US Legal Forms - among the largest collections of legal documents in the United States - offers a selection of legal document templates that you can download or print.

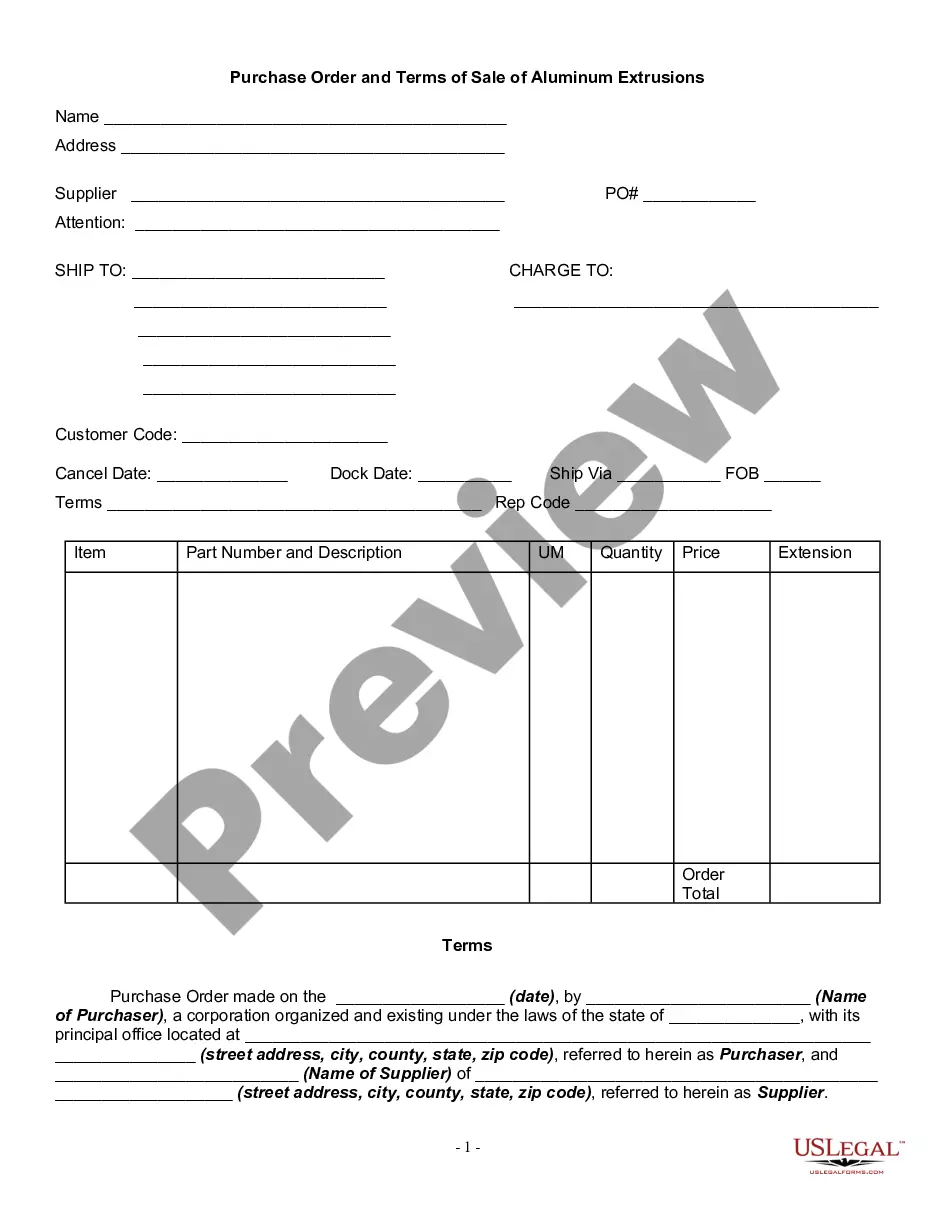

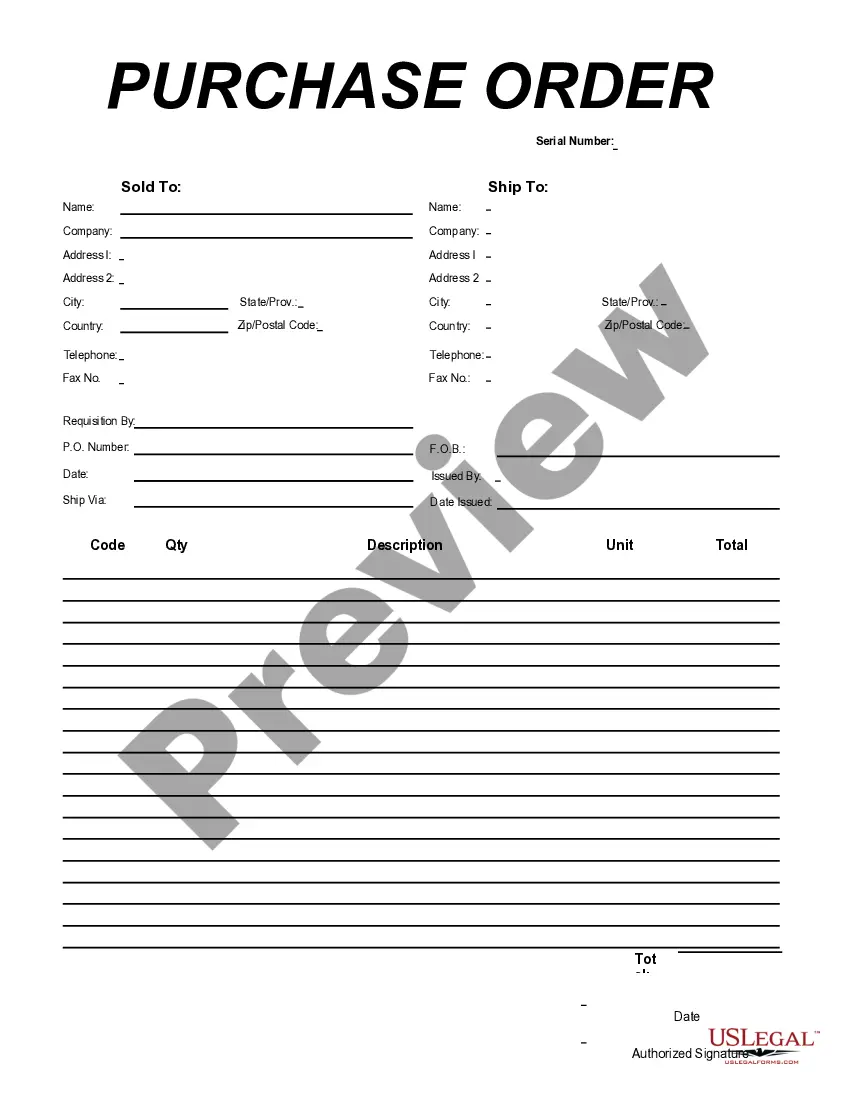

While utilizing the site, you can find thousands of forms for business and personal purposes, organized by categories, states, or keywords. You can acquire the latest versions of forms such as the Kansas Purchase Order of Aluminum Extrusions in no time.

If you possess a monthly subscription, Log In and retrieve the Kansas Purchase Order of Aluminum Extrusions from your US Legal Forms library. The Download button will appear on each form you view. You can access all previously acquired forms in the My documents section of your account.

Complete the transaction. Use your credit card or PayPal account to finalize the purchase.

Choose the format and download the form onto your device. Edit. Fill out, modify, print, and sign the downloaded Kansas Purchase Order of Aluminum Extrusions. Every template you added to your account has no expiration date and is yours permanently. Therefore, if you wish to download or print another copy, simply navigate to the My documents section and click on the form you need.

- Make sure you have selected the correct form for your region/county.

