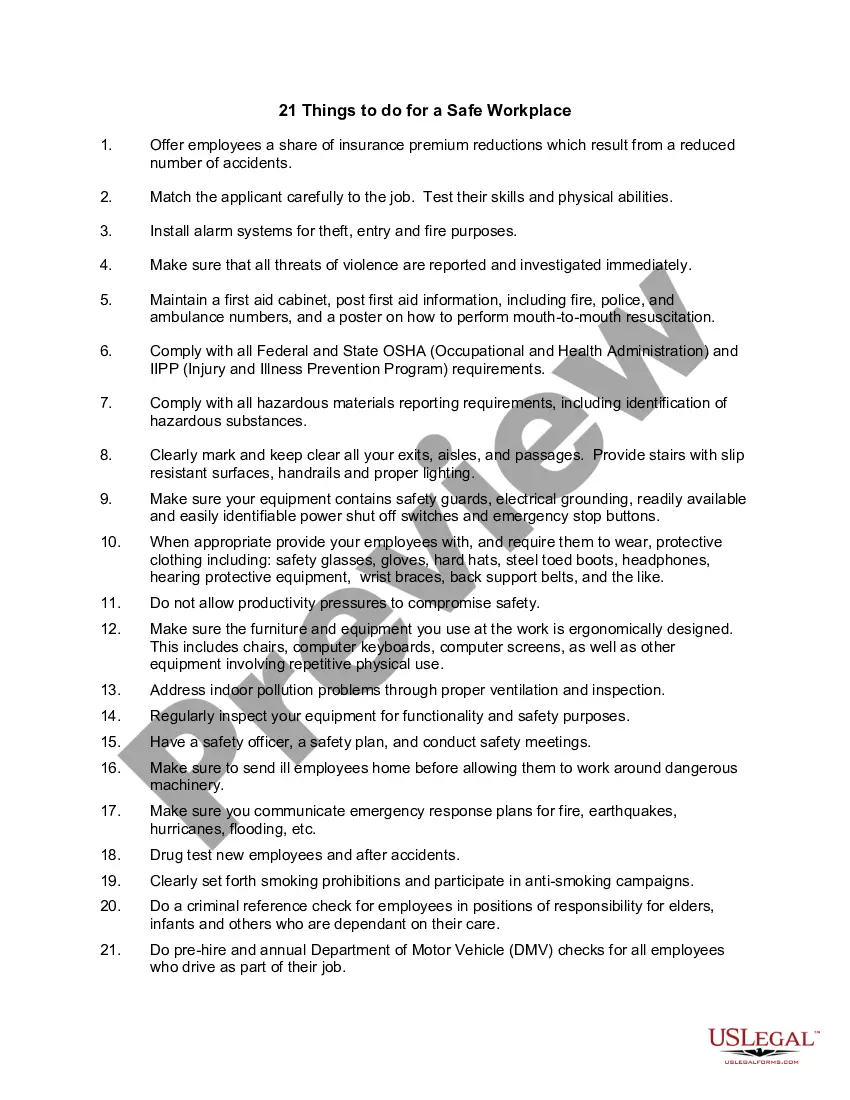

Pennsylvania 21 Things to do for a Safe Workplace

Description

How to fill out 21 Things To Do For A Safe Workplace?

