Maryland Maintenance Assistance - Technician Checklist

Description

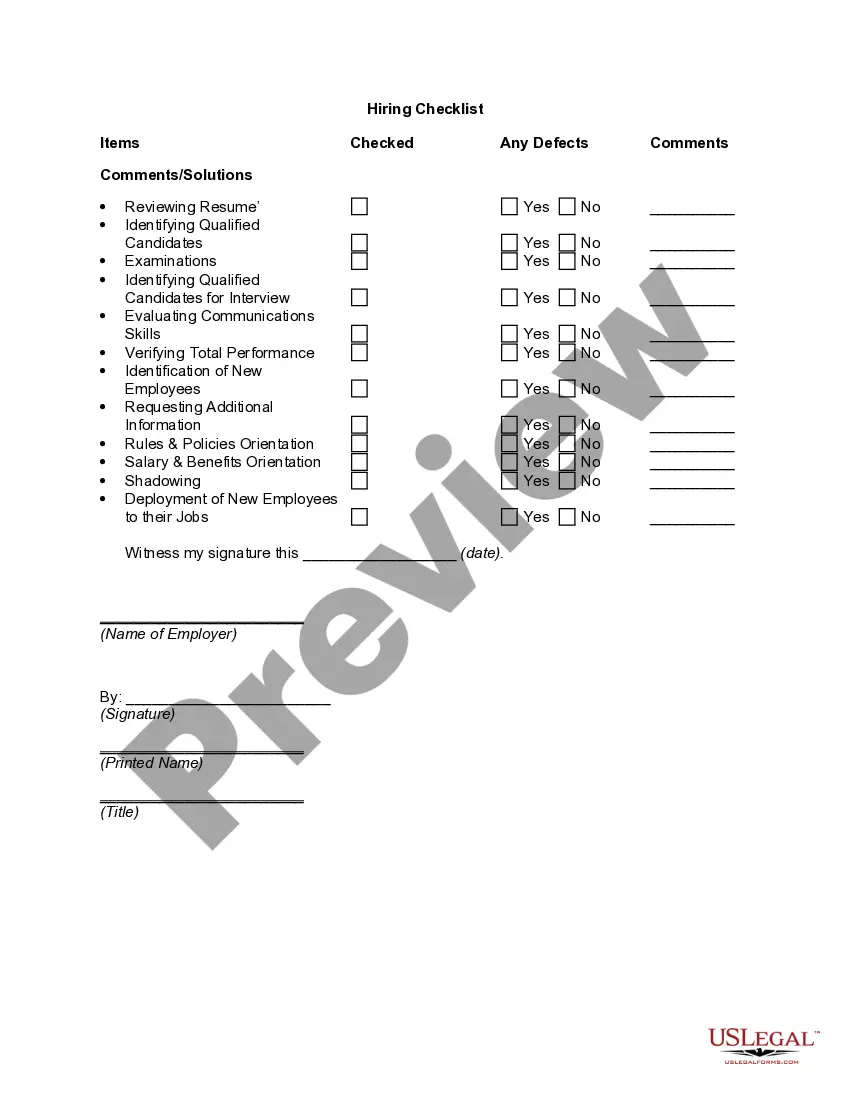

How to fill out Maintenance Assistance - Technician Checklist?