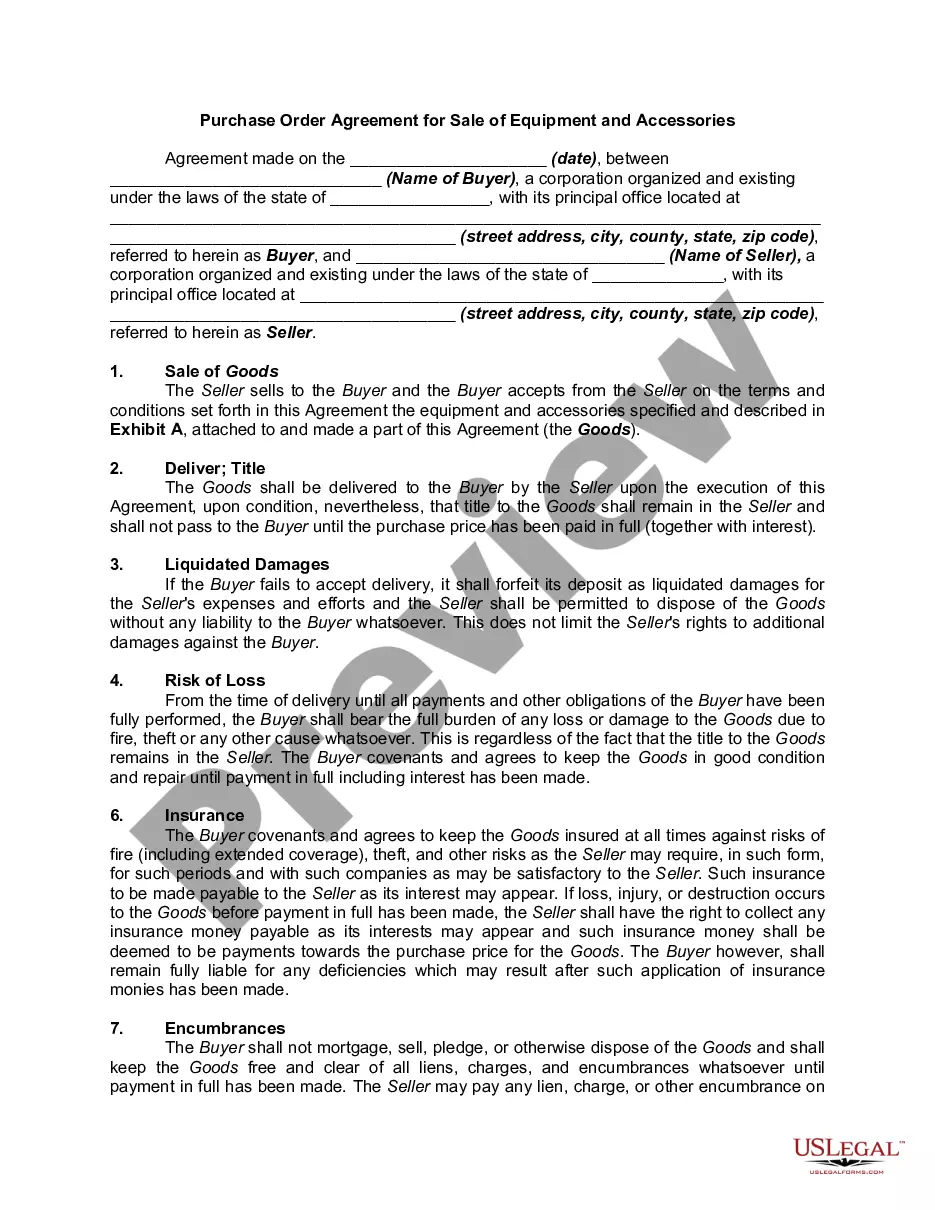

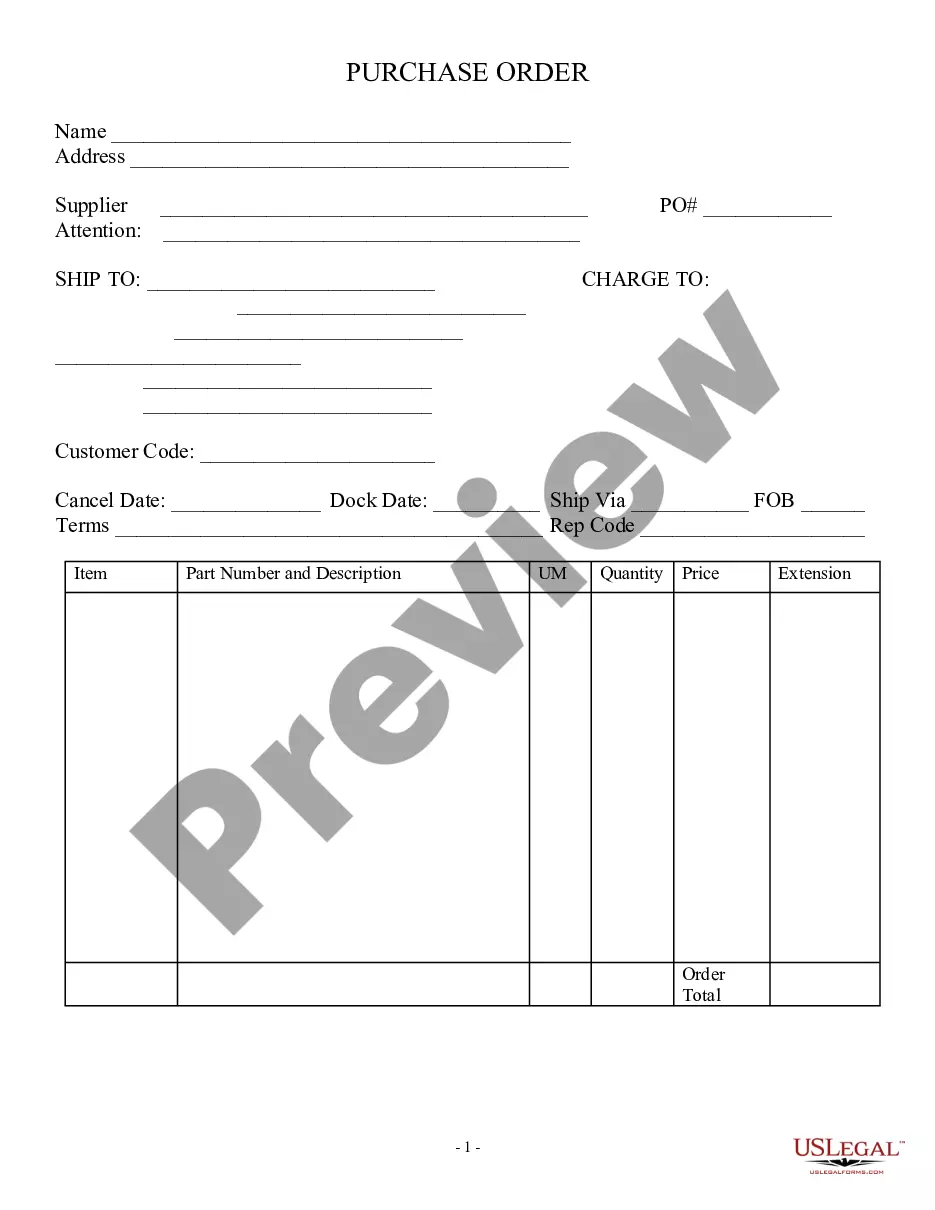

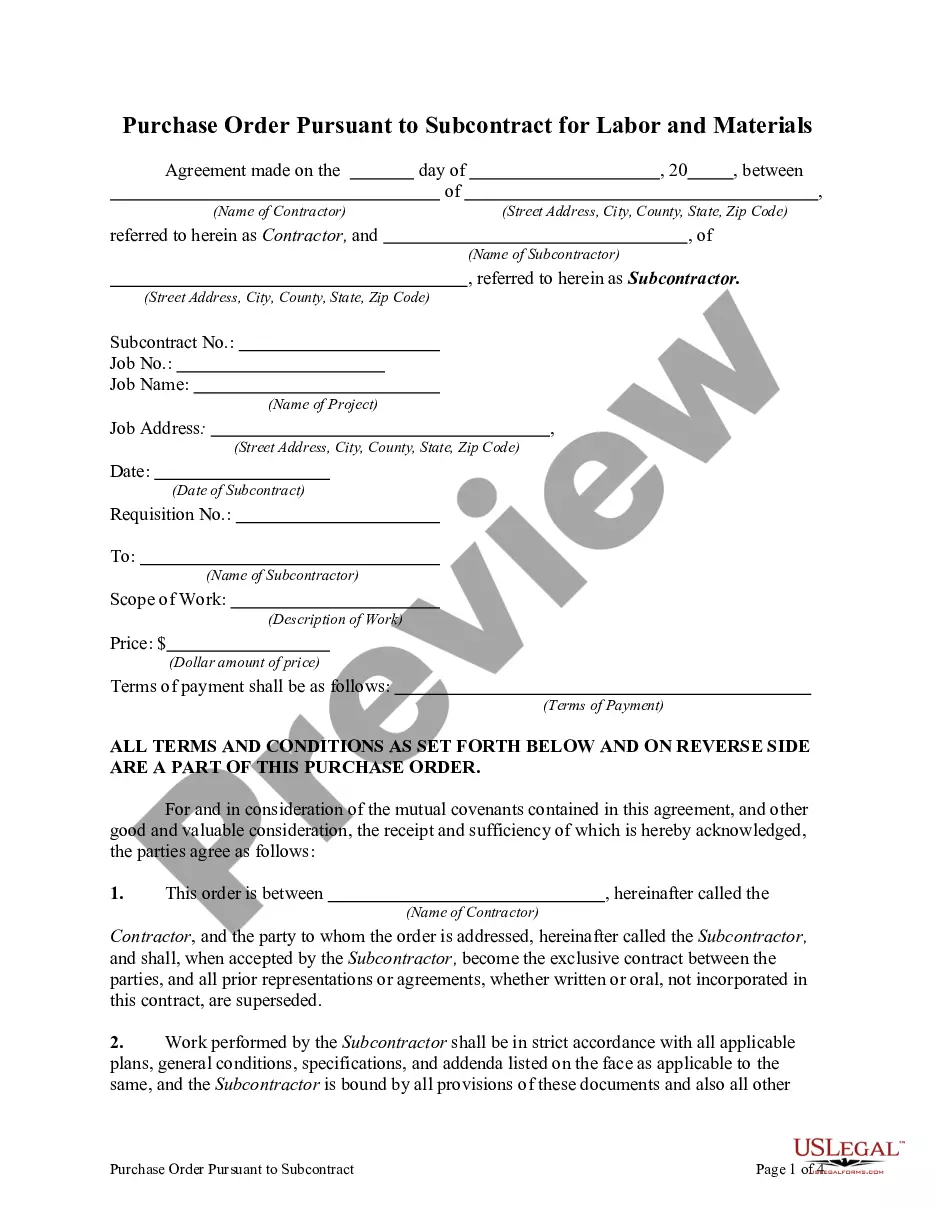

