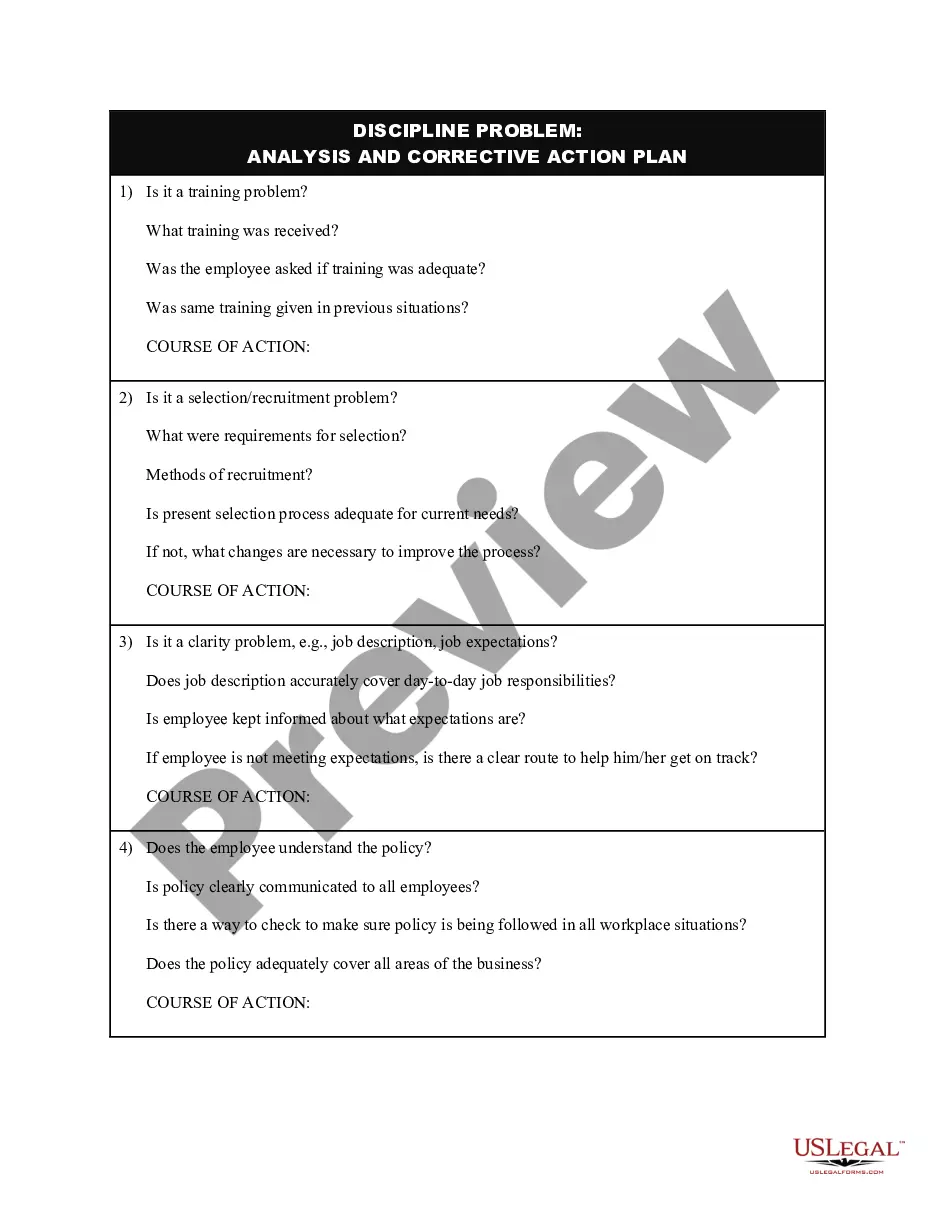

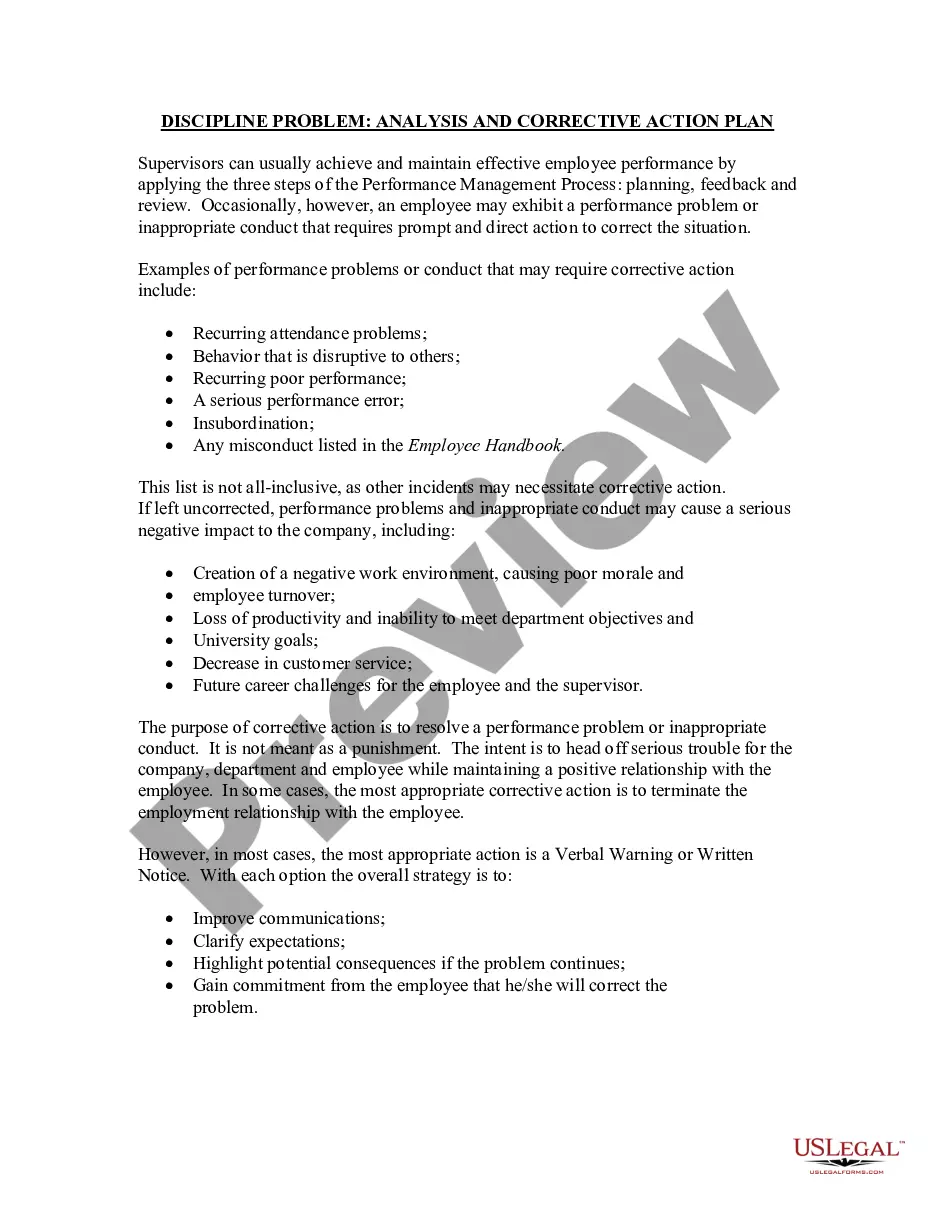

Georgia Discipline Problem - Analysis and Corrective Action Plan

Description

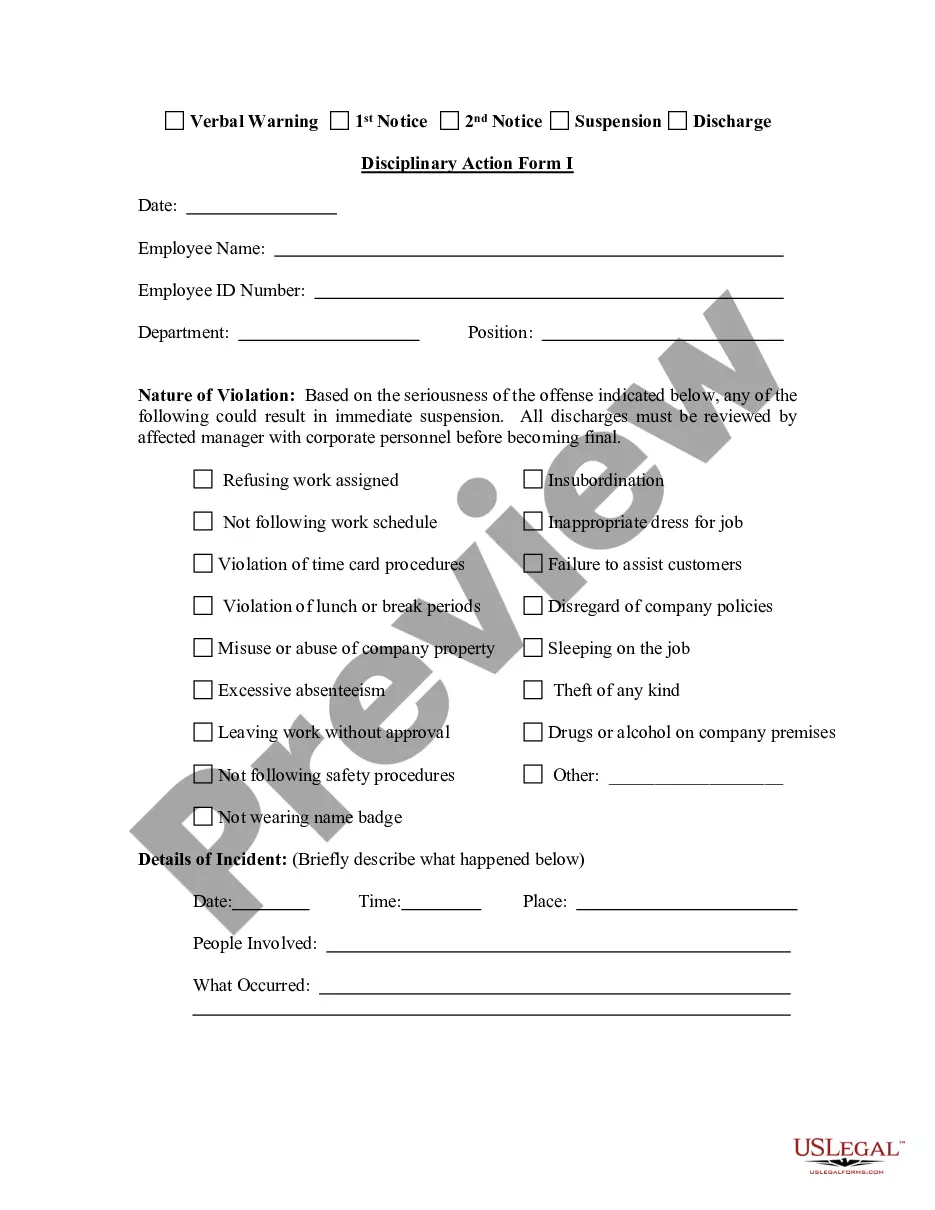

How to fill out Discipline Problem - Analysis And Corrective Action Plan?

Locating the suitable official document template can be a challenge. Clearly, there is a multitude of templates accessible online, but how can you find the official form you need? Utilize the US Legal Forms platform.

The service provides thousands of templates, including the Georgia Discipline Issue - Assessment and Corrective Action Plan, which can be utilized for business and personal purposes. All forms are verified by experts and comply with state and federal regulations.

If you are already a member, Log In to your account and click the Download button to receive the Georgia Discipline Issue - Assessment and Corrective Action Plan. Use your account to search through the official forms you have previously ordered. Visit the My documents section of your account and retrieve another copy of the document you need.

US Legal Forms is the largest collection of official forms from which you can access various document templates. Use the service to download professionally crafted documents that adhere to state requirements.

- First, ensure you have selected the correct form for the city/county. You can preview the form using the Review button and read the form summary to confirm it is suitable for your needs.