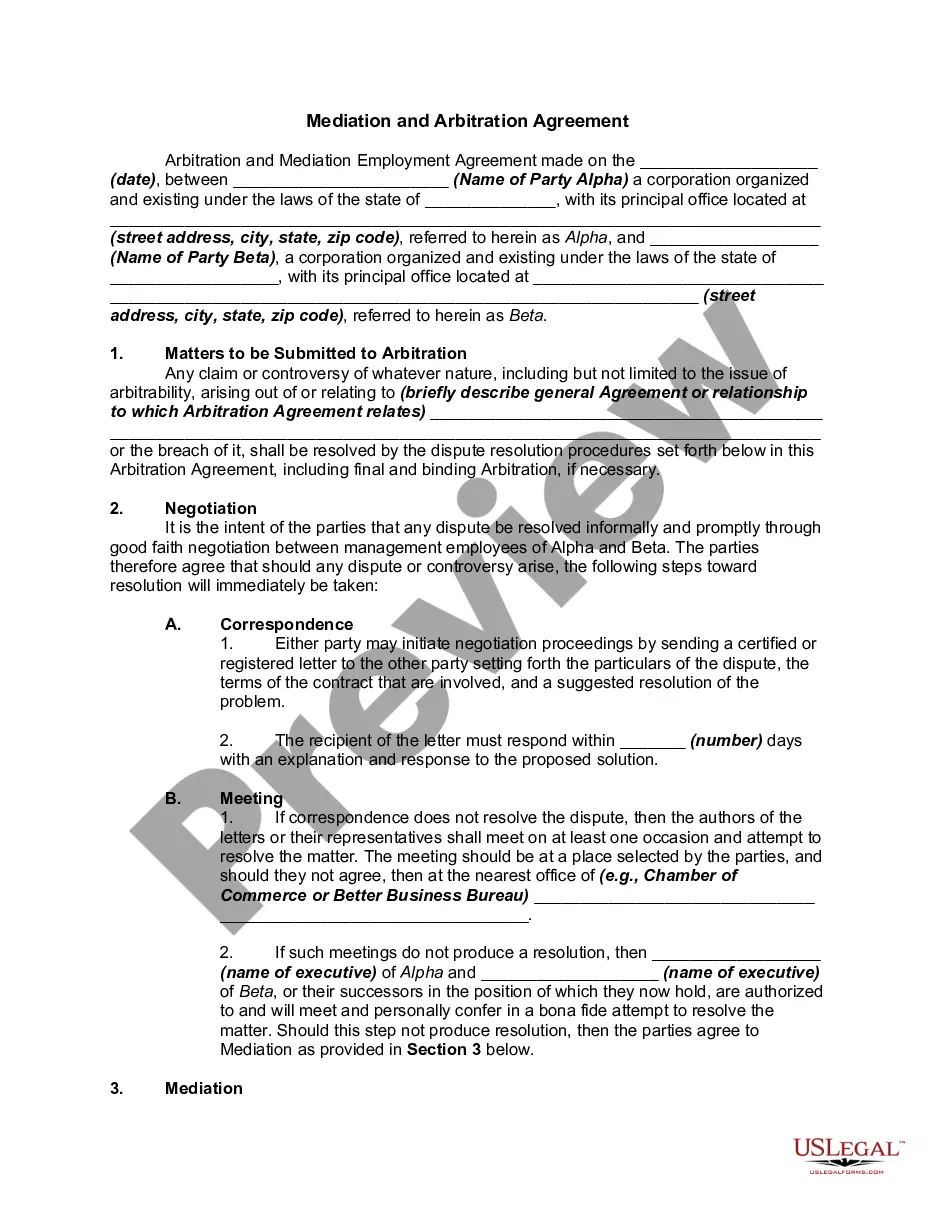

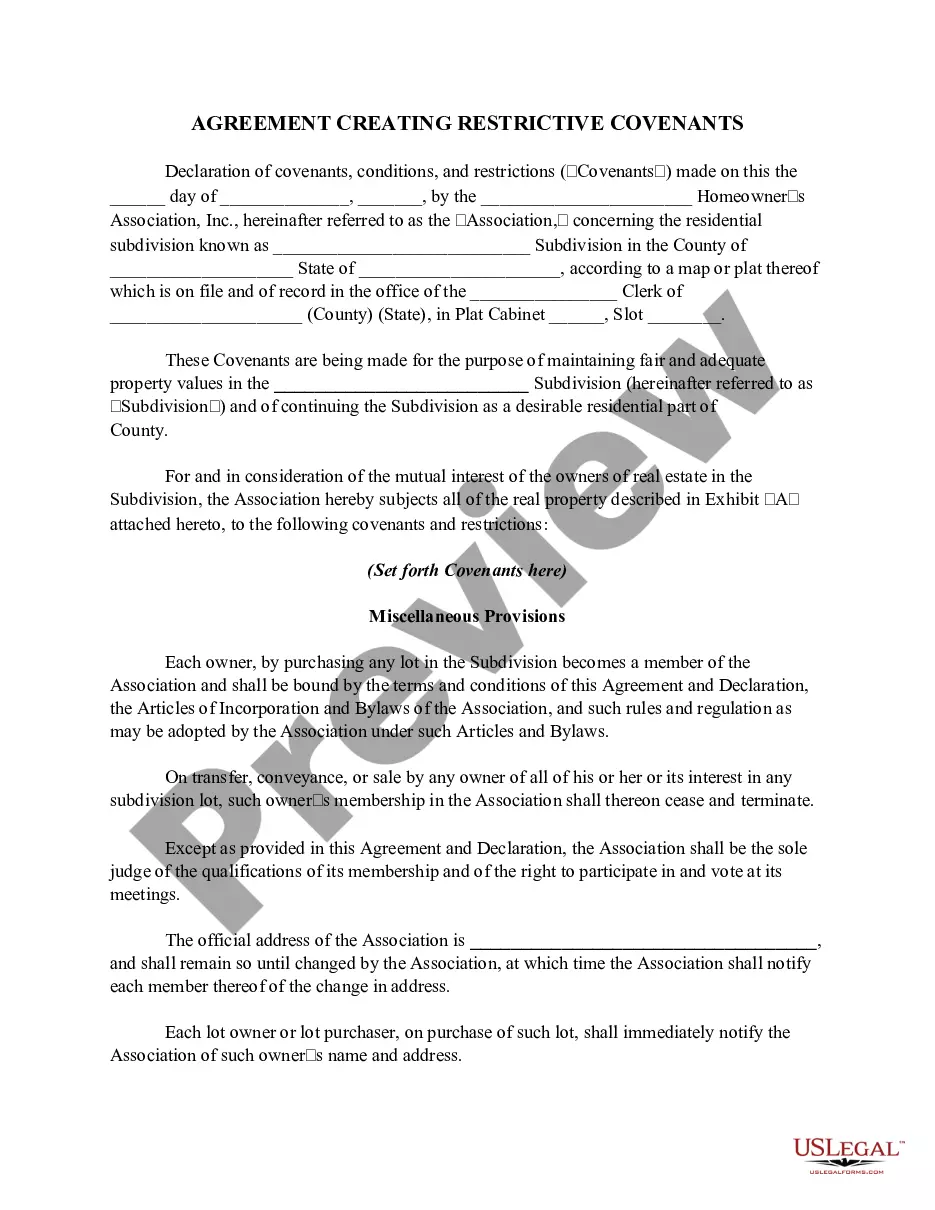

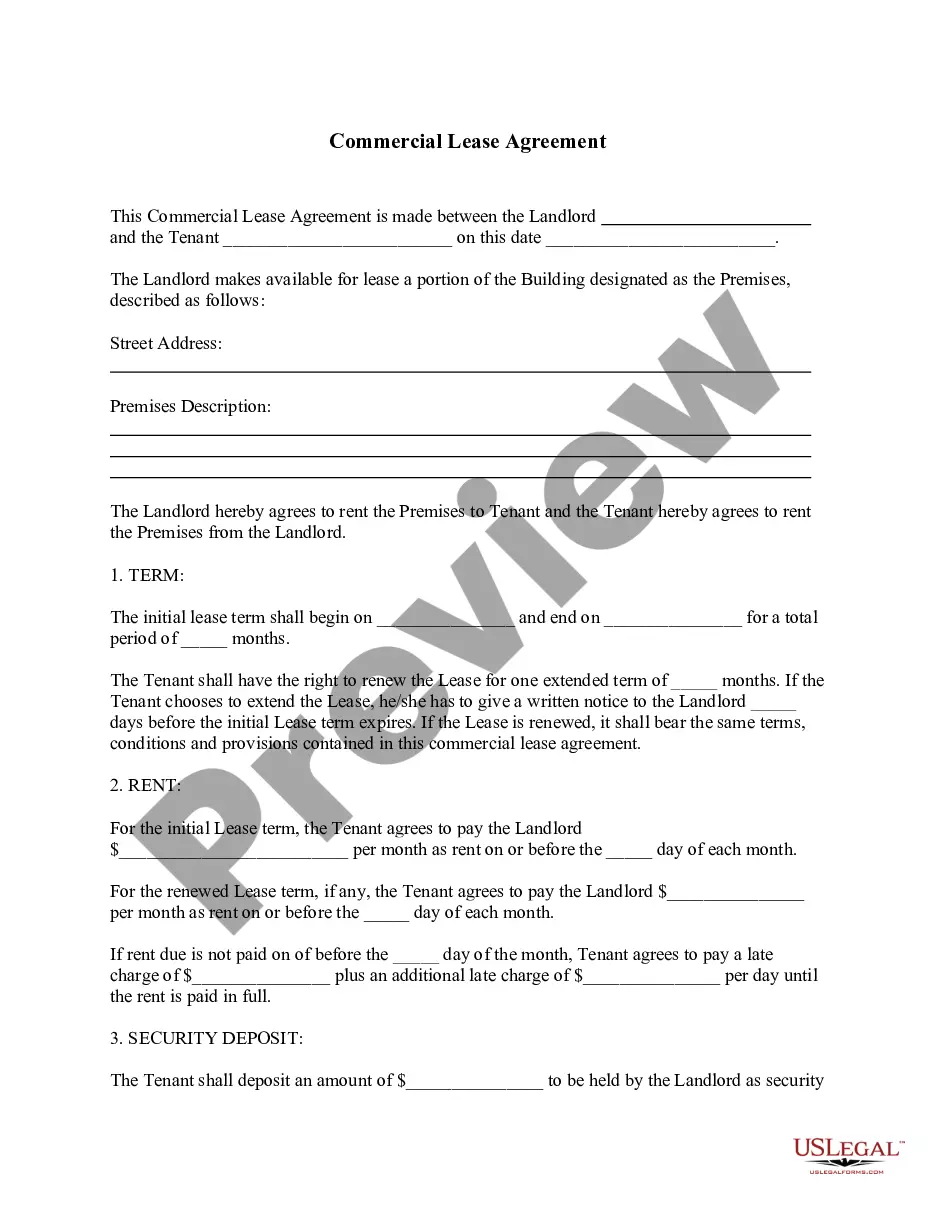

If you need to finalize, obtain, or print authentic document templates, utilize US Legal Forms, the largest collection of legal forms, readily available online.

Take advantage of the website's straightforward and user-friendly search feature to locate the documents you need.

A variety of templates for business and personal applications are categorized by types and states, or keywords.

Step 4. Once you have found the form you need, click the Order now option. Choose the pricing plan you prefer and enter your information to create an account.

Step 5. Complete the transaction. You can utilize your credit card or PayPal account to finalize the purchase. Step 6. Select the format of the legal form and download it to your device. Step 7. Complete, edit, and print or sign the Maryland Maintenance Support - Technician Checklist.

- Employ US Legal Forms to find the Maryland Maintenance Support - Technician Checklist with just a few clicks.

- If you are already a US Legal Forms customer, sign in to your account and select the Download option to retrieve the Maryland Maintenance Support - Technician Checklist.

- You can also access forms you have previously saved from the My documents section of your account.

- If you are using US Legal Forms for the first time, follow the instructions below.