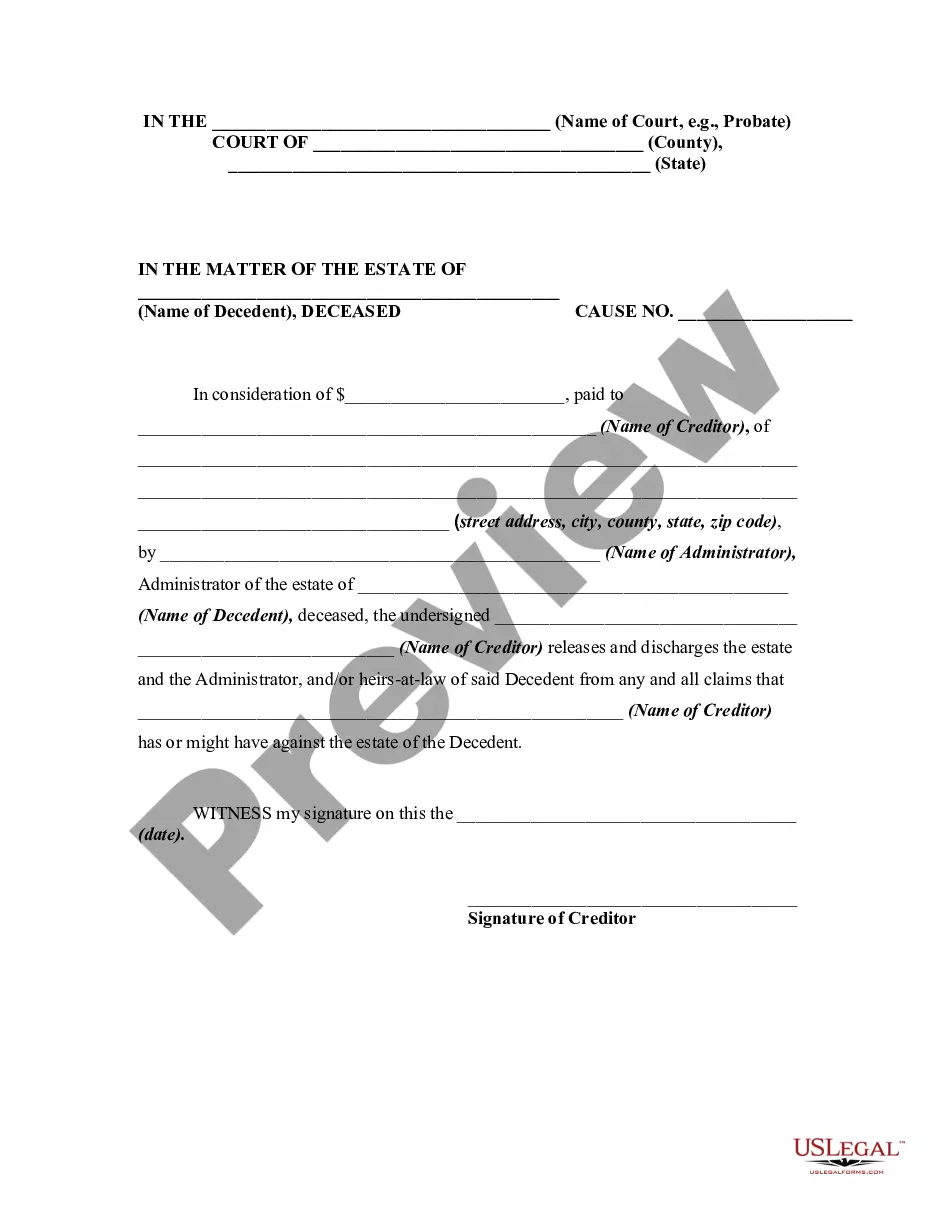

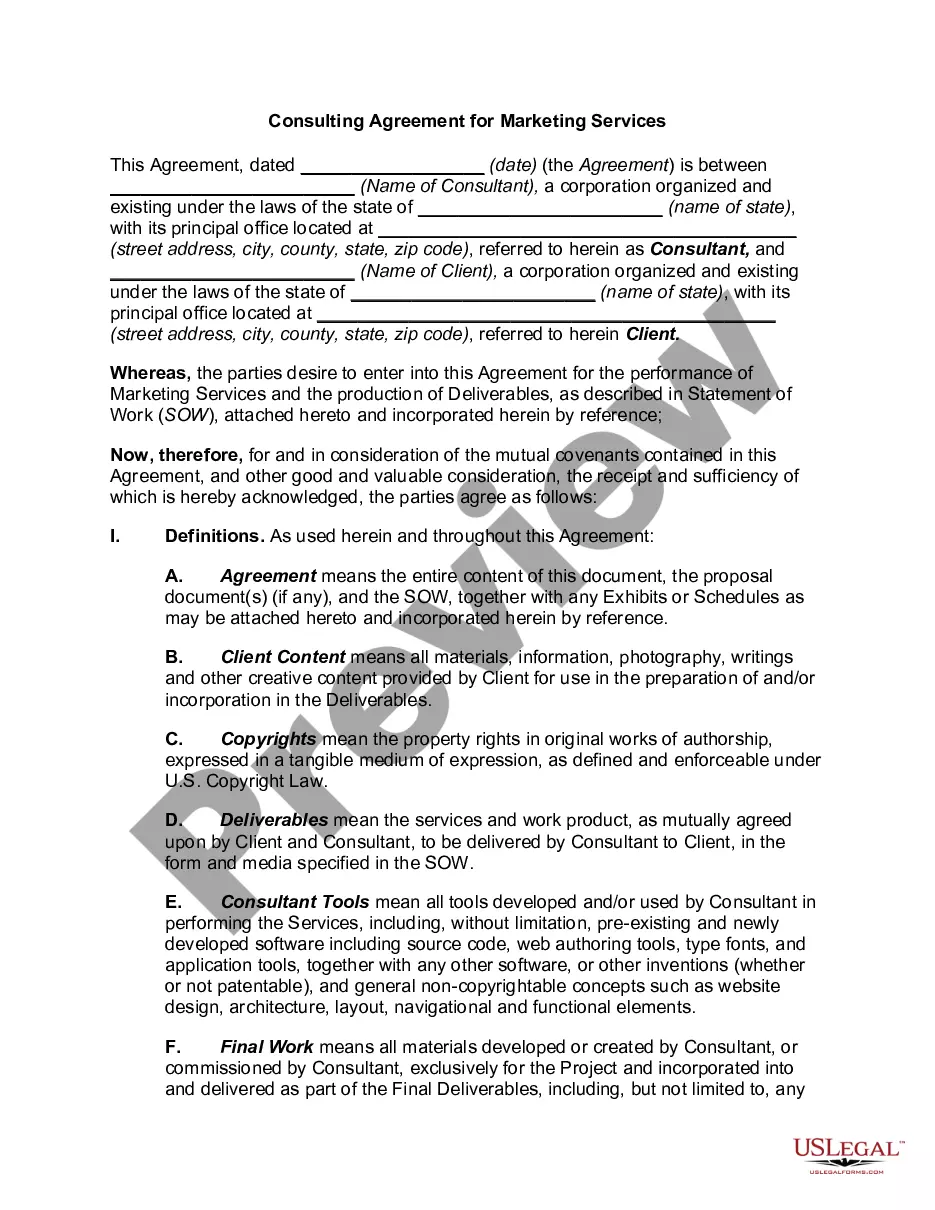

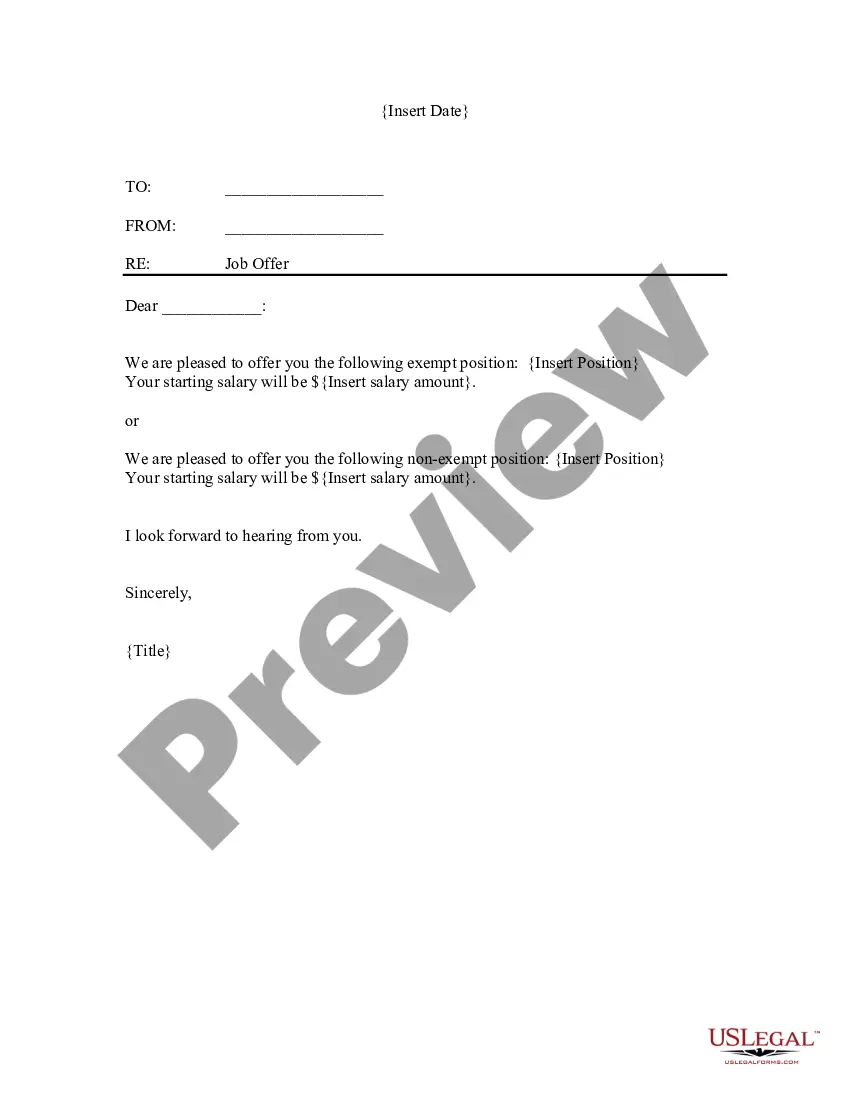