- If the form does not meet your needs, use the Search area to find the correct form.

- Once you are confident that the form is appropriate, click the Buy now button to obtain the form.

- Choose the pricing plan you wish to use and input the necessary information. Create your account and pay for your order with your PayPal account or credit card.

- Select the file format and download the official document template to your device.

- Complete, edit, print, and sign the acquired Georgia Discipline Issue - Assessment and Corrective Action Plan.

Form popularity

FAQ

The 8D methodology is a structured and systematic approach to problem-solving. From an 8D problem-solving example it's clear that it not only identifies a problem but also recognizes the weaknesses in the system. Analysis of an 8D report example prevents future occurrences of similar issues.

Ford Motor Company developed this problem solving methodology, then known as Team Oriented Problem Solving (TOPS), in the 1980s. The early usage of 8D proved so effective that it was adopted by Ford as the primary method of documenting problem solving efforts, and the company continues to use 8D today.

8D Report1D: Team Formation. 8D procedures are used for solving exact problems.2D: Problem Description.3D: Interim Containment Actions.4D: Root Cause Analysis.5D: Corrective Actions.6D: Verification of Corrective Actions.7D: Preventive Actions.8D: Team and individual recognition.

Your 8D report documents the below steps.Team approach.Describe the Problem.Containment Action.Root Cause Verification.Implement Corrective Action.Verify Corrective Action.Prevent Recurrence.Congratulate the Team.