- Step 1. Ensure you have selected the form for the correct city/state.

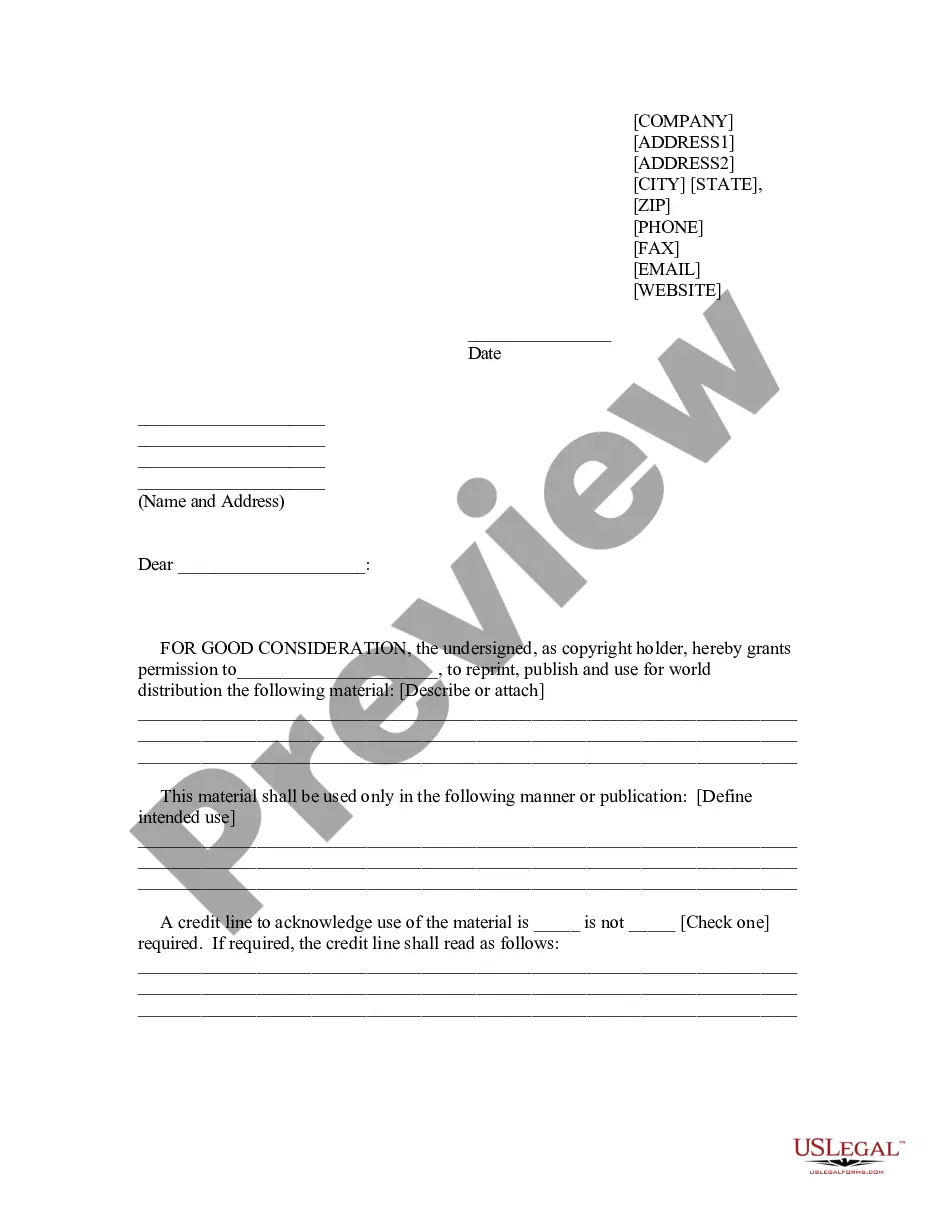

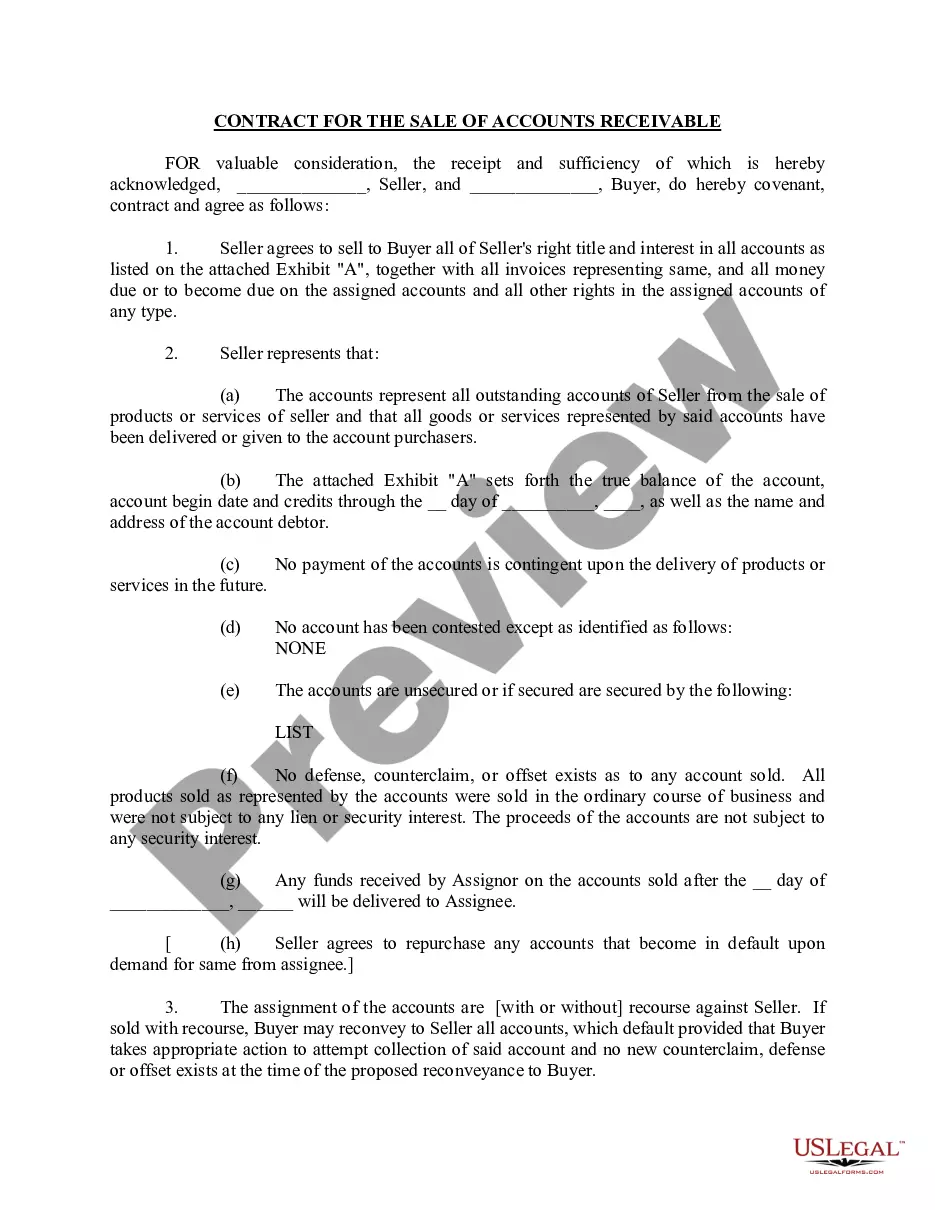

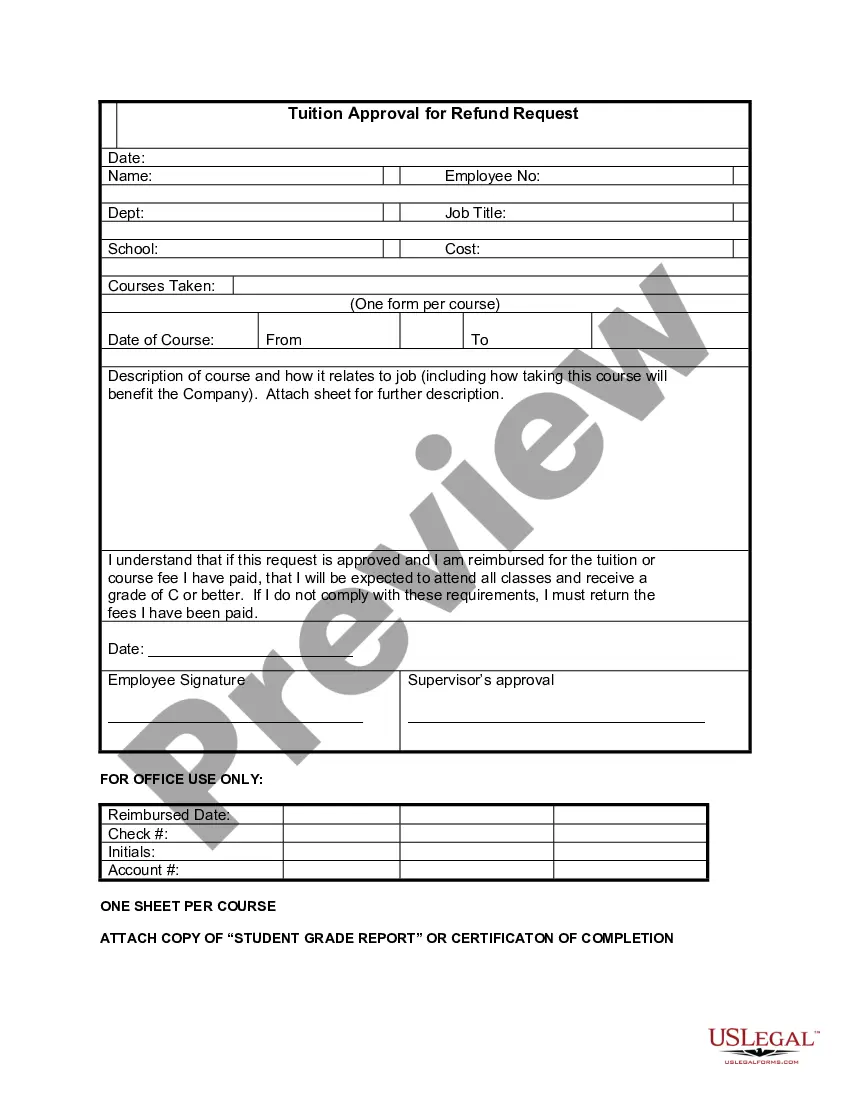

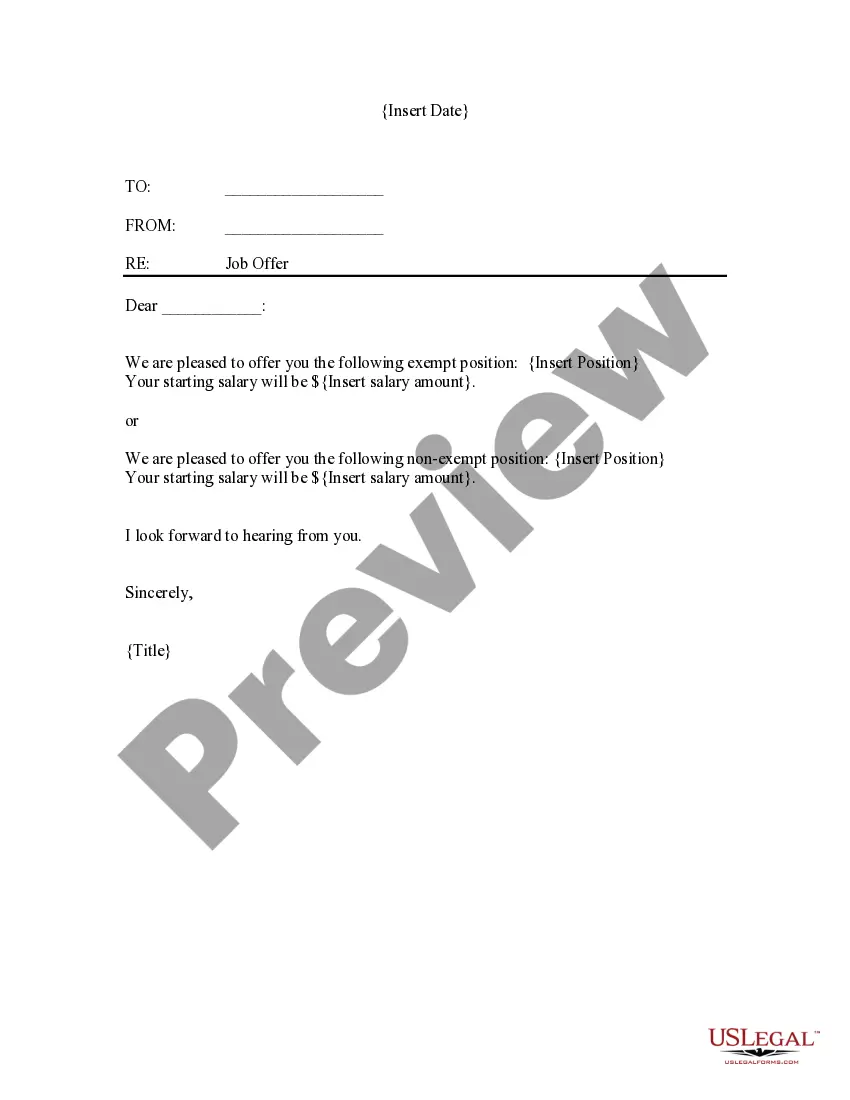

- Step 2. Use the Preview option to review the form's details. Don’t forget to read the summary.

- Step 3. If you are not satisfied with the form, use the Search field at the top of the screen to find other versions of the legal form template.

Form popularity

FAQ

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