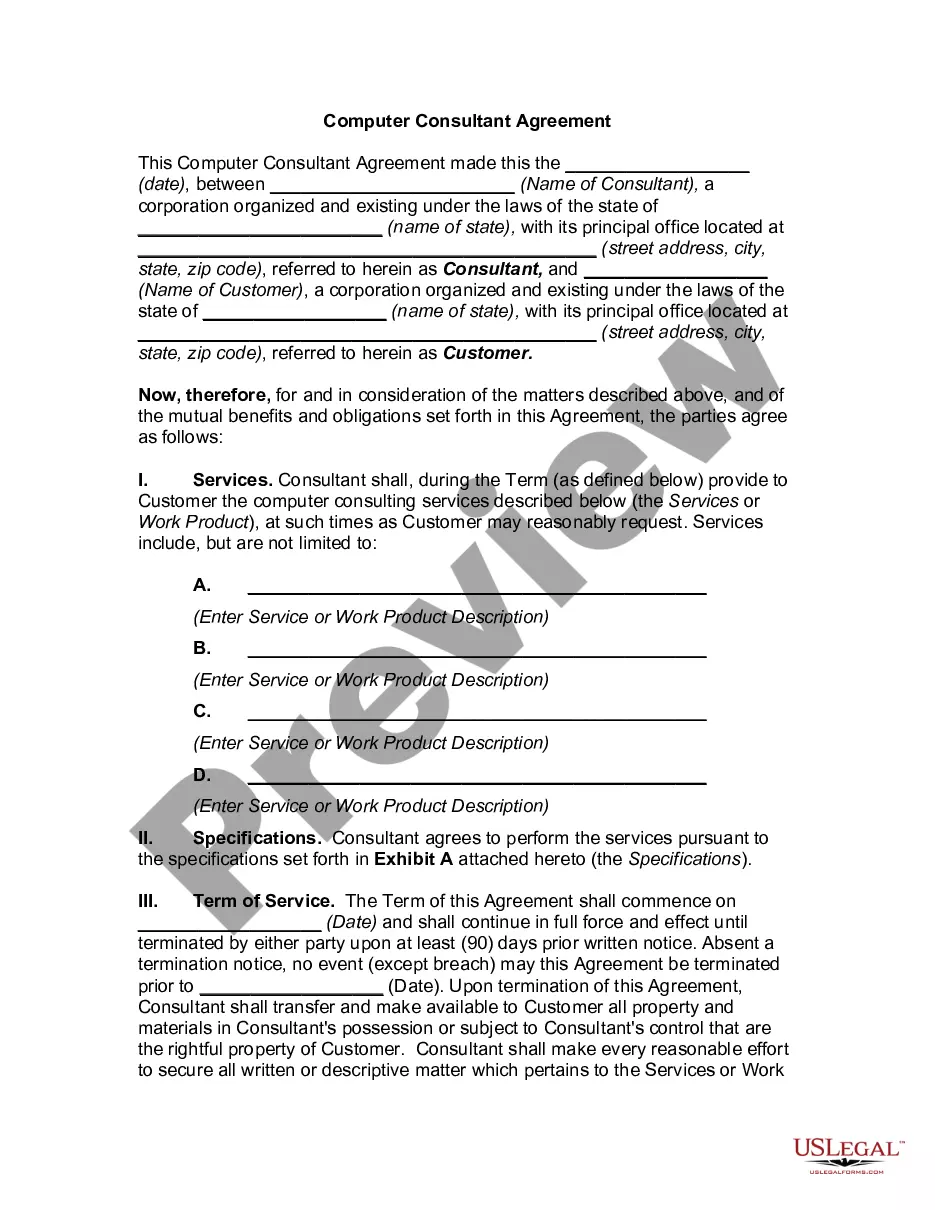

Selecting the best valid document template can be a challenge.

Of course, there are numerous templates accessible online, but how do you find the right one you need.

Utilize the US Legal Forms website.

First, ensure you have selected the correct document for your region/county. You can review the form using the Preview button and read the form details to confirm it is suitable for you.

- The service offers thousands of templates, including the Pennsylvania 21 Things to do for a Safe Workplace, suitable for business and personal needs.

- All of the documents are reviewed by professionals and comply with state and federal requirements.

- If you are already registered, Log In to your account and click the Download button to get the Pennsylvania 21 Things to do for a Safe Workplace.

- Use your account to view the legal documents you have previously purchased.

- Visit the My documents section of your account and download another copy of the document you require.

- If you are a new user of US Legal Forms, here are simple instructions for you to follow.