How to Use the 8D Method to Find the Root Cause of NonconformancesD0: Plan.D1: Form Your Team.D2: Define the Problem.D3: Contain the Problem.D4: Identify the Root Cause.D5: Analyze and Select Corrective Actions.D6: Implement and Validate Corrective Actions.D7: Implement Preventive Actions.More items...

In the Loop (Quality Progress) An 8D report is a quality report suppliers use to inform a customer about the status of complaint-related actions. Use this refresher to help track the status of customer complaints. Adapted from Modular Kaizen: Continuous and Breakthrough Improvement, ASQ Quality Press.

The 8D problem solving process is a detailed, team oriented approach to solving critical problems in the production process. The goals of this method are to find the root cause of a problem, develop containment actions to protect customers and take corrective action to prevent similar problems in the future.

The Eight Steps of the 8D MethodologyD0 Plan.D1 Put Together A Team.D2 Define the Problem.D3 Implement a Temporary Fix.D4 Identify Root Causes and Chose a Solution.D5 Confirm The Solution Resolves The Problem.D6 Fully Implement the Solution.D7 Prevent Recurrence.More items...

The escape point is the place in the process of D8 methodology where the root cause of a problem that should have detected the problem but failed to detect so. This considers not only the root cause but also went wrong with the control system in allowing this problem to escape.