In order to build a most effective checklist that fits their enterprise, businesses should first:Delegate maintenance duties to relevant people.Set preventive maintenance program goals.Gether information about existing equipment.Shortlist equipment before including in the checklist.More items...?

The purpose of maintenance is to ensure the maximum efficiency and availability of production equipment, utilities and related facilities at optimal cost and under satisfactory conditions of quality, safety and protection for the environment.

By identifying components or parts that are wearing out and repairing or replacing them before they fail, an effective preventive maintenance program can help limit production downtime and extend the service life of equipment and facilities.

For example: performing regular business and equipment inspections, cleaning and lubricating essential equipment, and tidying your business's grounds are all examples of preventive maintenance. The goal of preventive maintenance is to prevent equipment failure before it occurs, and to reduce the risk of accidents.

Simply put, maintenance performed on a regular basis to reduce the likelihood of failure is preventive maintenance. Also called planned or preventative maintenance, PM is conducted throughout an asset's normal operating conditions.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

The primary objective of planned maintenance is to maximize equipment performance by keeping equipment running safely for as long as possible, without that equipment deteriorating or having unplanned outages. Planned maintenance activities include any maintenance work scheduled in advance.

Six Tips for Creating a PM ChecklistInvolve the Right People in the Process. When planning the assets to maintain and creating PMs for each one, it helps to have the right types of expertise on board.Be Detailed, but Concise.Include Pictures.Include Safety Measures.Make Your Checklists Mobile.Update as Needed.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.