Form popularity

FAQ

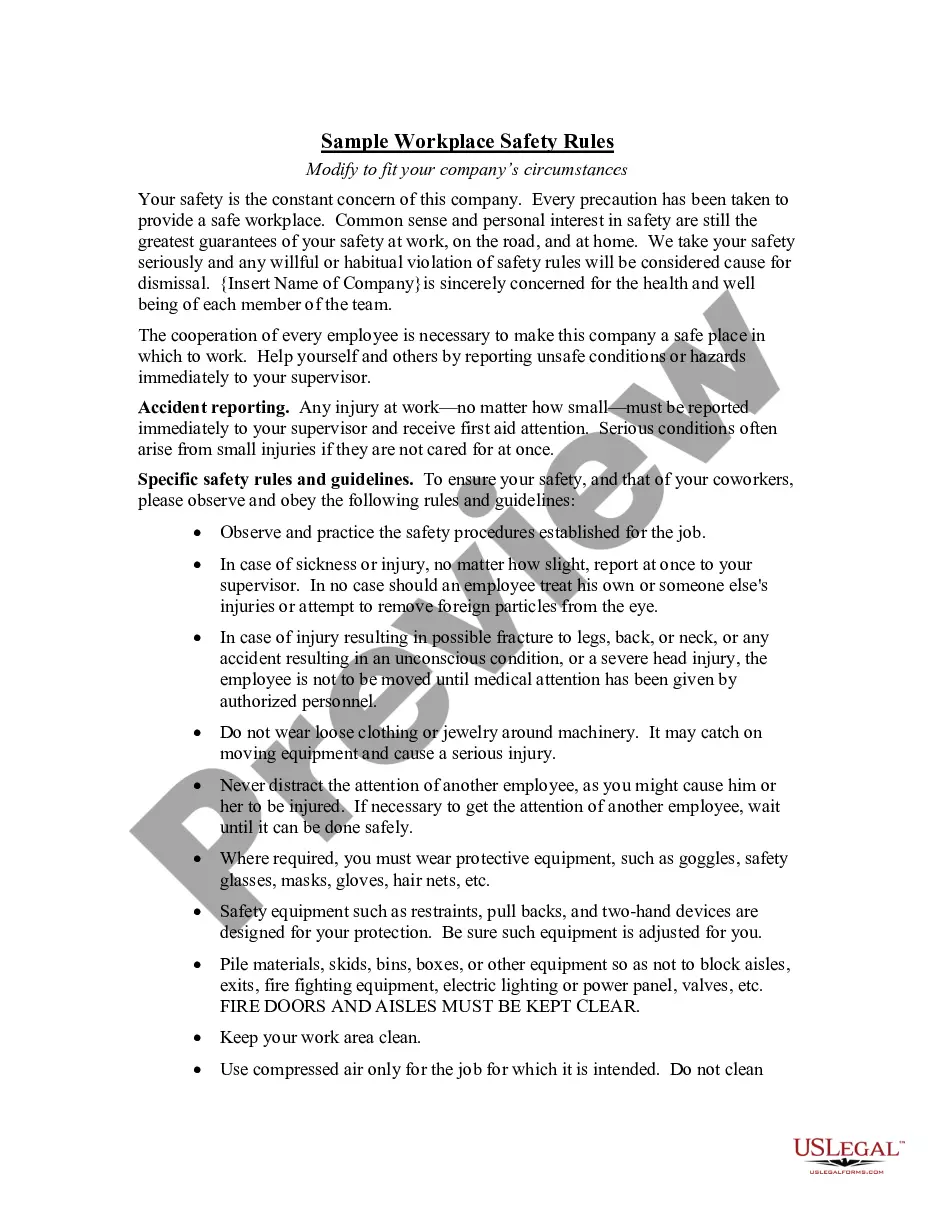

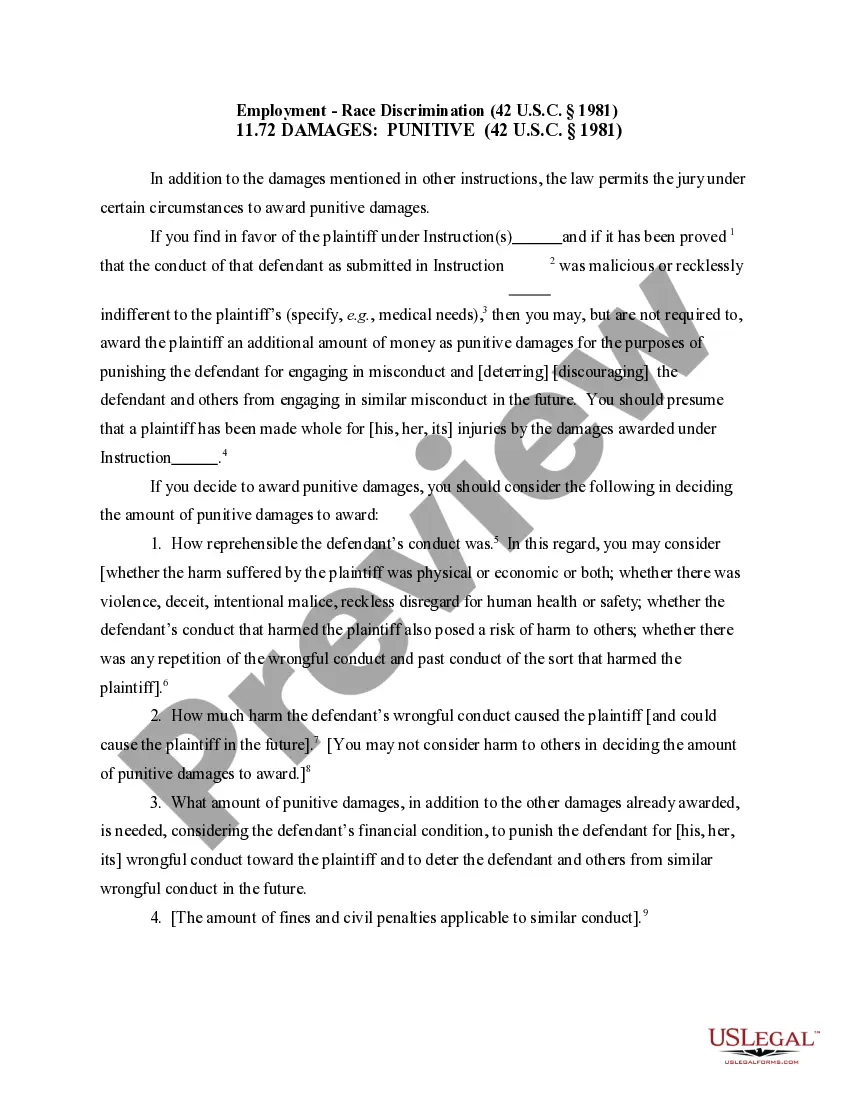

The Occupational Safety and Health Administration (OSHA) general safety policy serves as a framework for ensuring safe and healthful working conditions. OSHA sets and enforces standards that employers must follow to minimize risks in the workplace. Familiarizing yourself with the Pennsylvania 21 Things to do for a Safe Workplace can help you align your practices with OSHA's policies and protect your workforce.

The safety zone law in Pennsylvania is designed to protect workers from workplace hazards by establishing specific areas where employees can work safely. These zones require clear markings and signage to alert workers of potential dangers associated with machinery or hazardous materials. Understanding the Pennsylvania 21 Things to do for a Safe Workplace will help you create and maintain these safety zones effectively, ensuring employee safety.

In Pennsylvania, the general safety law emphasizes the importance of maintaining a safe work environment for all employees. It requires employers to implement standards that protect workers from hazards. The Pennsylvania 21 Things to do for a Safe Workplace outlines the essential protocols and guidelines for achieving compliance. By following these laws, businesses can foster a safer and healthier workplace.

OSHA recommends seven guidelines for workplace safety, including identifying hazards, implementing safety precautions, training employees, maintaining equipment properly, ensuring effective communication, encouraging employee involvement, and regularly reviewing safety practices. Following these guidelines fosters a safer work environment for everyone. To learn more, check out our Pennsylvania 21 Things to do for a Safe Workplace, where we detail these guidelines further.

