Toll Manufacturing Vs Contract Manufacturing For Cosmetics

Description

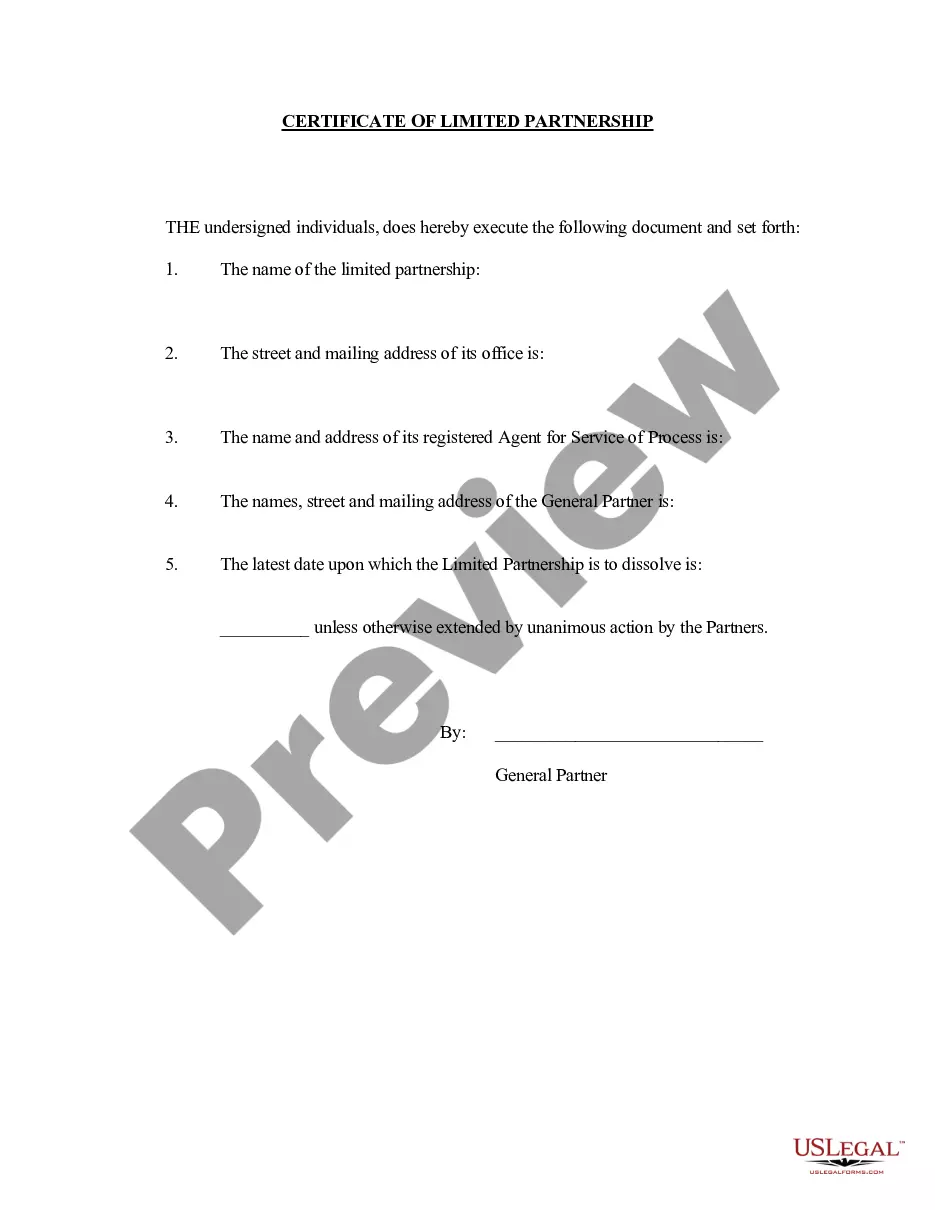

How to fill out Toll Manufacturing Agreement?

The Toll Manufacturing Vs Contract Manufacturing For Cosmetics you see on this page is a multi-usable legal template drafted by professional lawyers in accordance with federal and regional laws. For more than 25 years, US Legal Forms has provided people, organizations, and attorneys with more than 85,000 verified, state-specific forms for any business and personal situation. It’s the fastest, simplest and most reliable way to obtain the documents you need, as the service guarantees bank-level data security and anti-malware protection.

Acquiring this Toll Manufacturing Vs Contract Manufacturing For Cosmetics will take you only a few simple steps:

- Browse for the document you need and review it. Look through the sample you searched and preview it or review the form description to ensure it satisfies your requirements. If it does not, use the search option to get the appropriate one. Click Buy Now once you have found the template you need.

- Sign up and log in. Choose the pricing plan that suits you and register for an account. Use PayPal or a credit card to make a quick payment. If you already have an account, log in and check your subscription to proceed.

- Acquire the fillable template. Select the format you want for your Toll Manufacturing Vs Contract Manufacturing For Cosmetics (PDF, Word, RTF) and download the sample on your device.

- Complete and sign the paperwork. Print out the template to complete it by hand. Alternatively, utilize an online multi-functional PDF editor to quickly and accurately fill out and sign your form with a legally-binding] {electronic signature.

- Download your papers one more time. Use the same document again anytime needed. Open the My Forms tab in your profile to redownload any earlier downloaded forms.

Sign up for US Legal Forms to have verified legal templates for all of life’s scenarios at your disposal.

Form popularity

FAQ

Contract structure: There are different types of contract manufacturing agreements to choose from. This category includes private label manufacturing, contracts for manufacturing individual components or parts, labor or service subcontracting, and end-to-end service contracts.

The main difference is that contract manufacturers are hired by other companies to produce items on their behalf. Manufacturers can either produce finished products intended for the end user/customer, or they can make components that are used to manufacture other products.

Toll manufacturing or tolling is outsourcing all the production or part of it to a third-party company where you provide all the raw materials or semi-finished products. The work of the third-party company is to process the products or raw materials to the required specification.

Returning to toll manufacturing, Apple supplies Foxconn with all the raw materials, such as the screens, chips, and components required for its products, and pays Foxconn only for the manufacturing services. Clearly, toll manufacturing worked wonders for both Apple and Foxconn.

In contract manufacturing, a business uses another company's production facilities from procurement to the emission of the finished goods. In toll manufacturing, the parent company supplies the manufacturer with raw materials and design, retaining a degree of control over the production process and supply chain.