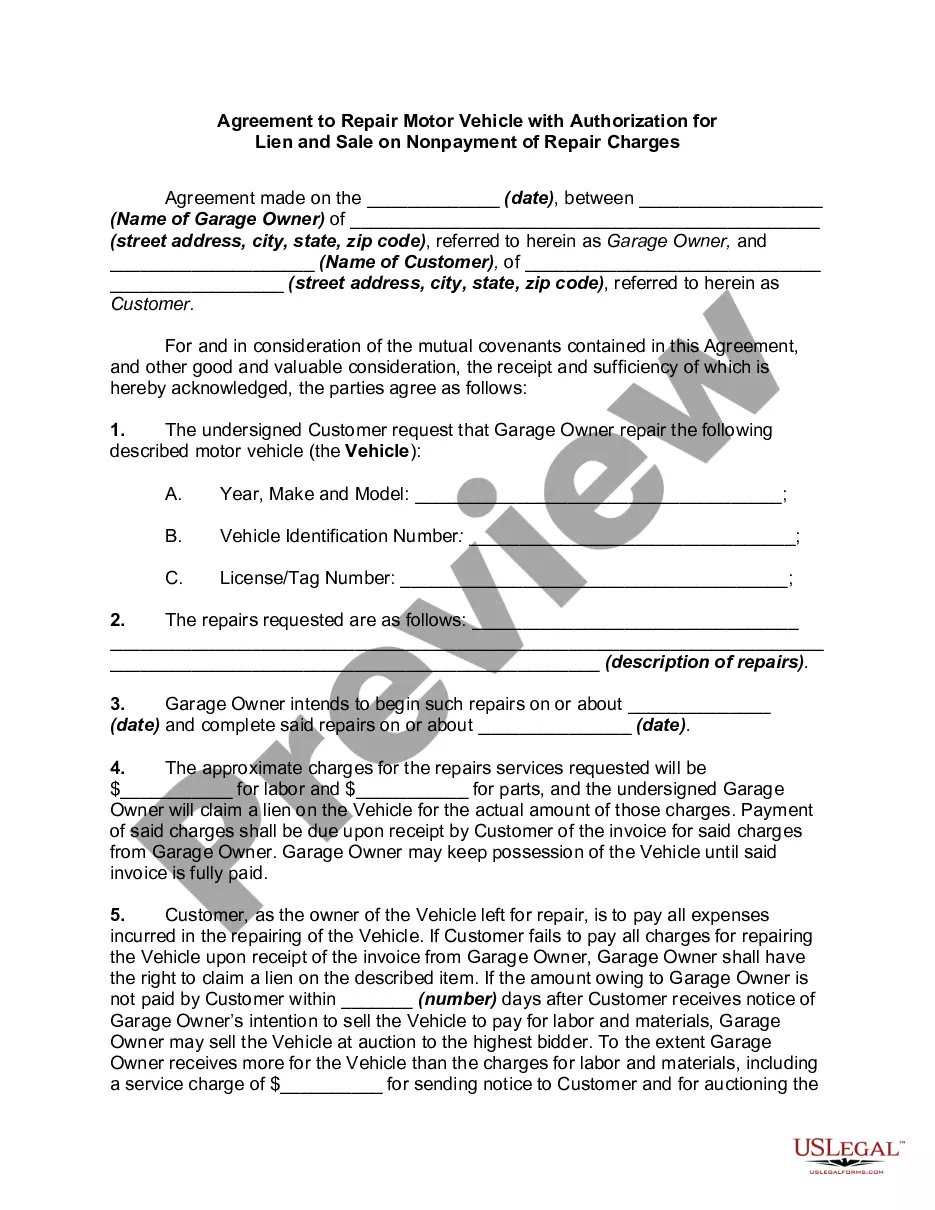

- Click on the Review button to evaluate the form's content.

- Check the form description to confirm you have chosen the right document.

- If the form does not meet your needs, use the Search box at the top of the screen to find a suitable one.

- If you are satisfied with the form, confirm your choice by clicking the Purchase now button.

- Then, select the pricing plan you prefer and provide your credentials to register for an account.