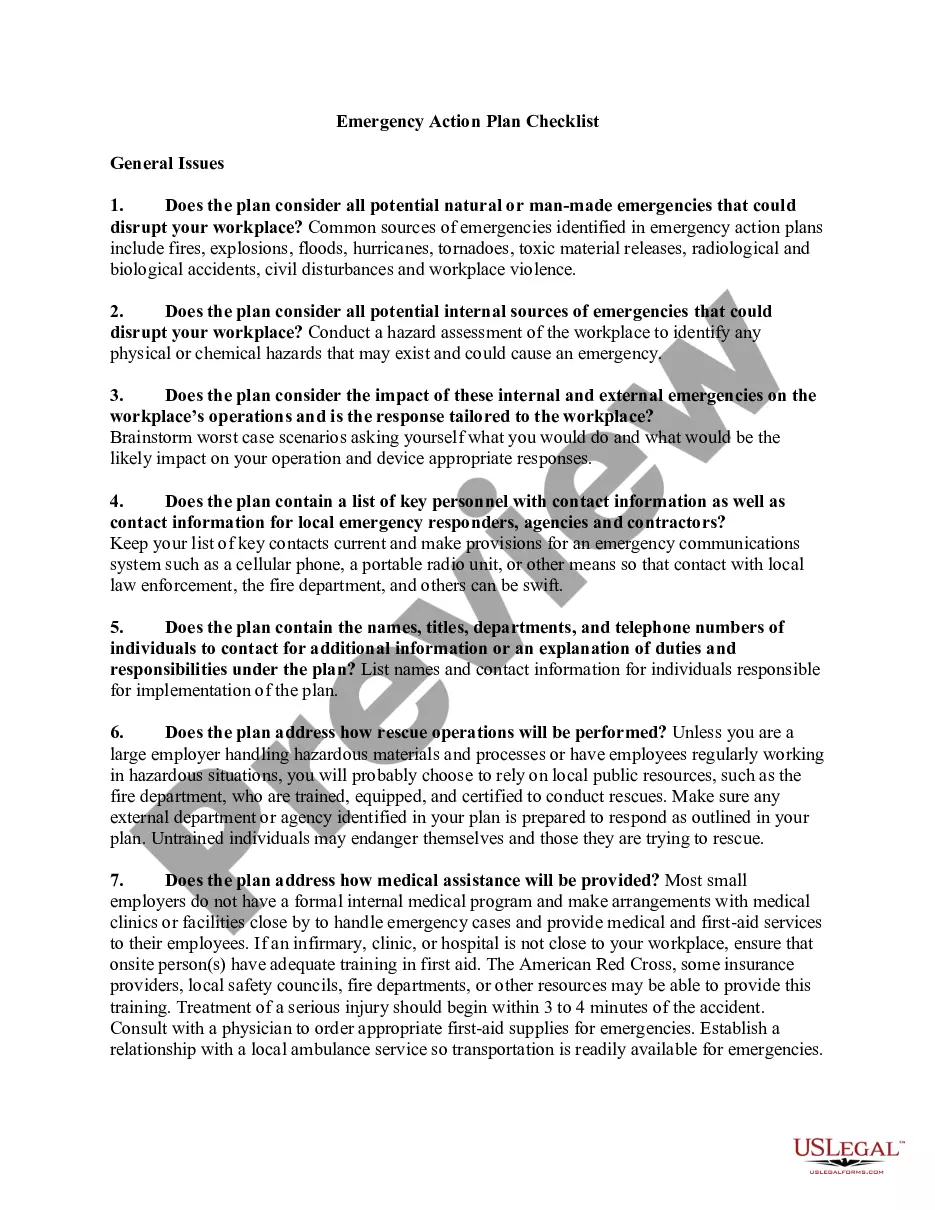

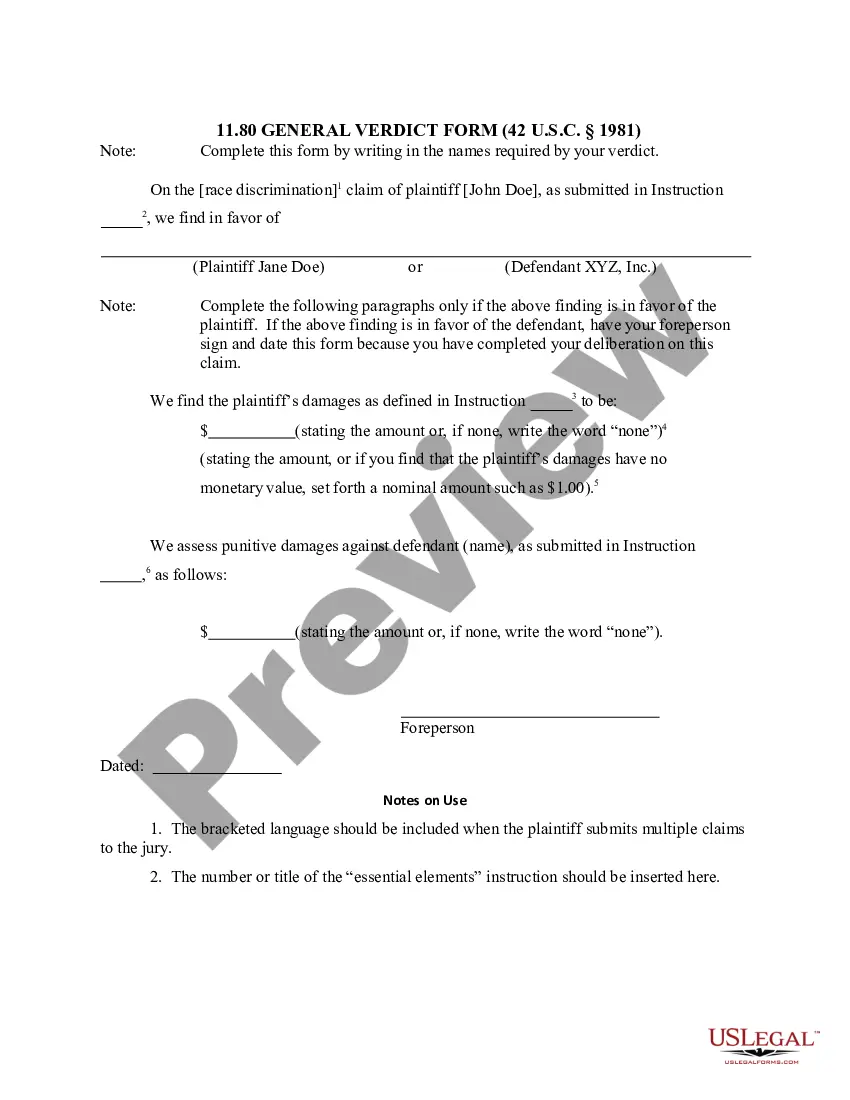

In Pennsylvania, employers must report any workplace incidents that result in fatalities or serious injuries within a specific timeframe. This includes incidents involving hospitalization, amputation, or loss of an eye. Reporting these incidents is crucial for maintaining safety standards and preventing future occurrences. Our Pennsylvania 21 Things to do for a Safe Workplace provides information on effective reporting practices.

The five steps to a safer workplace include identifying potential hazards, assessing risks, implementing safety measures, providing training, and maintaining clear communication. Companies should continuously monitor safety protocols and encourage employee feedback. These steps align with the Pennsylvania 21 Things to do for a Safe Workplace, which offers practical tips for enhancing workplace safety.

OSHA protects employees by setting and enforcing safety regulations and by providing resources for safety training. They conduct inspections to ensure compliance and respond to reports of unsafe conditions. Their efforts aim to minimize workplace hazards and promote a culture of safety. For more insights, explore our Pennsylvania 21 Things to do for a Safe Workplace.

OSHA requires companies to follow specific safety standards that promote a safe working environment. Employers must identify potential hazards, provide safety training, and ensure the use of protective equipment. Additionally, they must maintain records of workplace injuries and illnesses. For guidance, refer to our Pennsylvania 21 Things to do for a Safe Workplace, which outlines essential steps to enhance safety.

Employers are required to report work-related fatalities and severe injuries immediately to OSHA. Specifically, incidents resulting in hospitalization, amputation, or loss of consciousness must be communicated without delay. This level of urgency is crucial for compliance with the Pennsylvania 21 Things to do for a Safe Workplace. Timely reporting ensures that necessary investigations and interventions can occur promptly.

related incident becomes OSHA reportable when it causes a fatality, permanent disability, or requires hospitalization. Additionally, any loss of consciousness or significant injury that prevents employees from performing their regular work is reportable. Being familiar with what makes an incident reportable helps uphold the Pennsylvania 21 Things to do for a Safe Workplace. Prompt reporting ensures corrective actions can be taken swiftly.