Connecticut Maintenance Engineer Checklist

Description

How to fill out Maintenance Engineer Checklist?

Selecting the optimal legal document design can be a challenge.

It goes without saying that there are numerous templates available online, but how can you find the legal form you need.

Utilize the US Legal Forms website. The service offers a vast array of templates, including the Connecticut Maintenance Engineer Checklist, available for both business and personal use.

You can preview the form using the Preview button and review the form description to confirm it is suitable for you.

- All forms are reviewed by experts and comply with state and federal regulations.

- If you are already registered, Log Into your account and click the Obtain button to retrieve the Connecticut Maintenance Engineer Checklist.

- Use your account to browse the legal forms you have previously purchased.

- Visit the My documents tab in your account to access another copy of the documents you need.

- If you are a new user of US Legal Forms, here are straightforward instructions you should follow.

- First, ensure you have selected the correct form for your city/region.

Form popularity

FAQ

Section 20-302 of the Connecticut General Statutes outlines the requirements for obtaining a Professional Engineer license. This section details educational qualifications, examination criteria, and the importance of ethical practices in engineering. Understanding this statute is vital for engineers who want to adhere to the Connecticut Maintenance Engineer Checklist. By following these guidelines, you can simplify the licensing process and remain compliant with state regulations.

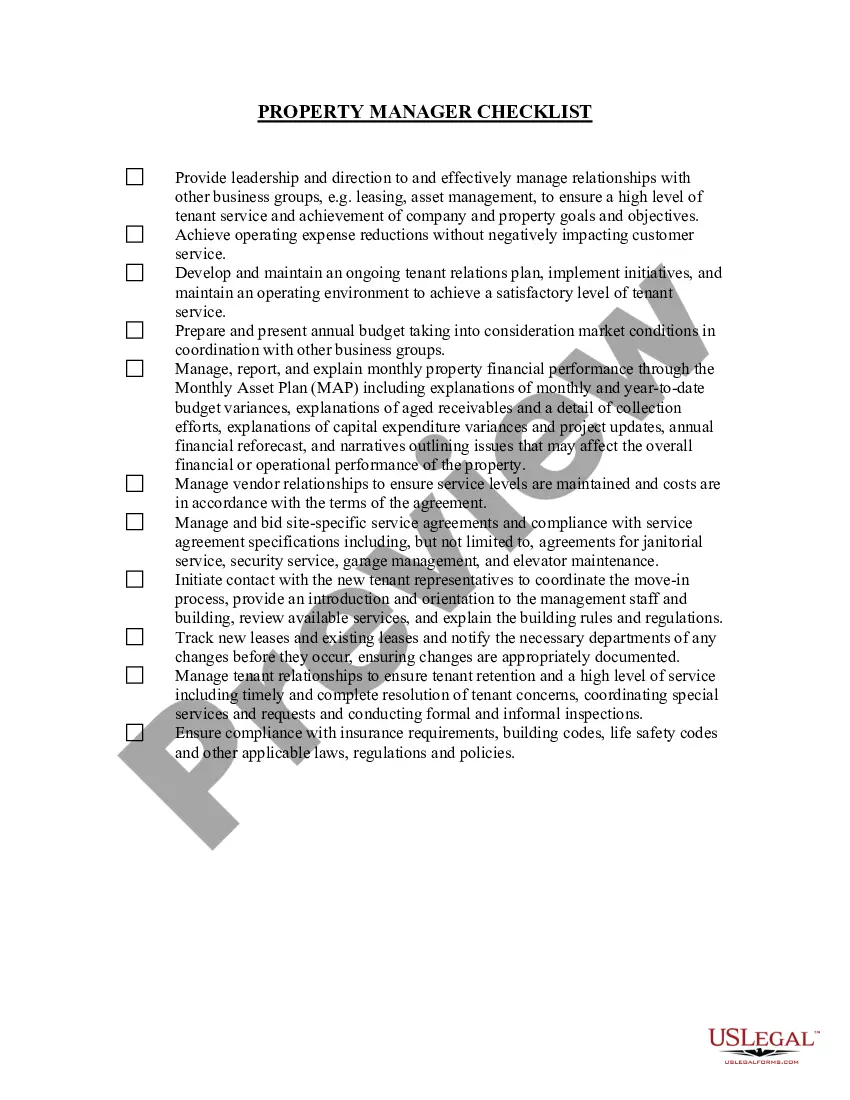

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

Six Tips for Creating a PM ChecklistInvolve the Right People in the Process. When planning the assets to maintain and creating PMs for each one, it helps to have the right types of expertise on board.Be Detailed, but Concise.Include Pictures.Include Safety Measures.Make Your Checklists Mobile.Update as Needed.

Follow the 7 basic preventive maintenance elements. The effective preventive maintenance consists of 7 major milestones. These are testing, servicing, calibration, inspection, adjustment, alignment and installation. Every maintenance team member should be conversant with and apply them accordingly.

For example: performing regular business and equipment inspections, cleaning and lubricating essential equipment, and tidying your business's grounds are all examples of preventive maintenance. The goal of preventive maintenance is to prevent equipment failure before it occurs, and to reduce the risk of accidents.

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

In order to build a most effective checklist that fits their enterprise, businesses should first:Delegate maintenance duties to relevant people.Set preventive maintenance program goals.Gether information about existing equipment.Shortlist equipment before including in the checklist.More items...?